REVIEW ARTICLE

The Effect of Nanosilica Incorporation on the Properties of Cement-Based Materials with and Without other Supplementary Admixtures – A Literature Review

Laísa do Rosário Souza Carneiro1, *, Manuel Houmard2, Vanessa Vilela Rocha1, Péter Ludvig1

Article Information

Identifiers and Pagination:

Year: 2022Volume: 16

E-location ID: e187483682207290

Publisher ID: e187483682207290

DOI: 10.2174/18748368-v16-e2207290

Article History:

Received Date: 28/3/2021Revision Received Date: 19/5/2022

Acceptance Date: 20/5/2022

Electronic publication date: 13/10/2022

Collection year: 2022

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

The development of nanotechnology has made it possible to design new materials and improve existing ones. Regarding new supplementary admixtures for cement-based materials, nanosilica is more advantageous than any other nanomaterial. This is due to its high pozzolanic reactivity, besides its filling and seeding effects, which are a consequence of the higher and more reactive specific surface area of the nanosilica and its amorphous structure. Nonetheless, when used improperly or in an inadequate dosage, such a nanomaterial may negatively affect the cement admixture, compromising both fresh and hardened properties. Hence, it is fundamental to understand the nanosilica’s behavior inside the cementitious medium. This review paper is based on recent literature about the incorporation of nanosilica in cementitious materials. The analyses showed that, once incorporated in the cement matrix, nanosilica tends to agglomerate. The behavior of such agglomerates influences both the pozzolanic filling and seeding effects. Therefore, a suitable dispersion of the nanoparticles must be achieved. In this sense, third-generation superplasticizers are used, usually up to 3% of cement mass. The mechanical properties of cement-based materials with nanosilica depend on the amount of nanomaterial and on its specific surface area. There is not an agreement on the optimum dosage of nanosilica, however, percentages up to 5% in cement mass seem to provide a better performance, when compared to greater ones. It is not worthy to use nanosilicas with excessive specific surface area values, because they tend to form large agglomerates, reducing fluidity and compressive strength. Particles with surface areas up to 300 m2/g usually present good performance. Nanosilica improves the early age strength and contributes to the pore refinement of cement-based materials. The combination of nanosilica with other nanomaterials or industrial by-products can improve the mixture’s performance. Nonetheless, the use of silica nanoparticles with agricultural wastes negatively affects the mechanical properties at early ages.

1. INTRODUCTION

The development of nanotechnology has made it possible to design and build new materials and improve existing ones. In the cement industry, nanoparticles with a dimension measuring less than 100 nm have been observed to be the most favorable for improving the durability of concrete. Hence, several nanomaterials, i. e., nanosilica [1-3], nanotitania [4, 5], carbon nanotubes [6-8], and graphene oxide [9-11], have been used as a supplementary admixture to improve the fresh and hardened properties of concrete, mortars, cement pastes, etc.

Nanosilica (NS) is an artificially manufactured item with sphere-shaped particles in the size range of 1-50 nm. It has received a great deal of attention, mainly due to its high pozzolanic reactivity, along with its filling and seeding effects. In this sense, nanosilica is more advantageous than any other nanomaterial which can be exploited in cementitious materials [12]. Understanding how NS affects the properties of cement-based materials, either in fresh or hardened states, is crucial to properly using it as an addition. This work is a literature review of studies involving the incorporation of nanosilica into various types of cement-based materials. The effect of NS on fresh and hardened properties is analyzed and compared.

2. EFFECT ON THE PROPERTIES OF CEMENT-bASED MATERIALS

One of the most fundamental concepts to understand when working with nanosilica is that such material presents high specific surface area and, consequently, high surface energy, which leads the particles to agglomerate. Nanosilica typically exists in solid form (powder form), and suspension form (nanosilica hydrosol). Nanosilica hydrosols are usually preferred once the nanosilica powder naturally agglomerates [13, 14]. Nevertheless, according to several authors, at high pH values (≥12), such as in cementitious mediums, silica sols lose their stability and coagulate as well (due to the attractive van der Waals forces) [15-18]. Hence, regarding nanosilica in cementitious materials, it is the behavior of the final silica agglomerate that controls the main effects of the nanomaterial over the fresh and hardened properties of concrete, e. g. the pozzolanic activity, filling and seeding effects [19]. This behavior will be further explored in the following subsections.

