All published articles of this journal are available on ScienceDirect.

A Short Overview of Soft Computing Techniques in Tunnel Construction

Abstract

Tunnel construction is a complex technology, with a huge number of effective parameters, which cannot be accurately analyzed/designed using empirical or theoretical methods. With the rapid development of computer technologies, Soft Computing (SC) approaches have been widely used in tunnel construction. Typically, the two common tunneling methods, blasting and mechanical excavation (e.g., tunnel boring machine, shield, pipe jacking method), have been used in conjunction with some SC techniques to solve specific problems and have shown a good fit. On this basis, this paper first summarizes the current research on the application of SC techniques in the field of tunnel construction methods. For example, in the case of blasting, the application of SC techniques is focusing on the environmental problems induced by blasting, such as the prediction of peak particle velocity and over-break. As for mechanical tunnel construction, the SC techniques were used to analyze the boring characteristics of the machine, such as the estimation of penetration rate and advance rate. Additionally, an important aspect for the application of SC techniques is the identification of the influencing factors for each of the study subjects, i.e. the necessary input parameters for the SC. Finally, this paper elaborates on the working process of the supervised learning models, highlights the points that need to be taken care of in each step, and points out that the SC technique, which is synergistic with the physical process, is more useful to explain the actual phenomenon.

1. INTRODUCTION

Tunnels, as underground space structures on transport routes, have some economic and social benefits. For example, tunnels built in mountainous areas can overcome topographical or elevation obstacles, improve the alignment of the route, shorten route mileage and save travel time; tunnels built in cities can reduce land use on the ground and play a positive role in guiding the traffic on the ground; tunnels built in river and strait areas do not interfere with waterway navigation, are more discreet and are less affected by the weather. The foregoing shows that tunnels play a positive role in the development of transport and accessibility to resources.

At this stage, the construction scale of the tunnel is increasing, and with the rapid development of monitoring equipment and technology, researchers have access to a large amount of data during the construction process of tunnels. Based on this data, some researchers used theoretical and empirical models to analyze some specific engineering problems. For example, some researchers attempted to use theoretical models, empirical models, or statistical techniques to analyse specific engineering problems such as environmental issues caused by tunnel blasting [1], tunnel boring machine (TBM) performance characteristics [2-4], and so on. However, owing to the limitations of computing power, traditional theoretical and empirical models cannot accurately describe highly complex and nonlinear systems [5]. Moreover, the computational performance of these techniques can be weakened by the presence of outliers and extreme values in the data [6]. Thus, the application of these techniques has been limited and the computed results are questioned.

With the development of Soft Computing (SC) technologies in recent years, a large number of SC methods have been widely used to address some special related issues. Typically, the two common tunneling methods, including blasting and mechanical excavation, have been used in conjunction with some SC techniques to solve specific problems. Further, numerous studies indicated that the SC techniques are able to predict some specific engineering problems more accurately than the theoretical and empirical models [7, 8]. Therefore, this perspective aims to provide a general view of the application of SC techniques to solve some tunneling construction problems. The SC techniques available in the literature with their strengths and shortcomings will be discussed. Finally, a new direction of SC techniques for solving practical problems in the area of tunneling will be described.

2. APPLICATIONS OF SC TECHNIQUES ON TUNNEL BLASTING

The blasting method, also known as borehole blasting, is a method of excavating rock by drilling, charging, and blasting. When blasting operations are conducted, many environmental issues such as harmful vibrations and over-break arise. For blasting operations in tunnels, vibrations and over-break are two important issues that need to be focused on, as both of them harm the safety of the tunnel structure. In this regard, a great deal of research has been carried out by scholars to predict vibration (i.e., peak particle velocity) and overbreak to keep them within reasonable and safe limits. Table 1 presents some representative SC techniques proposed for the prediction of over-break and Peak Particle Velocity (PPV) as the main indicator of blast vibrations. In this table, the type of parameters, proposed SC techniques, size of database, model accuracy, most and least effective factors are presented for all references.

