All published articles of this journal are available on ScienceDirect.

Understanding the Characteristics of Regional Building Construction Systems

Abstract

Background:

Pandemics have increased the importance of understanding future building construction systems' regional characteristics due to the increasing number of country-specific industrial systems and the growing potential for international collaboration through video conferencing.

Objective:

This study aims to develop a method to objectively understand the characteristics of regional building construction systems.

Methods:

The “architecture concept” tool was used to develop the proposed idea and ensure objectivity. This concept focuses on the interdependence of the components to be created. However, considering that all construction projects are conducted under different conditions, a relative discussion between projects tends to exist. This study aims to transcend this relative discussion to achieve sophistication in the proposed approach. Therefore, this work focuses on a detailed view of the most complex construction parts standardized in each region.

Results:

As a case study, we examined the approaches adopted in the UK and Japan, i.e., in Europe and Asia, respectively. The proposed concept confirmed that the approaches adopted in the UK exhibited modular characteristics, whereas those in Japan had integral characteristics pertaining to the fundamental design concept of construction.

Conclusion:

This study developed a method for the utilization of the characteristics of each region by understanding the trends of the unique fundamental design concepts of building construction in the UK and Japan. Based on the results, the characteristics of many other regions in the construction industry can be understood.

1. INTRODUCTION

Over recent years, technologies related to the construction industry have evolved and become more complex. Given that buildings are constructed by combining several parts and products, construction is generally affected by developments in several technical and product fields. In particular, the developments in fundamental technologies, such as arithmetic processing and communication technologies, represented by computers and the Internet, respectively, influence a wide range of building construction methods in a complicated manner, given that these approaches are used to produce several building-related products and parts.

The 2020 pandemic has highlighted the need to update several aspects of the building industry, such as building demands, planning ideas, and construction processes, including the supply chains. In particular, owing to the difficulties faced by people in moving across countries and the increase in remote work and video conferencing, the perceptions of physical distance have changed. Consequently, although working physically at a workplace will continue, it is believed that processes such as design sharing and component production could be conducted through video conferencing systems. Furthermore, it is believed that virtual meetings are likely to increase in the future. Therefore, building construction process trends within and across areas are changing simultaneously.

Considering this, it is important to understand the characteristics of the building industry in all regions to recommend the future direction of construction systems while making the best use of the changing characteristics. However, each project is implemented considering various factors, such as the site conditions, surrounding environmental conditions, client requirements, and legal situations in the area, thereby making it impossible to develop unified standards across the industry.

Therefore, this study aims to develop a method to describe the characteristics of building construction in all regions by considering the characteristics of the building industry based on industrial analyses and by providing a new perspective on practical building industry analyses using the “architecture concept.” The architecture concept considers the design concepts that form the basis of an artificial system, and its fundamental principle is the system concept, commonly used in designing complex artifacts, including engineering products [1, 2]. Several industries have already been analyzed using this concept [3-6], based on the idea that the functions of a system, wherein the elements are connected, correspond to the structure of the system. It is fundamental that the process corresponds to the structure to create artificial objects, such as products and services, considering the purpose of realizing the functions of the target system using the designed structure. This concept encompasses several aspects created for buildings and spaces and is considered to have a high affinity toward the building industry [1]. Furthermore, several studies have been conducted to understand the characteristics of various industries with this concept [5-7].

Using this concept, one can consider the product and process architectures that target the structures and functions. This study mainly focuses on examining the product architecture to help understand the industrial characteristics of the building industry in each region. To this end, the product architecture is described and expressed clearly.

Architecture is created with different conditions such as site conditions and owner's requirements therefore it is quite difficult to compare all architectural projects simultaneously. Furthermore, architects and builders have their own ideas about design. Moreover, it cannot be denied that each region or country has its own tendencies toward specific architectural designs. Therefore, this study focuses on 'standard details' that clearly express the design thought tendencies of the designers in each region. This approach is rarely used in the research of the construction industry and can be academically considered a novel attempt.

2. THEORETICAL BACKGROUND

Researchers from different fields have challenged the description of industry characteristics and conducted discussions to understand practical corporate activities and client situations. However, most previous studies using the architecture concept have targeted mass-produced products, such as automobiles, computers, and electronic components [6, 8-10].

Typically, the concept of architecture has two indexes: “modular–integral” and “open–closed” [5, 8]. The “modular–integral” index is based on the interface between elements [5]; that is, if the system is an “integrated architecture,” the design rules of the interface must be coordinated with each other and the system must be tuned to maximize its potential performance [8, 11]. Conversely, the “modular architecture” provides a standardized interface for linking different components and modules [7, 12]. Therefore, independent components can be combined to manufacture various systems, provided they are compatible with these standardized interfaces. Although modular architecture maintains the independence of each module and accelerates the evolution of the system, the standardization of interfaces between the modules limits the overall performance potential of the system [5, 13].

Modularity can be classified as open-type or closed-type [8, 12]. “Open architecture” is a type of modular architecture with an industry-standard interface that enables the collection of parts and modules across enterprise and product boundaries. Modular architecture simplifies interface design information. The open-closed index is an important parameter, especially for designers of products with mass production. Several researchers have studied the modularity and integrality of such mass production systems [6, 13-15]. One important advantage of system modularity is that the commonality of components can allow for the use of various products from multiple markets [5, 16]. Although a clear distinction exists between structure modularity and process modularity [17], many previous studies have focused on modularity as a structure based upon static views [13, 18, 19]; by contrast, process modularization has not received much attention. In many industries, designing a standardized interface for a process is not considered important. The advantage of process modularization is that the designer can design a product within a module [6]. Consequently, several companies are attempting to modularize the structure of their products for competitive advantage [20, 21]. However, every company requires a significant amount of knowledge and information to ensure component compatibility and to implement mutual coordination [22].

Previous studies have discussed the relationship between the modularity of the creator's organization and the product structure when a product is created, also known as the mirroring hypothesis [23]. Based on this hypothesis, products with modular structural architectures are devised by organizational capabilities, which tend to be modular design ideas [18, 24, 25]. Each organization may design a product with a modular structure based on specific conditions. Therefore, it is essential to study the cause of the modularization of the structural architecture of the products [20]. If the manufacturing organization is modular, the structural modules of the product can be made compatible by establishing an interface in the structural architecture of the product [26]. Furthermore, restructuring the organizational units can potentially create highly effective inter-organizational interfaces and facilitate effective collaboration [25, 27]. However, previous studies have been unsuccessful in clearly explaining this mechanism because they did not entirely focus on the ability of organizational unit structures and interfaces to facilitate the modularization of the systems being created. Moreover, the dynamic relationships are unclear, making it difficult to understand the overall creative mechanism.

