All published articles of this journal are available on ScienceDirect.

The Effect of Fiber Hybridization on the Permeability and Porosity of Concrete Aerodrome Pavement: A Review

Abstract

Concrete pavements in aerodromes experience high stress due to aircraft loading, temperature fluctuations, and long-term fatigue, often leading to premature cracking and failure. Traditional concrete solutions reinforced with single fibers do not sufficiently address both micro- and macro-cracking. This study investigates the novel use of hybrid basalt fibers (BF)—a combination of micro- and macro-scale basalt fibers—to improve the mechanical, durability, and shrinkage-related performance of concrete for aerodrome pavement applications. Using a qualitative review methodology, over 50 studies were analyzed, focusing on the properties of fiber-reinforced concrete (FRC) and hybrid fiber systems. The reviewed studies include experimental works that tested mix proportions with fiber volumes ranging from 0.5% to 1.5% and cementitious matrices incorporating various BF geometries. Findings show that hybrid BF-reinforced concrete enhances flexural strength by up to 27%, compressive strength by up to 41.24%, and splitting tensile strength by 16%. Additionally, shrinkage strain was reduced by 10–34%, and water absorption decreased from 3.5% to 1.2%. The proposed innovation—a dual-layer reinforcement strategy involving a basalt fiber textile layer on the base course, combined with hybridized BF concrete—has not been previously reported in any international studies. This approach offers a cost-effective, high-performance, and sustainable solution for future airport infrastructure development. The outcomes are highly relevant to global engineering research in advanced pavement materials, particularly in countries seeking resilient and low-maintenance airfield construction solutions.

1. INTRODUCTION

Aerodromes are important resources because they facilitate the flow of people and goods around the area and beyond the globe. Aerodrome pavement, which has adequate load-bearing capacity to guarantee safe aircraft operation, is an aerodrome's most crucial infrastructure [1]. During aerodrome operations, the pavement progressively deteriorates due to various factors, including age, construction problems, aircraft loads, and environmental conditions [2]. By carrying out regular maintenance, repair, and rehabilitation, aerodrome pavements can be restored to their intended design life. As a result, the pavement is shielded from extreme stress and deterioration [3]. Airfield restoration with the application of a fresh layer of pavement over the existing structure is the most popular type of rehabilitation.

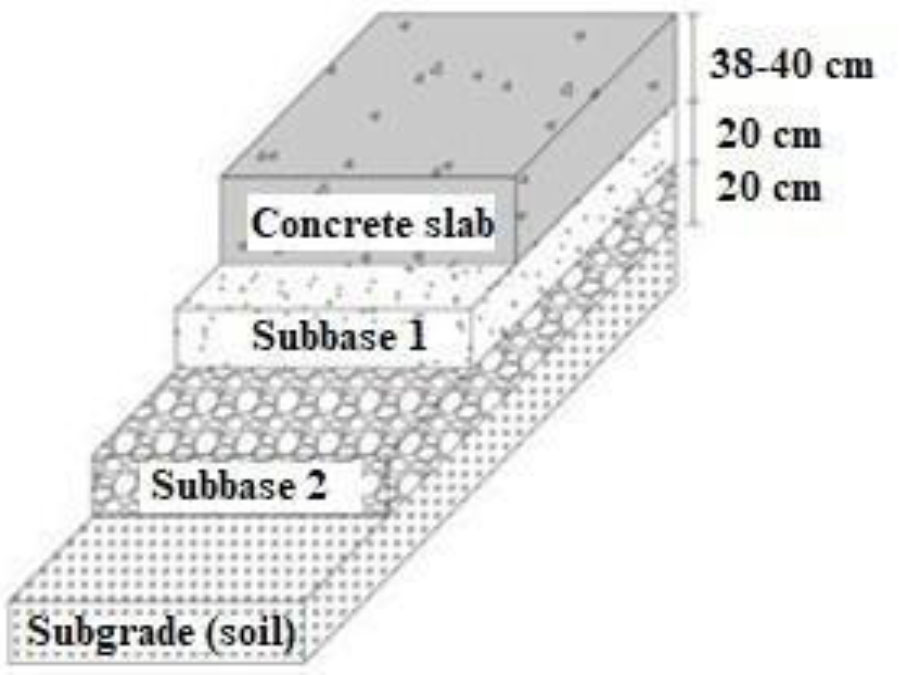

Aerodrome pavements come in two varieties: flexible and rigid. Rigid pavements are made of Portland cement concrete slabs that are either directly on a granular subgrade or rest on a prepared granular material subbase (Fig. 1a and 1b). The plate theory, as opposed to the layered theory, should be used to study rigid pavements. A condensed form of the layered theory known as the plate theory assumes that the concrete slab is a medium-thick plate that is plane before bending and remains flat after bending. One or two surfaces can be used for rigid pavement installation: the prepared subgrade or a single layer of stabilized or granular material. Some refer to it as a base course, while others term it a sub-base because there is just one layer of material above the subgrade and beneath the concrete [4]. Load is transferred from the slabs to the subgrade beneath via their flexure.

As stated in the study [5], key elements like the properties of the concrete, the supporting strength of the subgrade or subbase-subgrade combination, the type of aircraft and loads anticipated on the pavement, the approximate frequency of operation, and the type of pavement being designed, such as runway, taxiway, apron, or hangar floors, all contribute to the structural design of concrete aerodrome pavement.

The deformation of concrete pavement due to wheel loads generates compressive and flexural stresses [6]. Compressive stresses are considerably lower than the compressive strength, making them insignificant in affecting slab thickness. The ratios of flexural stress to flexural strength are significantly higher, frequently surpassing 0.5. Consequently, flexural stresses and flexural strength of the concrete need to be taken into account in the thickness design. Flexural strength is assessed through modulus of rupture (MR) tests, following the American Society for Testing and Materials C78, utilizing third-point loading. Tests for modulus of rupture are typically conducted at 7, 14, 28, and 90 days. The 7- and 14-day test outcomes are evaluated against specification standards for job management and for deciding when pavements can be utilized. Typically, for airport pavements, the design strength is based on the results from the 90-day test. Condition assessments and evaluation studies indicate that employing a lower strength value, such as the 28-day value, typically leads to an over-engineered pavement. Due to the ongoing rise in strength occurring throughout the pavement's lifespan, the modulus of rupture quickly surpasses the 28-day value [7].

Layers of a rigid pavement [14].

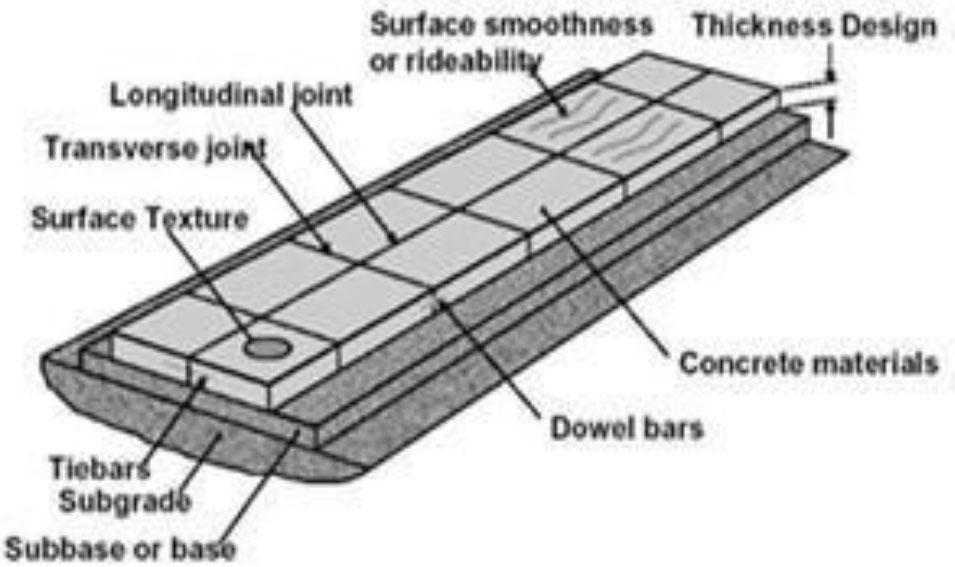

The design structure of a rigid pavement [15].

Similar to other structural materials, concrete is affected by the impact of fatigue. A flexural fatigue failure takes place when a material breaks due to ongoing repetitions of loads that induce flexural stress ratios below one [8]. In design evaluation, presumptions are established concerning the behavior of the subgrade or the subbase-subgrade combination [9, 10]. The majority of concrete pavement designs rely on Westergaard's modulus of subgrade reaction, k, which is established through load tests utilizing a 30-in.-diameter plate [11]. This approach considers the subgrade as if it has the load-bearing characteristics of a thick liquid. Influence charts created by Pickett and Ray are advancements of the Westergaard analysis and were designed for both the dense-liquid subgrade assumption and the elastic-solid subgrade assumption. The former has been utilized most often for designing pavements [12, 13].