The input parameters that affect the PPV and over-break induced by tunnel blasting can be divided into three categories: controllable parameters, uncontrollable parameters, and semi-controllable parameters [9]. The controllable parameters include blast design parameters like burden, the charge per delay, total charge, hole diameter, hole depth, hole length, spacing, number of holes, stemming, special drilling, and so on. The uncontrollable parameters include the rock mass properties or geological characteristics like rock mass rating, rock mass strength, and quality. Semi-controllable parameters indicate the tunnel geometry and size like the tunnel cross-section area. We considered these three groups of effective factors as input parameters for predicting PPV and over-break (Table 1).

Some of the SC techniques used for predicting PPV and over-break include single models like ANN, SVM, GA, DT, GEP, fuzzy logic, ANFIS, and hybrid models like MFO-ANN, GA-ANN, ANFIS-PSO. According to the results of testing accuracy (Table 1), it can be seen that each SC technique, except the GEP algorithm, has a favourable predictive ability. This is because a single model is more likely to fall into the dilemma of obtaining a local optimum value than a hybrid model, and the optimization algorithm in the hybrid model can help the model eliminate this shortcoming. Thus, compared with single models, hybrid models have a higher prediction accuracy [10-18].

| Reference | SC Technique | Type of Parameter | Database Size |

Accuracy (Testing) |

Most Effective Factor | Least Effective Factor | |

|---|---|---|---|---|---|---|---|

| Input | Output | ||||||

| Monjezi et al. [9] | ANN | MC, DI, ST, HD | PPV | 182 | 0.949 | DI | ST |

| Jang and Topal [10] | ANN | Sc, RQD, Js, Ja, Jo, Jw, RMR. | Over-break | 49 | 0.945 | RMR | / |

| Hasanipanah et al. [11] | SVM | DI, MC | PPV | 80 | 0.957 | MC | / |

| Hasanipanah et al. [12] | GA | MC, DI | PPV | 85 | 0.920 | / | / |

| Mottahedi et al. [13] | ANN | SPC, SD, PB, TCS, RMR. | Over-break | 267 | 0.930 | RMR, SC, SD | TCS, PB |

| Fuzzy logic | 0.960 | ||||||

| ANFIS | 0.970 | ||||||

| SVM | 0.870 | ||||||

| Mottahedi et al. [14] | ANFIS-PSO | TCS, PF, SD, HS/B, RMR. | Over-break | 270 | 0.961 | PF, SD, HS/B, RMR | TCS |

| ANFIS | 0.945 | ||||||

| Koopialipoor et al. [1] | GA-ANN | ND, SD, B, HS, PF, AL, RMR. | Over-break | 406 | 0.881 | RMR | ND |

| ANN | 0.693 | ||||||

| Koopialipoor et al. [15] | ANN | RMR, AL, SPC, B1, B2, HS1, HS2, ND | Over-break | 255 | 0.923 | / | / |

| Rana et al. [16] | ANN | TC, TCS, MC, NH, H, DI, HD, CPH | PPV | 137 | 0.930 | TC, CPH, MC | / |

| DT | 0.950 | ||||||

| Lawal et al. [17] | MFO-ANN | HL, CPD, NH, TC, DI, RMR | PPV | 56 | 0.958 | CPD, NH | RMR |

| GEP | 0.499 | ||||||

| ANN | 0.691 | ||||||

Finally, to determine the importance degree of each input parameter, the sensitivity analysis is commonly employed to assess the influence of each input parameter on PPV and overbreak. Based on the weight of each input parameter, the importance of the input parameters can be analyzed [5]. The most effective factors for PPV prediction include DI, MC, TC, CPH, MC, CPD, and NH while the least effective factors are ST and RMR. For over-break prediction, the most effective factors include RMR, SPC, SD, PF, HS, and B, while the least effective factors are ND, TCS, and PB.

