REVIEW ARTICLE

Strengthening/Retrofitting Techniques on Unreinforced Masonry Structure/Element Subjected to Seismic Loads: A Literature Review

Chuanlin Wang1, *, Vasilis Sarhosis2, Nikolaos Nikitas3

Article Information

Identifiers and Pagination:

Year: 2018Volume: 12

First Page: 251

Last Page: 268

Publisher ID: TOBCTJ-12-251

DOI: 10.2174/1874836801812010251

Article History:

Received Date: 7/4/2018Revision Received Date: 24/7/2018

Acceptance Date: 12/9/2018

Electronic publication date: 26/10/2018

Collection year: 2018

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: (https://creativecommons.org/licenses/by/4.0/legalcode). This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Masonry structures commonly exist in reality and still are popular all over the world. It has been reported and studied that these buildings are vulnerable to strong external loadings imposed by earthquake, strong wind, blast etc. In the past few decades, different seismic retrofitting and strengthening approaches for masonry structures/elements have been developed and implemented. In this paper, the previous studies on the strengthening/retrofitting techniques for Unreinforced Masonry (URM) buildings subjected to seismic and extreme loads are reviewed and summarized. The fundamental concept of strengthening/retrofitting approaches is to (i) reduce the influence of external loading, (ii) upgrade the individual element’s load-carrying capacity and (iii) improve the integrity of masonry structure. A comparison and assessment of the advantages and disadvantages of each method is presented to identify the most suitable method in different cases. It is expected that this paper will provide some helpful information and guidance for the engineers and householders in choosing an appropriate technique in strengthening/retrofitting URM structures.

1. INTRODUCTION

Masonry is a composite material made of masonry units and mortar, which has been used for centuries. Though Masonry is an old and out-of-date construction material, it is still common and popular in some countries. Unreinforced Masonry (URM) buildings still possess a big portion (about 70%) of existing buildings [1]. The most frequently seen type of URM is the Masonry Heritage Structures (MHS), which presents value contexts such as aesthetic, social, archaeological, cultural, economic and technological, making them a real treasury of human civilization [2]. The design, construction technologies and the initial materials used in those masonry heritages are often drastically vulnerable subjected to present days’ hazard. Therefore, the retrofitting work to help those structures survive under seismic and extreme loads is essential. In addition, masonry walls are often used as infill in reinforced concrete frames, which has been observed from experimental observations and analytical studies that the lateral load-carrying capacity of bare frame can be greatly improved if the frame is fully infilled with masonry. Nevertheless, observations from past earthquakes also displayed that catastrophes and loss of life could occur in such buildings. The collapse is more likely to occur in the out-of-plane direction or in the partially infilled RC frame, which has led to the idea that this type of structure possesses some poor seismic performance [3]. Normally, the masonry infill is not taken as a structural element but as secondary. However, it should be noted that the masonry infills can contribute in causing casualties if the buildings are subjected to strong external loadings, especially out-of-plane loading.

A large number of masonry structures were built only under empirical rules (there were no corresponding building codes at that time), and the seismic actions were not taken into consideration when the structures were constructed, which led its inability to absorb the seismic load induced by an earthquake [4]. Consequently, taking this reason into account, URM buildings or masonry elements often require to be strengthened prior to seismic actions or retrofitted following earthquake events to guarantee that they can dissipate the energy and relieve the forces induced by earthquakes. Investigators have developed and implemented various types of technical approaches to strengthen/retrofit the mechanical performance of URM wall panels as well as whole structures. However, many strengthening or retrofitting techniques have only been studied on individual cases, which means the result cannot be extended and applied directly to other cases with different types of construction materials or systems. The analytical techniques are not reliable enough to assess the seismic performance of strengthened/retrofitted masonry structures as the strengthening or retrofitting method may work differently in masonry structures made of different materials. Furthermore, there is little literature on the effect of strengthened/retrofitted masonry infill on the whole structure as most of the studies were carried out on the individual elements. It should be noted that the strengthened/retrofitted masonry element may change the structural period of the original structure, thus changing its dynamic performance under an earthquake. It is more meaningful if the whole structure is considered when doing the strengthening/retrofitting. Besides, the numerical simulation method was not applied widely in the research of strengthening/retrofitting on masonry. Most of the previous studies were only carried out experimentally. One of the biggest issues that cause its unpopularity is the mechanical performance, especially the long-term behavior between the masonry-strengthening interface is not known clearly. The numerical simulation can be a powerful tool in such studies and can be applied to analyze the mechanical performance of retrofitted/strengthened masonry regarding the efficiency of retrofitting/strengthening.

In this paper, a review on the previous strengthening/retrofitting methods has been compared and assessed aiming to provide an overall understanding on the state-of-the-art strengthening/retrofitting techniques on masonry buildings and masonry elements.

2. STRENGTHENING/RETROFITTING TECHNIQUES FOR URM

So far, massive research has been carried out to investigate reinforcing or strengthening of URM structures. The aim of the retrofitting is to improve their load carrying capacity or increase their collapse time under unexpectedly large external loading. There are three concepts in retrofitting masonry structures: i) to reduce the external force; ii) to upgrade the existing building; and iii) to improve the integrity. The first two concepts have been summarized and demonstrated in a few research documents [5, 6] while the third one has been barely mentioned. Those concepts and their practical application will be presented in detail in this section.

2.1. To Reduce Earthquake Forces

2.1.1. Base Isolation

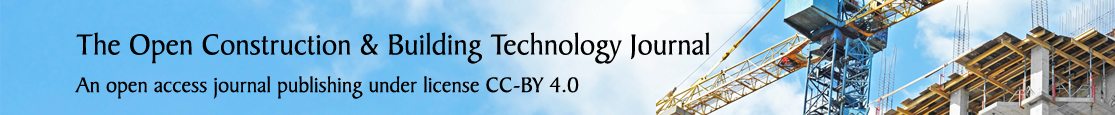

The idea of base isolation is to uncouple the masonry building and the foundation by placing flexible pads between them, thus preventing the earthquake motions from transmitting up through the building, or at least reducing them greatly [7], as demonstrated in Fig. (1). When the ground shakes, only a small portion of the shaking from the base will be transmitted to the superstructure. Previous research has presented that the appropriately chosen flexible pads can reduce the forces induced by earthquake 5 to 6 times compared with the structures without using base isolation. In the experimental result of [8], the masonry part retrofitted with isolators experiences a 2.8 up to 24 times smaller displacement and the forces are reduced from 1.5 to 15 times compared with the one registered in the fixed foundation. The base isolation technique can be perfectly applied in low to mid-rise masonry buildings. Particularly, the base isolation is a suitable retrofitting strategy for the heritages of historical importance as it can preserve their original appearance while the conventional rehabilitation would be destructive to the appearance of the buildings [9]. However, it is so far not easy to implement this technique under the existing building. The base isolation system is usually seen as a presentation of maximum capacity to resist seismic loads, which could be achieved for the structure without additional invasive retrofitting measures [10]. [11] retrofitted an old masonry chapel building using base isolation technology, which used the laminated rubber bearing and damper together. It was found out that this feasible technique could resist seismic loading and keep its architectural feature. Similarly, [12] found that the retrofitted masonry building using pure friction base isolation system has a 50% reduction in maximum roof acceleration in comparison to the conventional fixed base structure. The base isolation technique could be applied in combination with other strengthening materials, Fibre Reinforced Polymer (FRP) for instance, [13] concluded that the improvement of this technique alone is not sufficient, while the use of horizontal and vertical CFRP laminate strips greatly improves the seismic behaviour. This technique cannot be only applied to the structural masonry buildings, but also to the heavy non-structural monolithic objects, such as the pinnacles. [14] implemented this system on a pinnacle to resist earthquake action expressed through base isolation, whose spectrum is compatible with the design seismic action. The best application of this technique is on the newly built building as the construction of the flexible pad would be easier. Though it would be perfect if this technique can be implemented on the masonry heritage as it can preserve its authenticity, the mechanical work would be cumbersome which may destroy the whole structure out of a sudden. Besides, the cost would be huge as the expense to install a hybrid base isolation system can be as much as 3% of the total cost of the building [15]. It also should be noted that this technique cannot be implemented on tall buildings.