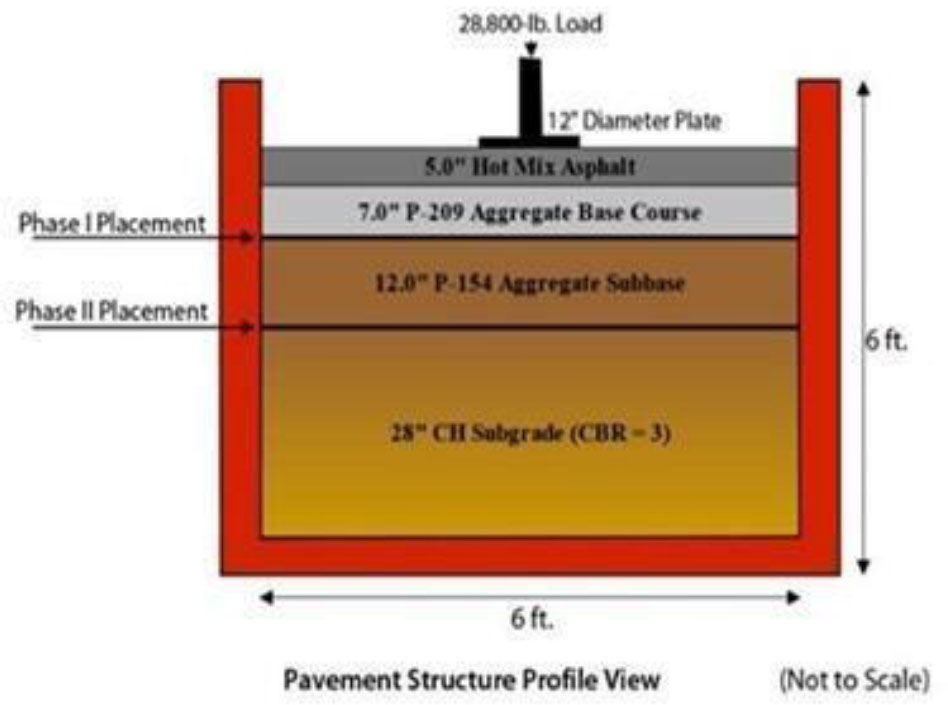

Flexible pavements (Fig. 2) are made of several layers of bituminous concrete or asphalt overlaid on a granular prepared subgrade. A surface course of bituminous material, as well as base and subbase courses beneath it, make up a flexible pavement. The bituminous substance is mostly asphalt, whose viscosity permits considerable plastic deformation [16]. While some full-depth asphalt surfaces are constructed directly on the subgrade, the majority of asphalt surfaces are constructed on gravel bases. Asphalt is classified as either hot mix asphalt, warm mix asphalt, or cold mix asphalt based on the temperature at which it is applied. Flexible pavement gets its name from the fact that when traffic loads are applied to it, the pavement surface itself reflects the overall deflection of all layers underneath it [4].

The pavements disperse the concentrated aircraft wheel loads over their depth until the base load of the pavement is less than the in-situ strength of the soil. The strength of the pavement should, at all depths, be at least equivalent to the stresses that aircraft wheels put on it. The main requirement for pavements on roads, airports, and fast-setting concretes is flexural strength, enabling values of 2.8–5.0 MPa for flexural strength (ff) to be reached after the first day of hardening. Full-depth repair technology is being used more and more to repair cement concrete pavements [17, 18].

Since the landing gear systems of aircraft mostly affect conventional aerodrome pavement design procedures, they have also presented some difficulties for civil engineers. The critical stress condition, which governs the structural performance of concrete aerodrome pavement, is the maximum flexural bending stress that develops in the slab as a function of temperature and wheel load. Using the notion that an elastic plate resting on a viscous or elastic base constitutes a rigid pavement, an elastic theory is applied to study rigid pavements. Some strategies to boost the structure's structural capacity should be taken into account throughout the design phase to improve the suitability for more aircraft [19].

Airport flexible pavement [16].

2. METHODOLOGY

2.1. Study Design

This study utilized a qualitative systematic review design to examine, interpret, and synthesize experimental findings on the performance of hybrid fiber-reinforced concrete (HFRC) in aerodrome pavement applications. Particular emphasis was placed on the hybridization of basalt fibers—specifically the combined use of micro-scale and macro-scale basalt fibers—due to their promising mechanical and durability characteristics. The review also integrated evidence from studies evaluating the incorporation of nano-admixtures (e.g., nano-silica, graphene oxide) into cementitious systems, given their known influence on hydration kinetics, microstructural refinement, and fiber–matrix bonding. The primary objective of this review was to explore the synergistic performance effects resulting from the combination of multi-textural basalt fibers and nanomaterials on critical concrete properties such as compressive and flexural strength, permeability, shrinkage resistance, and long-term durability—particularly under dynamic loading and environmental conditions typical of airfield pavements.

This study did not involve original laboratory experimentation. Instead, it systematically draws on existing peer-reviewed empirical studies, creating a narrative synthesis and thematic analysis using inclusion and exclusion criteria to identify trends, gaps, and promising design propositions. The goal is to inform future experimental research and practical applications by compiling the most relevant, high-quality evidence on advanced concrete reinforcement strategies for airport infrastructure.

2.2. Data Sources and Search Strategy

A comprehensive literature search was conducted across four major academic databases:

Scopus, Web of Science, ScienceDirect, and Google Scholar. The search spanned publications from 2000 to 2024 using combinations of the following keywords and phrases:

i. “basalt fiber”

ii. “hybrid fiber-reinforced concrete”

iii. “aerodrome pavement”

iv. “fiber concrete permeability”

v. “nano-admixtures in concrete”

vi. “concrete durability under aircraft loading”

Boolean operators and truncation techniques were employed to refine the search. Additionally, backward citation tracking was used to capture relevant sources not initially retrieved through by database queries.

2.3. Inclusion and Exclusion Criteria

To ensure the relevance and rigor of the included literature, the following criteria were applied:

2.3.1. Inclusion Criteria

i. Peer-reviewed journal articles or conference papers.

ii. Published between 2000 and 2024.

iii. Experimental studies on concrete reinforced with single or hybrid fibers (e.g., basalt, polypropylene, steel, cellulose).

iv. Reports with quantitative results for at least one of the following:

a. Compressive strength.

b. Flexural or tensile strength.

c. Permeability or porosity.

d. Shrinkage.

e. Water absorption.

v. Studies simulating or directly addressing aerodrome or high-stress concrete pavement environments.

2.4. Data Screening and Selection Process

A two-phase screening process was adopted:

1. Title and Abstract Screening: Studies were initially reviewed for relevance based on titles and abstracts.

2. Full-Text Review: Articles that passed the first phase were evaluated in detail to determine if they met the inclusion criteria.

From an initial pool of over 100 studies, more than 50 experimental papers met the criteria and were included in the final synthesis.

2.5. Data Extraction and Analysis

For each included study, the following data were extracted and charted:

i. Fiber characteristics (type, size, volume fraction—typically 0.5% to 1.5%)

ii. Nano-admixture types (e.g., nano-silica, graphene oxide)

iii. Performance metrics:

a. Compressive and flexural strength.

b. Modulus of rupture.

c. Shrinkage and permeability.

d. Water absorption rates.

iv. Testing protocols used (e.g., ASTM C1202 for chloride permeability, ASTM C642 for porosity).

The extracted data were organized thematically under key performance domains:

i. Single vs. hybrid fiber systems.

ii. Fiber texture and dimensional effects.

iii. Influence of nano-admixtures.

iv. Crack control mechanisms (micro-crack vs. macro-crack behavior).

Where relevant, percentage improvements in performance were calculated and compared. Studies that included Scanning Electron Microscopy (SEM) analysis were examined to better understand fiber–matrix interactions and microstructural improvements in crack-bridging and pore structure refinement.

2.6. Design Proposition

Although the study is literature-based, it proposes a novel dual-reinforcement system for high-performance aerodrome pavements. This design consists of:

i. A basalt fiber textile reinforcement layer placed at the base course (to act as a structural and moisture barrier), and

ii. An overlay of hybrid basalt fiber concrete, combining micro- and macro-scale fibers to enhance toughness, crack resistance, and impermeability.

This proposed system is theorized to deliver multi-scale reinforcement, greater resilience under thermal and dynamic loading, and improved long-term pavement durability. While no field or lab validation was conducted in this review, the synthesis provides a sound foundation for future experimental trials and field implementation.

3. RESULTS

The reduction in strength of concrete aerodrome pavement caused by factors like the impact of stress from the landing gear systems of aircraft and the brittle nature of concrete has grown more noticeable due to rising traffic loads, as seen by the emergence of cracks, settling, voids, and other issues during operation. High-strength concretes (HSC) exhibit enhanced brittleness, which is especially critical under dynamic transport stresses [20]. Additionally, because of the high concentration, shrinkage deformations increase with increased cement quantity, particularly during the first stages of hardening [21]. To enhance the strength of concrete aerodrome pavements and prevent concrete from being brittle, fibers are added to the concrete mix and referred to as fiber-reinforced concrete airport pavements. Fiber-reinforced concretes have been widely used in highway engineering to solve the above-mentioned issues. For reinforcement, researchers have looked into various fiber types, including steel, polyester, basalt, polypropylene, asbestos, glass, and carbon (Fig. 3) [21-24], while the advantages and disadvantages of these fibers are discussed in Table 1 [25-28].

Fiber inclusion in concrete improves fracture resistance and is one of the two most important requirements for stiff pavements: reduced abrasion and flexural strength [29, 30].

Fiber reinforcement is a widely used technique to boost strength and resistance to cracking [31, 32]. The type of fiber used in common fiber-reinforced concrete products is the same. A single fiber has a restricted strain range and fracture-opening effectiveness. Therefore, it is necessary to blend fibers with various chemical and mechanical qualities to generate a cementitious composite with enhanced strength and ductility [33].

| Fibers | Advantages | Disadvantages | Refs. |

|---|---|---|---|

| Steel | Good mechanical behavior. i. Very well developed. ii. Inexpensive |

i. Authorities in some countries (like Sweden) do not allow the combination of conventional steel reinforcement in a chloride environment. ii. Possible corrosion spotting on surfaces. |

[25] |

| Polyester | i. Good flexibility. ii. Good heat resistance and thermoplasticity. iii. Good light resistance. iv. Good chemical resistance. v. High strength and elastic recovery. vi. Good water absorption |

i. Poor dyeability. ii. Poor resistance to melting. iii. Easy to play. iv. Poor hygroscopicity. |

[26] |

| Basalt | i. High tensile strength (higher than glass fibers). ii. Exceptional temperature resistance. iii. Non-flammable. iv. UV-stable. v. Natural product. vi. High corrosion resistance. vii. Low moisture absorption. |

i. High density (specific weight). ii. Not electrically conductive. |

[26] |

| Polypropylene | i. Extremely durable. ii. Resistant to many chemicals. iii. Non-absorbent. iv. Lightweight material. |

i. Limited heat resistance. ii. Poor resistance to ultraviolet radiation. iii. Low impact strength. iv. Not suitable for all chemical environments. Some chemicals, such as strong acids and oxidizing agents, can degrade polypropylene over time. |

[27] |

| Asbestos | i. A very good thermal insulator that increases the energy efficiency of the building. ii. Highly resistant to fire. iii. Forms a very strong material when mixed with cement. iv. Very inexpensive. v. Used as a protective roofing material in corrugated form. vi. Highly durable and weatherproof. vii. Resistant to damage from termites. viii. Very easy to clean and maintain. |

i. It is seriously hazardous to health. | [28] |

| Glass | i. High strength. | i. Strength decreases with time. ii. Sensitive to alkali attack |

[25] |

| Carbon | i. Alkali resistant. ii. Dimensionally stable. iii. High strength. |

i. Hard to obtain a good distribution in a concrete mix. | [25] |

Fracture examination of fiber-reinforced composites (FRC) identifies three phases of fracture development: the production of microcracks before peak load, the coalescence of small microcracks into a single microcrack, and the subsequent spread of macrocracks. Studies [34-37] discussed the impact of incorporating fibers into concrete on the properties (tensile strength, ductility, toughness, durability, dynamic modulus, creep compliance, rutting resistance, moisture susceptibility, and freeze-thaw resistance) of the concrete. Their studies concluded that the fibers improved these concrete properties. Initiatives have been made to employ different types of fiber to improve the toughness and ductility of cementitious composites [38, 39].