Sharing knowledge between organizations can be facilitated by providing and receiving information regarding specific tasks. In such cases, knowledge sharing between multiple organizations involves collaboration to develop creative processes and product concepts [28], given that this can significantly impact product and new technology development and also problem solving [29]. Furthermore, it can promote knowledge sharing through communication between the designers and engineers of other organizations [30, 31].

The relationship between the characteristics of organizational ability and knowledge sharing has attracted wide attention [32, 33]. In many cases, sharing of critical knowledge can be understood as the process of creating different types of relevant information [34]. Some studies have stated that organizational ability can be achieved by sharing [32] and transferring knowledge and design information [33, 35]. Organizational capabilities are based on the constantly changing internal and external environments, and these capabilities must be continuously upgraded [36, 37].

Inter-organizational interfaces, which are important for knowledge sharing in multiple organizations, are recognized as mutually coordinated platforms [38-40]. However, previous studies have not been able to adequately identify the appropriate combination of elements necessary for creating an effective inter-organizational interface. Therefore, it is important that the factors and mechanisms effective in creating efficient organizational interfaces are analyzed for knowledge sharing as these factors and mechanisms have a significant impact on the organizational structure and the modularity of the system thus created.

A good understanding of the modularization process of a system can improve the understanding of the characteristics of the system, considering that it affects the degree of modularization [7, 17]. However, it is difficult to understand the modularization process entirely as it includes technical aspects, along with the organizational aspects, such as the interaction between organizations and information sharing by multiple organizations [41, 42].

In addition, there have been only a few technical discussions on modular construction projects [43-45]. Modular construction can potentially decrease project complexity and the time and cost associated with engineering development while also increasing construction productivity. The characteristics of the project and individual technologies have also been discussed. Specifically, previous studies have discussed the technical possibilities from the perspective of mass customization [46] and practical consideration of interfaces [47]; most of these studies aimed to reduce the complexity of the construction industry. However, studies discussing the characteristics of the industry or region have not been reported thus far.

Therefore, this study presents concepts for understanding the regional characteristics of the construction industry. The complexity of the construction industry, the large number of parts, and the breadth of the related technical areas suggest that careful consideration of structure is required, as compared to other industries. Moreover, each project was conducted under specific conditions, including regional conditions. Through our study, we believe one can acquire a deeper understanding of the regional characteristics of the construction industry while focusing on other issues. The technical characteristics of the construction organization in each region have been described, given that the characteristics and availabilities of the organization affect the product architecture. A better understanding of the unique product architecture pattern of each region can result in a better understanding of the aspects of the technical characteristics of each region. Moreover, although the production process is important, it is difficult to completely clarify the process based on previous studies. Therefore, this study focuses directly on understanding the characteristics of the completed structural system instead of the process.

3. RESEARCH METHODS

Based on the architecture concept mentioned in the previous section, we examined actual construction technologies as a case study. Initially, this study focused on multiple regions to understand their different characteristics in terms of distance and culture. In particular, only two regions, Europe and Asia, were analyzed at first, considering that this is new research in the construction field. Thereafter, we targeted areas that had less direct influence than other areas owing to their maturity in the technical aspects of construction. Furthermore, we considered the high technical maturity of other industrial areas based on international competition and the possibility that certain strengths and weaknesses have been established in each region [8, 48]. Lastly, we assumed that the construction industry of the target area tended to be independent of the other areas because of law, language or logistics, etc.

As it was necessary to ensure reproducibility and objectivity, we assumed that the same study could be performed for the building technology in any region. Thus, this study developed into a comparative study of the construction industry by considering only two regions; nevertheless, previous studies were also considered to enable the reproduction of the same study for the other industries in many regions [5, 6, 45, 49].

Herein, we conducted a case study in the UK and Japan while considering the above-mentioned points. The two regions are geographically separated by the sea, have a clear boundary with their surroundings in terms of regulations, are highly independent of their surroundings in terms of the flow of people and goods, and are technically mature. Therefore, surveys in these two areas were deemed suitable to meet the above-mentioned conditions.

However, all construction projects are planned under unique conditions (such as the purpose, main use, owner's requirements, and site conditions). Therefore, it is difficult to establish the characteristics of each region by comparing projects individually. Additionally, given that a building comprises several components, it is difficult to understand the overall trends immediately. In summary, each building is original and enormous and also comprises several elements, thus making it difficult to understand the technical nuances of the construction industry.

However, one can observe the flow of the construction design methods to understand the trends. During building design, there is a mechanism to deal with the size characteristics and a large number of elements. Many organizations in the same area share standard ideas concerning architecture. Therefore, it is important to develop an accurate budget and construction schedule when planning a project. However, being active in the same region makes it difficult to notice the diversity in thinking pertaining to other areas.

Therefore, this study focuses on the “standard details” established based on the region. Consequently, it may be possible to understand the characteristics of each region by comparing the composition of elements in the standard details in order to retain the interdependence of elements.

We compare the points at which elements of the building physically overlap and explore the standard details of particularly complex areas. Specifically, we focus on three primary sections, which are located around the foundation, opening, and parapet, where construction structures and finishes overlap frequently. These are the points of contact between the outer wall (vertical structure) and floor slab (horizontal structure), and they contain numerous complex elements. The foundation is in contact with the ground, the opening comprises many window frames and sealing components, and the periphery of the parapet is influenced by the parapet and waterproof layers. Considering that these three sections have multiple functions requiring advanced technologies, such as waterproofing and sound insulation, their production would necessitate additional technology, components, and processes, as compared to the other parts of the building. Therefore, in most projects, architects and designers study the standard details of these three highly complex sections mainly, and these parts of the actual building are built using these standard details.

4. RESULTS

This section describes the product architecture for the standard details of complex parts in the UK and Japan in order to clarify the design concepts considered for these parts. Subsequently, we examine the possibility of determining the technical characteristics of each region using this method.

