RESEARCH ARTICLE

A Preliminary Study on the Physical Properties of an Alternative Coarse Aggregate Made with Red Soil and Fly Ash

J. Bright Brabin Winsley1, *, M. Muthukannan2

Article Information

Identifiers and Pagination:

Year: 2018Volume: 12

First Page: 1

Last Page: 8

Publisher ID: TOBCTJ-12-1

DOI: 10.2174/1874836801812010001

Article History:

Received Date: 05/10/2017Revision Received Date: 13/12/2017

Acceptance Date: 20/12/2017

Electronic publication date: 23/01/2018

Collection year: 2018

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Background and Objective:

The demand for course aggregate is increasing every day. Natural aggregate used for ordinary concrete is obtained by quarrying, which cause serious environmental issues. An alternate course aggregate is needed for sustainable development. The objective of this research is to produce an alternative course aggregate in combination with soil available locally near site along with fly ash, to test its properties to make it fit for concrete.

Method:

An alternative coarse aggregate is produced from red soil and fly ash mixed at various ratios, 100:0, 90:10, 80:20, 70:30, 60:40, 50:50, fresh aggregate granules of different sizes less than 10mm is prepared using hand press, the aggregates were sundried in shade for 24hours, oven dried at 110°C, burned in Muffle furnace at temperature of 950°C and cooled gradually to reach room temperature. After the production, the specific gravity, bulk density, water absorption, Impact and aggregate crushing of the aggregates were tested.

Result:

Test results showed that aggregates produced are of lesser specific gravity, density with relatively appreciable impact value and crushing value.

Conclusion:

The test results show that the aggregates produced can be used in construction as replacement for natural aggregates.

1. INTRODUCTION

Concrete is an essential material used in construction, in which 65% of its volume is occupied by coarse aggregates. Yearly tons of huge rocks are blasted to get coarse aggregate, which we commonly used for concrete production. The demand for concrete is large in India in the forthcoming years. Availability of high-quality rocks, their affordability and legal clearance make difficult to get them in abundance in near future. The method of quarrying, blasting and production of these aggregates have a negative impact on our environment. In India, most of the residential constructions are made with concrete. Several regions in India are facing problems in shortage of aggregates and have started importing from other countries. The soil is widely available in all places; the red soil available in Kanyakumari district of Tamil Nadu State in India is used for construction purposes like brickwork, mud plastering and brick manufacturing in the past. Fly ash is a waste material but can be effectively used in concrete either as aggregate fillers, replacement for fine aggregates or as brick material [1]. Studies conducted shows fly ash aggregate produced by palletisation and sintering can be effective aggregate in concrete, the concrete made with fly ash aggregate gave a lower compressive, split and flexural strength than conventional concrete, but from experimental results they can be categorized as structural concrete. Strength and durability of light weight concrete prepared with Lytag compared with normal weight aggregate showed positive results [2]. Fly ash from the industry is also blended with the soil to get good filling between soil particles. The thermal and acoustical performance of the concrete can also be increased due to the presence of voids and pores in the aggregates [3-6]. Compared with granite aggregates, lower density aggregates reduce dead weight of structure, size of the footing and cost of construction [7, 8]. Crushed bricks made with soil, partially replaced granite aggregates in concrete showed possibility of using as aggregate in concrete [9]. The aggregate is produced by mixing the red soil proportion and fly ash fused at 1200oC [10]. An increase in the volume of the aggregate occurs due to the vapour and gases formed at different temperatures, when trapped inside the body and unable to escape.

The main objectives of these experiments are to produce an alternative coarse aggregate for concrete which is light weight and from locally available clay and fly ash with properties similar to that of natural aggregate and to compare the physical properties of aggregates produced in various mix proportion with natural aggregate.