3. APPLICATIONS OF SC TECHNIQUES ON THE MECHANIZED TUNNELING

TBM, a relatively high-efficiency, safe, and environmentally friendly construction method compared with blasting operations, has been widely used for the construction of underground buildings. Generally, the two crucial factors affecting TBM performance are penetration rate (PR) and advance rate (AR). Another mechanical tunnelling method similar to TBM is the shield tunnelling technique, which is a method of stabilizing the excavation surface by balancing the earth or mud pressure in front of the cutter head. The difference between shield tunneling and TBM is that shield tunneling is used for urban underground tunnels or small pipelines in soft soils, whereas TBM is used for mountain tunnels or large water diversion projects in hard rock formations. For shield tunneling, the prediction of the maximum surface settlement (Smax) is a major concern. Table 2 shows some representative SC techniques employed in predicting TBM performance and Smax [18-25].

Regarding the prediction of PR and AR using SC techniques, the first step to perform the modeling is to select proper input parameters. The input parameters can be grouped into three categories: rock mass properties, machine characteristics, and tunnel geometry [24]. There are some suggested model inputs, such as UCS, BTS, BI, CP, CT, DPW, TF, α, and SE. Concerning the used SC techniques, single models like SVR, GMDH, ANN, and ANFIS show good performance for predicting PR and AR. Moreover, the hybrid intelligent models like PSO-ANN and ICA-ANN outperform the simple models on predicting the TBM performance. In addition, some studies indicated that there are some groups of parameters are considered as the effective factors affecting TBM performance, including RQD, UCS, RMR, RMW, BTS, rock-mass weathering, tunnel diameter, type of rock, and disc cutter normal force [7, 18, 26-28].

As for the prediction of Smax, as shown in Table 2, different types of predictors can be used as input parameters, which indicate that there are no uniform input parameters for Smax predictions. Therefore, the selection of input parameters for Smax prediction should be formulated based on the measured data available in practical engineering and should synchronously take into account the geological conditions, machine operational parameters, and tunnel geometry. Furthermore, it is obvious that the hybrid model outperforms the single model in terms of prediction accuracy. For the determination of the most effective parameters, similar to the important analysis of parameters in TBM, sensitivity analysis is also used for determining the important input parameters in the prediction of Smax. For example, Zhou et al. [22] utilized RF to estimate the Smax induced by shield tunnelling and concluded that VL is a significant input parameter affecting the Smax while GL is a non-sensitive parameter. Chen et al. [29] proposed that Th and MUCS are two dominant parameters for the prediction of Smax. Another published study indicated that H and ST are the most important input parameters [30].

| Reference | SC Technique | Types of Parameter | Database Size |

Accuracy (Testing) |

|

|---|---|---|---|---|---|

| Input | Output | ||||

| Alvarez Grima et al. [5] | ANFIS | CFF, UCS, RPM, Dc, TF | PR | 640 TBM projects | 0.899 |

| ANN | AR | - | |||

| Benardos and Kaliampakos [18] | ANN | UCS, RQD, RMR, permeability, N, WTS, WZ | AR | 11 | - |

| Yagiz and Karahan [19] | PSO | UCS, BI, DPW, α | PR | 151 | 0.737 |

| Salimi et al. [20] | SVR | UCS, BTS, Jc, RQD, α, RMR, Q, GSI | PR | 75 | 0.920 |

| Armaghani et al. [8] | ICA-ANN | WZ, RMR, RQD, UCS, BTS, RPM, TF | PR | 1286 | 0.912 |

| PSO-ANN | 0.905 | ||||

| Bouayad and Emeriault [21] | ANFIS | Sc, Ra, S, Cl, Pf, Pw | Smax | 432 | 0.930 |

| Zhou et al. [22] | RF | D, Z, VL, GL, CM, Vs/Vt, Cu | Smax | 40 | 0.940 |

| Armaghani et al. [23] | ICA-ANN | WZ, RMR, RQD, UCS, BTS, RPM, TF, q | AR | 1286 | 0.958 |

| PSO-ANN | 0.961 | ||||

| Koopialipoor et al. [24] | GMDH | UCS, BTS, RQD, RMR, WZ, TF, RPM | PR | 209 | 0.924 |

| Liu et al. [25] | ANFIS-PSO | Z, DS, GL, GC, GI, Pr, Pf, PE, Gp, Gf, S, Cl | Smax | 49 | 0.830 |

SVR: support vector regression, GMDH: group method of data handling, ICA: imperialism competitive algorithm, RF: random forest, GRNN: general regression neural network, sRVM: smooth relevance vector machine.