2.1. Fresh Properties

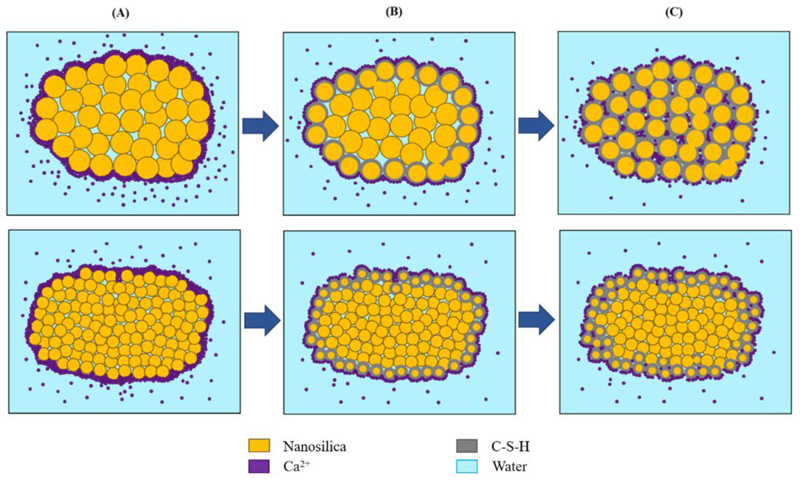

According to several authors, the incorporation of nanosilica into cement-based materials significantly increases the amount of water required in the mixtures [1, 3, 20-22]. As stated before, this phenomenon is attributed to the high specific surface area of the silica nanoparticles, which leads them to agglomerate. Depending on the size of the agglomerate, the NS could theoretically improve the fluidity of the paste if all agglomerates were small and acted as fillers to occupy the void space among cement particles. Nonetheless, the number of large NS agglomerates is commonly expressive, which tend to push away the cement particles around them, increasing the void space [2]. Even worse, very large NS agglomerates absorb some of the free water that originally contributed to the fluidity of the paste [2, 15, 23]. This water remains entrapped in the pores of the agglomerates and does not contribute to the flowability [24]. Consequently, both the torque and viscosity of the mixture increase and the workability of the cementitious paste is dramatically compromised [25-28]. Fig. (1) illustrates these three scenarios.

According to García-Taengua et al. [29], to ensure good workability, the nanosilica content should be less than 2%. In fact, the amount of nanosilica in cementitious materials must be controlled, being usually lower than 5%. Additionally, the nanoparticles must be as uniformly dispersed as possible in the mixture; otherwise, both fresh and hardened properties will be negatively affected [30].

A simple way to establish adequate workability is to introduce more water into the mixture. Nonetheless, the excess water might lead to more pores in the final structure and negatively affect the mechanical properties of concrete. Hence, several authors propose the use of superplasticizers, e.g., polycarboxylate-based [21, 31-39], polycarboxylate ether-based [28, 40-42] naphthalene-based [,2, 17] superplasticizers, to reduce the strong cohesive van der Waals forces between the nanoparticles and breakdown the agglomerates [43].

The incorporation of nanosilica into cementitious materials decreases the flowability of the paste, which can be quantified by the slump value [1, 3, 21, 22]. Nonetheless, according to Berra et al. [1], small percentages of superplasticizers can raise the slump value to an appropriate and workable value. The amount of superplasticizer needed will depend on the amount of nanosilica incorporated [17, 36, 41, 44] and on its specific surface area [37, 45]. Based on some of the papers analyzed in this work, in ordinary Portland cement pastes, concretes, and mortar, the amount of superplasticizer varied from 0.125% to 2.7%, with an average value of 1% [17, 29, 31-33, 35, 37-39, 41, 46]. According to Berra et al. [1], the addition of a superplasticizer to the mixing water containing nanosilica, before cement addition, must be avoided. Instead, the delayed addition of the superplasticizer would lead to a better dispersion of the mixed ingredients and simultaneously ensure the NS reactivity.

|

Fig. (1). Illustration of the filling effect of the nanosilica agglomerates: (a) The smaller agglomerates act as fillers to release some free water in the gap to enhance the fluidity of the paste. (b) The larger agglomerates cannot act as fillers, and they tend to push away the particles around them, increasing the void space. (c) The very large agglomerates absorb some free water, originally contributing to the fluidity of the paste (Illustration was based on KONG et al. [2]). |

Increasing the rate of superplasticizer would naturally lead to a delay in the cement hydration reaction. Nevertheless, due to the pozzolanic and nucleation side effects, the addition of NS into the mixture could significantly compensate for the delay effect of the superplasticizers [28].