4.1. Description of Product Architecture

This section describes the typology of interface design ideas based on the basic indicators, according to the standardization of the interface and the contacts of related components. Specifically, the following three design ideas, which are considered to be similar, were examined. The first focuses on the form, materials, and parts of the interface being standardized. The second examines the need for fine-tuning around the interface at the construction site. The third focuses on the standardization of the form and installation methods of the related components.

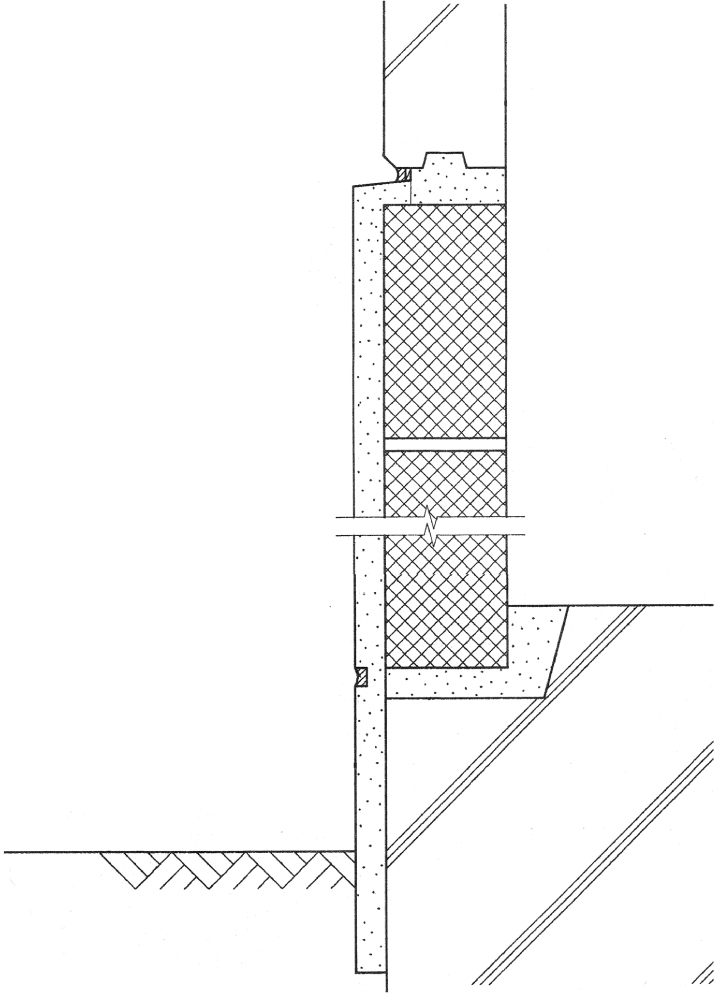

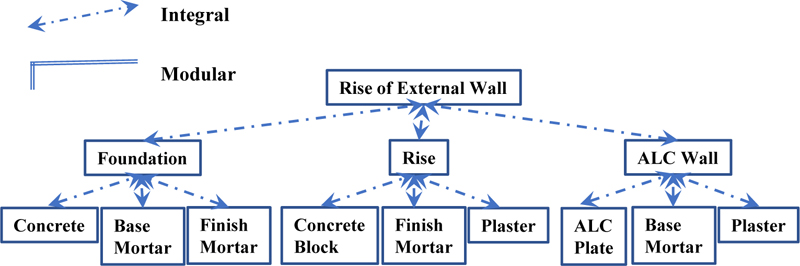

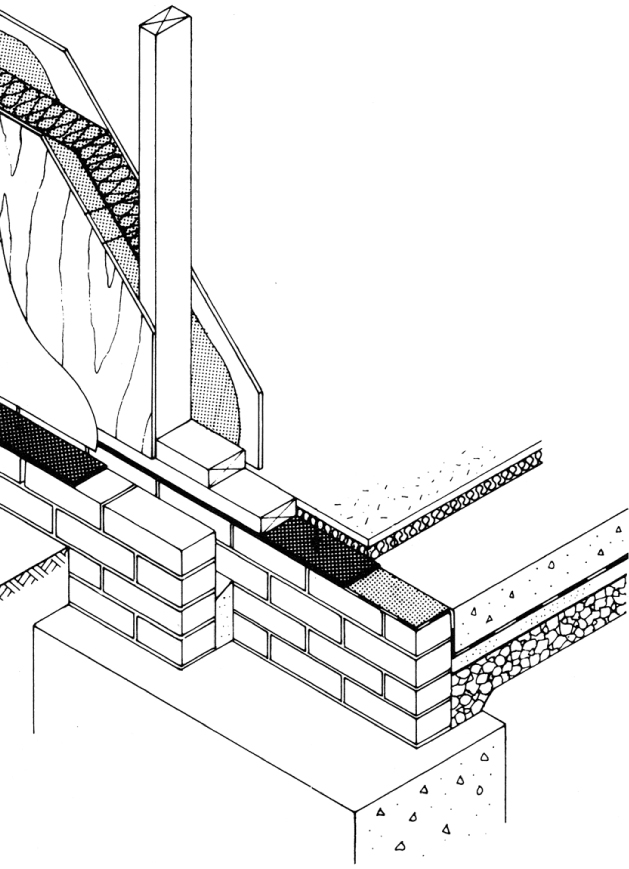

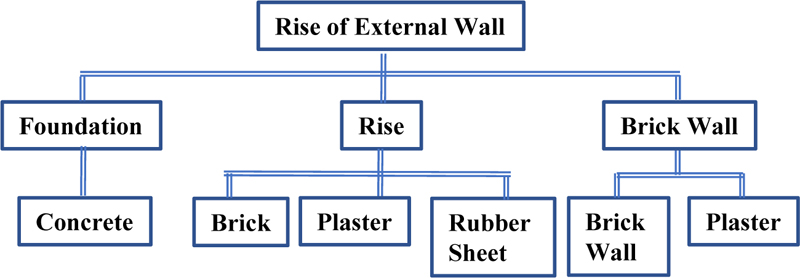

4.1.1. Standard Details of the Rise on Baseplate

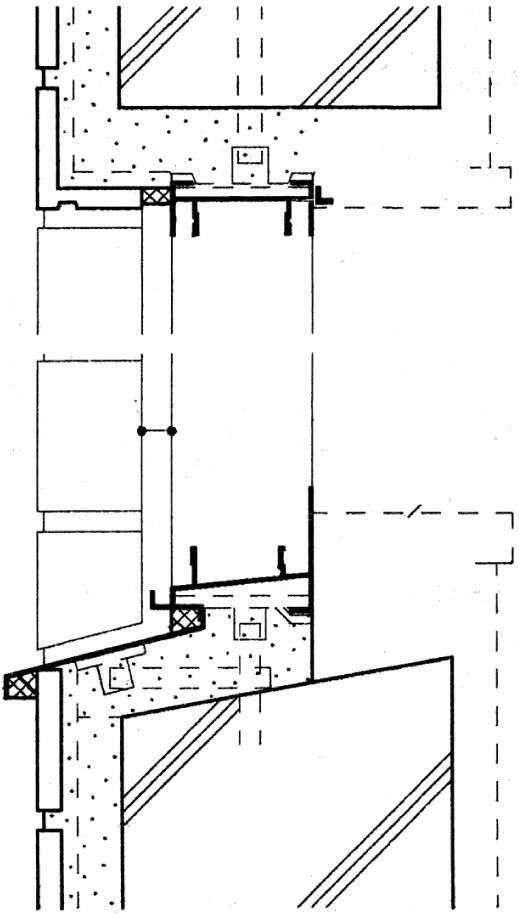

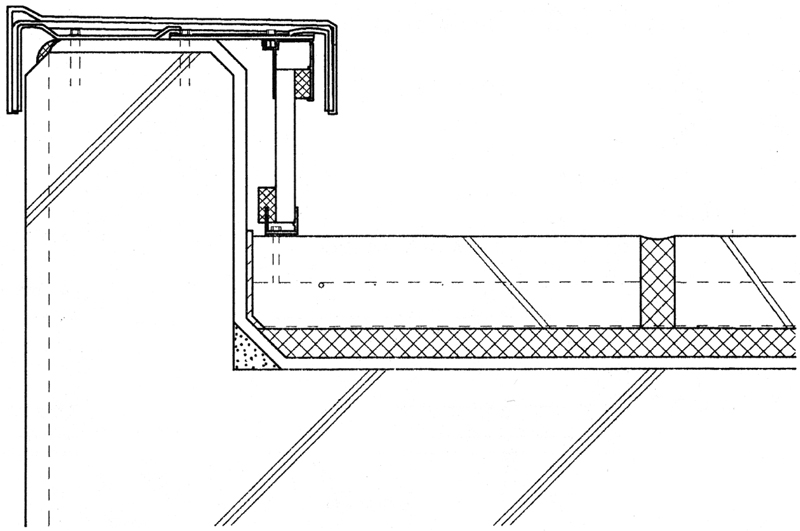