Different reactions to the cracking process are induced at different loading stages in cement composites that contain two or more mixed fibers [40]. Fiber-reinforced concrete composed of two or more fibers is generally known as hybrid FRC. As a result, several types of fibers are added to fiber-reinforced hybrid concrete to generate hybrid capabilities that are greater than the sum of the qualities of the individual fibers [33, 41]. According to study [42], hybrid fibers bond with the cement composites, thereby drawing advantages from every constituent fiber. Studies [43, 44] reported that the hybridization of two or more fiber types produces cementitious composites with greater tensile strength (ft), deformation capacity, and work-hardening behavior. Another method of hybridization involves combining fibers with varying diameters, lengths, moduli, and tensile strengths [45].

Fibers in concrete aerodrome pavements strengthen the pavements by bonding adequately to other concrete aggregates to improve the ft strength of the concrete. Numerous factors, such as the kind and amount of load, the climate, the properties of the materials, and the interactions between the materials, can lead to pavement distress. Pavement engineers face difficulties with persistent deformation (rutting), fatigue cracking, thermal cracking, and raveling, among other major pavement problems [46].

It has become essential to construct more sustainable and low-maintenance concrete aerodrome pavements due to the anticipated rise in aviation traffic movements worldwide and their effects on the environment. One way to improve the performance of these concrete aerodrome pavements and provide a more sustainable whole-life cost solution is by using dispersed fiber reinforcement in the concrete aerodrome pavement mix during the production process. It was discovered that improvements in concrete airfield pavement properties were achieved by incorporating a single type of dispersed fiber reinforcement, fiber hybridization of different fiber types, or by using reinforcement bars. No research has been identified where basalt fiber hybridization (basalt fiber (BF) of different textures and dimensions) was used in the reinforcement of concrete aerodrome pavements.

Hybrid fiber-reinforced concrete (HFRC), which combines two or more types of fibers with different geometries and properties, leverages the synergistic effects of each fiber type to mitigate the weaknesses of individual fibers [47, 48]. By facilitating multi-scale crack bridging, hybridization enhances energy absorption, ductility, and fatigue resistance. Nevertheless, the specific roles of fiber texture, size, and hybrid combinations—particularly those involving basalt fibers—remain underexplored, especially in the context of airport pavements.

Simultaneously, advances in nanotechnology have introduced nano-admixtures such as nano-silica and graphene oxide that significantly influence the hydration process, pore structure, and interfacial transition zone (ITZ) in cementitious systems. These nano-additives accelerate pozzolanic reactions, densify the microstructure, and enhance the bond between fibers and the cement matrix [49]. Their inclusion has been shown to improve compressive strength, reduce permeability, and prolong durability, offering promising enhancements for infrastructure exposed to aggressive operational environments.

The workability of the fresh concrete mixture should fall within an optimal range—neither too fluid nor too stiff—to ensure proper compaction and a uniform fiber distribution. Additionally, the mechanical properties of hardened concrete, including compressive strength, flexural strength, abrasion resistance, and overall durability, are critical performance indicators [50].

To examine the effect of fiber hybridization on the permeability and porosity of concrete used in aerodrome pavements, a targeted experimental approach can be implemented. The procedure begins by designing a control concrete mix suitable for aerodrome applications, followed by the preparation of hybrid fiber-reinforced concrete specimens incorporating combinations of fibers such as steel, basalt, polypropylene, or cellulose at various volume fractions (e.g., 0.5% to 1.0%). These mixes are cast into standardized molds and cured under controlled conditions for 28 days. Permeability is assessed using the Rapid Chloride Permeability Test (ASTM C1202), which measures the electrical charge passed through the specimen to indicate its resistance to fluid ingress. Porosity is evaluated in accordance with ASTM C642, where the specimens are oven-dried, immersed in water, and boiled to determine the volume of permeable voids. These tests collectively quantify the effectiveness of fiber combinations in reducing a concrete’s susceptibility to moisture and chemical penetration. Results are compared against the control mix, and statistical analyses such as ANOVA can identify significant improvements. This approach supports the development of durable, low-permeability concrete mixtures for high-performance aerodrome pavements [51].

3.1. Conventional Airport Pavements

As the global aviation sector has expanded over the last ten years, aircraft have become larger and heavier. The performance of aerodrome pavements is now under more pressure due to the rise of larger aircraft. Concrete airfield pavement designed in the 1940s was based nearly exclusively on data and experience. Later, as engineering mechanics advanced, the thin-slab theory and Winkel's elastic foundation assumption were used to construct airport pavement [52].

Concrete pavement cracking has been better understood because of the studies based on fracture mechanics, which have also encouraged associated numerical simulation research. Nevertheless, the pavement's load response as determined by these fracture mechanics-based investigations and computational techniques is very different from the real scenario. The design approaches for airport pavement may be roughly divided into three groups based on a summary of the design specifications: mechanical, empirical, and mechanical-empirical methods [53].

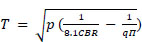

The California Bearing Ratio (CBR) curve represents the empirical method of pavement design. In the 1940s, the U.S. Army Corps of Engineers established a CBR curve for pavement thickness design based on comprehensive tests to determine the relationship between aircraft landing gear wheel load, number of load actions, pavement thickness, and CBR values. Since then, specifications from several countries have adopted an empirical method-based approach to airport pavement design [54]. The developed equation to correlate the CBR, the pavement thickness (T), and the magnitude of the wheel load, kg (q), tyre pressure, kg/cm2 (p) is shown in Eq. (1) [55].

|

(1) |

Like the CBR, the Present Serviceability Index (PSI), although referred to as a semi-empirical approach, considers two design criteria: serviceability and reliability. Theoretically, PSI varies between zero (a failed pavement) and five (a good pavement) [56]. Other relevant properties for pavement design include stripping test values, permeability test values, etc.

Due to the difficulty of describing the working behavior of airport pavement with precision, the empirical method is still a commonly used method for designing pavement today. Since 1980, the design of concrete airport pavement decks has been profoundly influenced by thin slab theory and the Winkler elastic foundation theory. Such design methods based on mechanical principles are included in both Chinese and American design codes [57].

Many concrete pavement evaluation methods or studies related to the mechanical properties of concrete pavement materials have also emerged in recent years. For example, study investigated the effect of the variation in physical-mechanical parameters of concrete on the final load-carrying capacity of pavements [58]. Study validated an indirect data collection method for pavement condition assessment [59]. In addition, the mechanical properties of concrete pavement materials have been studied more extensively in recent years, and a systematic characterization of concrete as a composite material has emerged [60].

Airfield pavements eventually degrade due to many factors, such as environmental conditions and traffic volume. To achieve the required design life, regular maintenance, repair, and rehabilitation must be carried out. Numerous studies have looked at the design, rehabilitation, and overlay of standard airport pavements, with a particular emphasis on pavements with conventional structures [61].

The M40 grade concrete has a ff of 40 kg/cm2, classifying it as standard or conventional strength, and is now used in the majority of aerodromes. It is discovered that thicker slabs have less curling stress than thinner slabs for a given joint spacing. Even if a slight increase in slab thickness has no impact on the total cost of the pavement, the pavement life is significantly extended. Pavement performance in terms of fatigue life can be increased even with higher concrete ff. Furthermore, the study concluded that mixes containing higher percentages of glass fiber with a maximum of 0.4% can result in a reduced design thickness [62]. The life of the pavement is also significantly extended by providing a solid base or subbase layer [63].

The purpose of concrete pavements is to provide twenty years of service for an anticipated number of load applications at the lowest possible initial and ongoing expenses, according to the standard [64]. The primary design parameters for concrete slab thickness are thermal loads and cracking caused by aircraft wheel gears. An airplane with a single design gets transformed by repeated loading from the traffic mix. The most destructive heavy aircraft has been identified as the design aircraft.

3.2. Fiber-Rrinforced Asphalt Aerodrome Pavement

A control mixture and a densely graded, fiber-reinforced asphalt combination from a field test location have been evaluated [65]. A combination of aramid (Kevlar) and polypropylene was included in this composition. In the triaxial strength test, the researchers demonstrated higher residual strength and shear deformation resistance. Tests of persistent deformation showed that, compared to the control combination, fiber-reinforced asphalt concrete (FRAC) mixes exhibited significantly greater flow numbers and less permanent strain. The values of the dynamic modulus of the FRAC mixture showed a discernible rise at higher temperatures, but at lower temperatures, they were comparable to the control mix's values. Furthermore, FRAC combinations showed improved ft, total fracture energy, and slower crack propagation, respectively, according to the Indirect Tensile Strength test (IDT) and the C* line integral test. Finally, at 4.4°C, or 40°F, the FRAC showed superior fatigue resistance; at high strain levels, however, the control performed better at 70 °F (21.1 °C).

An examination of the use of recycled asphalt pavement (RAP) reinforced with fibers for surface course pavements at airports constructed using both virgin and modified binders was carried out [66]. The inclusion of cellulose fibers increased the ideal binder concentration in all mixes, enhanced Marshall stability, and reduced mass loss as measured by the Cantabro test, according to the scientists. When a modified binder was utilized, the benefits of fibers were more noticeable. The authors concluded that airports with high traffic should use RAP with a modified binder since the fiber addition improved dynamic stability (wheel tracking test).

The study assessed the indirect tensile test with repeated load, creep, indirect tension, and Marshall stability characteristics of asphalt mixes enhanced with carbon fibers [67]. Due to the addition of carbon fibers, the authors observed a decrease in flow and an increase in air voids. On the other hand, the inclusion of carbon fibers extended fatigue life, decreased permanent deformation, and enhanced Marshall stability.

