All published articles of this journal are available on ScienceDirect.

Evaluation of Characteristics of Concrete Mixed with Bamboo Leaf Ash

Abstract

Background:

Concrete production around the globe is in billions of tons. Consequently, million metric tons of carbon dioxide are produced annually due to the cement consumption and production which, in turn, cause environmental menace.

Objective:

This research work examines the use of Bamboo Leaf Ash (BLA) as supplementary cementitious materials.

Methods:

The physical, mechanical, and durability properties were studied by partial substitution of cement with BLA at 0, 5, 10, 15, and 20% sequentially. Concrete cubes were cast and cured at 7, 28, 56, and 90 days. Beams were cast and cured at 28 days. A total number of five mixes were investigated, four out of the mix were dedicated to examining the impacts of BLA on the characteristics of concrete.

Results:

Soundness, consistency, initial and final setting time of cement paste values were lower than bamboo blended paste values at 5%, 10%, 15%, and 20% percentage replacement, respectively. The split tensile, compressive, and flexural strength values of conventional concrete were lower than bamboo leaf ash concrete accordingly. Water absorption, permeable voids, sorptivity, and bulk dry density of conventional concrete were higher than bamboo leaf ash concrete at all level of replacements.

Conclusion:

According to the analysis and experimental results obtained, BLA improved split tensile, compressive, and flexural strength benchmark at 10% as the optimum level of replacement. BLA reduced setting time, consistency, compacting factor, slump, water absorption, permeable voids, sorptivity, and density. To this end, BLA can be considered as a good pozzolanic material which can save the cost of construction, and improved concrete properties.

1. INTRODUCTION

Over 10 billion tons of concrete are largely produced around the world [1]. The global inhabitant was forecasted to grow from 1.5 billion to 9 billion by the end of 2050. This will lead to high demand in term of housing, thus, the need for concrete was also projected to increase to 18 billion tons yearly by 2050 [2]. Furthermore, cement was found to be one of the major principal binding materials with reference to the volume produced. Cement is produced at elevated temperatures which use a huge amount of heat of around 4 GJ [3]. Aside from the fact that it uses a huge amount of heat, it is believed to discharge dangerous fumes which contaminate the environment [4]. According to the study [5], cement production around the world was estimated to be 4100 million metric tonnes.

The production of one ton of cement releases 0.94 ton of carbon dioxide into the environment [6]. The cement products also faced durability problems which have an impact on resource utilization for reconstruction and maintenance [7].

These issues have led to rigorous research into various materials that can be used as pozzolans so as to save construction cost, eliminate environmental hazards, and need to improve the performance of concrete. Pozzolans contain silica and alumina which could react with lime at ordinary temp-eratures in order to produce cementitious compounds like calcium silicate, calcium aluminate, and calcium sulpho-aluminate hydrates in the presence of moisture and finely divided form [8]. Innovative and structural building constituents are regarded to possess the capability for solving the over-reliance on unrenewable elements such as, cement, gravel, sand, etc. which are being utilised worldwide for construction works. This will certainly assist towards harnessing the associated environmental deterioration that emanates as a result of extrication of unrenewable elements. Most inventive structural elements so far are achieved through partial substitution of one key constituent of concrete with any of the wastes materials such as agricultural, construction, industrial, etc. and non-waste elements. A couple of waste materials that have been utilised extensively for the purpose of structural concrete are, silica fume [9], palm kernel fuel ash [10], fly ash, and rice husk ash [11]. Wastes (agriculture, construction, industrial, etc.) [12], pulverized bone [13], and bagasse ash. The application of waste elements which contains pozzolanic features in concrete production is gaining global attention. The evaluation of the activity of cement supplementary cementitious materials is turning out to be necessary due to the demand for more sustainable cementing materials.

Bamboo (Bambusa vulgaris) is an unexceptional prevailing composite element which germinates extensively in most humid regions and is regarded as a complex material due to its glucose fibres placed in a lignin pattern. More than 1200 bamboo breeds have been recognised worldwide [4].

The yearly production of bamboos across the globe amounts to twenty million tonnes. However, about ten million tonnes are produced in China, Japan and India [14]. Bamboo is doubtlessly the swiftest growing and dominant generating construction elements and natural resources accessible to humankind. Nonetheless, the utilisation of bamboo creates other excesses which are not used as fibres, namely, the bamboo leaf. Some regions manufactured a substantial quantity of bamboo which generates a huge amount of refuses. These refuses are mostly incinerated in an unclosed dump which in turn causes a negative impact on the environment.

Bamboo leaf ash as investigated by Asha et al. [15] revealed that BLA is a pozzolanic agricultural waste due to its high silica content and it is said to be amorphous in nature. Consequently, pozzolanic reactivity studies unveiled that bamboo leaf ash had high reactivity at early ages [16] and its pozzolanic behaviour can be compared to silica fume [17, 18]. Bamboo leaf ash is obtained as a result of the combustion of bamboo leaves. The ash components of bamboo consist of inorganic elements, basically, silica, potassium, and calcium. Magnesium and manganese are among the two other normal elements. A high proportion of silica was found in the epidermis, that is, a small amount was found in the nodes, and none in the internodes [19]. Bamboo leaf ash oxidises with calcium hydroxide to liberate extra calcium silicate hydrate (C-S-H) which is the main cementitious element [17, 18], [20]. Application of these waste as cement replacement not only reduces the economic and environmental problems associated with the waste disposal [21, 22] but also reduces the CO2 emissions during cement manufacture which requires extreme heat [23].

Therefore, the primary objective of this research was to examine the impact of BLA blended cement concrete in term of mechanical, workability, and durability properties of concrete.