On the other hand, authors like Quercia et al. [20] tried to determine an optimal amount of water that, being proportional to the specific surface area of the nanoparticles, would cover all of them with a water layer of a certain thickness. This should guarantee the workability of the mixture and reduce the need for superplasticizers. The authors found that a water layer of 24.8 nm of thickness around the spherical nanoparticles could maintain the mix fluidity and that the concentration of nanosilica in the mix should be less than 7 wt.% of cement.

The addition of nanosilica particles in cement-based materials reduces the initial and final setting time of the mixture [3, 47-51]. In their work, Zhang et al. [48] verified that the incorporation of 2 wt.% of NS reduced the initial and final setting time by 95 and 105 min. Babu et al. [51] found that the setting process is accelerated as the nanosilica content increases. By introducing 2, 4, 6, 8, and 10 wt.% of NS into cement mortar, the initial setting times were 152, 147, 142, 136, and 130 min, respectively, and the final setting times were 262, 259, 254, 244 and 239 min, respectively. In comparison, the initial and final setting times of the reference mortar without NS were 265 min, respectively. In this context, the cement type and fineness should be taken into account when adding nanosilica to the mixture since the binder and the nanomaterial’s combined reactivity will directly affect the setting time as well as the hydration heat, concrete shrinkage, etc. Hence, an experimental study to investigate the fresh and hardened properties of concrete and mortars made with different types of cement, e. g., Brazilian type CP-III, CP-IV, and CP-V cement, with the incorporation of nanosilica is suggested. Therefore, the combined reactivity of each cement type and nanosilica could be explored and its effects on the properties of the material could be investigated.

2.2. Mechanical Properties

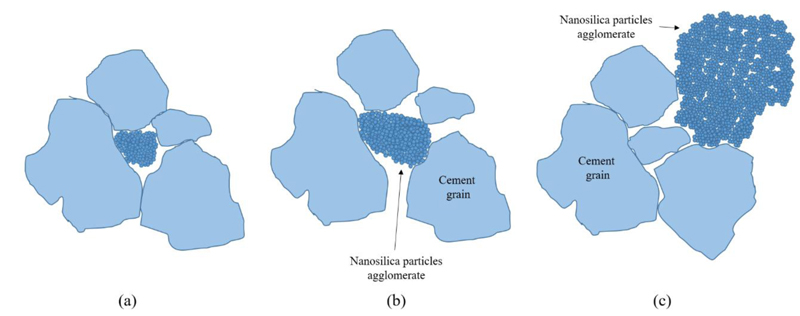

Since it is composed of 99.9% of amorphous SiO2 and presents a high surface area, NS has high pozzolanic activity. Therefore, when incorporated in an aqueous cementitious medium, the nanosilica atoms rapidly form H2SiO42- ions, which react with Ca2+ ions (from Ca(OH)2, present in hydrated cement) to form additional C-S-H gels, which serve as seeds for the formation of more compact C-S-H phase [47]. Hence, the nanosilica particles act as nucleation sites, accelerating the growth of hydration products in their vicinity [35]. They also act as a filler by filling the meso- and micropores between the cement particles [27, 39]. Thus, both the pozzolanic and filler effects contribute to the improvement of early age properties of the fabricated concrete, such as compressive and flexural strengths [23, 27, 52, 53].

In concretes, the Interfacial Transition Zone (ITZ) between aggregates and the bulk cement paste is also densified by the nanosilica insertion, leading to an enhancement in both compressive and tensile strengths [27, 54-59]. Fig. (2) illustrates the scheme of the ITZ in ordinary concretes and in nanoengineered concretes. Notably, the nanoengineered concrete presents a denser ITZ, with a greater number of hydration products.