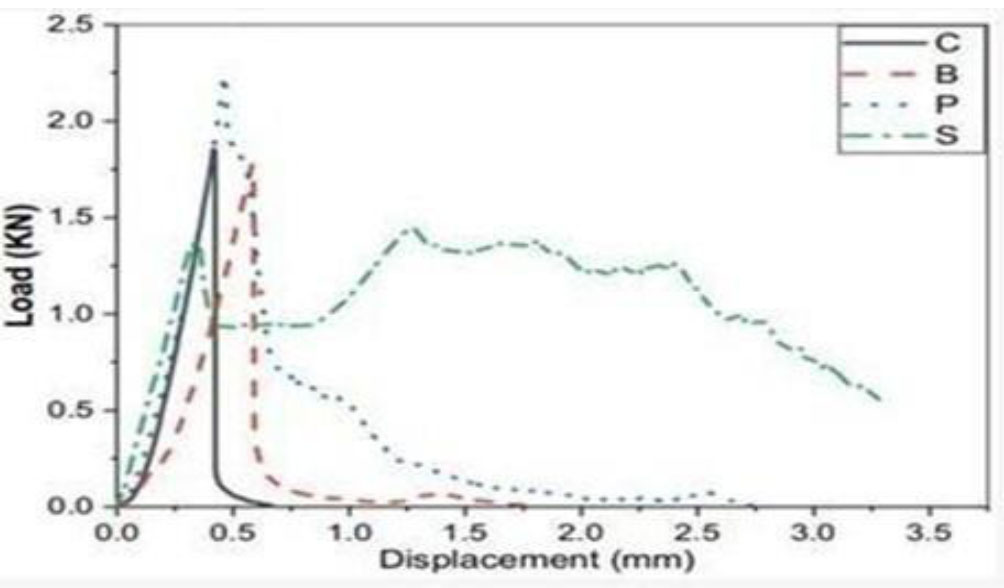

The study comprehensively stated that the controlled addition of fibers to one-part polymers can improve the ff properties of the composites [68]. The study highlighted that composites with no fibers experienced abrupt failure at peak load due to their brittle nature [69]. The PVA fiber composite sustained 20% more load before failure, and its failure was not as sudden as the fiber-free counterparts. However, basalt fiber composites were less impressive, the basalt fiber composites' ultimate load was lower and still experienced sudden failure. Lastly, the steel fiber composites' ultimate load was also below that of the non-fiber composites, but unlike the other three types of composites, the steel fiber composites did not experience any sudden failure at peak load; rather, they gradually failed after reaching their peak load (Fig. 4). In addition [70], also stated that the addition of fibers reduces the fluidity of the mixture, but due to the good cohesion of the fibers when they come into contact with water, the fibers are closely combined with the matrix. Thus, this justifies the improved toughening and strengthening attributes of fiber-reinforced polymers.

The investigation included dense-graded hot mix asphalt (HMA), cellulose, polyester, and waste or recycled fibers in their study [71]. Across all the fiber types used in the research, a rise in the ideal binder content was discovered, which may improve the performance of the mixture. In addition, their study indicates that Asphalt concrete containing cellulose fiber can result in improved stripping test value, i.e., 38% higher dry strength than the control mix, but slightly lower wet strength than the control mix. The study concluded that the fibers used in the investigation often do not raise HMA's resistance to stripping.

The fatigue and rutting performance of roadways is enhanced by FRAC. However, it is still unclear how FRAC is expected to function for airport pavements in different climates [72]. The study employed basalt, glass, carbon, and polyolefin/aramid fibers, with two binder grades (PG76-22 and PG58-28) for two different climates. The findings demonstrated that PFA fibers perform similarly well with both binders and locations in terms of fatigue life and rutting. Carbon fibers, however, suffered less damage from PG76-22. Lastly, the pavement condition rating (PCR) data revealed that pavements in colder areas had stronger bonds than those in warmer areas.

Load displacement curves under flexural loading. PVA fibers (P), basalt fibers (B), micro-steel fibers (S), and control (C: no fibers) [69].

Numerous experimental findings support the significance of identifying the threshold for dispersed reinforcement and modifier effectiveness, as any amount over what is reasonable can have a detrimental impact on the physical and mechanical characteristics as well as the longevity of fiber-reinforced concrete [73, 74]. For instance [75], demonstrated the beneficial impact of steel fiber, whose concentration ranged from 0 to 62 kg/m3, on concrete's ability to withstand cold. The study concluded that adding the right amount of steel fibers improves the carbonation resistance of concrete with nano-SiO2, but too much steel fiber lowers this resistance [76]. Steel fibers also decrease permeability resistance. While steel fiber reinforcement boosts freeze-thaw and crack resistance, increasing the fiber content further enhances freeze-thaw resistance but gradually reduces crack resistance. FRC with steel fibers and modifiers has therefore been thoroughly researched by [77]. However, when employing full-depth repair technology, intricate investigations of the characteristics of FRC for the repair of rigid road and airfield pavements are required. The combined impact of hardening accelerators and anchor steel fiber on the characteristics of concrete for rigid pavement repair is also not well studied. Abrasion, shrinkage, frost resistance, and early flexural strength are essential markers for these kinds of materials.

3.3. Fiber-reinforced Airfield Pavement Concrete

FRC's excellent and satisfying performance in the construction and industry has led to its widespread usage in several different technical contexts. Nonetheless, the majority of scientists and engineers have considered how and why the fibers function so well. Thus, in order to identify the use of fibers in concrete, the majority of studies conducted over the past forty years have focused on the behavior of FRC in pavements.

FRC is increasingly utilized in the construction and maintenance of airport infrastructure due to its enhanced mechanical properties and crack resistance. Its primary applications include the construction of new pavement slabs for runways, taxiways, and jetways, where high load-bearing capacity and durability are essential. FRC is also widely used in the repair of damaged sections in existing pavements, providing a quick and effective solution that improves structural performance and extends service life. Additionally, FRC overlays are employed for the rehabilitation and strengthening of existing runways and taxiways, offering a cost-effective method to upgrade aging infrastructure while minimizing downtime and operational disruption.

In frigid and high-latitude regions, aerodrome pavement concrete frequently sustains deterioration from freeze-thawing. Additionally, applying aircraft deicer causes salt-freezing damage to the concrete pavement at aerodromes. In this work, modified polyester synthetic fiber (PSF), cellulose fiber (CF), and BF-reinforced concrete were produced to increase the durability of airport pavement concrete [78]. The pore structure, mechanical strength, and frost resistance (salt freezing and freeze-thawing) of FRC were investigated. The study looked at how surface treatment techniques (spraying and impregnating silane) and fiber (content and type) in combination affected concrete's ability to withstand cold. Based on the data, it can be concluded that while the elastic modulus of fiber and concrete ff are positively associated, the fc is not significantly affected. Fiber can help concrete that has been damaged by frost lose less bulk and dynamic modulus. The amount of concrete that was sprayed or soaked with silane was reduced by 65.5% and 55.5%, respectively, following 30 cycles of salt freezing. Concrete that has fractured might be decreased by up to 70.5% by adding fiber and impregnating with silane. To improve the frost resistance of concrete, when treating concrete, silane spraying is more effective than silane impregnation, because it produces a better silane condensation reaction [79].

Conventional concrete aerodrome pavement may be strengthened and made to last longer. The study highlighted three different types of FRC (polyacrylonitrile, reticular polypropylene, and single polypropylene) that were tested for impermeability, frost resistance, and abrasion resistance [80]. The impermeability test was conducted using the hydrostatic pressure technique and the chloride penetration method; the frost resistance test was conducted using the quick freeze-thaw method; and the abrasion resistance test was conducted using the ball bearing method. According to the test results, the levels of frost resistance and impermeability for FRC increased by 40%–160% and their abrasion resistances increased by 23%–50% when the fraction was within 0.15%–0.18%. The highest levels of frost resistance and impermeability were observed when the fiber volume fraction was 0.10%.

A study was conducted in where it was discovered that the ff, ductility and fracture energy of concrete increased with the inclusion of BF and glass fiber (GF) [81]. Scanning electron microscopy (SEM) was used to determine that the addition of BF improved the substrates' ability to bind. The issue of airport pavement cracking and durability deficiencies has been taken into consideration, and the use of BF in airport pavement concrete (BFAPC) has been studied using numerical modeling and static mechanical tests [82]. Airport pavement is impacted by both dynamic impact loads from aircraft landings and the static loads of airplanes due to pavement roughness [83-85]. Examining how concrete aerodrome pavement fractures under dynamic conditions is essential, as the material is prone to breaking under such conditions, and the ensuing degradation and damage can significantly impact an aircraft's ability to take off and land safely.

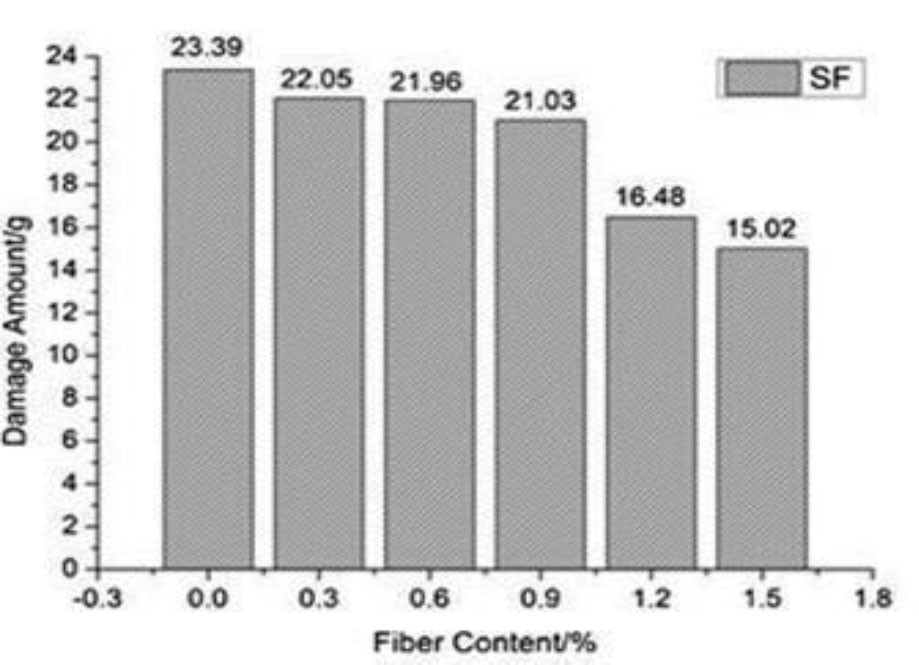

The research studied the effects of polyacrylonitrile synthetic fibers (PaSF) and modified polyester fibers (MPF) on the strength and durability of airport pavement concrete, and found that adding PaSF and MPF to concrete enhanced the ff of the concrete by 6%, concluding that the wheel impact resistance of the aerodrome pavement concrete was substantially enhanced and aging cracking was greatly reduced in an environment with high temperatures when 1.5% steel fiber (SF) was added [86].