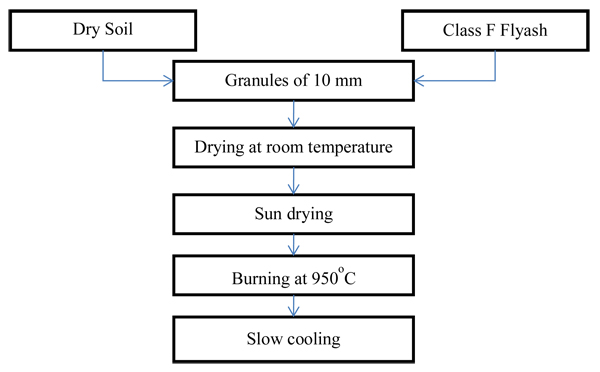

2. METHOD OF PRODUCTION OF SAMPLE

In this study, the aggregate were produced from the red soil available in the regions of Kanyakumari District of Tamil Nadu State, India and class F fly ash from Tuticorin thermal power plant as raw material. The red soil is collected and dried on sun to remove excess surface moisture content. Soil retained on 300micron, 90 micron and pan is taken for mixing in the ratio 20:30:50.

The flowchart shows the working methodology in aggregate preparation process (Fig. 1).

|

Fig. (1). Aggregate preparation process. |

Fly ash is added with the soil mix by weight in different ratio to get 6 different batches (aggregates produced with a specific mix) of sample as one for each mix as shown in the Table 1.

| Batch Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Fly ash content % | 0 | 10 | 20 | 30 | 40 | 50 | NA |

Portable water is added to soil and fly ash till the mix reaches plastic state of uniform consistency. Fresh granular aggregates of size less than 10mm are prepared by portable hand press; granular shape is obtained by shaping with hands. Fresh aggregate is processed in three stages to attain strength. The fresh aggregate is kept at room temperature for about 24 hours, and then it is sun-dried for one day. On the second stage, it is kept in hot air oven at 110oC for 24 hours. On the third stage, it is burned in Muffle furnace at 950oC. Muffle furnace LI141 is used for burning the aggregate. The temperature is gradually increased at the rate of 100oC till it reaches around 950oC (Fig. 2).

|

Fig. (2). Burning aggregates in muffle furnace. |

The burnt aggregate is cool down slowly to reach room temperature. The aggregate is then sieved and graded to the size similar to that of natural coarse aggregate.

3. TESTS ON AGGREGATES

After the production, the specific gravity, bulk density, water absorption, Impact and aggregate crushing value of the aggregates were tested as per Indian standards [11-13].

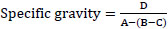

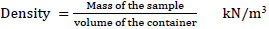

3.1. Specific Gravity, Density, Water Absorption

Pycnometer of 1 litre capacity with a weigh balance of 0.5g accuracy is used for the experiment. Sample aggregate of 1 kg between 10 mm to 4.75 mm size is placed in a tray and covered with distilled water at 28°C. Soon after immersion, air entrapped on the surface of the aggregate is removed by gentle agitation with a rod. The sample is immersed in water for 24 hours. The water is carefully drained from the sample, by decantation through a filter paper. The saturated and surface dry samples were weighed (A).The aggregate is placed in the pycnometer and filled with distilled water, the trapped air is eliminated. The pycnometer is topped up with distilled water to remove any bubbles from the surface of the water and so that the surface of the water in the hole is flat. The pycnometer is dried on the outside and weighed (B). The contents of the pycnometer were emptied into the tray, care being taken to ensure that all the aggregate is transferred. The pycnometer then is refilled with distilled water to the same level as before, dried on the outside and weighed (C).The sample is then placed in the oven in the tray at a temperature of 110°C for 24 hours, during which period it is stirred occasionally to facilitate drying. The samples were cooled in the air-tight container and weighed (D). The specific gravity, density and water absorption are calculated for the 7 samples using the following formulas, Eq. (1-3).

|

(1) |

|

(2) |

|

(3) |

Where: A is the weight of saturated dry sample, B is the weight of dry pyconometer, C is the weight of pyconometer filled with distilled water, D is the weight of dry sample.