The effect of nanosilica addition on the mechanical properties of cementitious materials depends on many factors, such as the dosage and the specific surface area of the nanomaterial [37, 43, 45], as well as the water/binder (w/b) ratio, curing conditions, curing age and superplasticizer content [50]. Table 1 presents the compressive strength improvement of various cementitious materials with nanosilica. The results reflect the optimum amount of nanosilica determined as a function of the mechanical strength improvement.

|

Fig. (2). Scheme diagram of traditional and nanoengineered concrete hydration process (Illustration was based on LIU et al. [35]). |

| Nanosilica |

Supplementary Materials |

Superplasticizer | Matrix | Water /Binder Weight Ratio | Compressive Strength Increase (%) | Reference | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Amount WT.% OF Cement | Specific Surface Area (M2/G) | Average Particle Size (NM) | Type | Amount WT.% of Cement | Type | Amount WT.% of Cement | 1 Day | 7 Days | 28 Days | |||

| Nanosilica hydrosol | 4% | 500 | 15 – 20 | - | - | - | - | Ultrafine Cement Paste |

0.4 | 2.9 | 8.5 | 16.2 | Kontoleontos et al. [24] |

| Nanosilica powder | 1% | 200 | - | Ground ceramic powder | 10% | Polymer-based | 0.125% | Concrete | 0.5 | - | 29 | 18.9 | Heidari & Tavakoli [46] |

| Nanosilica Sol-Gel calcinated at 400ºC | 2% | 190.6 | - | Silica Fume | 15% | Polycarboxylate- based | 1.5% | Cement Paste | 0.23 | 291 | - | - | Shakhmenko et al. [31] |

| Nanosilica powder | 5% | - | 15 | - | - | Polycarboxylate-based | 1% | Cement Mortar | 0.25 | - | ~58 | ~58 | ABD.EL.Aleem et al. [32] |

| Nanosilica powder | 3% | 160 | 15 | Silica Fume | 27% | Polycarboxylic acid-based | 3% | Ultra-High Performance Concrete | 0.2 | - | ~12.4 | ~6.8 | Ghafari et al. [21] |

| Nanosilica powder | 9% | 200 90 50 |

12 20 40 |

- | - | Polymer-based | Enough to achieve flowability | Cement Mortar |

0.65 | 57.9 65.5 92.4 |

32 67.5 74.1 |

23.9 52.9 54.4 |

Haruehansapong et al. [44] |

| Nanosilica powder | 4% | - | 15 | - | - | Polycarboxylate-based | 1% | Cement Paste | 0.27 | ~20 | ~20.7 | ~21 | Heikal et al. [33] |

| Nanosilica hydrosol | 5% | 100 | 30 | - | - | Polycarboxylate ether-based | 0.85% | Concrete | 0.45 | 29.8 | 18.4 | 22.9 | Madani et al. [41] |

| Nanosilica slurry | ~4% | 22.7 | 120 | - | - | Polycarboxylate ether-based | 10.41% | Ultra-High Performance Concrete | 0.4 | - | ~16.1 | ~15.8 | YU et al. [28] |

| Nanosilica hydrosol | 2% | 220 | 12.4 | - | - | Polycarboxylate-based | 1% | Lightweight Concrete | 0.42 | ~8.5 | ~9.4 | ~2.4 | DU et al. [34] |

| Nanosilica hydrosol | 1% | 220 | 12.4 | Slag | 60% | Polycarboxylate-based | 1% | Lightweight Concrete | 0.42 | ~6.9 | 0 | ~0.9 | DU et al. [34] |

| Pyrogenic nanosilica | 1.5% | 200 | 12 | - | - | Polycarboxylate-based | 1.2% | High-Performance Concrete | 0.35 | - | 25.1 | 12.1 | Mobini et al. [36] |

| Pyrogenic nanosilica | 1.5% | 200 | 12 | Steel Fiber | 1% | Polycarboxylate-based | 1.5% | Fiber-Reinforced High-Performance Concrete | 0.35 | - | 20.1 | 9.1 | Mobini et al. [36] |

| Nanosilica powder | 2% | 220 | - | - | - | Polycarboxylic acid-based | 1% | Cement Mortar | 0.29 | - | 9.5 | 7.5 | LIU et al. [35] |

| Nanosilica hydrosol | 5% | 100 | 36.2 | - | - | Polycarboxylate-based | 2.4% | Cement Mortar | 0.485 | - | 13.6 | 21.3 | Zahedi et al. [37] |

| Nanosilica powder | 3% | 116 | - | - | - | - | - | Cement Mortar | 0.4 | - | ~25.6 | ~38 | Singh et al. [12] |

| Nanosilica powder | 3% | 116 | - | - | - | - | - | Cement Paste | 0.4 | ~60 | ~22 | ~20 | Singh et al. [12] |

| Nanosilica hydrosol | 1% | 129 - 155 | 20 – 24 | metakaolin epoxy resin coconut fiber bar chip fiber |