Relationship between the damage Δmn of different types of fiber content [86].

The largest augmentation impact on frost resistance and impermeability was obtained with the addition of MPF and PaSF, respectively. As shown in Fig. (5), the damage amount decreases with an increase in the fiber content.

A study investigated the effects of polypropylene fibers (PP) of different shapes and volume fractions of 0.0%, 0.2%, 0.4%, and 0.6% on the modulus of rupture, flexural toughness, load-deflection curve, and fc concrete used in aerodrome pavement, considering how fatigue causes the concrete pavement at airports to break. It was found that the fc, ff and equivalent ff ratio of concrete increased about 11%, 25%, and 40%, respectively, with the addition of a 0.6% volume fraction of twisted PP. The impact of polyoxymethylene fiber (POMF) on the flexural fatigue performance of airport pavement concrete was also studied [87]. The analysis indicated that FRC offers a wide range of potential applications in the construction of airport highway surfaces [88].

3.4. Replacement of Rebar with Fiber in Concrete Reinforcement

Concrete cracks cannot be avoided; instead, concentrate on keeping microcracks from getting deeper. Because the fibers are equally dispersed and thoroughly blended into the concrete, microcracks can be prevented. To generate a three-dimensional reinforcing mesh, FRC is made of separate synthetic fiber materials of different densities, lengths, and mixes.

The advantages of FRC go beyond narrower cracks; they also include longer service lives, quicker building times, lower labor costs, and increased worker safety. Small-diameter steel reinforcement and welded wire reinforcement (WWR), which are commonly utilized as supplementary reinforcement in concrete constructions to sustain temperature and accommodate natural shrinkage, are no longer necessary when using FRC. These days, it is frequently utilized in concrete pavements, architectural panels, whitewashed and composite metal flooring, industrial and warehouse floor tiles, and residential and commercial floor tiles.

There are immediate as well as long-term advantages to redistributing stress via fibers. Fibers help moisten concrete by keeping the water-to-cement ratio consistent, which decreases shrinkage cracking and increases concrete strength. The first post-cracking residual strength that the macro synthetic fibers supply to the concrete after it has hardened makes it more ductile. Additionally, fibers may be employed to enhance joint separation, which lowers the need for ongoing maintenance in commercial and industrial settings.

Many reasons warrant the use of fibers to replace rebars as reinforcements in concrete. The reasons are listed as [89, 90].

3.4.1. Effective and Tight Crack Control

i. Offering outstanding management of settlement cracking.

ii. Enhancing green strengths and enabling quicker form stripping with fewer rejections.

iii. Shortening the time needed for construction and the total cost of labor and supplies.

iv. Reducing the impact of stress from handling and transportation.

v. Increasing impact resistance, shatter resistance, and flexural toughness.

3.5. Concrete Aerodrome Pavement Reinforced with Basalt Fiber

One type of material that has a high elastic modulus and tensile strength is basalt fiber (BF). In contrast to other fibers, BF is inexpensive, resistant to acid and alkali, and has great temperature resistance [91-93].

When compared to other fibers, BF possesses superior qualities that have been studied for decades by several researchers. These qualities include a high strength-to-weight ratio, strong ductility and durability, high heat resistance, good corrosion resistance, and cost-effectiveness [94, 95].

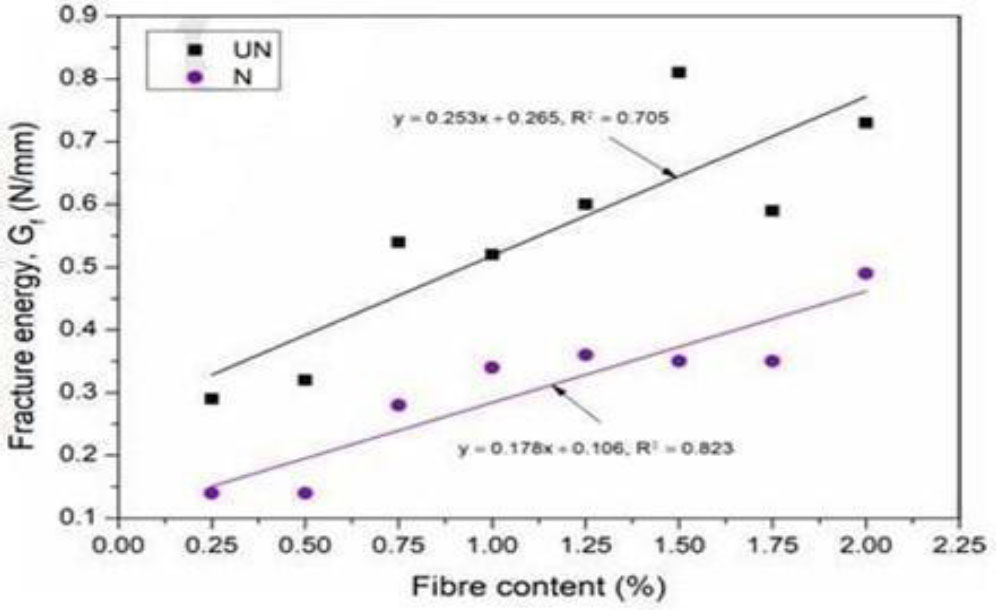

Concrete can be made more resilient to cracks, bending, and impacts by adding a certain volume percent of BF to the mixture. This also helps to refine the pore structure and reduce the size of the pores in the concrete [19, 96]. Furthermore, researchers have discovered that basalt fiber-reinforced concrete (BFRC) offers superior fracture characteristics. The introduction of BF can greatly increase the fracture energy and fracture toughness of fly ash geopolymer concrete (FAGC), according to research [97]. When it comes to preventing concrete cracks from spreading, BF may be quite helpful. In a high-performance basalt fiber-reinforced concrete (HPBFRC) three-point bending fracture test, the study discovered that the specimens' fracture energy rose gradually as the fiber content increased, exhibiting a positive linear relationship as shown in Fig. (6) [98].

Basalt fibers have, considerably enhanced the flexural characteristics of concrete [26]. BF may greatly enhance the flexural characteristics of concrete [29, 99]. BFRC has been shown to successfully prevent cracks by restricting the expansion of existing cracks and lowering free shrinkage [100].

The impact of aircraft landing gear on aerodrome pavements during landing and the reaction in the runway pavement material, depending on the kind of concrete used, have been examined [25]. There was a comparison between two materials: special concrete that included basalt fiber and conventional concrete. An aerodrome pavement was selected as the study's practical target. Their investigation revealed that concrete products reinforced with basalt fibers have superior strength properties. They can support heavier loads, endure more elastic deformations, and have superior compressive and flexural tensile strength.

Relationship fitting curves of fracture energy and fiber content [98].

Micro and macro-BF were the two forms of BF that were utilized to enhance the properties of the concrete. The most prevalent kind is the micro-BF, often referred to as BF only or chopped BF. The new kind is referred to as MiniBars BF or macro-BF. The impact of chopped BF on the mechanical characteristics and fracture energy of both regular and high-performance concrete has been the subject of several investigations [70, 101].

Research has indicated that incorporating a 1-1.5 percent macro basalt fiber content can increase ff by 17–23 percent and splitting tensile strength (fsts) by 16 percent [102]. More significantly, the addition of macro basalt fiber also enhanced flexural toughness and post-cracking behavior [103].

3.6. Concrete Aerodrome Pavement Reinforced with Hybrid Fiber

Since they are durable, have high fc, and easy to work with, cementitious composites, such as concrete, grout, and mortar, are the most often utilized materials for a variety of infrastructure projects worldwide. Nevertheless, a few drawbacks include their poor fracture toughness, brittleness, shrinkage, and low tensile strength [104]. Therefore, to improve the qualities of cementitious composites, it is important to blend different materials [105].

The addition of fibers facilitated the development of typical fiber-reinforced cementitious composites (FRC) and high-performance cementitious composites, also referred to as strain-hardening cement-based composites (SHCC), ultra-high toughness cementitious composites (UHTCC), high-performance fiber-reinforced cementitious composites (HPFRCC), and engineering cementitious composites (ECC) [106-109].

To improve the behavior of the overall system, an increasing number of researchers are combining two or more distinct fibers (different kinds and/or geometries) [110]. The notion is that these hybrid systems should function better together—that is, in a synergistic way—than they would if each type of fiber worked alone [92, 111].

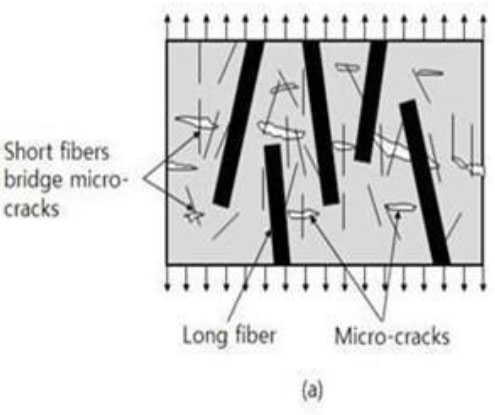

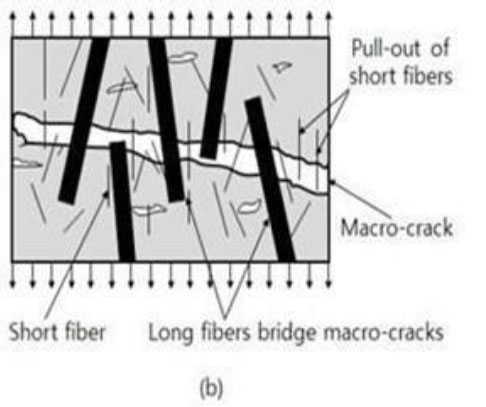

The effectiveness of hybrid fiber-reinforced concrete lies in the complementary constitutive responses of the fibers used. Typically, one fiber is more ductile and provides high-stress resistance, while the other is stiffer and stronger, contributing to enhanced overall strength [112]. This synergy forms the foundational concept behind hybridization. In such systems, the larger, more robust fiber acts as a bridge across macrocracks, delaying their propagation, whereas the smaller fiber controls microcracks during the initial stages of loading. Additionally, hybrid fiber systems are strategically designed so that one type of fiber improves the hardened properties, such as strength and toughness, while the other enhances the workability and processing behavior of the fresh mix. This dual-function mechanism makes fiber hybridization a promising approach for optimizing both the fresh and hardened performance of concrete.