4. DISCUSSION

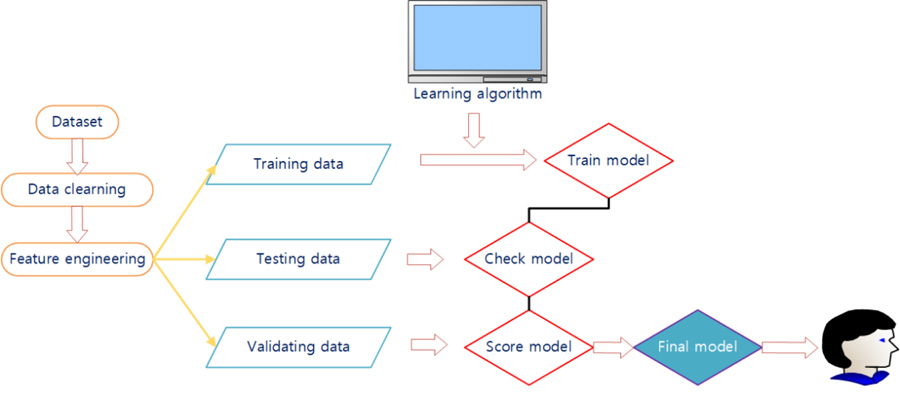

There is no doubt that SC methods can be used more effectively to analyze complex problems or phenomena. The aforementioned models used for solving problems in tunneling are almost entirely based on supervised learning techniques. The distinctive feature of this approach is that it is trained by labeled datasets, i.e., to first determine the input and output parameters and then establish the architecture of the SC models. The general execution flow of this method is shown in Fig. (1).

Regarding the supervised learning techniques mentioned in this paper, the selection of input parameters is a crucial part when conducting the SC techniques in tunneling. In this step, for the data collected from the construction sites or laboratory results, the selection of data is mostly based on the knowledge and experience of the researchers, and then, the raw data must be cleaned, that is, to remove the inaccurate and irrelevant outliers or to fill in the missing values through some technical means to eliminate their interference in the modeling. Next, the main work is to choose the appropriate SC models to analyze the relationships between the input and output variables. SC models are data-driven methods that develop models almost entirely through training data to determine the hyperparameters of the models, thus establishing the architecture of the models [31]. Compared to empirical formulas, physical models, and statistical methods, the SC techniques are more capable of clearly characterizing the relationship between the independent and dependent variables because they do not require simplifying the problems or setting up some conjectures. In soft computing, data sets are generally divided into three groups, namely: training set, test set, and validation set. Among them, the training set is used to build the framework and determine the hyperparameters of the models, while the test set is used to check the performance of the obtained models. Moreover, the validation set is used to evaluate the accuracy of the models and choose the best model. Finally, feature importance analysis is commonly used to determine the influence of each input parameter on the output parameter, which helps researchers or engineers more clearly determine which features are the main factors affecting the target object, so that further and more effective adjustments can be made to cope with the complex construction environment.

In terms of the application of SC techniques, supervised learning is the most widespread method applied in tunnel engineering and its common applications are classification or regression tasks [32]. For the high-quality datasets and well-extracted features, single models, such as ANN, SVM, DT, are able to predict and characterize the implied relationship between input and output data very well. However, for datasets with insignificant features and weak correlations, integrated or hybrid models have better performance in terms of elaborating relationships between input and output data.