|

Fig. (1). The technique of base isolation. |

2.1.2. Seismic Damper

The seismic damper is a mechanical device to dissipate the energy caused by the earthquake in a building. During an earthquake, the seismic energy will be transmitted from the substructure to the superstructure. A portion of the energy will be absorbed and dissipated by dampers, and in such case, the shaking of the building is damped. Damper was first used in tall buildings to resist wind effects. Later it was introduced to the buildings against earthquake effects. Quite a lot of different types of seismic dampers have been developed and applied, and the most commonly applied types in low-rise buildings include viscous dampers, friction dampers and yielding dampers. In an earthquake, some energy will be dissipated in the forms of heat and friction by the viscous dampers, thus resulting in less likelihood of failure. For the friction damper, it maintains the integrity by redressing the floors back to their relative positions in the beginning, while yielding dampers absorb the energy and yield before the floors do. In such a way, the structural failure of the building itself will be prevented. The use of seismic dampers can significantly reduce seismic vulnerability as well as encounter the complicated effects of the unknown as well as uncertain interventions during the building’s lifetime [16]. So far, most of the application of seismic dampers are conducted on the framed structure, only a small number of research is carried out on masonry buildings [17, 18] as it is suitable for insertion within a chevron bracing system. [19] improved the seismic response on a historical chimney by using Tuned Mass Damper (TMD) and this technique improves the seismic response in terms of compressive stress value, base shear and top displacement [20]. rehabilitated an old unreinforced masonry building using hysteric dampers system (Fig. 2). [21] has also proposed this technique to retrofit stone masonry buildings, and significant improvement has been achieved. Conventional retrofitting with seismic damper requires heavy demolition and long construction times on masonry buildings, therefore, [21] proposed an alternative damper called Added Damping and Stiffness (ADAS) dampers, which is characterized by the addition of new external concrete walls equipped with ADAS dampers, thus reducing the intervention on the initial building. Moreover, [22] retrofitted a masonry building using a combination of steel bracing and dampers. The results found that the dampers dissipated a huge amount of seismic energy and prevented the masonry of excessive deformation and cracking. However, [13] argued that this technique might not be efficient as the seismic damper requires large deformations to be efficient, while the masonry structure is generally rigid. So far, as previously stated, the seismic dampers are more commonly applied in rehabilitating framed structures but not that popular in masonry structures.

2.2. To Upgrade the Element Strength

For the masonry structures or masonry bearing walls, including the vertical and horizontal masonry elements, to upgrade the element strength can improve the load resistance of the whole structure, thus improving the possibility of a masonry structure or masonry element to resist unexpected external loadings. This concept is the most frequently applied in retrofitting/strengthening masonry structures.

|

Fig. (2). View of the retrofitted building: (a) S-W facade; (b) N-E facade [20]. |

2.2.1. Surface Treatment

The general surface treatment involves attaching strengthening materials to the original structure and tied together by using mortar or steel links. The most frequently used approach in surface treatment is shotcrete and ferrocement.

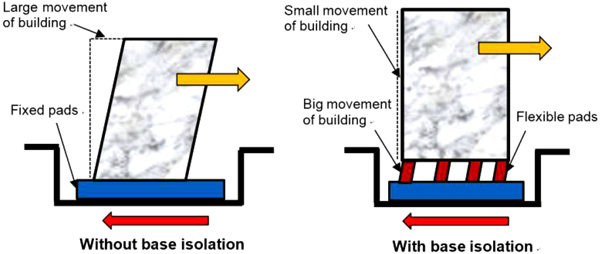

Shotcrete is applied by spraying shotcrete over a mesh of wire installed on the surface of the masonry wall. (Fig. 3a). In general, the thickness of the overlay ranges from 70mm to 150mm [23, 24]. Normally, the shear dowels need to be used as well for the sake of transferring shear between the masonry-shotcrete interface. Before the application of shotcrete, the removal of wythes of bricks and filling the voids should be carried out first. [25] did a series of experiments on masonry wall panels using this technique. The ultimate lateral strength was increased by nearly 3.6 times. Furthermore, the stiffness at peak loading was increased by a factor of 3, though the initial stiffness was unaffected by this method. [24] found that shotcrete jacketing on both surfaces can reduce masonry tension on an average of 50% while one-sided shotcrete jacketing reduces the tension by about one-third. Besides, the roughness of the masonry surface plays an important role as well in determining the effectiveness of retrofitting. The retrofitting of shotcrete will be improved if the substrate surface is particularly rough after removal of loose or deteriorate portions [26].

|

Fig. (3). Surface treatment. (a) Shotcrete [25] (b) Ferrocement [29]. |

The ferrocement consists of closely spaced multiple layers of hardware embedded in a high strength (15-30MPa) cement mortar layer (10-15mm thickness) [27], shown in Fig. (3b). The mechanical properties of ferrocement depend on mesh properties as the mesh improves the in-plane inelastic deformation capacity by confining the masonry units after cracking. In a static cyclic test [28], this retrofitting technique increased the in-plane lateral resistance about 150%. [29] found that only 0.29% reinforcement in the longitudinal direction can increase the strength of masonry wall panel in out-of-plane direction by more than 10 times.

In general, the surface treatment method can significantly improve the strength and stiffness of masonry structure. Furthermore, they both increase the wall height-to-ratio, the in-plane lateral resistance, out-of-plane stability and arching action are increased accordingly [30]. Obviously, this technique is suitable for the vertical masonry element and it will be harmful if being implemented on the horizontal masonry elements like arches. Nevertheless, the shortcomings of this method are the much time consumption in the application and it destroys the original aesthetics. Therefore, this technique is not suitable for the retrofitting of masonry heritage,

2.2.2. Mortar Joint Treatment

Sometimes, the masonry units in the buildings are still of good quality but the mortar is poor or it was not fully filled. Therefore, the mortar could be replaced or refilled by new bonding material with higher strength. Grout injection and re-pointing are the most often used techniques.

Grout injection is implemented by filling the voids and cracks [31] developed different types of grouts for filling spaces ranging in size from very narrow cracks to large voids and empty joints. This technique has been found to be effective at restoring the initial stiffness and strength of masonry, but no significant improvement in the initial stiffness or strength. Though the grout can be replaced with material of higher strength, the improvement is still not remarkable [32] found that the addition of 2% Ordinary Portland Cement to the mortar made little or no difference to the ultimate acceleration resistance. However, the effectiveness of this technique can be improved if it is used in combination with other techniques [33] conducted a study by combining FRP rods and re-pointing technique on masonry structure. The results displayed that using re-pointing technique combined with FRP laminates is the most effective retrofitting technique. It should be noted that this approach will work efficiently only if the mechanical property of the mix and its physical and chemical compatibility with the masonry to be retrofitted has been achieved [34].

In the retrofitting of masonry heritages, the preservation of the original aesthetics and the compatibility in terms of physicochemical and mechanical characteristics are the most important concerns [35]. The former means that the authenticity of masonry heritages need to be preversed after retrofitting while the latter means that masonry and the retrofitting material should have a good compatibility in terms of physicochemical and mechanical performance. The use of incompatible retrofitting materials may initiate decay mechanisms or even lead to catastrophic results [36]. The application of grout injection and re-pointing can preserve the original appearance of masonry heritage. As previously stated, the physical and chemical compatibility between masonry heritage and retrofitting materials is critical, while the interaction between retrofitting material and masonry is still not known clearly. Therefore, recent research regarding the design and selection or restoration mortar is interlinked with compatibility assessment to ensure the long-term durability of masonry heritage [35] presented a methodological approach for the selection of restoration mortars regarding fragility analysis. In the paper, selection of the optimum mortar, complying with the set compatibility and performance requirement can be accomplished by setting requirements during the characterization of the retrofitting materials and the investigation of masonry heritage.

This technique is suitable for most masonry buildings, especially for the masonry heritage as the authenticity can be preversed after retrofitting. The prerequisite is that the retrofitting mortar does not have a detrimental effect on the initial masonry. Another ideal area of application is multi-leaf masonry walls where the connection between different layers are poor as well as the voids in the dry rubble stone’s inner core. This method becomes popular and practical because of its minimal cost and ease of implementation, and most importantly, its sustainability.