3.2. Aggregate Impact Value

Aggregate impact tester (AIM-456-1) confirming the requirement [13] is used for conducting this experiment. The equipment has a hammer of 13.5kg falling from a height of 380mm with quick release trigger mechanism and automatic blow counter, a steel cylindrical cup of measure 75mm diameter and 50mm deep is used with tamping rod. The test sample of aggregate sample passes through 12.5-mm IS sieve and retained on a 10-mm IS sieve. The aggregate comprising the test sample is oven dried for four hours at a temperature of 100oC to 110°C and cooled. The steel cylindrical cup is filled about one-third full with the aggregate and tamped with 25 strokes with the rounded end of the tamping rod for three layers, The net weight of aggregate in the steel cup is determined to the nearest gram (A).The cup is fixed firmly in position on the base of the machine; The hammer is raised and dropped until its base is 380 mm above the upper surface of the aggregate in the cup and allowed to fall freely onto the aggregate. The test sample is subjected to a total of 15 such blows, each being dropped at an interval of not less than one second. The crushed aggregate is then removed from the cup and the whole of it sieved on the 2.36-mm IS Sieve until no further significant amount passed in one minute. The fraction passed the sieve is weighed to an accuracy of 0.1 g (B). The aggregate impact value is calculated by the formula, Eq. (4).

|

(4) |

Where: A is the weight of aggregate in the steel cup; B is the weight of crushed aggregate from steel cup passing through 2.36 mm sieve.

3.3. Aggregate Crushing Value

Aggregate crushing value apparatus (AIM- 455) confirming the requirement [13] is used for conducting this experiment. The equipment consists of an open ended steel cylinder with internal diameter of 11.5cm and height 18cm. A compression testing machine of capacity 100 tonnes capable of applying total load of 40 tonnes in 10 minutes is used. The samples are filled about one-third full in the cylindrical cup with the aggregate and tamped with 25 strokes with the rounded end of the tamping rod for three layers. The weight of material comprising the test sample is determined (A).The surface of the aggregate is carefully levelled and the plunger is inserted so that it rests horizontally on this surface. The apparatus with the test sample and plunger in position is placed between the platens of the testing machine and loaded at a uniform rate to a total load of 10 tones is reached in 10 minutes. The load is released and the whole of the material removed from the cylinder and sieved on a 1.7-mm IS sieve. The fraction passing the sieve is weighed as (B), Eq. (5).

|

(5) |

Where: A is the weight of aggregate in the steel cup; B is the weight of crushed aggregate from steel cup passing through 1.7 mm sieve.

4. RESULTS AND DISCUSSIONS

The results of the tests for the 7 samples are as given in the Table 2. For every sample mix 3 sets of samples were tested and the mean value is taken. Chi square test is conducted for the values obtained: with null hypothesis, there may be no error among the observation and the values are accepted.

| Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| % fly ash | 0 | 10 | 20 | 30 | 40 | 50 | NA |

| Specific gravity | 1.57 | 1.56 | 1.55 | 1.54 | 1.54 | 1.53 | 2.82 |

| Bulk density kN/m3 | 11.0 | 10.8 | 10.6 | 10.4 | 9.87 | 9.7 | 14.9 |

| Water absorption % | 11.9 | 14.8 | 16.3 | 17.8 | 18.8 | 21.3 | 0.66 |

| Impact Value | 29.8 | 28.7 | 28.3 | 27.8 | 30.6 | 45.2 | 30.1 |

| Crushing Value | 1.48 | 1.47 | 1.51 | 1.53 | 1.34 | 1.13 | 2.68 |

The specific gravity of the prepared aggregates and NA (natural aggregate) is shown in Fig. (3).

|

Fig. (3). Specific gravity values for different aggregate sample. |

According to the results, the specific gravity of the aggregates produced from the red soil and fly ash mixture from sample 2 to 6 shows a lesser specific gravity compared to the pure soil aggregate of sample 1. Sample 1 to 6 shows relatively lesser specific gravity than natural aggregate in sample 7. When compared to the normal aggregate the specific gravity is on average 50% lesser for the aggregate produced. It is found that the specific gravity decreases gradually with the increase in the addition of fly ash.

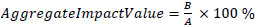

The bulk density of aggregates as shown in Fig. (4) also represents the same feature.

|

Fig. (4). Bulk density values for different aggregate sample. |

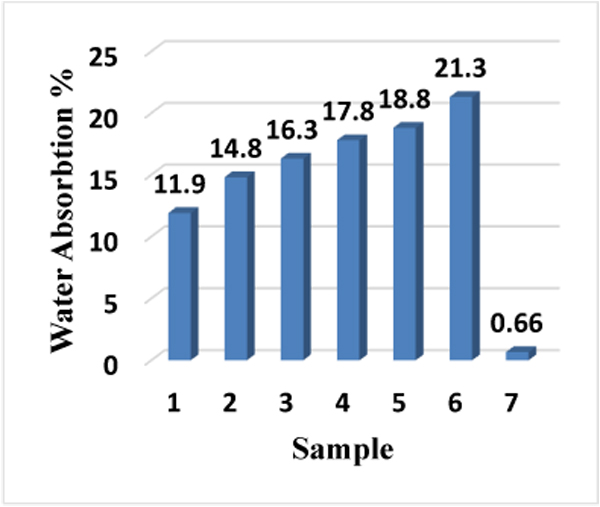

The water absorption properties of the aggregates produced are shown in Fig. (5).