2. MATERIALS AND METHODS

2.1. Materials

The resources utilised for this research comprise of Bamboo Leaf Ash (BLA), Ordinary Portland Cement (OPC) type 1, water, Coarse Aggregate (CA), Fine Aggregate (FA), and superplasticizer. Fig. (1) shows the bamboo leaf ash used for this study. Every single material adopted in this research were obtained from various regions in Kenya. The river sand and coarse aggregate were procured from Masinga and Mlolongo located in Machakos county Kenya. Bamboo leaves were fetched from Mau forest located in the rift valley of Kenya. Superplasticizer and cement were purchased in Kenya. Lastly, contaminant-free tap water was used.

2.2. Methods

The methods employed in the course of this study are listed in Table 1, all methods shall be discussed in successive section.

2.2.1. Test Methods for Material Characterization

Sampling process for the fine and coarse aggregate was carried out in tandem with ASTM C 33 (2003) [24] techniques using sieves in accordance with BS ISO 3310-2 (2013) [25], furthermore, aggregate sampling was conducted in line with BS EN 932-1 (1997) [26] requirements for the purpose of batching. Bamboo leaves were allowed to sun-dry to expel water content, later undergo burning to remove inorganic materials that might be present in it. Further, it was calcined at 6500C using muffle furnace at 2 hours retention time. After cooling, it was sieved using 0.15 mm sieve. Void in aggregates and bulk density were obtained in line with the techniques stipulated by ASTM C29 (2003) [27]. Specific gravity and water absorption of aggregates were investigated in accordance with BS EN -1097-6 (2013) [28]. Hygrometer test was carried out in order to obtain the particle size distribution for BLA in line with ASTM D7928 (2017) [29].

| Test on Component Materials | – | Test on Fresh and Hardened Concrete | – |

|---|---|---|---|

| Test Conducted | Standard Adopted | Test Conducted | Standard Adopted |

| Aggregate Specific Gravity (SG) | BS EN 1097-6 | Compacting factor | BS EN 1881-103 |

| Sieve Analysis (BLA) | ASTM D7928-7 | Slump | BS EN 12350-2 |

| Sieve Analysis | ASTM C33 | Compressive strength | BS EN 12390-3 |

| BLA and Cement SG | ASTM C 188 | Tensile strength | BS EN 12390-6 |

| Fineness Modulus | ASTM C136 | Flexural strength | BS EN 12390-5 |

| Aggregate Water Absorption | BS EN 1097-6 | Water absorption | ASTM C642 |

| Voids in Aggregate | ASTM C29 | Permeable voids | ASTM C642 |

| Aggregate Density | ASTM C29 | Hardened density | ASTM C642 |

| Setting Time | BS EN 196-3 | Sorptivity | ASTM C1585 |

| Consistency | IS 4031-4 | – | – |

| Soundness | BS EN 193-3 | – | – |

2.2.2. Mix Design and Mix Procedure

The mix design for the Portland concrete grade 25 was performed in line with BS EN 206 (2014) [30] and BS 8500 -2 (2012) [31]. A total of 5 mixes were made. Table 2 depicts the details of all the mix proportions. Water binder ratio (w/b) of 0.5 was kept constant for all the mixtures using 195kg/m3 of water. The cement was partially replaced by 5%, 10%, 15%, and 20% BLA by weight of cement. Superplasticizer was utilised at 1.56, 1.482, 1.404, 1.326, and 1.248 (0.8% by weight of cementitious material) for percentage replacement at 5%, 10%, 15%, and 20% BLA content, respectively. Mixing was done manually as stated by BS EN 1881-125 (2013) [32] and was controlled with a device in order to guard against the escape of water and cementitious elements during mixing apportioning. The specific gravity for both BLA and cement was executed in line with ASTM C188 (2016) [33] and particle size distribution for BLA was performed in line with ASTM D 7928 (2017) [29]. Chemical analysis for both BLA and cement was performed through the use of x-ray diffraction equipment which conformed to BS EN 196-2 (2013) [34].

2.2.3. Test Methods for Fresh Concrete Properties

The fresh concrete properties were examined by carrying out compacting factor and slump. Three samples each were produced for each test. Sampling was in line with techniques stated in BS EN 12350-1 (2009) [35]. Compacting factor, the slump was examined in line with stipulated procedures in BS 1881-103 (1993) [36] and BS EN 12350-2 (2009) [37], respectively.

| Mix Description | Cement (kg/m3) | BLA (kg/m3) | Superplasticizer (kg/m3) | C.A (kg/m3) | F.A (kg/m3) | Water (kg/m3) |

|---|---|---|---|---|---|---|

| Control | 390 | 0 | 1.5 | 993 | 662 | 195 |

| 5% BLA | 370.5 | 19.5 | 1.482 | 993 | 662 | 195 |

| 10% BLA | 351 | 39 | 1.404 | 993 | 662 | 195 |

| 15% BLA | 331.5 | 58.5 | 1.326 | 993 | 662 | 195 |

| 20% BLA | 312 | 78 | 1.248 | 993 | 662 | 195 |

2.2.4. Test Methods for Hardened Concrete Properties

Cubes of sizes 100mm*100mm*100, cylinders with a diameter of 100mm*200mm long, and 150mm*150mm* 550mm long in line with BS 12390-1 (2012) [38] and BS EN 12390-5 (2009) [39] specifications were employed to produce concrete specimens for compressive strength, tensile strength, and flexural strength test. A total number of 60 cubes, 60 cylinder specimens, and 15 beams were prepared and cured according to the methods stipulated in BS EN 12390-2 (2009) [40] for 7, 28, 56, and 90 days compressive strength and tensile strength, 28 days for the flexural strength test. Three samples were produced for each test. Compressive strength, split tensile strength, and flexural strength test were performed in line with BS EN 12390-3 (2009) [41], BS EN 12390-6 (2009) [42], and BS EN 12390-5 (2009) [39] test methods. Each sample was being subjected to loading at failure using an automated electronic testing machine which conforms to BS EN 12390-4 (2000) [43], beams were loaded under four-point loading system.