Short fiber types are used to greatly increase the quantity of fiber used in concrete, minimizing cracking and boosting durability, depending on the material qualities employed, in contrast to long fibers, which are frequently utilized to improve the mechanical properties of concrete. The performance of concrete has been enhanced by the inclusion of hybrid fibers, and improved classes of mono-fiber-reinforced concrete have also shown considerable overall benefits [113]. The study concluded that concrete with hybrid fibers showed a 41.24% increase in compressive strength after 28 days, and the hybrid fiber concrete had a higher slump value (50 mm), indicating better workability compared to concrete without fibers, which had a slump of 25 mm [114]. Concrete with hybrid fibers absorbed less water (3.2%) compared to regular concrete (3.5%), and using macro fibers further reduced absorption to just 1.2%.

The study investigated the impact of fiber hybridization on the mechanical characteristics of concrete and concluded that composites with better mechanical properties are made when different types of fibers are combined [115]. This study, wrote about the benefits of hybrid fiber systems and how durable fibers get stronger and more resilient with age [116].

Fig. (7) shows the behavior of the hybrid fibers in the cement matrix's bridging fractures. The bending performance and impact resistance are anticipated to be enhanced by the stitching of the macrocracks at the macrocrack stage (Fig. 7b) and the microcracks at the microcrack stage (Fig. 7a). Compared to short microfibers with microcracks, comparatively long macrofibers are more resistant to massive fractures [24].

The study examined the impact of mineral admixtures on basalt and polypropylene fiber-reinforced concrete through modeling and analysis [117]. For the impact testing, split Hopkinson rods with a 75 mm diameter were used. Based on the collected data, basalt polypropylene (PF) fiber reinforced concrete's (BPFRC) dynamic modulus, critical strain, and compressive strength all rise as the strain rate increases. The impact of strain rate on dynamic modulus, dynamic compressive strength, and deformation capacity of concrete was all enhanced by the addition of BF and PF. Compared to the BF, the PF significantly affects how concrete deforms under dynamic resistance. The impacts of BF and PF on the dynamic concrete fabric module's response to deformation speed, however, were identical. There was a notable positive correlation found between the strain rate and the hybrid fiber's volume as a result of the dynamic compression and mechanical behavior of BPFRC. The study found that the dynamic mechanical behavior of BPFRC may be faithfully represented by the constitutive viscoelastic damage model. A thorough investigation was conducted into how strain rate impacted the hybrid basalt polypropylene reinforced concrete (HBPRC) dynamic modulus of elasticity, critical strain, specific energy absorption, and characteristic length [118]. The results showed that the mechanical properties of HBPRC were all enhanced when the strain rate rose.

Initial loading phase of the hybrid with short fibers bridging micro cracks [24].

Subsequent loading phase of the hybrid with long fibers bridging macro cracks [24].

The study discovered that the dynamic growth rates of compressive strength and elastic modulus rose linearly with an increase in the decimal logarithm of strain rate, but the critical strain and characteristic length expanded linearly with an increase in strain rate [119]. It has been identified that no research has been done on the use of micro-basalt fiber and macro (minibar) basalt as fiber hybridization in airport concrete pavement reinforcement. The properties of these fibers make them suitable for airport pavement concrete reinforcement. As this study is a review and design-based proposal, no new experimental sample size was used. Rather, previous studies were explored and compiled comprehensively. Also, in referenced studies where testing was conducted, fiber dosages ranged from 0.5%–1.5% volume fractions, with sample sets of 3–10 specimens per test group.

Despite the growing interest in fiber-reinforced concrete, several limitations remain in the existing body of research. Notably, there is a lack of studies specifically addressing the performance of concrete used in airport pavements under actual aircraft loading conditions, which differ significantly from typical traffic loads in terms of intensity and frequency.

Among available fiber types, basalt fiber (BF) stands out due to its superior tensile strength, corrosion resistance, and high-temperature tolerance. Despite these advantages, the hybrid use of basalt fibers—especially combinations of micro- and macro-scale basalt fibers—remains underexplored in pavement-specific applications. Furthermore, no prior research has examined a dual-reinforcement system incorporating a basalt fiber textile base layer beneath a hybrid BF concrete overlay.

Additionally, research evaluating the synergistic effects of combining micro and macro basalt fibers for multi-scale crack control is limited, leaving a gap in understanding how such combinations could enhance both early-age and long-term performance. Furthermore, few studies have explored the integration of basalt fiber textile layers with hybrid fiber (macro- and micro-basalt fibers) mixes, which may offer enhanced structural integrity and durability through layered reinforcement mechanisms. These gaps highlight the need for more targeted investigations to optimize fiber hybridization strategies for demanding applications such as aerodrome pavements.

The study addresses a critical knowledge gap in the field of concrete aerodrome pavement reinforcement by exploring the hybridization of basalt fibers (BF)—specifically, the combination of micro- and macro-scale basalt fibers—as a reinforcement strategy. While numerous previous studies have assessed the performance of single fibers like steel, polypropylene, or carbon in concrete pavements, none have comprehensively investigated the effects of hybrid basalt fibers on aerodrome pavement performance. This omission is significant, given the high tensile strength, durability, and thermal resistance properties of basalt fibers. The study responds to the inadequacy of single-fiber systems in addressing both micro- and macro-crack formation in concrete. Traditional fiber-reinforced concrete (FRC) often fails to prevent premature cracking under the combined effects of dynamic aircraft loading, environmental stressors, and long-term shrinkage. By reviewing and synthesizing data across diverse studies, the research demonstrates that hybrid fiber systems—especially those involving basalt—provide synergistic benefits.

This study aims to address these gaps by evaluating the potential of hybrid basalt fiber-reinforced concrete (HBFRC) for aerodrome pavement applications. It specifically explores the combined use of micro- and macro-scale basalt fibers, supported by a textile fiber layer at the base course, to improve crack resistance, shrinkage performance, and overall durability. The novelty of this study lies in its focus on multi-textural basalt hybridization for airport pavements—a strategy not yet reported in the current literature. By reviewing and synthesizing data from published experiments, the study proposes a dual-layer, fiber-optimized pavement system as a cost-effective and structurally resilient solution for future airfield infrastructure.

Despite the advancements, existing research is limited in several respects. Most notably, few studies have examined how variations in fiber texture and dimension, particularly those of basalt fibers, interact with nano-admixtures to influence the multi-scale reinforcement mechanism in concrete. Moreover, most experimental investigations do not link their findings explicitly to the demanding service conditions of aerodrome pavements. There remains a substantial gap in understanding how these materials can be optimally combined to produce high-performance concrete with long-term reliability under dynamic and thermal stresses.

The motivation behind this study is to address these knowledge gaps by developing and analyzing a novel hybrid composite concrete system suitable for aerodrome pavements. Specifically, this research hypothesizes that combining nano-admixtures with hybrid basalt fibers of varied textures and dimensions will lead to multi-scale reinforcement effects that enhance both the physicochemical and microstructural properties of concrete. These enhancements are expected to translate into improved mechanical strength, durability, and resilience under service loads.

The novelty of this research lies in its exploration of fiber texture and size as active parameters in hybridization and its integration of nanomaterials to enhance multi-scale reinforcement. This study thus contributes to the advancement of next-generation pavement materials by offering a scientifically grounded mix design strategy for performance optimization in harsh operational environments.

The key objectives of this study are to evaluate the impact of hybrid basalt fibers—differentiated by texture and size—on the mechanical performance of concrete; to analyze the influence of nano-admixtures on hydration behavior, pore structure, and fiber–matrix interactions, and to determine the combined effect of these modifications on the structural integrity and durability of concrete for aerodrome pavement applications.

Fiber hybridization has been shown to have effects on certain properties, like physical, mechanical, tribological, thermal, and so on. For instance, in a study [120], the findings revealed that incorporating 5 wt.% TiO2 particles led to enhancements in tensile strength (by 6–10%), flexural strength (by 3–5%), and hardness (by 11–22%) compared to composites without fillers. Among the parameters studied, fiber content had the most significant impact on reducing the sliding wear rate, followed by sliding velocity, while sliding distance and normal load had minimal effect. According to a study [121], bidirectional rice stubble fiber (RS), glass fiber (GF), and Linz-Donawitz sludge (LDS) were incorporated as reinforcements in the development of epoxy (EP)-based hybrid composite materials. The mechanical properties—tensile, flexural, and compressive strength—as well as physical properties such as density and void content, were assessed following ASTM standards. The inclusion of 6% RS in the EP-LDS-GF-RS composite significantly enhanced the mechanical performance, increasing the tensile strength from 45 MPa to 111 MPa, compressive strength from 22.5 MPa to 58 MPa, and flexural strength from 84 MPa to 140 MPa compared to neat epoxy. As the RS content increased, the composite density showed a gradual decline, while the void content increased slightly, by up to 0.1%—though both values remained lower than those of the pure epoxy resin. The study conducted experimental investigations and material characterization to assess how varying amounts of clamshell filler (0, 5, and 10 wt.%) influence the mechanical behavior of basalt fiber-reinforced composites [122]. A range of mechanical tests—including tensile, flexural, microhardness, and impact testing—were performed to determine the composites’ strength, stiffness, and durability under external loads. The study revealed that the addition of clamshell filler significantly enhanced the mechanical performance of the composites, particularly in terms of tensile strength, flexural strength, and surface hardness. Furthermore, improvements in impact resistance suggest that these composites hold promise for use in environments where resistance to sudden forces is essential. The study found that as impact velocity increases, the wear rate also rises, while higher fiber content contributes to a reduction in wear rate [123].