10% 1% 1% 1% |

High Range Water Reducing | 1% | Hybrid Cementitious Composites | 0.30 | - | 5.25 | 33.1 | Alonge et al. [60] |

| Nanosilica powder | 5% | 280 | 20 | polypropylene fibers | 0.75% | polycarboxylate-based | 2% | Fiber- Reinforced Concrete |

0.60 | - | - | ~43.5 | Adetukasi et al. [61] |

As verified in Table 1, the dosage of the silica nanoparticles is usually lower than 5% in cement mass. Several authors report that higher percentages of nanosilica are more difficult to disperse, leading the particles to agglomerate [3, 24, 62, 63]. Such agglomerates enable the formation of weak spots throughout the microstructure of the cementitious composite, resulting in high-stress concentration sites. This might compromise both the compressive and tensile strength development of the mixture [2, 19, 57].

An interesting point to be highlighted is that the pozzolanic reactivity of nanosilica is directly affected by its specific surface area [15, 64, 65]. Nanosilicas with high surface area rapidly react with Ca(OH)2 crystals. However, at later ages, such a reaction rate could be reduced. Such fact was observed by Zahedi et al.. [37] and Joshaghani and Moeini [45], as they verified that nanosilicas with BET specific surface areas of 300 m2/g and 200 m2/g would improve the compressive strength of mortars more than those with 100 m2/g, at early ages. However, along with the hydration development, nanosilicas with a BET area of 100 m2/g would be more efficient. According to Madani et al. [15], during the first hours of hydration, the rate of pozzolanic reactivity is controlled by the rate of silica dissolution in the fluid present in the structure pores, which increases for higher silica specific surface area. Nonetheless, with the hydration progress, a layer of hydrate products precipitates on the surface of silica agglomerates. This layer slows down the rate of silica dissolution, thus slowing down the rate of pozzolanic activity. Another hypothesis is that once agglomerated, high specific surface area silica may present micropores. Therefore, a large fraction of the surface area might be within these very thin pores, which are not readily reached by the calcium ions. Hence, after a fast initial reaction, the pozzolanic activity would drop at later ages [64] Fig. (3). illustrates such different behavior of nanosilica particles with high specific surface areas. As verified in Table 1, nanosilicas with surface areas up to 300 m2/g seem to contribute more significantly to the mechanical strength development of cementitious materials

The addition of nanosilica in other types of cement-based materials seems to be promising as well. In self-compacting concrete (SCC), for example, nanosilica addition results in a homogeneous microstructure, characterized by compact and small-sized C-S-H gels. Thus, the interfacial transition zone is densified, improving the mechanical properties of SCC [66]. Some authors stated that 4% of nanosilica would be the optimum value for obtaining the maximum compressive strength in SCCs [23, 67]. Beyond that value, nanoparticles would stick to each other through a physical reaction, leading to unstable agglomerates [23]. The introduction of nanosilica in fiber reinforced concrete (FRC) contributes to the compressive strength development of the composite. In this case, the use of fibers like polypropylene fiber, macro-polymeric fiber, steel fiber, glass fiber, basalt fibers, and mineral fiber is reported [22, 23, 36, 53, 61, 68-72]. Atewi et al. [53] reported that the improvements of compressive and splitting strength were detected up to 4% of NS and 1.5% of glass fibers in self-compacting concrete. A 34% enhancement in splitting tensile strength was observed by the authors within 90 days, compared to that of the plain concrete. According to Mobini et al. [36], the addition of nanosilica with 200m2/g specific surface area into a fiber-reinforced high-performance concrete (FRHPC) with 1% of steel fiber, led to the development of a denser ITZ between the matrix and the fibers and, therefore, a tight bonding between them was achieved. Consequently, both the tensile and flexural strengths of FRHPC were increased.

The pozzolanic activity and filler effect also contribute to the pore structure refinement of cement-based materials containing nanosilica [55, 73, 74], which improves durability as a whole [52]. Several authors recorded that the total porosity of cement matrix with nanosilica is reduced, since additional C-S-H gels fill the capillary pores [75]. According to Jalal et al. [76], in self-compacting concretes, the incorporation of 2% of nanosilica decreased the capillary water absorption by 58% when compared to the reference mixture. This NS dosage was also satisfactory for reducing water penetration and sorptivity in high-performance concretes [77] and lightweight concretes [34].