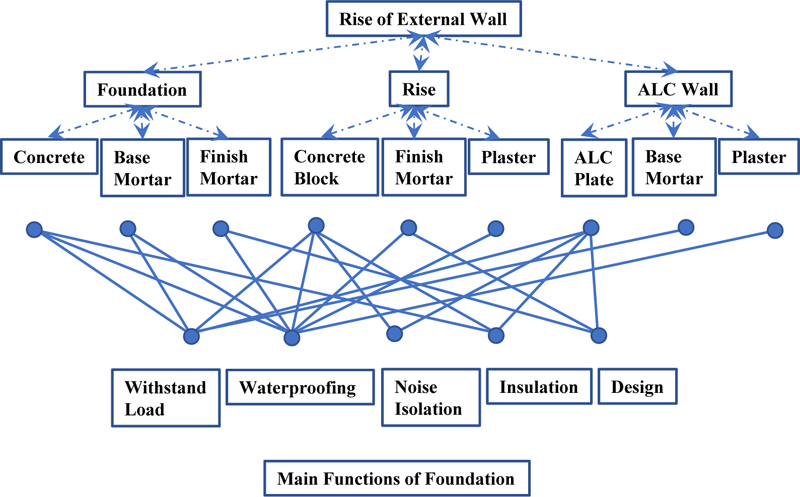

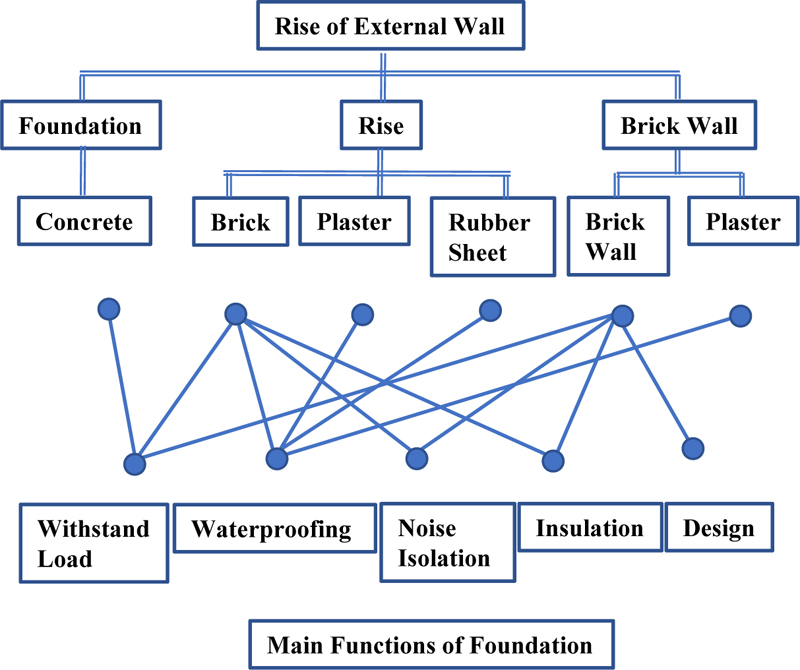

Although the rise on a baseplate is one of the most complicated parts of construction technology, it is possible to identify clear differences between the Japanese and UK standard details (Figs. 1-3).

In the Japanese standard, all elements, including the small parts, are integral, especially for waterproofing (Fig. 2), considering that the baseplate has a slanted surface. However, the interface is not standardized. The interface part is constructed and customized according to the surrounding shape and material. In other words, each component is not standardized and is instead customized via fine-tuning based on the surrounding components. Most Japanese standard details are built using an integral design concept. By contrast, the UK standard detail only includes a few integral elements (Fig. 4).