2.2.3. External Steel Reinforcement

The application of this technique is to install steel elements next to the original masonry element, which might be tied together or not. During an earthquake, small cracks are expected to occur and they will develop and propagate if external loading exceeds its load carrying capacity. However, the new steel system has a considerably large stiffness and will stop the cracking on the masonry wall from propagating [37, 38]. In such cases, the external load will be carried by the stronger steel system while the initial masonry system may work as a structural element instead of carrying loads. [39] conducted a research by attaching steel members directly on the masonry wall, and the results presented that the lateral strength in in-plane direction of the reinforced wall was improved about 4.5 times. Other studies concluded that this steel reinforcing system is significantly effective in improving the masonry structure’s resistance, ductility, and energy absorption [38, 39]. This technique is very effective in improving the load resistance of a structure as steel is a strong retrofitting material. Therefore, this approach is applicable for the weak masonry structures or the structures that need to be improved remarkably. However, as the appearance of steel will change the aesthetics of the original masonry structure, thus, it is not a suitable retrofitting approach for masonry heritage. Furthermore, the high cost is another concern of its implementation in developing countries.

2.2.4. Post-tensioning

In the post-tensioning strengthening method, the pre-stressed reinforcements are placed along the vertical elements for the sake of improving the strength and ductility of the lateral load resisting frame of the structure [37]. In detail, this method is carried out by drilling a hole through the masonry wallets, and vertically placing pre-stressed reinforcement in the drilled hole. The compressive force will be provided by the pre-stressed reinforcement, which can counteract the tensile force occurred in masonry wall, thus improving its load carrying capacity. Experiments illustrated that the lateral load resistance of masonry walls can be doubled [40, 41] implemented this approach on masonry walls in out-of-plane direction to analyse the flexural behaviour. Though the results presented that the ductility of the reinforced masonry panel was not improved, the strength and stiffness were increased remarkably. However, in the results of experiments conducted by [42], some difference regarding the ductility was found. The maximum strength can be increased by a factor of 2.1 to 2.8, while the ductility by values was improved with an average value of 2.7 times. Similarly, [43] found that the shear capacity and ductility can be improved significantly, while the ability of energy dissipation is also increased remarkably. Besides the application on bare masonry panels, this technique can be used to improve the seismic performance of RC frame infilled with masonry wall [44] conducted such a study to find that the engagement between RC frames and masonry infill has been improved through this retrofitting technique, thus leading to a postponed failure mechanism. It should be noted that the axial force provided by the pre-stressing bar and the vertical load should be smaller than a certain limit. Exceeding the limit, the ductility will decrease [43].

The center core is similar to the post-tensioning technique to some extent, which involves of installing a reinforced core in the vertical direction of the masonry walls. The differences between this technique and post-tensioning are that the steel bar is not pre-stressed and the drilled hole is much bigger. The idea of this technique is to improve the masonry’s ability to resist cracking and increase the ductility while keeps the stiffness unchanged [45]. This method has successfully doubled the strength of a masonry panel in a static cyclic test [28, 46] has successfully applied this technique on more than 60 projects to mitigate the earthquake hazard.

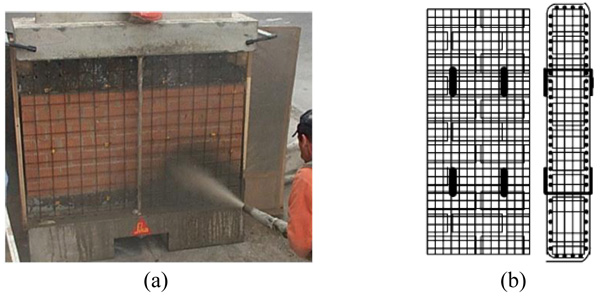

2.2.5. Mesh Reinforcement

Some of the shortcomings in the above approaches, adding mass, for instance, can be overcome by using mesh reinforcement. FRP is the most commonly used mesh reinforcement to reinforce URM structures (Fig. 4). FRP composite was first used to retrofit or strengthen the existing concrete structures. It has been extended and applied on other (masonry, timber) structures and extensively studied as well [47].

In general, strengthening/retrofitting of URM walls using FRP composites can improve the strength of masonry wallets about 1.1 to 3 times [34, 48] found that the resistance of the wallets can be improved by 13-84% by doing an analysis on masonry wallets retrofitted with carbon fibre. The improvement might be much more dependent on the to be retrofitted structure. In the study of [49], FRP has been found to improve the shear resistance of the masonry buildings by 3.25 times. The study concluded that if the economy and mechanical behaviour are both concerned, it is better to choose unidirectional FRP laminates or fabric strips instead of using two-dimensional fabrics [50] carried out research to investigate the effectiveness of the FRP with different configurations: grid arrangement and diagonal strips. It is noted that the asymmetrical application of the reinforcing is not effective in improving the shear resistance of masonry walls. Moreover, it is found that the grid strips provide a better stress redistribution, which results in a less brittle failure, while the diagonal strips are more effective in enhancing the shear capacity. FRP can be applied in combination with other strengthening/retrofitting materials [51] found that the combined use of FRP and PP-band performed much better than the application of either individual usage. In terms of the failure type of masonry panels retrofitted with FRP, the detachment of FRP from masonry surface plays an important role [51]. The effectiveness of retrofitting will be lost if the FRP starts debonding from the masonry surface [52] found that the failure modes are masonry crushing, FRP rupture and debonding.

|

Fig. (4). FRP strengthening approach on masonry wall. |

The reinforcing of masonry panels using FRP possesses the merits of little added mass, low disturbance and relatively high improvement in strength. Nevertheless, the shortcomings of this technique are that it is expensive, requires high technical skill and changes the structure’s appearance. The initial cost of FRP material is about 5 to 10 times more expensive than steel [53], which is a big concern in choosing the retrofitting approaches. In addition, the property and performance, especially their long-term behaviour, of FRP materials have not been thoroughly understood [54]. Moreover, the FRP is normally applied by externally attaching the strips or sheets on the surface of masonry wall, and a water-proof barrier and prevention of the natural transpiration of the masonry structure might be created. Finally, this type of strengthened structures will be particularly weak if the epoxy-based bonding material is used in the strengthening with FRP composites [30].

If FRP is too expensive to afford in the developing countries, the Polypropylene (PP) band and bamboo meshes can be alternatives. PP band is a universal cheap packing material having considerable elongation capacity, which has been introduced as a cheap reinforcing approach in Japan. [55] did a test on both retrofitted and unretrofitted masonry panels, and the result displayed that the reinforced panel with PP mesh provide a higher residual strength after the occurrence of cracks. This strengthening approach is often used in reinforcing adobe masonry structure. [56] applied this technique on the non-engineered (adobe) masonry in rural Nepal. This retrofitting approach has found to be helpful in preventing the loss of material and maintaining wall integrity. This approach possesses the same merit that it is suitable on the low-strength masonry structure/element. With the application on high-strength masonry structure, the effectiveness will be much less significant. [51] retrofitted a brick masonry house using this technique, and the results showed that the retrofitted masonry structure was unable to withstand a severe shaking condition. With the bamboo meshes. [57] conducted a research on retrofitting an adobe house using bamboo band meshes. The retrofitted adobe house could withstand over twice larger input energy than the non-retrofitted specimen. The advantages of pp-band and bamboo meshes are their low cost and easy availability.

The mesh reinforcement is not only effective in reinforcing the vertical masonry structures but also significant in the strengthening of horizontal elements like vaults and arches, especially the composite materials made with textile fibers both with polymeric and cementitious matrices [58] strengthened masonry arches and vaults with different composites (TRM, SRG and FRP), all the experimental results showed that all the reinforcement systems were very efficient in increasing the maximum load [59] used the post-strengthening method with C-FRP on masonry vaults, and a similar result was found. More research about retrofitting/strengthening on masonry vaults and arches can be found in the work of [58, 60, 61] reviewed the strengthening of masonry arches using composite regarding the reinforcement position, and the result pointed out that the best type of reinforcement position is continuous at the intrados and extrados of the arches.

Though the polymer-reinforces fibers are the most commonly used to strengthen vaults and arches, they still possess the disadvantages of lack of water vapor permeability [62] proposed an alternative method by embedding long steel fibers and basalt textiles in the mortar to provide a steel-basalt reinforce mortar-based composite. The retrofitting results are compared with the polymer composites and both cases are effective in strengthening masonry vaults in terms of increasing of load and deformation capacity [6] agrees with the work of [62] that basalt on a mortar matrix provides both higher capacity and better ductility compared with polymer matrix.