Due to the water absorption reduction, some authors observed that the incorporation of nanosilica also improved both sulfate [73, 75] and chloride [18, 23, 41, 78] resistance of cement-based materials. Beigi et al. [23] revealed that a replacement of 4 wt.% of nanosilica decreased chloride ion penetration in fiber-reinforced concrete containing steel, polypropylene, and glass fibers, by 40%, 28%, and 20%, respectively. Kooshafar and Madani [18] reported that nanosilica hydrosol outperforms nanosilica powder in water sorptivity and rapid chloride migration tests. According to Massana et al. [74] and Li et al. [79], the combination of silica fume and nanosilica in the mixtures produces concretes with high compactness, which can further enhance the sulfate and chloride resistance to higher than possible with the single addition of silica fume or NS.

3. Effect of Nanosilica Addition on Cement-based Materials with other Supplementary Admixtures

The search for sustainability has led several researchers to substitute a part of the ordinary Portland cement with supplementary admixtures, such as silica fume (SF), fly ash (FA), metakaolin (MK), furnace-blast slag (FBS), rice husk ash (RHA) and sugar cane bagasse ash (SCBA) [80]. Besides, certain nanomaterials like nanosilica, i. e., nanotitania (nano-TiO2) [4, 81] and graphene oxide (GO) [9, 10], may improve the mechanical and transport properties of cementitious materials when incorporated into them. This might allow a reduction in the need for cement as a whole. In this sense, a better understanding of the effect of nanosilica addition on cement-based materials with supplementary admixtures may elucidate the possibilities of the use of this nanomaterial in particular.

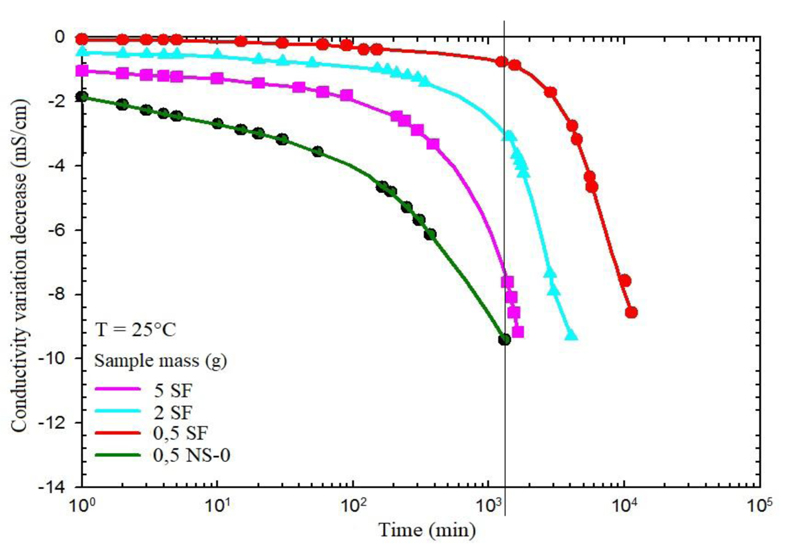

3.1. Nanosilica with Industrial by-products

Silica fume (SF) is a widely used supplementary material. As a by-product of silicon and ferrosilicon alloy production, this amorphous material is the majority composed of amorphous silicon dioxide (SiO2), which gives it great pozzolanic activity. Nonetheless, due to the considerable difference between the specific surface area values of silica fume and nanosilica, mixtures with the nanomaterial could present higher strength values at early ages, while mixtures with SF could present higher strength gains at later ages [41, 43, 57]. This behavior is also reflected in terms of electrical resistivity performance [41]. Hence, the simultaneous use of nanosilica and silica fume could lead to a great strength development enhancement [39, 57, 82, 83]. Indeed, this was confirmed by Nili et al. [52], who verified that higher strength improvement was achieved by adding 5 wt.% of nanosilica and 5 wt.% of silica fume in concretes and cement pastes when compared to the same amount of NS and SF added solely. Gesoglu et al. [84] also observed that samples of UHPC containing both NS and SF gave better results than concretes containing only NS. Hendi et al. [39] concluded that compressive strength, mass loss, and calcium hydroxide consumption are considerably improved by using binary pozzolans, i. e., two kinds of pozzolans used together. Through electrical conductivity measurements, performed in calcium hydroxide saturated solutions on our own, we verified that, for the same mass of 0.5g, silica fume with a specific surface area of 19.4m2/g and average pore size of 12.9nm reacted considerably slower than 0.5g of nanosilica particles with a specific surface area of 597.1m2/g and average pore size of 6.3nm. Then, during the time, after most nanosilica was consumed, the pozzolanic reaction of silica fume sped up (Fig. 4). Hence, such experimental results support the hypothesis of using NS and SF together to improve the final material performance. It is important to highlight, although, that enhancing the amount of silica fume will increase the pozzolanic reaction rate as well, as can be also seen in Fig. (4).