From the previous studies, the properties of some fibers have been outlined in Table 2 [24, 49, 51-54, 56, 71, 76]. It has been identified that many fibers have been combined to produce hybrid fiber-reinforced aerodrome concrete pavement. However, no research has demonstrated the use of basalt fiber hybridization in aerodrome concrete pavement (Table 3) [24, 55-85]. Further in the study, it was identified that basalt fiber hybridization has been applied to concrete production intended for buildings and other constructions.

Due to the properties associated with basalt fiber, the use of basalt fiber hybridization is a good option for aerodrome concrete pavement. With the advancement of construction materials, concrete possessing hardness, high strength, and longevity is becoming increasingly important. One robust, long-lasting type of concrete that may be utilized to obtain mechanical qualities better than those of normal concrete is high-performance concrete reinforced with fiber [124, 125]. Table 3 highlights that the incorporation of hybrid fibers in concrete has proven to significantly enhance mechanical properties and durability, making them ideal for structural and aerodrome pavement applications. Basalt fibers, for instance, improve compressive strength by 41.24% over 28 days, compared to 21.78% in non-hybrid mixes [24, 55-85]. These fibers also reduce water absorption to as low as 1.2% in macro basalt composites. Basalt fibers also increase the flexural strength of composites, achieving up to 56% in normal-strength concrete. In addition, basalt fiber incorporation can result in increased frost resistance and abrasion resistance, further highlighting its suitability for demanding environments. Similarly, glass fibers have been shown to increase flexural strength by at least 70%, enabling a 39.28% reduction in pavement thickness, making them cost-effective and efficient for aerodrome pavements [126, 127]. Polypropylenes are highly versatile, offering improvements in frost resistance, impermeability, and fatigue performance, with flexural strength gains of up to 40% and fatigue resistance improvements of 92%.

| References | Fiber Types | Tensile Strength, MPa | Modulus of Elasticity, MPa | Density, g/cm3 | % Elongation |

|---|---|---|---|---|---|

| [49] | Polypropylene | 150-600 | 35000 | 0.91 | 20-150 |

| [24] | Aramid (Kevlar) | 3000-3600 | 60000-180000 | 1.45 | 2.4-3.6 |

| [49] | Glass | 1500-3500 | 75000 | 2.6 | 4.5 |

| [56] | Carbon | 2500-7000 | 200000-600000 | 1.73-1.95 | 0.7-2.1 |

| [51] | Cellulose | 300–500 | 10 | 1.2 | - |

| [49] | Polyester | 500 | 4000 | 1.36 | 15-30 |

| [24, 49, 52] | Micro basalt | 3500 | Not <70000 | 2.6 | 3.2 |

| [52, 71] | Macro basalt | 1080 | 44000 | 2.1 | 3.1 |

| [53] | Polyolefin | 275 | 2647 | 0.9 | 15 |

| [49] | Steel | 600-1500 | 190000 | 7.8 | 3-4 |

| [54] | Polyacrylonitrile synthetic fibers | 240–1000 | 2–3 | 1.18 | 20–45 |

| [76] | Polyoxymethylene | 967 | 8 | 1400 | 18 |

| References | Single and Hybrid Fiber for Concrete and Possible Aerodrome Concrete Pavement | Findings |

|---|---|---|

| [24] | Both macro and micro basalt fibers—basalt minibars and chopped soft basalt fiber—are present. | The study demonstrated a notable enhancement in the material's mechanical characteristics. Because of the hybridization process, the concrete's compressive strength increased, which is important for a structure's lifetime and durability. |

| [55] | Glass fiber | This resulted in reduced design thickness of the pavement slab. |

| [56, 57] | Aramid (Kevlar) and polypropylene | i. The study showed higher residual strength and shear deformation resistance. ii. Tests of persistent deformation showed that, compared to the control combination, fiber-reinforced asphalt concrete (FRAC) mixes collected had significantly greater flow numbers and less permanent strain. iii. The study showed improved ft, total fracture energy, and slower crack propagation. |

| [58, 59] | Cellulose fibers | The inclusion of cellulose fibers raised the ideal binder concentration in all mixes, enhanced Marshall stability, and reduced mass loss by the Cantabro test. |

| [58] | Carbon fiber | The addition of carbon fibers caused a decrease in flow and an increase in air spaces. On the other hand, the inclusion of carbon fibers extended fatigue life, decreased permanent deformation, and enhanced Marshall stability. |

| [60] | Waste carpet and tire fibers | Improved toughness. Permanent deformation and moisture susceptibility performance. |

| [60] | Cellulose and polyester fibers | Permanent deformation and moisture susceptibility performance. |

| [61] | Polyester, cellulose, and waste/recycled fibers | Showed resilience against fatigue cracking. Did not make hot-mix asphalt more resistant to stripping. |

| [62] | Basalt, glass, carbon, and polyolefin/ aramid fiber | The findings demonstrated that PFA fibers perform similarly well for binders and locations in terms of fatigue life and rutting. Carbon fibers, however, suffered less damage from PG76-22. Lastly, the PCR data revealed that pavements in colder areas had stronger bonds than those in warmer areas. |

| [63] | Steel fibers | Steel fibers also decrease the permeability resistance. While steel fiber reinforcement boosts freeze-thaw and crack resistance, increasing the fiber content further enhances freeze-thaw resistance but gradually reduces crack resistance. |

| [64] | Polyester synthetic fiber (PSF), cellulose fiber (CF), and BF | The elastic modulus of fiber and concrete ff are positively associated, the fc is not significantly affected. |

| [65] | Polyacrylonitrile, reticular polypropylene, and single polypropylene | The levels of frost resistance and impermeability for FRC increase by 40%–160% and their abrasion resistances rise by 23%–50% when the fraction is within 0.15%–0.18%, and their frost resistances and impermeabilities are at their peak when the volume fraction of fiber is 0. 10%. |

| [66] | Basalt fiber and glass fiber | The ff, ductility and fracture energy of concrete increased with the inclusion of basalt fiber and glass fiber. |

| [67] | Polyacrylonitrile synthetic fibers (PaSF), modified polyester fibers (MPF), and steel fiber | Adding PaSF and MPF to concrete enhanced the ff of the concrete by 6%, concluding that the wheel impact resistance of the aerodrome pavement concrete was substantially enhanced and aging cracking was greatly reduced in an environment with high temperatures when 1.5% steel fiber was added. The largest augmentation impact on frost resistance and impermeability was obtained with the addition of MPF and PaSF, respectively |

| [68] | Polypropylene fibers (PP) of different shapes and volume fractions | It was found that the fc, ff and the equivalent ff ratio of concrete increased about 11%, 25%, and 40%, respectively, by adding a 0.6% volume fraction of twisted PP. |

| [69] | Basalt fiber | The introduction of BF can greatly increase the fracture energy and fracture toughness of fly ash geopolymer concrete (FAGC) |

| [70] | Basalt fiber | BFRC has been shown to successfully prevent cracks by restricting the expansion of existing cracks and lowering free shrinkage. |

| [76] | Macro basalt fiber | Studies have indicated that incorporating a 1-1.5% macro basalt fiber content can increase ff by 17–23% and splitting tensile strength by 16%. |

| [77] | Macro basalt fiber | The addition of macro basalt fiber also enhanced the flexural toughness and post-cracking behavior of the concrete. |

| [78, 79] | Glass, carbon, or steel | Adding the different types of chopped fibers to cementitious composites improves the flexural strength, fatigue resistance, flexural toughness, and impact resistance of the concrete. |

| [80] | Basalt and polypropylene (PP) | Enhanced the impact of strain rate on concrete's deformation capacity, dynamic modulus, and dynamic compressive strength. The effects of basalt fiber and polypropylene on the dynamic concrete fabric module's deformation speed were the same. |

| [81] | Polyvinyl alcohol (PVA) and Steel Polypropylene | Compared to concrete reinforced with large-diameter monofilaments, the shrinkage strain of concrete reinforced with hybrid steel fibers was reduced. Permeability is decreased in concrete reinforced with hybrid fibers. |

| [82] | Short and long steel | Compared to ordinary concrete, hybrid fiber-reinforced concrete has less permeability. |

| [83] | Glass and Polypropylene | With aging, hybrid sheets' flexural peak load rose. |

| [84] | Polypropylene and Carbon |

The carbon-PP hybrid fiber reinforced concrete exhibited enhanced strength and toughness due to the hybrid fibers' capacity to eradicate fracture origins and prevent their propagation. |

| [85] | Steel and Polypropylene | The hardness and resistance of hybrid fiber-reinforced concrete to the onset of the initial crack were significantly higher than those of mono-fiber composites. |

When combined with basalt fibers, polypropylene demonstrates a combined effect, significantly enhancing dynamic compressive strength. Aramid fibers also perform exceptionally in high-stress environments, boosting fatigue life by up to 92% and reducing permanent deformation, making them well-suited for heavy-duty pavements. Meanwhile, carbon fibers improve fatigue resistance and crack prevention, and steel fibers enhance crack resistance by 40% while improving permeability and freeze-thaw durability [128, 129].

Eco-friendly alternatives, such as recycled fibers from carpets and tires, offer sustainable solutions while maintaining comparable performance. These fibers improve toughness, deformation resistance, and pore structure, reducing harmful pores by 49.7%. Across all types, hybrid fiber composites deliver significant improvements in durability, mechanical strength, and cost efficiency. Their adaptability and performance enhancements make them indispensable for concrete applications, especially in environments requiring enhanced longevity and resistance to cracking and fatigue. A few scientists have looked at the effects of fiber hybridization on concrete properties. Controlling different concrete cracking zones of different sizes, under different loads, and at different curing ages is the primary objective of using hybrid fibers [129]. Basalt fiber has been confirmed to be among the materials that satisfy all the aforementioned characteristics, but it also has a higher advantage.

Basalt fiber is an inorganic fiber type that is quickly drawn into continuous fiber after being melted at temperatures between 1500°C and 1700°C. The basic material is pure, genuine volcanic ejecta rock. Although not biodegradable, basalt fibers are still regarded as natural because of their lengthy product life and safe production procedures. It is a brand-new, environmentally friendly substance that is low-cost, highly effective, and perfectly clean [130].