2.2.6. Reticulatus System

The reticulatus system, was recently proposed by [63] to retrofit/reinforce rubble stone masonry. This system is carried out by inserting a continuous mesh of high strength reinforcement in the mortar joints, which are striped off about 40-60mm. Then, the mesh of reinforcement will be anchored to the masonry panel with transverse metal bars with the number of 5-6 per m2. After that, the reinforcement and anchoring bars will be covered by re-pointing mortar back to the joints. The dimension of the reinforcement mesh normally ranges from 300-500mm, and it must be smaller than the thickness of the panel [64]. The detailed configuration of a typical reticulatus system is displayed in Fig. (5).

|

Fig. (5). Configuration of reticulatus system (extracted from [63]). |

In the study of [65], the reticulatus system has been applied on historic masonry to investigate the flexural strengthening. The results have proved the improvement and the potential application of this technique. However, the improvement of bending force and the initial stiffness was realized only under appropriate pre-tension. In the work of [66], the reticulatus system made of fibre-reinforcement was used to retrofit an ancient building to provide a cross-interlock to resist against tensile strength produced by lateral forces. Though the compression, shear and flexural strength of stone or rubble masonry wall reinforced by the reticulatus system can be increased, the effectiveness of this reinforcing technique relies on the reinforcement mesh embedded in the mortar joints [63]. Besides the difference of improvement on retrofitting materials, the improvement of same retrofitting material on different masonry structures varies as well. [64] found that the shear strength of the retrofitted pebble masonry was improved about 40% while 17% for stone masonry by using the same retrofitting technique.

As this reinforcing system can keep the original aesthetic of the building, it is therefore suitable in reinforcing the fair-face masonry or the masonry heritages. Furthermore, this technique fits the masonry panels of both regular and irregular shape. Similar with FRP, the reticulatus system does not put on much extra load. So far, this technique is only applied on the stone/rubble/pebble masonry structure. Further investigation of the application of this technique on other masonry structures, such as brick masonry, should be conducted.

2.3. To Improve the Integrity

2.3.1. Confinement of URM with Constructional Columns

This technique involves constructional columns confining the masonry walls at all corners and wall intersections as well as the vertical borders of door and windows openings [27]. The integrity will be improved much more remarkably if the constructional columns relate to ring beams at floors levels. Both the constructional columns and ring beams confine the masonry structure at the same storey. This method could improve the resistance ability in both directions (out-of-plane and in-plane) [67] found that this approach could improve the lateral resistance about 1.5 times and the lateral deformations and energy dissipation about 50%. [68] has investigated this technique on half-scale specimens under cyclic loading, and the tests demonstrated that the energy dissipation of the wall has been improved as well as the deformability in in-plane direction. It is recommended to use this confined system for newly built masonry structure in Eurocode 8 as the integrity of the building can be guaranteed. The application of this technique on existed buildings will be hard and high cost.

2.3.2. Confinement of URM with Ring Beam

The reinforced concrete ring-beams were normally used in masonry structures to improve its mechanical behaviour. The masonry structures confined with constructional columns and ring beams are expected to perform well in earthquakes [69] concluded in a study on confined masonry structures that the mechanical performance (ductility and strength) of the masonry panels are maintained mostly by the confining elements. Furthermore, more strength of the masonry structure will be preserved during an earthquake with higher reinforcement ratio and more confining elements. In some cases, if the existing ring beam is damaged or weak initially, retrofitting/strengthening can be done on the ring beam to restore its original function [70] retrofitted the masonry building with masonry ring-beam reinforced with composites. The result showed that the masonry ring-beam reinforced with composites performs well in terms of load carrying capacity. Similarly with constructional columns, this technique is easy to install on newly built buildings.

2.3.3. Tie Bars

Tie bars can also be applied to increase the integrity of the masonry building. The function of the tie bar is to provide compression stress on the masonry wall horizontally or vertically, which is quite similar with the post-tension technique. In some cases where the foundation settled unevenly and building inclined, and the tie bars can be applied to redress the inclined parts back to its original level [42] did a series of tests on masonry panels retrofitted with vertical steel ties. The outcomes presented that the vertical ties can remarkably increase the seismic capacity of masonry structure both in strength and ductility. It should be noted that surface treatment of the bar should be carried out carefully to avoid corrosion.

2.3.4. Fibre/Textile-reinforced Mortar

Generally, the mortar in a masonry structure is too weak to consider its tensile strength. Therefore, the tensile and flexural strength of a masonry element are always ignored compared with its compressive strength. Mortar mixed with fibre/textile can possibly be used to improve the tension and flexural resistance, and accordingly improve the integrity of a masonry structure. Fibre/textile additives used in the mortar help to improve mortar’s tensile strength. [71] strengthened the masonry infill walls using plaster and hybrid glass fibres. The results demonstrated that it is not only effective in avoiding expulsion in out-of-plane direction of masonry panels, but also reducing the global in-plane damage. Similarly, [72] applied Textile-Reinforced Mortar technique (TRM) for the sake of preventing brittle failure. The result displayed that the ductility has been enhanced as well as the strength improved in out-of-plane direction. However, it should be noted that the improvement in integrity is not as remarkable as the above-mentioned methods. [73] employed Steel Reinforced Grout (SRG) which is made by embedding ultra-high tensile strength steel chords in the mortar in a convex masonry substrate. However, as the performance of SRG depends on the roughness of the masonry surface, as well as the curing conditions. Therefore, the result of this study was proved to be insufficient for a comprehensive understanding of this technique. This technique is very similar with the re-pointing and grout injection approaches.

3. NUMERICAL MODEL OF RETROFITTED/STRENGTHENED MASONRY

The numerical approach to model URM has been developed and applied in masonry research. The reason for its usage is that it provides the opportunity to study the mechanical behaviour of URM more thoroughly. Moreover, the numerical simulation can reduce the number of experiments needed to investigate its mechanical manner. Though over the past few decades, a huge number of experiments on retrofitting/strengthening have been carried out, only a small portion of them have been numerically simulated. Most of the simulation work carried out were on the investigation of masonry alone. The most frequently applied numerical approaches to model masonry include Finite Element Method (FEM) and Discrete Element Method. The case studies of modelling masonry using FEM can be found in the work of [74-78], while the researches on modelling masonry using DEM are explained in detail in the work of [79-82]. Most of the previous review papers on retrofitting/strengthening masonry structure are focused on the characteristics of each approach or technique, such as cost, application and sustainability etc. The property of masonry material is very complicated to model precisely, let alone to take the retrofitting/strengthening material into consideration. Moreover, the mechanical behavior of the interface between the original surface and the newly added surface provided by retrofitted material needs to be determined as well.

In the simulation work of retrofitted masonry, the original masonry element and retrofitting masonry are normally modelled separately. In the work of Wang et al. [54, 83], the strengthening layer was modelled as the same with the original masonry wall. The collar joint, which combines the two masonry leaves together, was modelled as a cohesive interface element. This numerical model works well only when the property of the retrofitting/strengthening materials is quite close to the URM. Mobarake et al. [84] presented a numerical platform to assess the seismic performance of unreinforced masonry buildings. The platform comprised a basic macro-element to model the solid bricks and a rigid-interface macro-element to model the nodal regions. In this model, the constitutive equations and specifications were calibrated and characterized based on the results of past experiments. In the study of Kalliontzis and Schultz [85, 86], finite element analyses has been employed to simulate the retrofitted masonry panel using post-tension technique. The masonry assemblies are modeled with three-dimensional stress eight-node linear elements while the post-tension bars with two-node linear 3D truss elements. Those models have the issue that the parameters haven’t been explained clearly. Besides the model applied on simulating masonry structures, some models have been used to analyze the RC frame infilled with masonry panels. In the research of Soltanzadeh et al. [44], an FE model was applied to simulate the retrofitted RC frame infilled with masonry wall using post-tension technique. In the model, the concrete and brick were modeled by the smeared isotropic damage-plasticity law while the mortar by a damage-based cohesive element with a finite sliding formulation. Besides, the reinforcement used in the post-tension technique was modeled with a 2-node 3-D truss element. The material properties were calibrated by comparing the numerical and experimental results.

Most recently, masonry wall retrofitted with FRP has become quite common and popular. In these retrofitting cases, the FRP-substrate interface is usually modelled as a zero-thickness interface. However, it should be noted that the constitutive model of this zero-thickness interface plays a significant role in simulating the retrofitted masonry structures, and its mechanical behavior should be determined carefully in advance. Maruccio et al. [87] modelled the interface using zero-thickness elements and the mechanical behaviour of the interface element is modelled with the incremental plasticity theory. Moreover, Malena et al. [88] applied fracture Mode-II Cohesive Material Law (CML) on the interface element, which is defined in terms of shear stress and slip at the interface. Besides, Gattulli et al. [89] modelled the FRP reinforcement by adopting truss elements. These truss elements were considered to carry only tensile forces, whose tensile response performed in a linear elastic behaviour in the beginning and then in an exponential degradation. A similar numerical model was applied in the work of Gattesco and Boem [90] as well. In the numerical model, the masonry is modeled with homogeneous material represented by smeared crack model while the GFRP wires modeled with truss element. The interface between the GFRP coating and the masonry was assumed to be perfectly attached. Similar with other researches, some of the parameters are estimated and assumed.