Water absorption, density, and permeable void spaces in concrete were conducted in line with ASTM C642 (2013) [44]. In each case, three samples were made using cube sizes of 100mm*100mm*100mm and 15 cubes in total were prepared and allowed to cure for 28 days. The samples were kept and dehydrated inside an oven for a period of 72h at the temperature of 1050C until a change of below 0.5% was noticed. Afterwards, the samples were kept inside the water at a moderate condition of 21.50C for a period of another 72h until there was an increment in saturated surface dry mass of below 0.5%. Lastly, the samples were kept in a container concealed with tap water and allowed to boil for 5h and later cooled down by the normal loss of heat for a period of 15h to a final average temperature of 22.50C.

Sorptivity was conducted in line with ASTM C 1585 (2013) [45] test methods. Three sample cubes were made using 100mm*100mm*100mm and were cured for 28 days, 15 cubes in total were prepared. The samples were kept and dried up in an oven for 24h at 1100C temperature and were tarried inside the oven for 72h at a temperature of 500C. After the expiration of 72h, each sample was kept inside airtight crucible and kept at an average temperature of 220C for a period of 15 days before the commencement of the absorption process. The samples were then brought out from the airtight containers and the five faces were coated appropriately to stop the ingress of water while the other side was laid open to the water. The weights of the samples after sealing were noted before submerging in the water of about 3-5.5mm above the bottom surface. Readings were recorded in term of weight gain for each test samples at 1, 5, 10, 20, 30, 60 min, 1, 2, 3, 4, 5, and 6 h, taking readings every day for 3 days, at 24 hours interval for 3 days, and 3 days taking one reading on the concrete samples.

3. RESULTS AND DISCUSSIONS

3.1. Material Characterization

Coarse Aggregate (CA), Fine Aggregate (FA), and Bamboo Leaf Ash (BLA) materials were characterised in term of grading. Aggregates, BLA, and cement are characterised in term of specific gravity. Aggregates are further characterised in terms of bulk density, water absorption, void content, and fineness modulus.

3.1.1. Physical and Mechanical Properties of Materials

The specific gravity for cementitious materials, aggregates, bulk density, water absorption, silt content, fineness modulus, among others, are shown in Table 3.

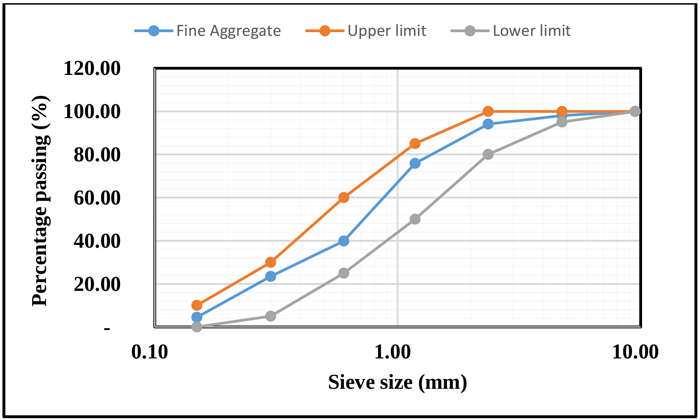

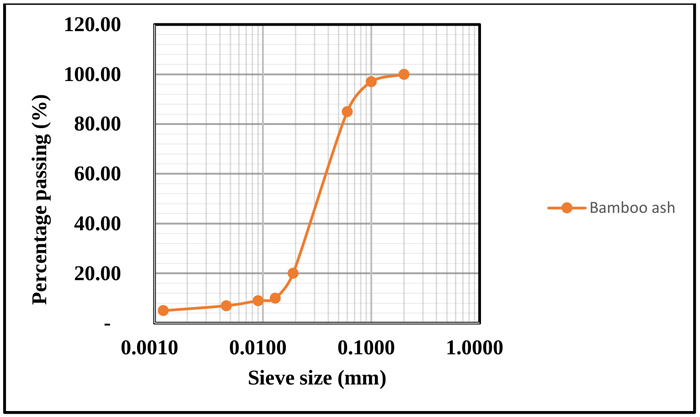

The gradation results for coarse aggregate, fine aggregate, and bamboo leaf ash are illustrated in Figs. (2-4) accordingly.

The gradation for coarse aggregate as seen in Fig. (2) shows that 90% of coarse aggregate was between 9.5mm and 25mm. This means most of the aggregate passed the 25mm sieve. The envelope curve was also between the upper and lower limit curve as stipulated by ASTM - 33 (2003) [24], so, therefore, it can be used for normal concrete weight concrete. Fig. (3) shows that the particle size of fine aggregate falls between 0.155 to 4.75mm within zone 2 which also satisfies the requirement that the fine aggregate should be less than 45% retained on any sieve by ASTM - 33 (2003) [24]. Fig. (4) depicts the particle size distribution of BLA. The figure illustrated that, about 20% of its particles falls within 0.001mm (1 µm) to 0.02mm (2 µm) and 80% falls within 0.02mm (2 µm) to 0.15mm (150 µm). This is in line with specifications of ASTM - D7928 (2017) [29]. Based on this fineness particle behaviour, the water demand and surface area of the bamboo leaf ash were enhanced. The maximum particle size for bamboo leaf ash adopted in this work was 0.150mm (150 µm). Fineness modulus of fine aggregate was found to be 2.55, which was within the limit 2.3-3.1 and conformed to ASTM -C33- (2003) [24]. Hence, the material can be used to produce good concrete. Silt content of 4.67% for fine aggregate was in line with the requirement of ASTM - C33 (2003) [24] of not exceeding 5%.