4.1.2. Standard Detail of the External Wall Opening

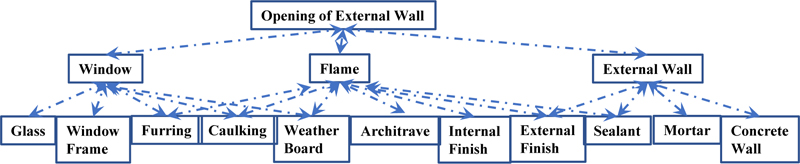

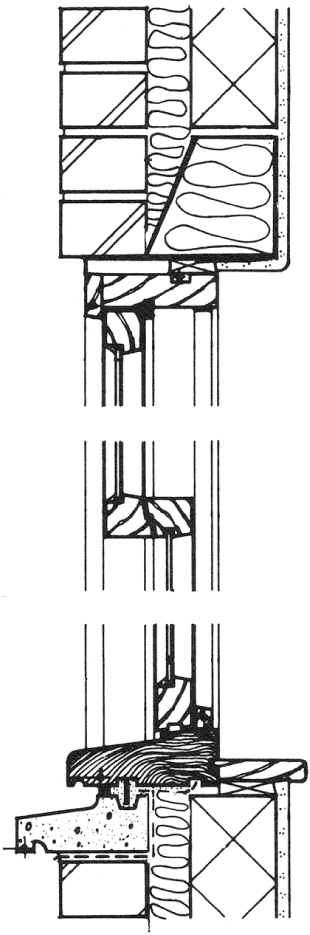

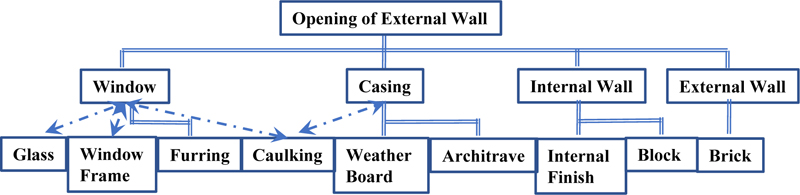

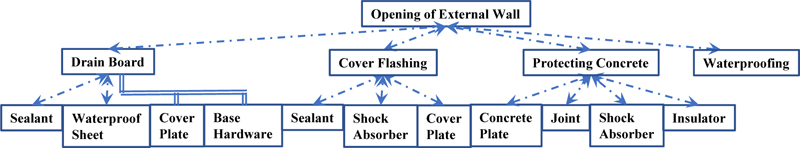

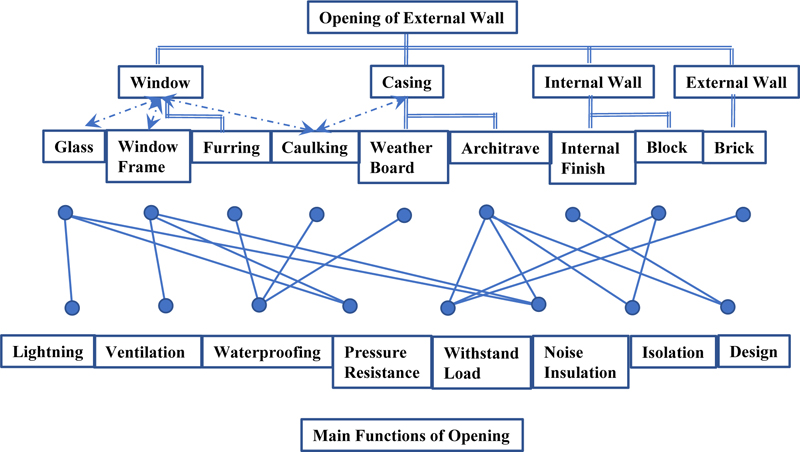

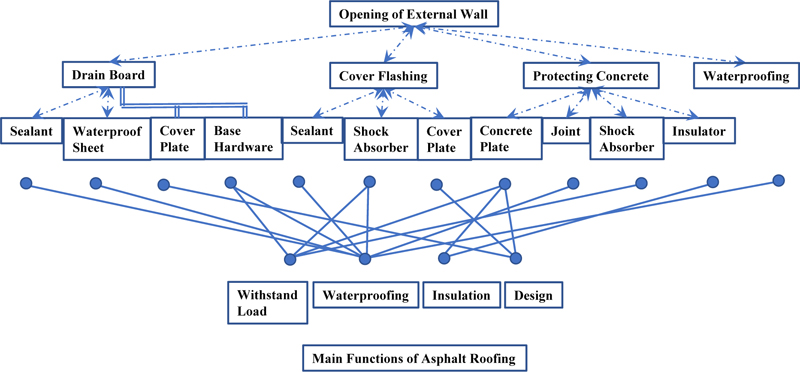

Many technological construction elements exist around the opening in an external wall, particularly for window systems, which comprise several elements and parts (such as windows, casings, sills, and aprons) (Figs. 5 and 6). Therefore, the integral element types can be determined anywhere in the Japanese standard detail of this part, which encompasses high-level waterproofing systems (Fig. 7). However, there are only a few integral parts and elements in the UK standard detail (Fig. 8).