3.7. Scanning Electron Microscopy (SEM) Analysis

Table 4 shows that hybrid fiber systems can arrest crack growth and dissipate energy, improving toughness and resistance to fracture [131-134]. This supports enhanced durability and likely reduced permeability, which is beneficial for applications like aerodrome pavement. It also indicates weaker resin–fiber interfacial bonding; optimizing the stacking sequence or surface treatment could mitigate this. SEM highlights abrasion effects—addressing fiber integrity under tribological loading is essential for wear-critical applications. SEM reveals that environmental exposure causes micro-cracking and debonding, potentially leading to long-term performance issues

While the results indicate strong potential for hybrid BF systems in pavement applications, this review does not include original laboratory testing. The conclusions are drawn from a synthesis of peer-reviewed literature. Additionally, the long-term durability under varying environmental conditions and repeated aircraft loading requires empirical confirmation. These limitations suggest a need for pilot field trials and performance validation under operational airfield conditions.

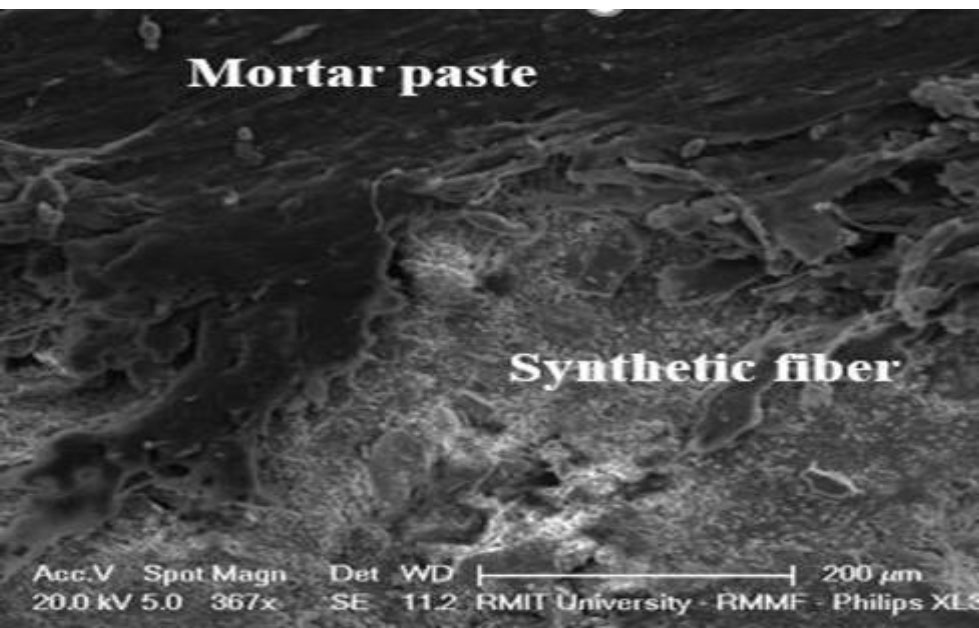

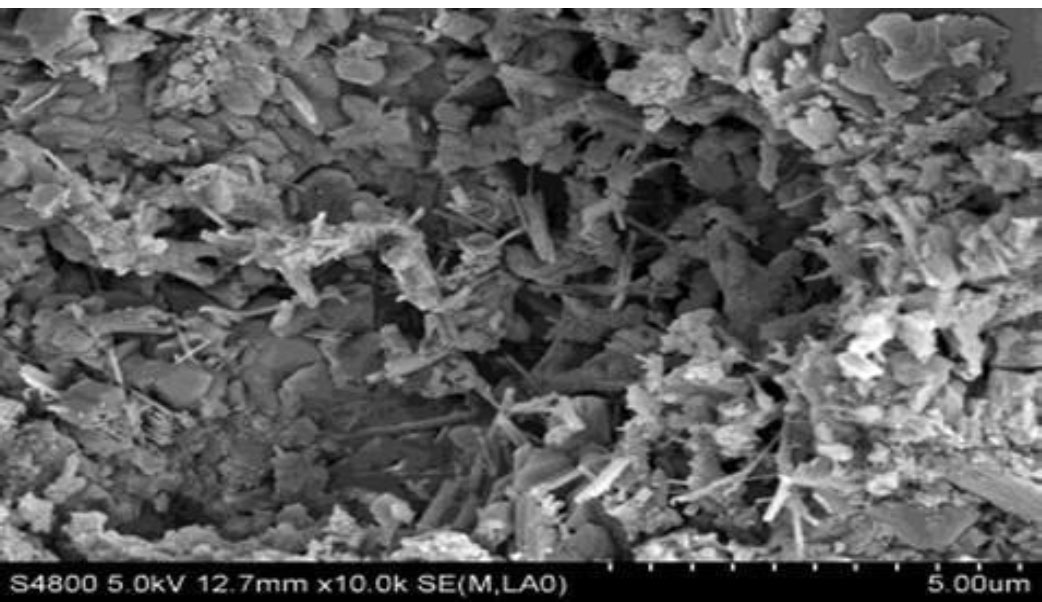

Fig. (8) is an SEM micrograph of FRC, captured at a magnification of 10,000 times with a scale of 5 micrometers. This high-resolution microstructure image provides valuable insight into the internal composition and morphological characteristics of the concrete matrix at the microscopic level. The image was likely obtained to analyze the distribution and interaction of fibers within the cementitious matrix, as well as to evaluate the formation of hydration products and the quality of the interfacial transition zones (ITZ).

An SEM analysis of mortar paste and synthetic fiber [135].

| Composite System | SEM Observation | Microstructural Significance | References |

|---|---|---|---|

| Basalt + E-glass epoxy hybrid | Scanning Electron Microscopy (SEM) images exhibited fiber pull-out and inter-laminar delamination as dominant failure mechanisms under tensile loading | Indicates limited inter-fiber bonding and highlights the need for improved matrix–fiber adhesion | [131] |

| Basalt & glass fabric epoxy (abrasive wear study) | SEM revealed plowing scratches, fiber damage, and fabric abrasion typical of three-body wear | These wear characteristics illustrate how fibers interact with abrasive particles, affecting tribological performance | [132] |

| Basalt fiber polymer composites after seawater aging | SEM failure analysis showed matrix cracking, fiber–matrix debonding, and fiber fracture post-aging | Demonstrates that seawater exposure degrades the fiber–matrix interface, reducing mechanical durability | [133] |

| Low w/c cement mortar with basalt, aramid fibres & CSW | SEM revealed fiber bridging across micro-cracks, refined pore structures, and fiber pull-out zones in specimens with hybrid aramid, basalt fibers, and calcium sulfate whiskers | Indicates enhanced toughness via crack-bridging and reduced porosity, which correlates with improved wear resistance and lower permeability | [134] |

An SEM analysis of a high fibre reinforced concrete [136].

The SEM image (Fig. 9) highlights the porosity of the matrix and the presence of voids or microcracks, which are essential indicators of the concrete’s durability and permeability. Lower porosity and fewer interconnected voids typically reflect better long-term performance, especially in applications exposed to harsh environments, such as aerodrome pavements. Overall, this SEM micrograph serves as a valuable tool for understanding the microstructural behavior of fiber-reinforced concrete.

CONCLUSION

This study identified concrete pavement as a suitable material for aerodrome pavement. However, such pavement faces challenges that could affect the strength and durability of the structure. Traditionally, the use of steel reinforcement bars has been the common practice in the construction of aerodrome concrete pavements. This practice faces many challenges, like soil factors, environmental factors, and even mechanical stresses, which cause a reduction in the strength of the concrete. With all these issues, researchers have made many efforts to solve these problems. One of the solutions investigated was the use of fiber reinforcement in the production of aerodrome concrete pavements. The review study showed that the incorporation of fiber in concrete for airport pavement improves the strength and durability of the airport concrete pavement. Concrete aerodrome pavements typically experience a variety of loads, including those associated with taxiing, takeoff, and landing. Additionally, concrete is a rate-sensitive material, meaning that its characteristics change when strain rates increase. Due to the individual properties of the fibers, negative impacts on the concrete pavement caused by aircraft loads can be mitigated.

This solution is limited, as cracking is one of the major factors that lead to concrete failure. It is necessary to identify ways to solve the problems of micro-cracks and macro-cracks simultaneously. To achieve this, fiber hybridization in aerodrome concrete pavement was investigated. This method is more effective than single-fiber reinforcement. The findings demonstrate that hybrid fiber incorporation can increase flexural strength by up to 27%, compressive strength by 41.24%, and tensile strength by 16%, along with substantial reductions in shrinkage and water absorption. These gains result from the dual-scale crack-bridging action of hybrid BF systems, improving crack resistance by approximately 15–20% compared to conventional single-fiber reinforcement. Furthermore, hybrid basalt fiber has been shown to reduce shrinkage strain by 10-34%, which is critical in preventing premature pavement cracking under high-load conditions from taxiing, takeoff, and landing operations. These enhancements translate to significantly higher resistance to load-induced stress and environmental degradation, making hybrid basalt fiber an ideal solution for demanding airport pavement conditions.

During the study, it was discovered that many fiber hybridizations have been used in the reinforcing concrete aerodrome pavement, but none were found to incorporate basalt fiber hybridization. Numerous researchers have investigated the use of different types of fibers from various origins and sources. However, most of these fibers exhibit significant variations in their properties, which directly influence the performance of concrete in aerodrome pavement applications.

Basalt fiber hybridization in concrete aerodrome pavement has been suggested for investigations and implementation due to its superior properties compared to other fiber hybridizations. This study recommends incorporating a basalt fiber textile layer on the base course (non-erosive) before casting the hybrid basalt fiber-reinforced concrete. This will improve the durability of the concrete pavement and protect the pavement from attack by certain elements from the soil. The proposed use of a basalt fiber textile layer beneath hybrid BF concrete is a novel contribution to pavement design, offering enhanced fatigue resistance and structural integrity. This approach may substantially reduce life-cycle maintenance costs while improving operational safety and longevity in airfield applications.

The future scope of this study lies in the fact that the use of fiber hybridization offers concrete aerodrome pavements superior compared to single-fiber reinforcement, as it addresses both micro- and macro-cracks in the concrete. This method of reinforcing concrete aerodrome pavement offers improved durability, resilience, and sustainability. Fiber-hybridized concrete pavements also provide greater economic advantages in the long run due to reduced cracking and maintenance costs.