| Property | BLA | OPC | CA | FA |

|---|---|---|---|---|

| Bulk Specific Gravity | 2.79 | 3.12 | 2.48 | 2.43 |

| Bulk Specific Gravity Based on SSD | – | – | 2.56 | 2.52 |

| Apparent Specific Gravity | – | – | 2.80 | 2.68 |

| Fineness Modulus | – | – | – | 2.55 |

| Silt Content (%) | – | – | – | 4.67 |

| Water Absorption (%) | – | – | 3.27 | 3.95 |

| Loose Bulk Density (kg/m3) | 365 | 1398 | 1417.5 | 1456 |

| Rodded Bulk Density (kg/m3) | 479 | 1435 | 1495 | 1577 |

| Voids in Loose Aggregate (%) | – | – | 45.75 | 39.33 |

| Voids in Rodded Aggregate (%) | – | – | 39.52 | 34.31 |

| Maximum Particle Size (mm) | 0.15 | 0.09 | 20 | 5 |

The specific gravity of 2.48 and 2.43 for coarse and fine aggregate also conforms to the limit stated by ASTM - 33 (2003) [24] of not exceeding 2.4 - 2.9. More so, rodded bulk density of 1495kg/m3 and 1577 kg/m3 for both aggregates falls within the range of 1200 - 1750 kg/m3 based on ASTM - C33 (2003) [24] standards. The water absorption for both aggregates was 3.27 and 3.95 which was in line with standards according to ASTM - C33 (2003) [24] of not exceeding 4.

The specific gravity for BLA was 2.79 which was 11% lesser than OPC, the bulk density of BLA was 33% lesser than that of OPC. The smaller values recorded in term of specific gravity and bulk density of BLA could definitely yield in the reduced density of concrete. The maximum particle size of BLA and OPC was 150mm and 90mm. Table 4 shows the chemical compositions of BLA and cement, respectively.

Table 4 shows the chemical analysis of OPC and BLA which unveiled their respective chemical compositions. The test was conducted by using X-ray diffraction (XRD). Based on Table 4, BLA consists of essential compounds which are known to have binding properties for better concrete work. The percentage composition of CaO was found to be 10.814 which means the ash was cementitious itself, though CaO for cement was found to be 62.927 which was higher than BLA. CaO is responsible for the formation of tri-calcium silicate and di-calcium silicate which both react with water to make up calcium silicate hydrate (C-S-H) which is the main agent in term of strength development for concrete. The percentage of SiO2 + Al2O3 + Fe2O3 was found to be 73.38% which was more than a minimum of 70% stipulated by ASTM C618 (2008) [8] for pozzolana. Furthermore, loss of ignition (LOL) for BLA was higher than OPC but still within the range of 12% stipulated by ASTM C618 (2008) [8]. Table 5 depicts the chemical and physical properties of superplasticizer employed in this research.

The physical properties of BLA blended cement paste in term of soundness, consistency, and setting time are tabulated in Table 6.

| Chemical Composition (%) | Cement | BLA |

|---|---|---|

| Silica (SiO2) | 20.600 | 69.112 |

| Calcium Oxide (CaO) | 62.927 | 10.814 |

| Aluminium (Al2O3) | 5.985 | 2.523 |

| Iron (Fe2O3) | 3.341 | 1.741 |

| Phosphorus (P2O5) | 0.639 | 1.525 |

| Chloride (Cl) | 0.151 | 0.670 |

| Sulphur (S) | 2.622 | 0.406 |

| Manganese (Mn) | 0.129 | 0.245 |

| Potassium (K2O) | 0.266 | 4.814 |

| Loss of Ignition (LOL) | 3.34 | 8.15 |

| Property | Superplasticizer |

|---|---|

| Colour/ Appearance | Light Brown Liquid |

| pH Value | 5.6 |

| Density (kg/L) | 1.06 |

| Chemical Base | Polycarboxylate Ether |

| Dosage | 0.2 – 2%(Weight of Cement) |

| – | BLA Replacement (%) | ||||

|---|---|---|---|---|---|

| Physical Property | 0% | 5% | 10% | 15% | 20% |

| Soundness (mm) | 1.1 | 1.4 | 1.5 | 1.7 | 2.0 |

| Consistency (%) | 37.5 | 46.0 | 51.4 | 55.8 | 65.6 |

| Initial setting time (min) | 104 | 130 | 190 | 242 | 270 |

| Final setting time (min) | 259 | 302 | 358 | 407 | 475 |

The soundness test was conducted in order to determine the presence of uncombined lime in cement. The test was performed based on BS EN- 196-3 (2005) [46]. From Fig. (6) , it was evident that soundness increased as the percentage replacement of BLA increased, but there was no volume change in all the blended cement. This could be as a result of the particle size of the bamboo leaf ash. The BLA for all the percentage replacement conforms to BS EN- 196-3 (2005) [16] of not exceeding 10mm. The percentage increment was 0.3%, 0.4%, 0.6% and 0.9%. Consistency was conducted based on IS 4031-4 (1988) [47]. From Fig. (6), it was deduced that consistency value increases as the percentage replacement of BLA increased with cement. This could be as a result of the particle size of the ash which requires more water for better lubrication. The penetration depth of 5mm was achieved at all replacement level which conforms to IS 4031-4 (1988) [47] standards of the limit between 5-7mm penetration depth. The highest consistency value was attained at 20% BLA replacement. The percentage increment was 22.6%, 37%, 48.8%, and 74.9%, respectively. This study conforms to previous findings [48]. Setting time was conducted according to BS EN - 196-3 (2005) [46]. From Table 6, it has been observed that setting time increased as the percentage replacement for BLA increases with cement. The initial and final setting time of bamboo leaf ash was higher as compared to that of cement paste in all the mixes. The percentage increment for the initial and final setting time was 26 minutes, 86 minutes, 128 minutes, 166 minutes, and 43 minutes, 99 minutes, 148 minutes, 216 minutes, respectively. This could be as a result of a high amount of potassium oxide (4.814%) found in BLA which hampers the heat of hydration. Thus, this slow process in term of the heat of hydration is an advantage during mass concrete production which in turn reduces thermal stress. The cement conforms to BS EN - 196-3 (2005) [46], not exceeding 2 hours for initial and 10 hours for final setting time. BLA does not meet the initial setting time but met the final setting time for all the mixes of not exceeding 10hours. This study was in line with the findings of this study [48].