The mechanical performance of the original material, the retrofitting material and the interface between the new and old surfaces should be investigated and determined carefully in advance before the simulation. The numerical result might be influenced remarkably if the properties are over- or under-estimated, as well as the choice of numerical model. In Table 1, the numerical approaches reviewed in this paper are summarized and listed to provide a more visual comparison.

| Researches | Masonry Unit & Retrofitting Material | Interface Between Old and New Surface |

|---|---|---|

| Wang et al. | Bricks are modeled as elastic material | Mortar joint and collar joint are modeled as cohesive interface element by implementing micro-scale model |

| Mobarake et al. | Macro-element is applied to model solid bricks | A rigid-interface macro-element is used to model nodal regions |

| Kalliontzis and Schultz | Masonry are modeled with eight-node linear element, the post-tension bars are modeled with two-node linear truss element. | The post-tension bars are unbonded, therefore, there is no interface effect between bars and surrounding masonry. |

| Soltanzadeh et al. | concrete and brick were modeled with smeared isotropic damage-plasticity law. The post-tensioning bars are modeled with truss element. | The mortar is modeled with a damage-based cohesive element with a finite sliding formulation. |

|

Maruccio el al. |

Brick and mortar are modeled with eight-node quadrilateral iso-parametric plane stress. The FRP is simulated by a curved beam element. | The interface is modeled with six-node curved zero-thickness elements and the constitutive law is represented with incremental plasticity theory. |

|

Malena et al. |

Interface element is modeled with fracture Mode-II cohesive material law. | |

|

Gattulli et al. |

FRP is modeled as truss element, and carry only tensile forces. Total strain rotating crack model to simulate masonry panel. | The interface elements are not used in this model. |

| Gattesco and Boem | Masonry is modeled with homogeneous material represented by smeared crack model. GFRP wires are modeled with truss element. | The interface between the GFRP coating and the masonry was assumed to be perfectly attached. |

The appropriate modelling of masonry building is a prerequisite to carry out the design and assessment of masonry structures against earthquake and extreme loads, therefore, the selection of modelling approach is critical. [91] proposed a stochastic computational framework for the seismic assessment of masonry heritages. The proposed methodology consists of ten distinct steps [92]: 1) to obtain historical and experimental documentation about masonry heritage; 2) material characteristics composing the structure; 3) to select the structural model (3D FEM applied in the authors’ researches); 4) which actions to resist; 5) analysis is performed; 6) failure criterion and damage index should be established; 7) seismic vulnerability assessment conducted by applying fragility analysis; 8) repairing/strengthening decisions should be made based on the results of previous steps and re-analysis the repaired/strengthened structure; 9) to make the final decision about the most suitable and effective restoration scenario; 10) the explanatory report includes all the information mentioned in the previous steps should be presented in fully detail. Based on this methodology, a ranking method is offered, which supports authorities and engineers in choosing the ones which present the highest levels of vulnerability among a plethora of structures [92]. Moreover, it helps to provide the optimal repairing scenario among many competing scenarios.

4. COMPARISON OF DIFFERENT STRENGTHENING/RETROFITTING METHODS

In the assessment of strengthening/retrofitting of masonry structures, effectiveness and cost are the most concerned factors. As the developed or selected method should be effective in reinforcing the initial masonry structures it should also be in a cost-effective way. Therefore, the comparison of different strengthening/retrofitting methods will be discussed in detail in terms of effectiveness and cost, which are shown in Tables 2 and 3. According to Tables 2 and 3, it can be revealed that the increase of different approaches differs. Each technique possesses its own merits and shortcomings, and there is no best approach. In order to provide an effective strengthening/retrofitting approach, engineers and householders should follow the following procedures to reinforce masonry buildings, and it is:

| Methods | Effectiveness | |||

|---|---|---|---|---|

| To reduce force | Base isolation | Forces will be reduced by a factor of 5 to 6 times. | ||

| Seismic damper | It can significantly reduce the seismic induced vibrations and improve the overall behaviour of the structure by increasing its internal damping through the energy dissipated by the seismic dampers. | |||

| To upgrade the existing buildings | Surface treatment | The shotcrete increases the lateral strength about 3.6 times and improves the stability in out-of-plane direction, while the ferrocement increases the lateral resistance about 150%. | ||

| Mortar joint treatment | Both the grout injection and re-point technique can only restore its original stiffness and strength. | |||

| External steel reinforcement | The lateral in-plane resistance was improved by a factor of 4.5. | |||

| Post-tension | It increases the lateral stiffness and strength up to a factor of 2, It also increase the strength in out-of-plane direction. The center core technique can double its load carrying capacity. | |||

| Mesh reinforcement | FRP increases the lateral resistance by a factor 1.1 to 3. It can also improve the out-of-plane stability. | |||

| Reticulatus system | The shear strength can be increased by 15 to 170% depends on the masonry to be retrofitted. | |||

| To improve the integrity | Constructional columns | The lateral resistance can be increased about 1.5 times and improve the deformability and energy adsorption about 50% | ||

| Ring beams | It improves the integrity of the structure and reserve much strength after earthquake. | |||

| Tie bars | It works quite similarly with the steel bars in post-tension method. The seismic capacity of masonry structure can be significantly improved. | |||

| Fibre/textile-reinforced mortar | The tensile strength of mortar will be improved, thus preventing the out-of-plane expulsion. | |||

| Methods | Cost | |

|---|---|---|

| To reduce force | Base isolation | It is very expensive to install. It costs about 3% of total construction cost to install a new hybrid base isolation system. |

| Seismic damper | It is very expensive to apply seismic damper. Furthermore, this technique requires advanced equipment and techniques. | |

| To upgrade the existing buildings | Surface treatment | It is expensive to install as it requires special equipment as well as manufacturing of concrete and use of steel. |

| Mortar joint treatment | It is cheap to use this technique as the mortar and masonry units are easy and cheap to obtain. | |

| External steel reinforcement |

It requires relatively high cost because of the steel usage. | |

| Post-tension | This technique is somewhat highly costly. | |

| Mesh reinforcement | It is expensive as FRP is 5 to 10 times more expensive than steel. | |

| Reticulatus system | It is cost-effective as it requires small portion of reinforcement mesh and some re-pointing mortar. | |

| To improve the integrity | Constructional columns | It is expensive to apply this technique as it requires demolition and reconstruction on the original structure. |

| Ring beams | It is expensive to construct ring beams on URM structure. | |

| Tie bars | The cost of this technique is close to that of post-tensioning | |

| Fibre/textile-reinforced mortar | The cost of this technique is somewhat cheap as only mortar and fibres should be considered. | |

- To Understand the behaviour of the buildings. It should be known that masonry structures made of different masonry materials perform totally different. Brick masonry structure inherently has a stronger performance than adobe masonry structure. The strengthening/retrofitting technique works on adobe masonry may not be effective on brick masonry structure.

- To identify the broken or weak parts. In some occasions, only a small part of the structure is broken, therefore, there is no need to retrofit the whole structure. However, if the overall structure is weak, it is necessary to retrofit the overall structure.

- Determination of the external loads to be resisted. As presented in Section 2, masonry structures may be subjected to different types of external loadings. The strengthening techniques will be different according to the external loading. The masonry structure should be strengthened in the purpose to resist the certain event.

- Selection of retrofitting/strengthening approaches. There are various types of strengthening/retrofitted methods for masonry structures. Both the effectiveness and cost should be considered in the selection of the most appropriate and cost-effective method.

- Application of connector. Connector is another important factor in determining the effectiveness of the selected approach. For example, the detachment of strengthening material from the surface of masonry wall when using FRP, shotcrete and ferrocement will significantly reduce the strengthening effectiveness. Therefore, the connection details should be carried out by skilled worker following instruction guide.

- Re-evaluating the strengthened/retrofitted approach. The strengthened/retrofitted approach should be assessed by engineers to determine whether it can resist the designed external loading. In the assessment of the retrofitted/strengthened structure, some small specimens should be tested to determine its mechanical performance via experiments.