5. FUTURE PERSPECTIVE

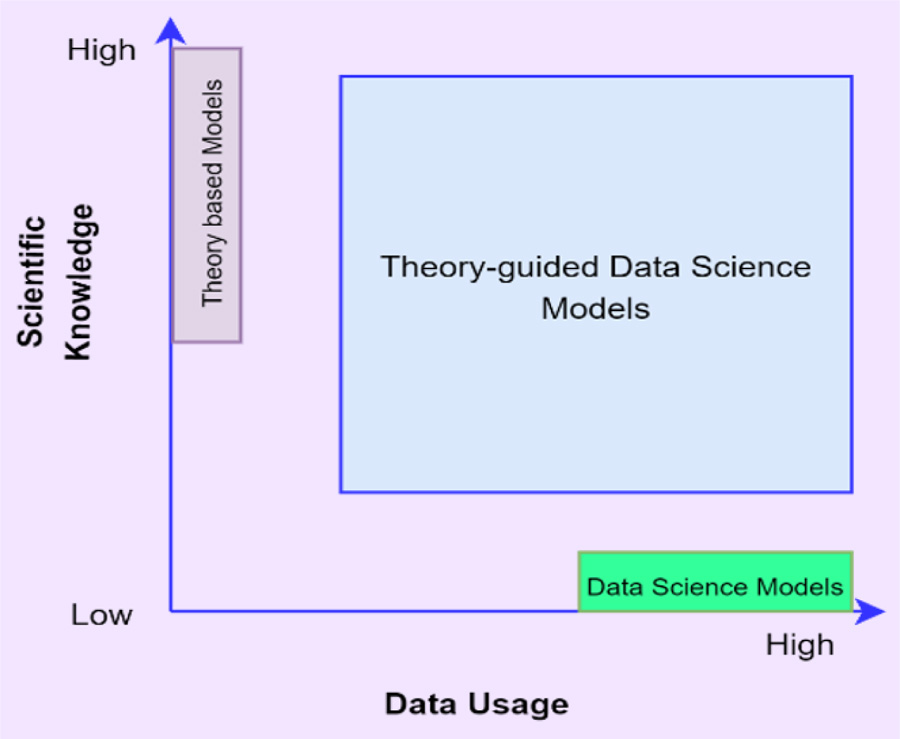

One of the problems regarding SC techniques is their limited practical application for tunnel engineers or generally geotechnical engineers. For applying the suggested SC techniques by a tunnel engineer, there is a need to have a deep knowledge of data science and SC approaches which is not available for tunnel engineers. In order to make SC techniques more applicable and interesting, theory guided data science (TGDS) or TGSC can be planned and used in future studies. TGDS, which was introduced by Karpatne et al. [33], is a new paradigm that attempts to improve the usefulness of SC models in allowing scientific discovery by using the abundance of scientific information. The primary goal of TGSC is to make scientific consistency a necessary component of learning generalizable models (Fig. 2). The idea is to apply well-known theories or empirical equations proposed in the area of tunnel construction, in order to establish a comprehensive database table is able to cover a wide range of effective parameters. Then, the same database will be used in novel and advanced SC techniques to develop a model with a high level of accuracy and generalization. TGSC techniques have been used in other disciplines of civil engineering like water and hydrology, while in the area of tunneling and geotechnical engineering, there is no published study as far as the authors know. A combination of the previous theories/empirical equations with SC techniques can be used by researchers in the field of tunneling. In this way, the proposed model will not be just a pure SC one and it would be possible for a tunnel engineer or geotechnical designer to apply it in practice.

CONCLUSION

Based on the findings from this perspective, the following conclusions can be drawn. For the selection of input parameters for tunnel blasting, two categories of parameters should be considered, i.e., design parameters and geological properties. Blast design parameters have a greater impact on the prediction of PPV and over-break than geological properties, as these design parameters directly determine the magnitude of energy after blasting. For the selection of input parameters for mechanical excavation methods, two categories of parameters should be focused on, i.e., machine characteristics and ground (rock mass and material) properties. Despite machine characteristics being very important for predicting specific objects, when a tunnel is constructed in different and complex formations, ground properties play a crucial role in estimating specific objects, as they govern the selection of construction machinery and methods used in practical engineering. The development of SC models is a crucial task for future research. For the tunneling projects that are carried out in different ground conditions, the geomechanical and hydrological properties, as well as the design parameters, gradually vary during the excavation. To overcome these difficulties, it is suggested to design TGDS techniques that are able to overcome the shortcomings of SC techniques. These techniques, with the advantages of both SC and previous theories, would be of interest and necessary for tunnel engineers and researchers.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.