|

Fig. (5). Water Absorption values for different aggregate sample. |

With the increase in the percentage of fly ash in the mix, the percentage of water absorption also increases. The percentage of water absorption is much higher.

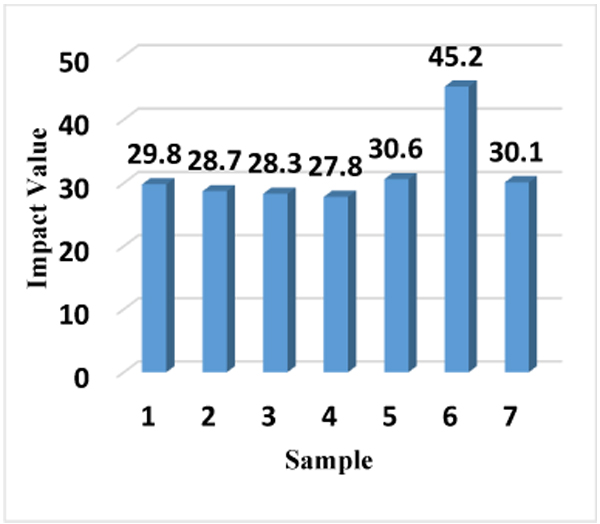

The impact value and crushing value for the aggregate produced is shown in Figs. (6 and 7).

|

Fig. (6). Impact values for different aggregate samples. |

|

Fig. (7). Crushing values for different aggregate samples. |

The impact value is much lower than the maximum 45% as prescribed by the Indian standard [12] for concrete other than wearing surface. A reduction of impact value equivalent to natural aggregate is achieved; the crushing value of the aggregate produced is within the range prescribed by the Indian Standard [12]. The percentage increase of fly ash from 40% to 50% made the aggregate more brittle due to the presence of higher fine particles causing sudden increase in impact value. However this made good bond strength in aggregate and made more resistant to gradual application of compressive load.

The air voids formed on the internal structure of the aggregate during burning process in the furnace made lesser specific gravity for the aggregate produced compared to normal aggregate in dry state. The cold bonded fly ash lightweight aggregate [1] showed bulk density of similar range. The water absorption of the aggregate produced is higher, these water stored in the pores of the aggregate can be used for hydration of cement. The higher percentage of water absorption cause increase in density during mixing of aggregate with water. The impact value for sample 4 with 30% fly ash is lesser than natural aggregate, but other samples showed a slightly higher impact value. Hence for the use of aggregates in impact resisting surface 30% fly ash can be preferred. The crushing value of the aggregate is acceptable for all batches. Burnt clay aggregate produced with 70% soil and 30% fly ash shows a better mechanical property compared with other samples prepared. Aggregate can be produced from soil available at site and reuse of fly ash can be done. Natural resources can be protected by reusing fly ash in aggregates. Dead loads acting on structures can be reduced and natural resources can be preserved.

CONCLUSION AND FUTURE WORK

The physical properties of burnt clay aggregates produced showed positive results make usable for construction. The aggregates produced can be used for making concrete with lesser bulk density and physical properties similar to natural aggregate. The workability, strength and durability aspects of the concrete with produced aggregate can be studied further. The contribution water content present in produced aggregate for hydration of cement in the concrete can be studied. The microstructure of the aggregate can be studied in detail for determining the bond between the binder and aggregate in concrete. The acoustic and thermal performance of concrete made with produced aggregates can be studied. Construction demolition waste having similar properties can be studied further so that wastes can be reused.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

The Authors would like to thank the Correspondent of Mar Ephraem College of Engineering and Technology Very Rev.Fr.Prem Kumar for his support in providing laboratory facilities to carry out the work.