According to Tables 2 and 3, it can be revealed that the improvement of different methods varies. Each approach has its own advantages and disadvantages, and there is no best approach. One strengthening approach that works in one structure doesn’t mean it works efficiently in another structure. Therefore, based on the material type and system type, a unique method should be selected. Based on the presented review, the suitable application of each strengthening/retrofitting approaches has been suggested, listed in Table 4. However, it should be noted that the application is only a suggestion, which is not unchangeable. The real structure is complex and it may encounter different issues. Therefore, the final decision should be made by both engineer and asset manager together.

| Methods | Application | |

|---|---|---|

| To reduce forces | Base isolation | This technique is suitable for newly built buildings, historical heritages and low-rise newly built structure as well as the structure located on hard foundation. |

| Seismic damper | It is desirable for the frames structures located in the seismic prone area, but not common on masonry buildings. | |

| To upgrade the existing buildings | Surface treatment | It is suitable for the structures whose function and appearance is not highly concerned while the reinforcement is more concerned, like the residential buildings. |

| Mortar joint treatment | It suits the exterior masonry wallets because collar jointed wall system is applied to improve thermal insulation and prevent water penetration. It also suits the masonry heritages as it preserves its authenticity. | |

| External steel reinforcement |

It suits the low-rise and weak building which lacks extensively ductility, it is not applicable on the masonry heritage.. | |

| Post-tension | It is desirable for the masonry structure built with perforated masonry units as there is no need to drill the masonry walls. | |

| Mesh reinforcement | It is desirable in the developed countries and with skilled technicians. It is also ideal for the structure to resist blast. It is preferable in strengthening vaults and arches. | |

| Reticulatus system | It is suitable for fair-face masonry and masonry heritages of both regular and irregular shape. | |

| To improve the integrity | Constructional columns | It is suitable for newly built structures. |

| Ring beams | It is suitable for newly built structures or the FRP can be used to retrofit/strengthen the already damaged ring beam. | |

| Tie bars | It fits the similar situation as the post-tension if the tie bar can be fixed along the masonry wall both vertically and horizontally. | |

| Fibre/textile- reinforced mortar |

It fits the same cases with grout injection or re-pointing if the mortar joint is weak or can be easily replaced. | |

CONCLUSION

The existing strengthening/retrofitting techniques for URM has been reviewed and discussed in this paper, and the results demonstrate that the efficiency of different strengthening approaches differs. Each method possesses its own merits and shortcomings. It is impossible to determine the best strengthening/retrofitting approach. The significance of the improvement of each reinforcing method is dependent on the material that made the original building, as well as the material used to strengthen. When the implemented approach has been found to be effective and economic for a certain type of structure, it cannot be extended and applied to other buildings. Therefore, the selection of reinforcing approaches should be made based on the factors that are most concerned. For example, if the effectiveness is of the most concern, then FRP is an appropriate approach. However, if the cost is the biggest issue, then ferrocement might be more suitable. After the strengthening/retrofitting work has been done, the retrofitted/strengthened masonry structure should be re-evaluated using the reviewed numerical simulation approaches. The most appropriate numerical model can be selected based on the types of retrofitting materials and the masonry construction system. No matter which simulation approach is chosen, the interface element between the brick and mortar or the interface between the brick surface and retrofitting surface is extremely important. The constitutive law and parameters should be determined and calibrated carefully in order to obtain a more accurate result. The research on the mechanical behaviour, especially the non-linear hysteretic behaviour, as well as the calibration of the parameters of the interface element haven’t been conducted thoroughly, more and deeper studies on these fields should be carried out in further research. Both experiments and numerical approaches should be applied in order to obtain the constitutive law and failure mechanism between masonry panel and retrofitting material.

In addition, in order to help and guide the engineers in selecting a strengthening or retrofitting method on a masonry structure/element, a procedure is provided. Furthermore, the suggestion on the application of each strengthening/retrofitting techniques has also been proposed. It should be noted that the real structure is complex, therefore, the selection should be decided together by both the house owner and engineer. All in all, a good reinforcing technique must consider the factors of aesthetics, function, strength, ductility and stiffness and the cost requirements [83].

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

The authors would like to thank Shantou University (NTF17011) and China Scholarship Council for the finical support.

REFERENCES

| [1] | H. Matthys, and L. Noland, "Strengthening and retrofitting masonry buildings", Proceedings of an international seminar on evaluation, TMS: Colorado, USA, 1989. |

| [2] | D. Lipe, "Value and meaning in cultural resources", Approaches to the archaeological heritage, pp. 1-11. |

| [3] | F. Crisafulli, A. Carr, and R. Park, "Experimental response of framed masonry structures designed with new reinforcing details", Bulletin of the New Zealand society for earthquake engineering, vol. 38, no. 1, pp. 19-32, 2005. |

| [4] | M. Ehsani, H. Saadatmanesh, and J. Velazquez-Dimas, "Behaviour of retrofitted URM walls under simulated earthquake loading", J. Compos. Constr., vol. 3, no. 3, pp. 134-142, 1999. |

| [5] | S.W. Chuang, and Y. Zhuge, "Seismic retrofitting of unreinforced masonry buildings-a literature review", Australian Journal of Structural Engineering, vol. 6, no. 1, pp. 25-36, 2005. |

| [6] | S. Bhattacharya, S. Nayak, and S.C. Dutta, "A critical review of retrofitting methods for unreinforced masonry structures", Int. J. Disaster Risk Reduct., vol. 7, pp. 51-67, 2014. |

| [7] | S. Julie, and R. Sajeeb, "Performance of base isolators and tuned mass dampers in vibration control of a multistoried building", IOSR Journal of Mechanical and Civil Engineering Volume, vol. 2, 2012. |

| [8] | A. De Luca, E. Mele, J. Molina, G. Verzeletti, and A.V. Pinto, "Base isolation for retrofitting historic buildings: Evaluation of seismic performance through experimental investigation", Earthquake Eng. Struct. Dynam., vol. 30, pp. 1125-1145, 2001. |

| [9] | J.M. Kelly, "Aseismic base isolation: Review and bibliography", Soil. Dyn. Earthquake Eng., vol. 5, no. 3, pp. 202-216, 1986. |

| [10] | V. Kilar, and S. Petrovcic, "Seismic rehabilitation of masonry heritage structures with base-isolation and with selected contemporary strengthening measures", Seismic Resistant Structures, p. 13, 2018. |

| [11] | M. Seki, M. Miyazaki, and Y. Tsuneki, "A masonry school building retrofitted by base isolation technology", Proceedings of the 12 World Conference on Earthquake Engineering, 2000.Auckland |

| [12] | R.P. Nanda, P. Agarwal, and M. Shrikhande, "Suitable friction sliding materials for base isolation of masonry buildings", Shock Vib., vol. 19, pp. 1327-1339, 2012. |

| [13] | M. Tomaževič, I. Klemenc, and P. Weiss, "Seismic upgrading of old masonry buildings by seismic isolation and CFRP laminates: A shaking-table study of reduced scale models", Bull. Earthquake Eng., vol. 7, pp. 293-321, 2009. |

| [14] | A. Chiozzi, M. Simoni, and A. Tralli, "Base isolation of heavy non-structural monolithic objects at the top of a masonry monumental construction", Mater. Struct., vol. 49, pp. 2113-2130, 2016. |

| [15] | T. Corp, Hybrid base isolation system used in super high-rise office building for the first time in the world., News Release, 2001. Available from: www.takenaka.co.jp |

| [16] | P.G. Asteris, "On the structural analysis and seismic protection of historical masonry structures", Open Constr. Build. Technol. J., vol. 2, pp. 124-133, 2008. |

| [17] | S.M. Zahrai, A. Moradi, and M. Moradi, "Using friction dampers in retrofitting a steel structure with masonry infill panels", Steel Compos. Struct., vol. 19, pp. 309-325, 2015. |

| [18] | A. Benedetti, L. Landi, and D.G. Merenda, "Displacement-based design of an energy dissipating system for seismic upgrading of existing masonry structures", J. Earthquake Eng., vol. 18, pp. 477-501, 2014. |

| [19] | N. Longarini, and M. Zucca, "A chimney’s seismic assessment by a tuned mass damper", Eng. Struct., vol. 79, pp. 290-296, 2014. |