The pozzolanic reaction of fly ash is relatively slow. It takes at least 7 days of hydration to increase the pozzolanic reaction rate of such by-products. However, the addition of nanosilica into fly ash blended cement mortars can accelerate the hydration, improving the early age compressive strength of the mixtures [86, 87]. As expected, this is due to the high pozzolanic reactivity of nano-SiO2 at early ages. On the other hand, fly ash can offset the reduction in fluidity caused by nanosilica [86]. Recently, Huang et al. [88] proved that the addition of nanosilica to high-volume (>50%) fly ash (HVFA) pastes reduced the water absorption and increased the compressive strength. These are promising results, the drawback of using HVFA cement is the increase of water absorption and reduction of the durability of cement-based materials. Zhang et al. [58] proposed a microfine-cement-based grout mixed with microfine fly ash (MFA), nanosilica hydrosol, and superplasticizer. Both MFA and SP improve the fluidity of the fresh grout, while nanosilica has positive effects on shortening the setting time and enhancing the mechanical properties. Hence, such grout might be desirable for geotechnical engineering.

|

Fig. (4). Conductivity variation decreased in lime solution as a function of time for tests performed with silica fume (SF) and nanosilica (NS) at room temperature. The specific surface area (SSA) of silica fume is 19.4m2/g, whereas the SSA of nanosilica is 597.1m2/g (Graphic was based on the results obtained by Carneiro et al. [64] and Carneiro [85]). |

3.2. Nanosilica and Agricultural Waste Ash

Agricultural waste ashes such as rice husk ash (RHA) and sugar cane bagasse ash (SCBA) usually show good performance when replaced up to 20% and 15% with Portland cement, respectively [89-91]. When blended with nanosilica, mixtures with agricultural ash seem to present a better performance in the long term rather than in the short term [37, 45]. Eramma and Mahesh [92] found that replacing 10% of SCBA and 2% nanosilica in cement yielded slightly better compressive strength at early ages when compared to 2% nanosilica replacement. However, Joshaghani et al. [45] and Zahedi et al. [37] agreed that both SCBA and RHA intensively decreased the compressive strength of mortars at early ages, when compared to those with nano-SiO2 only. According to Joshaghani and Moeini [45], the reduction in short-time compressive strength might be attributed to the excessive silica discharge in the matrix, which is higher than the required amount of silica to be mixed with the free lime during the process of hydration.

3.3. Nanosilica and Nanotitania

The use of nano-TiO2 in cement-based materials has won great attention due to its chemical stability, low price, nontoxicity, and high photocatalytic activity. Nano-TiO2 can act as a filler and a nucleation site, accelerating the hydration of cement and refining the pores of the matrix [4, 5]. Nonetheless, unlike nano-SiO2, it does not significantly contribute to the early age strength [93]. Recently, some research has further investigated the potential use of such nanomaterials combined with nano-SiO2.

Sun et al. [94, 95] synthesized and partially substituted core/shell TiO2/SiO2 nanoparticles into Portland cement at 1 wt.%. They found that cement pastes with such TiO2/SiO2 nanoparticles exhibited a higher degree of hydration, higher compressive strengths, and lower porosity than those pastes with nano-TiO2 only. Besides, 5 wt.% TiO2/SiO2 nanoparticles significantly improved the flexural strength by 73.73% at 3 days and 87% at 28 days and improved the compressive strength by 4.09% at 3 days and 10.32% at 28 days [96]. This is probably due to the pozzolanic reaction of nano-SiO2 that produces denser C-S-H gels, which also act as nucleation sites for the precipitation of hydration products [97]. It is interesting to highlight that TiO2/SiO2 nanoparticles become uniformly distributed inside the matrix, which makes it more compact [96]. Nevertheless, Ying et al. [98] blended simple nano-SiO2 and nano-TiO2 into recycled aggregate concrete (RAC) and verified that both nanoparticles refined the pore structure of RAC as well, which also led to an enhancement of the resistance to chloride diffusion. On the other hand, in the works of Senff et al. [25, 99], the compressive strength and water absorption of mortars with nano-SiO2 and nano-TiO2 remained almost invariable.