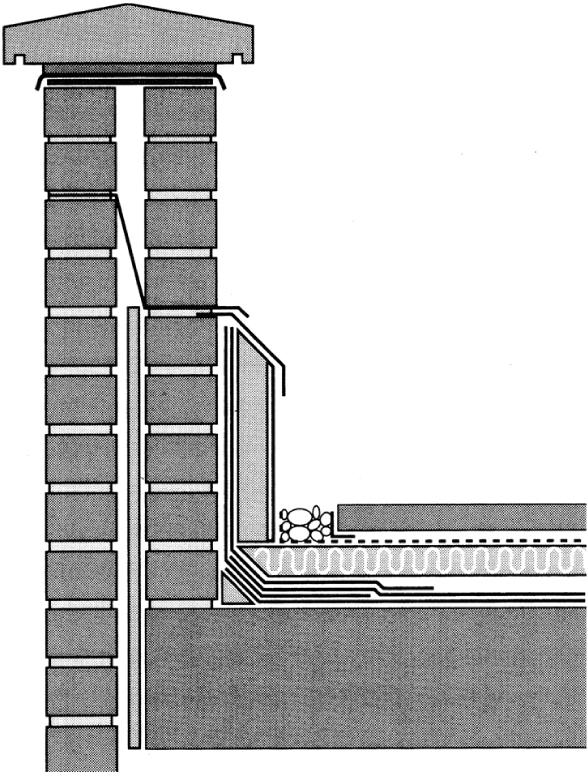

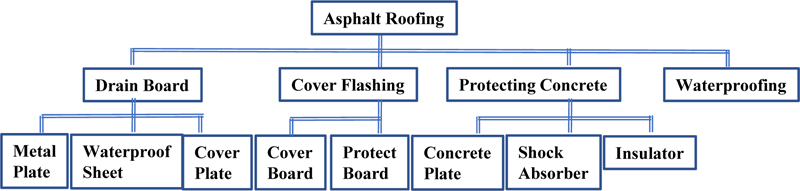

4.1.3. Standard Detail for Asphalt Roofing

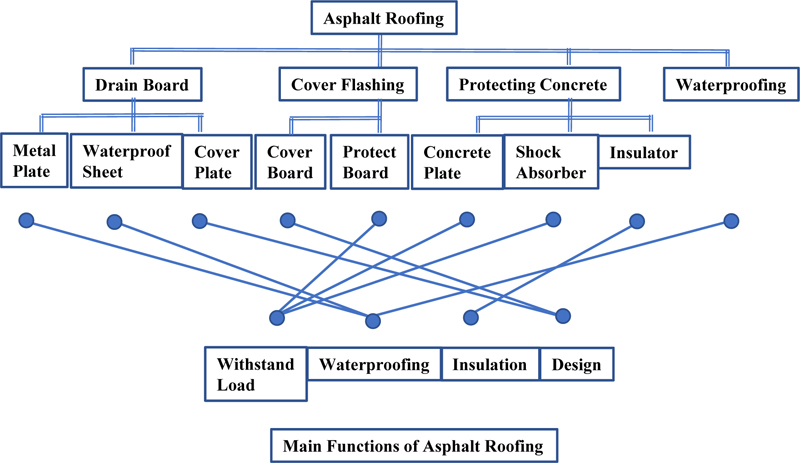

The most complicated part of asphalt roofing is the edge of the asphalt sheet, surrounded by many elements (Figs. 9-11). In the Japanese standard detail, all upper-level elements are combined with the integration of the lower-level elements (Fig. 10). However, in the UK standard detail, all the elements are developed using a standard combination with the lower-level elements (Fig. 12).

4.2. Description of Product Architecture and Functional Architecture

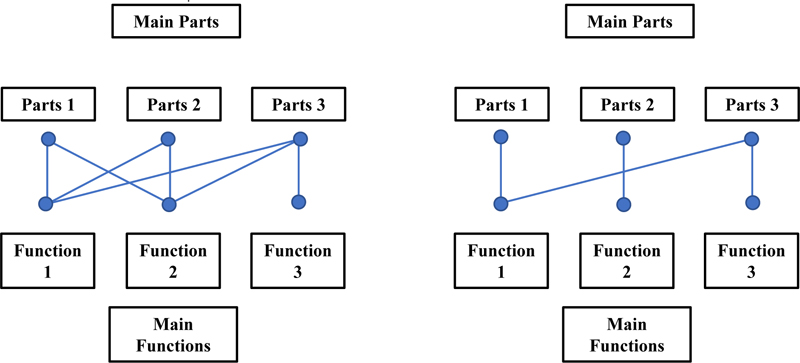

It is possible to understand the relationship between the functional and physical structures of artifacts [5, 48], which indicates the characteristics of the design thinking for each system. Compared to integral systems, wherein one physical part serves several functions, the physical part of a typical modular system only has one function. Moreover, one function is associated with one physical part in a modular system and several physical parts in an integral system.

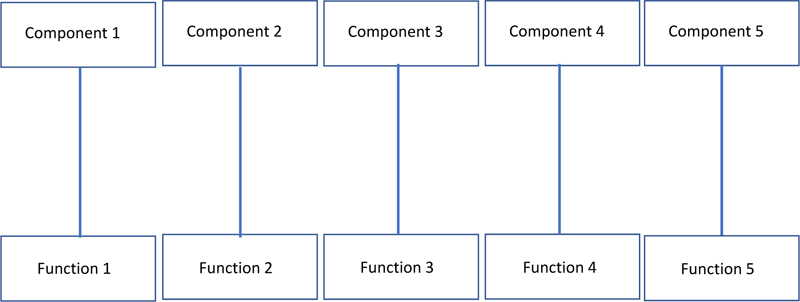

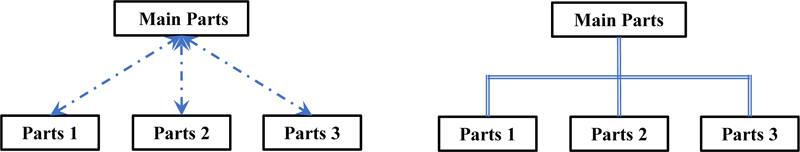

Ulrich presented an example using trailers, as shown in Figs. (13 and 14) [5]. Fig. (13) demonstrates a chart created using the modular design concept. The function and structure exhibit a one-to-one correspondence; that is, each module has only has one function. In this case, the development, design, and production of each module were performed on a module-by-module basis thus it is difficult to find functional integration.

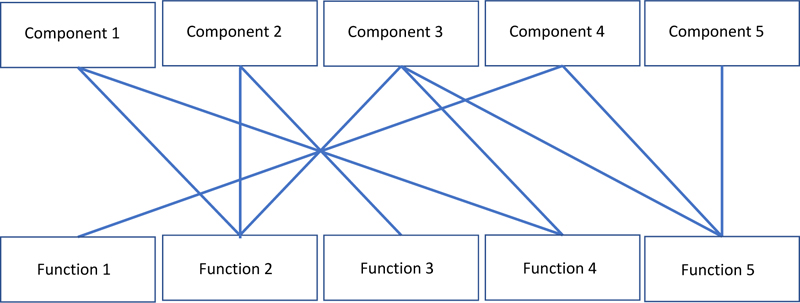

Fig. (14) shows an example of a chart created using the integral-type design concept, wherein the relationship between the functions and the structure is more complicated. Therefore, it is difficult to develop and design parts individually, as compared to designing the entire system. On the other hand, this approach is advantageous in terms of improving the overall performance. Consequently, the design concept can be understood by focusing on the relationship between the product and the functional architectures.

This section describes the product and functional architectures with reference to the description method. The description subjects are the three complex standard details, as mentioned in section 4.1, that express the technical characteristics of the UK and Japan systems.