3.2. Fresh and Hardened Properties of Concrete

3.2.1. Fresh Properties of Concrete

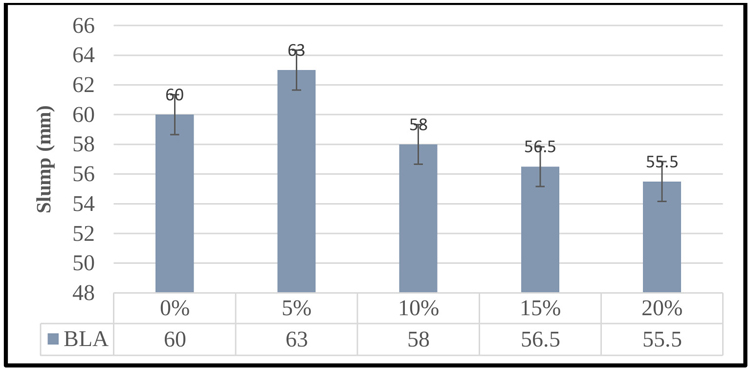

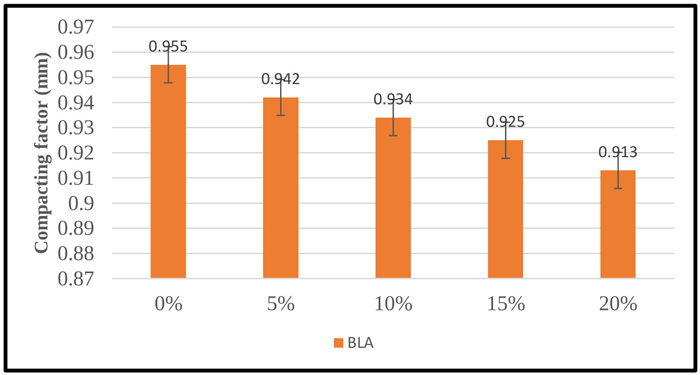

Table 7 depicts the slump and compacting factor of fresh concrete

| Fresh Properties | BLA Content (%) | ||||

|---|---|---|---|---|---|

| Control | 5 | 10 | 15 | 20 | |

| Slump (mm) | 60 | 63 | 58 | 56.5 | 55.5 |

| Compacting Factor (CF) | 0.955 | 0.942 | 0.934 | 0.925 | 0.913 |

3.2.1.1. Slump

Slump values of BLA at 0%, 5%. 10%, 15% and 20% percentage replacement were illustrated in Fig. (5). The result shows that slump value increased from 60mm at 0% to 63mm at 5% replacement BLA. This could be as a result of a high amount of Si02 and CaO present in BLA which improved the workability. Thereafter, there was a drastic drop in the slump as the percentage replacement increased from 10%, 15%, and 20%. This reduction could be connected to the huge surface area of the ash and excessive content of carbon which remained unburned in BLA. Superplasticizer of dosage 0.8% by total weight of cementitious material was adopted for all the mixes, the water was kept constant. The percentage increase was 5% while the percentage reduction was 3.33%, 5.8%, 7.5% at 10, 15 and 20% BLA content.

3.2.1.2. Compacting Factor (CF)

As illustrated in Fig. (6), the compacting factor of cement was higher than BLA at all level of percentage replacements. As the percentage replacement of BLA increases, the CF reduced as well. The values for CF are 0.955, 0.942, 0.934, 0.925, 0.913 at 0%, 5%, 10%, 15% and 20%, respectively. The values obtained falls within the range of 0.70- 0.98 based on BS 1881- 103 [36]. The reduction could be as a result of large surface area and particle size of the BLA. Percentage reduction were 1.36%, 2.20%, 3.14% and 4.40% accordingly.

3.2.2. Hardened Properties of Concrete

Table 9 displays the Compressive Strength (CS), Splitting Tensile Strength (STS), Flexural Strength (FS), Water Absorption (w), permeable Void spaces (v), Apparent Density (ad), and Sorptivity (k) of the concrete.

| CS (MPa) | TSS (MPa) | FS (MPa) | |||||||||||

| S.No. | 7 D | 28 D | 56 D | 90 D | 7 D | 28 D | 56 D | 90 D | 28 D | W (%) | V (%) | Bdd (kg/m3) | K (mm/h1/2) |

| 0% | 19.7 | 26.9 | 29 | 33.9 | 2.1 | 2.46 | 2.96 | 3.08 | 3.5 | 7.38 | 15.6 | 2.3 | 0.17 |

| 5% | 21 | 27.6 | 30.4 | 35.8 | 2.2 | 2.67 | 2.99 | 3.34 | 3.7 | 6.83 | 11.3 | 2.3 | 0.15 |

| 10% | 21.1 | 28.5 | 32.3 | 38.5 | 2.0 | 2.76 | 3.17 | 3.70 | 3.9 | 4.21 | 8.3 | 2.3 | 0.14 |

| 15% | 17.6 | 25.5 | 28.6 | 32.1 | 1.5 | 2.41 | 3.02 | 3.14 | 3.4 | 5.60 | 7.5 | 2.2 | 0.12 |

| 20% | 15.8 | 24.1 | 26.8 | 30.4 | 1.3 | 2.18 | 3.0 | 3.11 | 2.4 | 6.90 | 6.6 | 2.1 | 0.08 |

| Sample | 0% | 5% | 10% | 15% | 20% |

|---|---|---|---|---|---|

| Sorptivity, K (mm/h1/2) | 0.1666 | 0.1451 | 0.1417 | 0.1153 | 0.0828 |

| Coefficient of Determination (R2) | 0.9604 | 0.971 | 0.9737 | 0.9661 | 0.9298 |