3.4. Nanosilica and Graphene Oxide

Graphene oxide has proved to be a good additive to reduce the permeability and water absorption of concrete, whereas enhancing its chloride resistance [10, 11]. Small amounts of GO can also improve the mechanical performance of concrete [9]. Similarly to core/shell SiO2/TiO2, the use of core/shell nanoSiO2/GO shows a better performance than the simple use of GO [100] or even the simple blend of nano-SiO2 and GO [100]. Besides, the nanosilica particles on the surface form a physical barrier, which ensures good dispersion of the nanoparticles in the cementitious paste [100]. According to Gu et al. [101], the addition of 1.55 wt.% of core/shell nanoSiO2/GO in cement paste can increase the flexural strength by 48.5% at 3 days and 49.2% at 28 days. Newell et al. [102] blended nano-SiO2, GO, and a polycarboxylic ether-based superplasticizer and introduced it into cement pastes. The authors found that GO and NS additions of 0.018 wt.% and 2.2 wt.%, respectively, would reduce the water sorptivity coefficient by up to 22%. Moreover, increasing the superplasticizer dosage from 0.6 wt.% to 1.2 wt.% would reduce the water sorptivity by up to 35%.

CONCLUSION

From the literature review carried out in this work, the following conclusions can be drawn:

- Whether in the solid form or the suspension form, nanosilica agglomerates once it is incorporated in cementitious materials. The agglomerates behavior influences the pozzolanic, filling, and seeding effects, which directly affects both the fresh and hardened properties of cement-based materials.

- One of the greatest challenges of working with nanosilica is to guarantee a suitable dispersion of its particles. In this sense, third-generation superplasticizers, e.g., polycarboxylate-based, polycarboxylate ether-based, and naphthalene-based superplasticizers can be used in small amounts, usually up to 3%.

- The mechanical properties of cement-based materials with nanosilica are directly dependent on the amount of nanomaterial used and on its specific surface area. This study revealed that there is no agreement on the optimum nanosilica dosage in cementitious materials. However, percentages up to 5% of cement mass provide a better performance, when compared to greater ones. Silica particles with higher specific surface area tend to form large aggregates and to absorb too much free water, which reduces the fluidity of the paste and compromises the mechanical strength development. Hence, it is not worthy to use nanosilicas with excessive surface area values. In general, silica particles with surface areas up to 300 m2/g present a better performance in cementitious materials.

- The cement type and fineness should be taken into account when adding nanosilica in the mixture, since the binder and the nanomaterial’s combined reactivity will directly affect the setting time as well as the hydration heat, concrete shrinkage, etc. Hence, experimental studies on the addition of nanosilica in cementitious materials made with different types of cement and its effect on the properties of these materials should be encouraged.

- When properly added, nanosilica contributes to the pore refinement of cement-based materials, reducing water absorption and porosity. Therefore, it enhances the resistance to the ingress of aggressive ions inside the concrete, e.g., sulfate and chloride ions, which improves the composite durability.

- The combination of nanosilica with other nanomaterials, e.g. nano-TiO2 and graphene oxide, or with industrial by-products, e.g., silica fume and fly ash, can improve the performance of cementitious materials. Particularly, in the case of combining silica fume and nanosilica, the better performance is attributed to the pozzolanic reaction kinetics of each material, once nanosilica tends to react faster than silica fume. Then, nanosilica tends to improve the mechanical strength at early ages, while silica fume improves it at later ages. On the other hand, the use of silica nanoparticles with agricultural waste ash seems to negatively affect the mechanical properties at early ages.

LIST OF ABBREVIATIONS

| NS | = Nanosilica |

| ITZ | = Interfacial Transition Zone |

| SCC | = Self-Compacting Concrete |

| FRHPC | = Fiber-Reinforced High-Performance Concrete |

AUTHORS CONTRIBUTION

This paper was designed and written by L. R. S. Carneiro, edited and co-written by V. V. Rocha, and revised by M. Houmard and P. Ludvig.

CONSENT FOR PUBLICATION

Not applicable.

FUNDING

This work was financially supported by Conselho Nacional de Desenvolvimento Científico e Tecnológico (Grant number 306193/2020-5).

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGMENTS

The authors acknowledge support from CNPq, CEFET-MG, CAPES, and FAPEMIG.