4.2.1. Standard Detail of the Rise on Baseplate

Product design thinking involves several complicated elements (Figs. 1 and 3), and it is important to understand the structure of the physical elements and functions.

Based on the description of the product and function design thinking (Figs. 15 and 16), the difference between the Japanese and UK standard details can be determined. The Japanese system tends to be integral in terms of design thinking, whereas the UK system tends to be modular. For example, there are several complicated integrations involving waterproofing and insulation functions in the Japanese details, whereas the UK system simplifies the same.

4.2.2. Standard Detail of External Wall Opening

Although the external wall opening functions are complicated (Figs. 5 and 7), each function is important for the fundamental building quality, such as in terms of waterproofing, noise insulation, and lighting.

Figs. (17 and 18) present the descriptions of product and function design thinking for the external wall opening under the Japanese and UK systems, respectively. In the Japanese system, many elements are used to establish the functions. For example, the functions of pressure resistance and withstanding loads are based on many elements. By contrast, the relationship between the physical parts and functions is simple under the UK system. For example, in the UK system, casing and internal finishing are performed to improve the esthetic design, whereas, in the Japanese system, casing is an important element for noise insulation, pressure resistance, and waterproofing, among others.

4.3.3. Standard Detail for Asphalt Roofing

Given that waterproofing is the main function of asphalt roofing, it is established by employing many elements and parts in both systems.

It is possible to identify different details around the edge of the membrane used in both systems (Figs. 19 and 20). Numerous elements are used to design details around the edge of an asphalt membrane in the Japanese system. However, the details are quite simple in the UK system, comprising only a few elements. The details of insulation are almost identical in both systems, although there are many physical elements in the Japanese system. The insulation quality of the Japanese system is better than that of the other system, although there are certain drawbacks concerning the cost and terms of construction.

5. DISCUSSION

5.1. Characteristics of Design Thinking in Construction Work in the UK and Japan

There are three major differences between the standard details for windows under Japan and the UK systems. First, there exists a difference in the relationship between the window frame and the supporting structure. In the Japanese standard details for windows, approximately half of the metal support for the window is embedded in the concrete frame; therefore, the position of the window can be finely altered by adjusting the supporting material; this is followed by inserting waterproof, non-stretch mortar. Under the UK standard details for windows, temporary metal supports are installed with bolts after loading the concrete blocks, and the window frame is fixed using the supporting material. Therefore, the supporting material does not play a role in the final adjustment. The windows are set in position during the installation on site and then surrounded with waterproof mortar. Moreover, in Japan, metal support materials are essential to meet the total high-performance requirements for the strength, durability, and fine adjustment accuracy of window frames. However, in the UK, there are separate high-performance requirements for the strength, durability, and fine adjustment accuracy of window frames and their supporting structures.

Second, there exists a difference in the relationship between the outer wall and window frame. Under the Japanese standard details, mortar is filled at the base of the outer wall, and a seal is applied between the different materials. These seals should be highly compatible with the materials of the two parts involved. However, the UK standard details do not include the use of such mortar or seals.

Finally, there exists a difference in the relationship between the weatherboard and architrave. Under the Japanese standard details, the weatherboard and architrave are adjusted three-dimensionally, with multiple layers of coking and sealing. However, under the UK standard details, the weatherboard and architrave are combined by applying a single seal instead of directly adjusting them as different pieces.

These three differences between the standard details for the construction techniques in Japan and the UK highlight the regional differences in terms of material development, considering that they affect the seals, caulking, mortar, and base hardware, among others.

The Japanese standard details include high specifications for strength, elasticity, and weather resistance, which cannot be delivered by developing a single material or part. Therefore, achieving comprehensive performance requires the adjustment of multiple materials and parts. Additionally, maintenance with replacement scans is difficult as the materials and parts are adjusted in a complex manner. Although the materials and parts require good design and usability, it is not effective to set simple objectives and goals for developing individual materials and parts. Consequently, the materials and parts must be developed considering their applications; furthermore, their characteristics must be designed according to the demands of construction engineers and end users, while thoroughly understanding the characteristics of conventional materials and parts. Therefore, designers must understand the complex demands of architects and engineers and produce the materials and parts as specified. This outweighs the considerations of the cost and time spent on material development.

Figs. (21 and 22) summarize the trends of the survey results presented in Section 4. The structure of the product architecture offers clear results. The UK tends to use modular-type design concepts, whereas Japan uses integral-type design concepts. In the UK, the modular design concept aims to combine standardized parts and materials to achieve an overall optimal performance. Moreover, for this design concept, each part is developed individually [48]. For each case, the characteristics observed in the UK differ from those observed in Japan, indicating the relationship between the modular-type and integral-type design concepts.

The two types of design thinking (integral and modular) can be analyzed as follows. The integral type is based on the merger of multiple elements of a system to achieve optimal overall performance, making it suitable for customization [8]. Conversely, the modular type is based on a combination of standard elements to reduce production costs and time [48]. Therefore, a detailed discussion regarding specific industrial fields would help improve the understanding of this concept in almost every industrial field [9-11, 52]. If every firm in a particular region implements the integral thinking approach, that region can dominate the market for integral products. This is called the bespoke design [8]. Similarly, if every firm in a particular region adopts the modular approach, the region can dominate the market for easily interchangeable products. This is also known as the compatible open-source design [7, 12].

In other words, the tendency of an organization's design philosophy influences its creations. The integral-type Japanese technology takes advantage of its strengths when the target architecture (product architecture, relationship between product architecture, and functional architecture) is integral. Similarly, if the target product architecture is modular, the modular UK technology is likely to take advantage of its strengths. These strengths are more likely to be utilized if the creator's design concept and the architecture being created belong to the same category; by contrast, the weaknesses are more likely to be revealed if they belong to different categories. Table 1 summarizes these points.