| Coefficient of Correlation | 0.9800 | 0.9854 | 0.9868 | 0.98290 | 0.9643 |

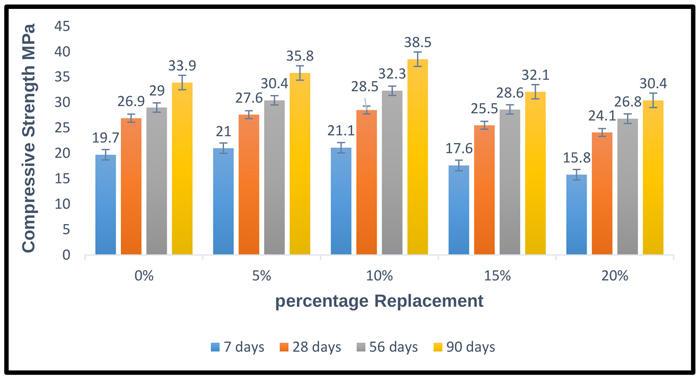

3.2.2.1. Compressive Strength (CS)

The compressive strength of normal concrete and concrete blended with BLA at curing age 0f 7, 28, 56, and 90 days is displayed in Fig. (7). It has been observed that there was an early strength generation at 7 days for percentage replacement from 5% to 10% replacement and a drop in strength at 15% and 20% replacements was noticed. These trends also apply to 28, 56, and 90 days of compressive strength. The increase in strength could be as a result of the presence of high amount of amorphous silica (SiO2 = 69.112%) present in the ash and high amount of CaO (10.814%) which was responsible for the formation of tri calcium silicate and di calcium silicate which both oxidises with water to form calcium silicate hydrate which was the determining factor for strength gain. Tricalcium silicate is mostly reactive at early ages which gave the ash more strength at 7 days for 5% and 10% replacement while di calcium silicate is most reactive at later ages but contributes very little to strength development unlike tricalcium silicate. The maximum strength was recorded at 10% BLA replacement at 7, 28, 56, and 90 days curing age, respectively. The drop in strength could be that C-S-H is most effective at 10% BLA replacement. Any further increase beyond 10% BLA replacement would lead to strength reduction. The percentage increase relative to the control sample at 5%, and 10% replacements was 6.60%, 2.60%, 4.83%, 5.60%, 7.11%, 5.95%, 11.38%, and 13.57% while percentage decrease at 15% and 20% replacements relative to the control sample were 10.66%, 5.20%, 1.38%, 5.31%, 19.80%, 10.41%, 7.59%, and 10.32%, respectively. The compressive strength obtained from this study produced better results when compared with those of the study [49-52].

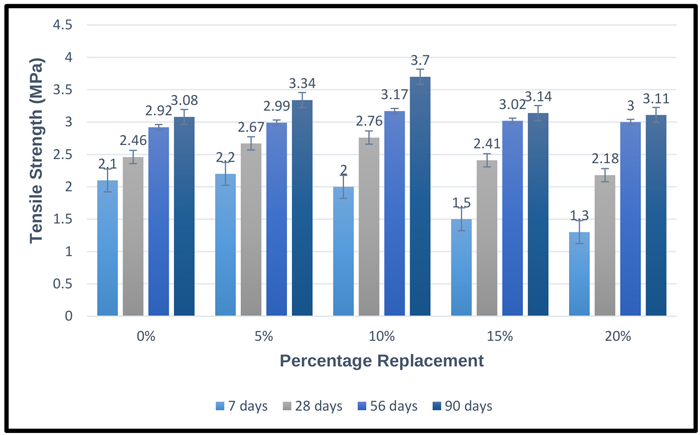

3.2.2.2. Splitting Tensile Strength

The STS of PCC concrete and concrete blended with BLA at curing age 0f 7, 28, 56, and 90 days is illustrated in Fig. (8). The figure indicated that there was a gradual increment in STS as the percentage replacement of BLA increased up to 10%. The STS peaked at 10% percentage replacement and later dropped at 15% and 20% percentage replacement of BLA. Thus, there was strength gain at 15% and 20% BLA replacement as the curing age goes beyond 28 days, the strength obtained was even higher as compared with the control sample. This implies that BLA replacing cement up to even 20% can increase the serviceability requirement of concrete as compared with that of reference structure. The strength increment could be as a result of high content of amorphous silica and CaO present in BLA. This trend in terms of strength gained and a reduction was similar to that of compressive strength results. The drop in strength could be that, the amount of BLA fragments shown in the mix was greater than the prescribed to integrate with the released lime during the heat of hydration operation which in turn led to excess silica leaching out, thereby resulting in reduction in strength as it partially substituted a segment of the cementing elements. The maximum strength was attained at 10% BLA content. The percentage increment relative to control sample at 5% and 10% was 6.60%, 2.60%, 4.83%, 5.60%, 7.11%, 5.95%, 11.38%, and 13.57%, thus, percentage increment relative to control sample at 15% and 20% was 2.03%, 1.95%, 1.35%, and 1.00% while its percentage reduction relative to control sample was 28.57%, 2.03%, 38.10%, and 11.38%, respectively. This study was in line with the findings of the sudy [53].