| [20] | R. Taleb, F. Bouriche, A. Remas, M. Boukri, and F. Kehila, "Use of ambient and forced vibration tests to evaluate seismic properties of an unreinforced masonry building rehabilitated by dampers", Proceedings of the 15th World Conference on Earthquake Engineering, 2012.Lisboa |

| [21] | D. Benedetti, "“Increasing available ductility in masonry buildings via energy absorbers”, Shaking table tests", Eur Earthq Eng, vol. 18, pp. 3-16, 2004. |

| [22] | V. Gocevski, and Z. Petraskovic, "Seismic analysis of existing masonry structures reinforced with “SYSTEM DC90” dampers", Proceedings of the Earthquake Engineering Conference, 2012.Skopje |

| [23] | D.P. Abrams, "New perspectives on seismic rehabilitation", Proceedings of the Asia-Pacific worshop on Seismic Design and Retrofit of Structures, 1998.Taipei, Taiwan |

| [24] | F. Karantoni, and M. Fardis, Effectiveness of seismic strengthening techniques for masonry buildings, . |

| [25] | M.A. ElGawady, P. Lestuzzi, and M. Badoux, "Retrofitting of masonry walls using shotcrete", Proceedings of the NZSEE Conference, 2006.New Zealand |

| [26] | N. Augenti, A. Nanni, and F. Parisi, "Construction failures and innovative retrofitting", Buildings, vol. 3, no. 1, pp. 100-121, 2013. |

| [27] | M.A. ElGawady, P. Lestuzzi, and M. Badoux, "A review of conventional seismic retrofitting techniques for URM", Proceedings of the 13th International Brick and Block Masonry Conference, 2004.Amsterdam a |

| [28] | D.P. Abrams, and J.M. Lynch, "Flexural behaviour of retrofitted masonry piers", Proceedings of the KEERC-MAE Joint Seminar on Risk Mitigation for Regions of Moderate Seismicity, 2001.Illinois, USA |

| [29] | S.B. Kadam, Y. Singh, and B. Li, "Out-of-plane behaviour of unreinforced masonry strengthened using ferrocement overlay", Mater. Struct., vol. 48, pp. 3187-3203, 2015. |

| [30] | A. Garofano, Structural behaviour of masonry walls strengthened with mortar layers reinforced with FRP grids, 2011.Master's thesis |

| [31] | M. Schuller, R. Atkinson, and J. Borgsmiller, "Injection grouting for repair and retrofit of unreinforced masonry", Proceedings of the 10th International brick/block masonry conference, 1994.Calgary, Alberta, Canada |

| [32] | R. Tetley, and G. Madabhushi, "Vulnerability of adobe buildings under earthquake loading", Proceedings of the 4th Conference earthquake geotechnical engineering, 2007.Thessaloniki, Greece |

| [33] | D. Tinazzi, M. Arduini, C. Modena, and A. Nanni, "FRP structural re-pointing of masonry assemblages", Proceedings of the Proc 3rd Int Conf on Advanced Composite Materials in Bridges and Structures, 2000.Ottawa, Canada |

| [34] | P. Alcaino, and H. Santa-Maria, "Experimental response of externally retrofitted masonry walls subjected to shear loading", J. Compos. Constr., vol. 12, no. 5, pp. 489-498, 2008. |

| [35] | M. Apostolopoulou, E. Aggelakopoulou, L. Siouta, A. Bakolas, M. Douvika, and P.G. Asteris, "A methodological approach for the selection of compatible and performable restoration mortars in seismic hazard areas", Constr. Build. Mater., vol. 155, pp. 1-14, 2017. |

| [36] | A. Moropoulou, A. Bakolas, and S. Anagnostopoulou, "Composite materials in ancient structures", Cement Concr. Compos., vol. 27, pp. 295-300, 2005. |

| [37] | A. Hamid, A. Mahmoud, and S. Abo El Maged, "Strengthening and repair of unreinforced masonry structures: State of the art", Proceedings of the 10th international brick and block masonry conference, 1994.Calgary, Canada |

| [38] | D. Rai, and S. Goel, "Seismic strengthening of unreinforced masonry piers with steel elements", Earthquake Spectrume, vol. 12, pp. 845-862, 1996. |

| [39] | M. Taghdi, Seismic retrofit of low-rise masonry and concrete walls by steel strips, PhD thesis, Universitá degli Studi di Pavia, Istituto Universitario di Studi Superiori: Pavia, Italy, 2000. |

| [40] | R. Amiraslanzadeh, T. Ikemoto, and M. Miyajima, "A comparative study on seismic retrofitting methods for unreinforced masonry brick walls", Proceedings of the 15th World Conference on Earthquake Engineering, 2012.Lisboa |

| [41] | A.A. Al-Manaseer, and W.V. Neis, "Load test on post-tensioned masonry wall panels", Structural Journal, vol. 84, no. 6, pp. 467-472, 1987. |

| [42] | A. Darbhanzi, M. Marefat, and M. Khanmohammadi, "Investigation of in-plane seismic retrofit of unreinforced masonry walls by means of vertical steel ties", Constr. Build. Mater., vol. 52, pp. 122-129, 2014. |

| [43] | H. Liu, L. Ban, C. Lan, and X. Yang, "Quasi-static test of unreinforced brick walls retrofitted with post-tensioning tendons", Journal of Building Structures, vol. 36, pp. 142-149, 2015. |

| [44] | G. Soltanzadeh, H.B. Osman, M. Vafaei, and Y.K. Vahed, "Seismic retrofit of masonry wall infilled RC frames through external post-tensioning", Bull. Earthquake Eng., pp. 1-24, 2017. |

| [45] | T.F. Paret, S.A. Freeman, G.R. Searer, M. Hachem, and U.M. Gilmartin, "Using traditional and innovative approaches in the seismic evaluation and strengthening of a historic unreinforced masonry synagogue", Eng. Struct., vol. 30, pp. 2114-2126, 2008. |

| [46] | D.C. Breiholz, "Centercore strengthening system for seismic hazard reduction of unreinforced masonry bearing wall buildings", Structural Engineering in Natural Hazards Mitigation, 2003, pp. 319-324. |

| [47] | J.G. Teng, J.F. Chen, S.T. Smith, and L. Lam, "Behaviour and strength of FRP-strengthened RC structures: A state of the art review", Proc. Inst. Civ. Eng., Struct. Build., vol. 156, no. 1, pp. 51-62, 2003. |

| [48] | M.A. ElGawady, P. Lestuzzi, and M. Badoux, "A review of retrofitting of unreinforced masonry walls using composits", Proceedings of the 4th International Conference on Advanced Composite Materials in Bridges and Structures, 2004.Calgary, Alberta b |

| [49] | H. Mahmood, and J. Ingham, "Diagonal compression testing of FRP-retrofitted unreinforced clay brick masonry wallettes", J. Compos. Constr., vol. 15, no. 5, pp. 810-820, 2011. |

| [50] | M.R. Valluzzi, D. Tinazzi, and C. Modena, "Shear behaviour of masonry panels strengthened by FRP laminates", Constr. Build. Mater., vol. 16, no. 7, pp. 409-416, 2002. |

| [51] | M.U. Saleem, M. Numada, M.N. Amin, and K. Meguro, "Seismic response of PP-band and FRP retrofitted house models under shake table testing", Constr. Build. Mater., vol. 111, pp. 298-316, 2016. |

| [52] | R.S. Nezhad, and M.Z. Kabir, "Experimental investigation on out-of-plane behavior of GFRP retrofitted masonry panels", Constr. Build. Mater., vol. 131, pp. 630-640, 2017. |

| [53] | "Does FRP have an economic future?", Proceedings of the 4th conference on advanced composite materials in bridges and structures, 2004.Calgary, Alberta |

| [54] | C. Wang, J.P. Forth, N. Nikitas, and V. Sarhosis, "Retrofitting of masonry walls by using a mortar joint technique; experiments and numerical validation", Eng. Struct., vol. 117, pp. 58-70, 2016. |

| [55] | N. Sathiparan, P. Mayorca, K. N. Nesheli, R. Guragain, and K. Meguro, "Experimental study on in-plane and out-of-plane behavour of masonry wallettes retrofitted by PP-band meshes", Production research, vol. 57, no. 6, pp. 530-533, 2005. |

| [56] | J. Macabuag, R. Guragain, and S. Bhattacharya, "Seismic retrofitting of non-engineered masonry in rural Nepal", Proc. Inst. Civ. Eng., Struct. Build., vol. 165, pp. 273-286, 2012. |