5.2. Summary of Design Thinking Studies

As mentioned above, the UK construction approach typically employs modular design thinking, which is based on the fundamental idea that the point of interface between parts should be standardized to enable the replacement or reuse of the modules. This design thinking tends to combine standardized parts and materials to achieve overall performance. Additionally, each part is created individually [48]; thus, part and material development are focused on modular construction. By contrast, the Japanese construction approach typically employs integral-type design thinking; hence, its performance can be continuously improved by finely adjusting the parts. However, when altering the specification or quality of an integrally designed product, it becomes necessary to adjust the entire system because partial alterations are more difficult to adjust.

| Production Organization | ||

| - | Modular Type | Integration type |

| Modular type |

●Value creation only through adjustments within each module ●Saving of inefficient mutual adjustments among modules |

● Existence of unnecessary inter-organizational interfaces ●Sharing of information on inefficient development/ improvement |

| Product configuration | ||

| Integration type | ● Loss of opportunity for development/improvement due to information non-concentration ●Difficulty in ensuring product performance |

● Possible performance enhancement of the whole system ●Highly efficient adjustments through information concentration/sharing |

| S.No. | Merits of Modularization |

| 1. | Resources, such as costs, taken for adjustments and alignments among architectural elements can be significantly reduced in some cases. |

| 2. | Each module’s independence can be maintained and any changes to the entire system can be kept to local level. |

| 3. | Reuse at module level is feasible. |

| 4. | .Development and innovation can focus on a modular unit. |

| S.No. | Merits of Integration |

| 1. | Setting rules for interfaces require deep knowledge of the system. ● Always effective for unknown systems. |

| 2. | Performance can be gained in accordance with input resources. ● Even the need for rule change can be handled. |

| 3. | High performance can be pursued. |

| 4. | Measures, such as improvement, can be taken among all the elements. |

Based on this analysis, one can logically determine the difference between the standard details in each region, which would afford an interesting interpretation. Considering that the Japanese and UK standard systems assume integral design thinking and modular design thinking, respectively, every detail is associated with a clear tendency (Figs. 20 and 21). Consequently, Japanese designers should employ integral design thinking during every step of the process. Many elements and parts are involved in performing one function, and individual elements are related to many functions [53]. Moreover, the importance and effectiveness of integral design thinking must be discussed from economic and rational perspectives to identify the integral tendencies within single and complicated details.

Tables 2 and 3 summarize the merits of the modular and integral design types, respectively [5, 54]. The merits of the modular type are the demerits of the integral type and vice versa. In other words, the two design types have more in common, despite their differences.

The modular type is advantageous for independent and individual work, given that the the structures and processes can be modularized. Concerning project management, a design configuration that can be used for the next process can be developed by concentrating on a module unit. Furthermore, in construction work, the probability of the standardization of materials and parts can be increased by creating interfaces. This indicates that the modular design concept can easily cope with the concept of uncertainty reduction. By contrast, under integral design thinking, many subjects must be examined in each process to achieve high performance while fine-tuning the entire system.

The integral-type design concept may be disadvantageous in terms of cost and construction duration [53, 54]; however, because it is based on the concept of repeated fine adjustments, it can ensure optimal adjustment performance for the overall project. Moreover, it could be advantageous in the production and reproduction stages depending on the characteristics of the project. In particular, during the early stages of the project, project management development based on integral design thinking is typical, owing to the minimal knowledge regarding modularization [5, 48].

It is important to design project management processes by adjusting to the characteristics, including the type of design thinking. The concept of project management is influenced by various factors, such as the novelty of the project area, degree of maturity of related technologies, the progress of commoditization, and the characteristics of design thinking. Therefore, it is necessary to consider the strengths and weaknesses of each aspect of the project while carefully assessing the major related factors. As mentioned above, in any construction project, designers think about the design contents based on their individual design thoughts, which they utilize in all cases, where a design target is an artificial object. Furthermore, the construction industry expressed by the design concept focuses on the standard details, which is a part of product architecture. In addition, construction projects involve the development of the design process (process architecture), zoning plan (product architecture), and construction process (process architecture). Therefore, the characteristics of individual projects (including traditional masonry and skyscrapers) can be clarified through careful analyses, such as by comparing them with those of similar projects. Moreover, although this concept is not often implemented in academic discussions in the construction industry, several studies in different industries, such as in the automobile and electronics industries, utilize it. Therefore, this approach has many possibilities associated with the study of the construction industry, including industrial comparison studies.

CONCLUSION

Considering the rapid technological developments and global pandemics, it is necessary to understand the characteristics of the building industry in each region in order to recommend the future directions of the construction system such that regional characteristics are used optimally. However, the notion of a project's relativity does not help develop a discussion. Therefore, this study developed a method to describe the characteristics of building construction in each region.

The “architecture concept” was used as a tool to focus on the interdependence of the components to be created and analyze the design information created by designers and engineers in the UK and Japan. This concept clarified that the UK and Japan followed the modular and integral characteristics, respectively, for the fundamental design concept of construction.

By analyzing the trends of the unique fundamental design concepts in the two regions pertaining to building construction through case studies and discussions, we developed a perspective regarding the characteristics of each region. The main aim of this study was to develop a method to understand the characteristics of the construction industry in different regions. Specifically, this research proposed a method to describe product architecture and the relationship between the product and functional architectures of the construction industry using the architecture concept.

The results of this study showed that the characteristics of the construction industry, such as the complexity of individual production, diversity of participating industry areas, diversity of participating technology areas, and regionality of rules, can influence the design concept during product creation. However, this study only discussed the possibility of describing the present construction techniques in two regions. Hence, it is necessary to understand the important points. For example, if the fundamental conditions change (fundamental development of technology or potent alteration of regulation etc.), the modular design concept would be transformed to the integral design concept, thus influencing the architecture dynamics [55]. Due to their lack of understanding about modularization and the creation of interface rules, designers prefer to have integral-type design concepts at first. However, the modular concept should become mainstream as organizations seek to reduce the invested economic resources (such as development costs, development time, and production costs). As mentioned above, the construction industry has been established through the participation of many technical and industrial fields. Therefore, technological innovations and changes in other industries can significantly affect the technologies pertaining to the construction industry.

For such inter-regional and inter-industrial comparisons, increasing the number of research targets, including construction standard detail in other areas and design information in other industrial fields is essential in the future.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data sets used during the current study can be provided from the corresponding author [S.Y], upon reasonable request.

FUNDING

This research was partially supported by the Ministry of Education, Science, Sports and Culture, Grant-in-Aid for Scientific Research(B), 2017-2021(17H02562).

CONFLICT OF INTEREST

The author declares no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

I express my sincere thanks to Prof. Takahiro Fujimoto and Prof. Tomonari Yashiro at The University of Tokyo and Dr. Rob Phaal and Dr. Yongjiang Shi at the University of Cambridge for the helpful discussions and comments on the manuscript. I also thank the editor and reviewers for their thoughtful suggestions during the review process.