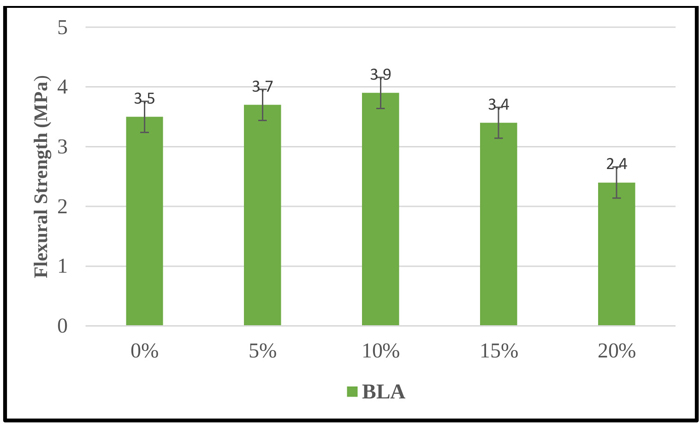

3.2.2.3. Flexural Strength

The 28 - days flexural strength of PCC concrete and BLA blended concrete is shown in Fig. (9). Based on the figure, flexural strength increased as the percentage replacement of BLA increased from 3.5MPa at 0% to 3.9MPa at 10%. There was a slight reduction in flexural strength at 15% and drastic decrement was noticed at 20% BLA replacement. The improvement in strength could be related to the high amount of amorphous silica and CaO which increased the strength. The maximum flexural strength was found at 10% BLA replacement. The reduction in strength could be that maximum percentage replacement should not exceed 10% - 15%. Any further increment would lead to a reduction in flexural strength. This trend suggests that BLA increased the brittleness of the concrete up to 15% percentage replacement. The results obtained satisfied the limit of between 3 - 4MPa based on BS EN 12390-5 (2009) [39] for grade 25 concrete except for percentage replacement at 20% BLA content. The percentage increment and reduction with relative to control beam at 5%, 10%, 15%, and 20% were 5.71%, 11.43%, 2.85%, and 31.43%. Furthermore, diagonal cracks were observed on all the concretes both for control and concrete containing BLA, an ultimate collapse occurred by concrete crushing within the compression zone for all the concrete. See appendix A1-A3 for diagrams.

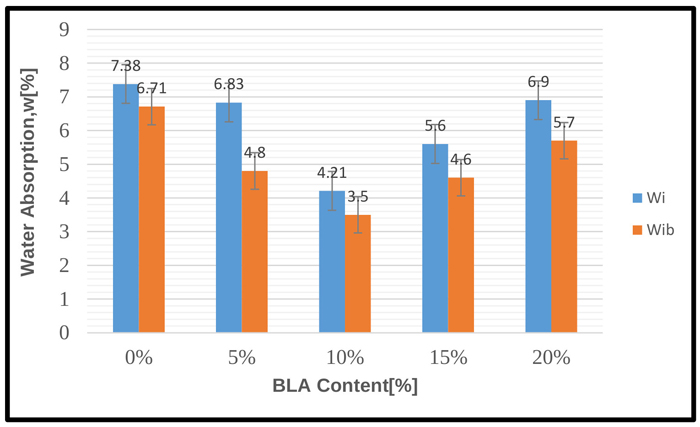

3.2.2.4. Water Absorption

The water absorption of BLA concrete, as well as PCC concrete, is shown in Fig. (10). It was discovered that there was a general reduction in water absorption after immersion (Wi) and water absorption after immersion and boiling (Wib) as the percentage replacement of BLA content increased. The lowest considerable percentage reduction of water absorptions was 0.5% for Wi and 1.01% for Wib at replacement level of 5% BLA content while the maximum percentage reduction was 0.6% and 1.91% for water absorption after immersion (Wi) at 20% BLA content. The Wib is a little bit higher than Wi as shown in Fig. (10). Generally, the water absorption of BLA concrete samples had low water absorption as compared with reference concrete. This reduction in water absorption could be as a result of initial filling of the voids by BLA concretes thereby acting as a water repellent. This study conforms to the previous research [53].

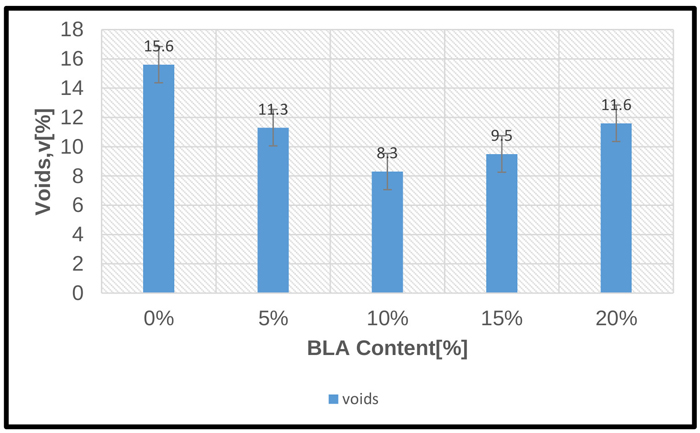

3.2.2.5. Volume of Permeable Void Spaces in Hardened Concrete

The permeable (porosity) void spaces of BLA concrete reduced slightly with an increase in BLA content as seen in Fig. (11). A sharp reduction in the void by 25.64% from 15.6% to 11.6% as the BLA content was increased from 0 - 20%. This reduction in void could be as a result of increased reactions which caused a denser porosity thereby reducing the permeable void spaces. The result of this work was in line with the previous investigation performed by the study [4].

3.2.2.6. Bulk Dry Density of Hardened Concrete

The Apparent Density (AD), Bulk Density after Immersion (BDI), Bulk Density after Immersion and Boiling (BDIB), and Bulk Dry Density (BDD) of PCC concrete and BLA concrete at 28 days of curing reduced with an increment in BLA content as demonstrated in Fig. (11). The drop in density could be ascribed to a lower specific gravity of BLA, thereby, directly decreasing the density of the matrix with an increase in BLA content. Thus, the bulk dry density was in the range of 2000 - 2600kg/m3 for normal concrete stipulated by BS EN 206 (2014) [30]. Furthermore, all the BLA concrete falls within the range, for that reason, BLA concrete can be classified as normal concrete. The result of these findings was in line with previous research [49].