| [57] | K. Meguro, R. Soti, S. Navaratnaraj, and M. Numada, "Dynamic testing of masonary houses retrofitted by bamboo band meshes", Journal of Japan Society of Civil Engineers, Ser. A1 (Structural Engineering and Earthquake Engineering (SE/EE)), vol. 68, pp. I-760-I-765, 2012. |

| [58] | F.G. Carozzi, C. Poggi, E. Bertolesi, and G. Milani, "Ancient masonry arches and vaults strengthened with TRM, SRG and FRP composites: Experimental evaluation", Compos. Struct., 2017. |

| [59] | L. Anania, A. Badalà, and G. D’Agata, "The post strengthening of the masonry vaults by the Ω-Wrap technique based on the use of C-FRP", Constr. Build. Mater., vol. 47, pp. 1053-1068, 2013. |

| [60] | P. Zampieri, N. Simoncelo, C.D. Tetougueni, and C. Pellegrino, "A review of methods for strengthening of masonry arches with composite materials", Eng. Struct., vol. 171, pp. 154-169, 2018. |

| [61] | F. Valvona, J. Toti, V. Gattulli, and F. Potenza, "Effective seismic strengthening and monitoring of a masonry vault by using glass fiber reinforced cementitious matrix with embedded fiber bragg grating sensors", Compos., Part B Eng., vol. 113, pp. 355-370, 2017. |

| [62] | L. Garmendia, P. Larrinaga, R. San-Mateos, and J.T. San-José, "Strengthening masonry vaults with organic and inorganic composites: an experimental approach", Mater. Des., vol. 85, pp. 102-114, 2015. |

| [63] | A. Borri, G. Castori, M. Corradi, and E. Speranzini, "Shear behavior of unreinforced and reinforced masonry panels subjected to in situ diagonal compression tests", Constr. Build. Mater., vol. 25, pp. 4403-4414, 2011. |

| [64] | M. Corradi, A. Borri, G. Castori, and R. Sisti, "The Reticulatus method for shear strengthening of fair-faced masonry", Bull. Earthquake Eng., vol. 14, pp. 3547-3571, 2016. |

| [65] | B. Csikai, L.F. Ramos, P. Bastos, S.M.T. Moreira, and P.B. Lourenço, "Flexural out-of-plane retroftting technique for masonry walls in historical constructions", Proceedings of the 9th International Conference on Structural Analysis of Historical Constructions, 2014. |

| [66] | R. Fonti, A. Borri, R. Barthel, M. Candela, and A. Formisano, "Rubble masonry response under cyclic actions: Experimental tests and theoretical models", International Journal of Masonry Research and Innovation, vol. 2, pp. 30-60, 2017. |

| [67] | M. Tomazevic, and I. Klemenc, "Seismic behaviour of confined masonry walls", Earthquake Eng. Struct. Dynam., vol. 26, no. 10, pp. 1059-1071, 1997. |

| [68] | S. Paikara, and D.C. Rai, "Confining masonry using pre-cast R.C. element for enhanced earthquake resistance", Proceedings of the 8th U.S. National Conference on Earthquake Engineering, 2006.San Francisco. California, USA |

| [69] | H. Okail, A. Abdelrahman, A. Abdelkhalik, and M. Metwaly, "Experimental and analytical investigation of the lateral load response of confined masonry walls", HBRC Journal, vol. 12, pp. 33-46, 2016. |

| [70] | A. Borri, G. Castori, and A. Grazini, "Retrofitting of masonry building with reinforced masonry ring-beam", Constr. Build. Mater., vol. 23, pp. 1892-1901, 2009. |

| [71] | F. Porto, G. Guidi, M.D. Benetta, and N. Verlato, "Combined in-plane/out-of-plane experimental behaviour of reinforced and strengthened infill masonry walls", Proceedings of the 12th Canadian Masonry Symposium, 2013.Vancouver, British Columbia, Canada |

| [72] | A. Martins, G. Vasconcelos, R. Fangueiro, and F. Cunha, "Experimental assessment of an innovative strengthening material for brick masonry infills", Compos., Part B Eng., vol. 80, pp. 328-342, 2015. |

| [73] | S.D. Santis, "Bond behaviour of steel reinforced grout for the extrados strengthening of masonry vaults", Constr. Build. Mater., vol. 150, pp. 367-382, 2017. |

| [74] | D. V. Oliveira, Experimental and numerical analysis of blocky masonry structures under cyclic loading, 2003. |

| [75] | P.J.B.B. Lourenço, Computational strategies for masonry structures, Delft University, 1997.PhD thesis |

| [76] | "Modelling masonry shear-compression: Role of dilatancy highlighted", J. Eng. Mech., vol. 130, pp. 1289-1296, 2004. |

| [77] | "Finite element model for masonry", J. Struct. Div., vol. 140, pp. 1367-1285, 1978. |

| [78] | “Constitutive models for nonlinear finite element analysis of masonry prisms and infill walls”, No. ERDC/CERL TR-08-19., US Army Coprs of Engineering, 2008. |

| [79] | "T. FD, A. PG, and V. Sarhosis, “Influence of column shear failure on pushover based assessment of masonry infilled reinforced concrete framed structures: A case study", Soil. Dyn. Earthquake Eng., vol. 100, pp. 98-112, 2017. |

| [80] | P. G. Asteris, C Repapis, L Cavaleri, and V. Sarhosis, "On the fundamental period of infilled RC frame buildings", Struct. Eng. Mech., vol. 54, pp. 1175-1200, 2015. |

| [81] | V. Sarhosis, K Bagi, and JV Lemos, Computational modelling of masonry structures using the discrete element method, IGI Global: USA, 2016. |

| [82] | V. Sarhosis, "M. G., R. Fangueiro, and F. F, “Evaluation of different approaches for the estimation of the seismic vulnerability of masonry", Bull. Earthquake Eng., vol. 16, pp. 1511-1545, 2018. |

| [83] | C.F.J. Wang, N. Nikitas, and V. Sarhosis, "Experimental and numerical investigation on collar-jointed masonry walls", Proceedings of the 16th international Brick and Block Masonry Conference, 2016.Padova, Italy |

| [84] | A.A. Mobarake, M. Khanmohammadi, and S. Mirghaderi, "A new discrete macro-element in an analytical platform for seismic assessment of unreinforced masonry buildings", Eng. Struct., vol. 152, pp. 381-396, 2017. |

| [85] | D. Kalliontzis, and A. Schultz, "Improved estimation of the reverse-cyclic behavior of fully-grouted masonry shear walls with unbonded post-tensioning", Eng. Struct., vol. 145, pp. 83-96, 2017. |

| [86] | D. Kalliontzis, and A.E. Schultz, "Characterizing the in-plane rocking response of masonry walls with unbonded posttensioning", J. Struct. Eng., vol. 143, p. 04017110, 2017. |

| [87] | C. Maruccio, I. Basilio, D.V. Oliveira, P.B. Lourenço, and G. Monti, "Numerical modelling and parametric analysis of bond strength of masonry members retrofitted with FRP", Constr. Build. Mater., vol. 73, pp. 713-727, 2014. |

| [88] | M. Malena, F. Focacci, C. Carloni, and G. De Felice, "The effect of the shape of the cohesive material law on the stress transfer at the FRP-masonry interface", Compos., Part B Eng., vol. 110, pp. 368-380, 2017. |

| [89] | V. Gattulli, G. Lampis, G. Marcari, and A. Paolone, "Simulations of FRP reinforcement in masonry panels and application to a historic facade", Eng. Struct., vol. 75, pp. 604-618, 2014. |

| [90] | N. Gattesco, and I. Boem, "Out-of-plane behavior of reinforced masonry walls: Experimental and numerical study", Compos., Part B Eng., vol. 128, pp. 39-52, 2017. |

| [91] | P.G. Asteris, M. Douvika, P. Karakitsios, P. Moundoulas, M. Apostolopoulou, and A. Moropoulou, "A Stochastic Computational Framework for the Seismic Assessment of Monumental Masonry Structures", Proceedings of the 5th International Conference on Integrity, Reliability and Failure, 2016pp. 24-28.Porto, Portugal |

| [92] | P.G. Asteris, M.G. Douvika, M. Apostolopoulou, and A. Moropoulou, "Seismic and restoration assessment of monumental masonry structures", Materials (Basel), vol. 10, p. 895, 2017. |