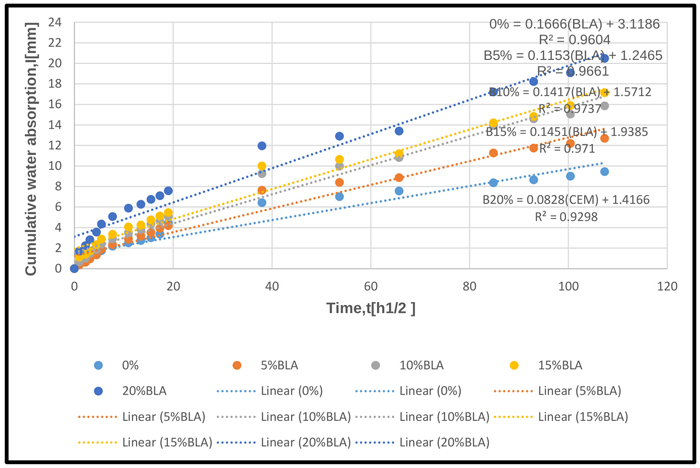

3.2.2.7. Sorptivity

The results of the rate of absorption of normal and BLA concrete are shown in Table 8. The water absorption rate is given in (mm/min1/2) and was obtained from the gradient of best optimum line to the accumulated water absorption (I) marked against the square root of time (mm1/2). Thus, the slope was obtained by employing least squares, linear regression analysis of the plot of I against the square root of time (t1/2). The effect of BLA with reference to sorptivity of concrete is shown in Fig. (12). From the figure, it was found out that, there was a linear reduction in sorptivity as the percentage replacement of BLA increased. The reduction rate was 50.3% from 0.1666 to 0.0828mm/h1/2 when percentage replacement of BLA mix heightened from 0 to 20% replacement. The lowering in sorptivity could be associated with the lighter particle of BLA which occupied the air spaces in the concrete, thereby hindering the percolation of water into the concrete. The sorptivity results of this research unveiled that, all the concrete samples conform the limit of sorptivity value to be less than 6mm/h1/2 based on the studies [54]. The concrete is regarded as durable concrete based on the results obtained.

CONCLUSION

The chemical content of BLA which consists of SiO2, Al2O3, and Fe2O3 was found to be 73.38%. This is more than the minimum requirement of 70% [8]. CaO content was found to be 10.814%.

Soundness values of cement and bamboo blended paste at 0, 5, 10, 15, and 20% percentage replacements were 1.1mm, 1.4mm, 1.5mm, 1.7mm, and 2.00mm, respectively (Fig. 13). Consistency values of cement and bamboo blended paste at 0, 5, 10, 15, and 20% percentage replacements were 37.5%, 46.0%, 51.4%, 55.8% and 65.6%, respectively. Final and initial setting time of cement and bamboo blended paste at 0, 5, 10, 15, and 20% percentage replacements were 104 minute, 130 minute, 190 minute, 242 minute, 270 minute, 259 minute, 302 minute, 358 minute, 407 minute and 475 minute, respectively. Compressive strength of concretes at 0, 5, 10, 15 and 20% percentage replacements for each value at 7, 28, 56 and 90 days curing were 19.7, 26.9, 29, 33.9, 21, 27.6, 30.4, 35.8, 21.1, 28.5, 32.3, 38.5, 17.6, 25.5, 28.6, 32.1, 15.8, 24.1, 26.8 and 30.4MPa, respectively. Split tensile strength of concretes at 0, 5, 10, 15 and 20% percentage replacements for each value at 7, 28, 56 and 90 days curing was 2.1, 2.46, 2.96, 3.08, 2.2, 2.67, 2.99, 3.34, 2.0, 2.76, 3.17, 3.70, 1.5, 2.41, 3.02, 3.14, 1.3, 2.38, 3.0, 3.11MPa, respectively. Flexural strength of concretes at 0, 5, 10, 15, 20% percentage replacements at 28 days curing was 3.5, 3.7, 3.9, 3.4, and 2.4MPa. Bulk dry density of concretes at 0, 5, 10, 15, and 20% percentage replacements at 28 days curing was 2.3, 2.3, 3.3, 2.2, and 2.1 kg/m3 .Water absorption of concretes at 0, 5, 10, 15, and 20% percentage replacements at 28 days curing was 7.38, 6.83, 4.21, 5.6, and 6.9%. Sorptivity values of concretes at 0, 5, 10, 15, and 20% percentage replacements were 0.17, 0.15, 0.14. 0.1, 0.18 mm/h1/2 . Permeable voids of concretes at 0, 5, 10, 15, and 20% percentage replacements at 28 days were 15.6, 11.3, 8.3, 7.5, and 6.6%.

From the above experimental results, analysis, and discussions, the following conclusions were reached: 1) The chemical analysis performed on BLA indicated that it contained essential chemical compounds. In summary, BLA is a good pozzolanic material and can partially replace cement. 2) The consistency, setting time, and soundness of blended bamboo cement paste reduced as the percentage replacement of BLA contents increased. Slump values and compacting factor of BLA concrete reduced as well as BLA content increased. 3) The compressive, split tensile, and flexural strength of BLA concrete increased. The optimum level of replacement was achieved at 10% BLA which yielded higher strength value in all the test conducted on hardened concrete. 4). BLA concretes had lesser density, water absorption, sorptivity, and permeable voids values as related to that of conventional samples.

AUTHOR CONTRIBUTIONS

O.O; S.M.S. J.M. and A.A.A. formulated the test to be conducted; O.O. collected data and conducted the experimental work; S.M.S; O.O. J.M. and A.A.A. analysed the data; S.M.S. facilitated resources; O.O; S.M.S. J.M. and A.A.A. wrote the paper.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data that support the findings of this study are available from the corresponding author, [O.O., S.M.S., J.M., A.A.A.], upon reasonable request.

FUNDING

The authors wish to express their profound gratitude to the African Union Commission (AUC) and the Japan International Cooperation Agency (JICA) (Grant no. 10.13039 / 501100004532) for funding this research work.

CONFLICT OF INTEREST

The authors affirm that there were no known conflicts of interest

ACKNOWLEDGEMENTS

Declared none.