All published articles of this journal are available on ScienceDirect.

Prospective Materials for Building Construction in Hot Countries: The Case of Straw Blocks

Abstract

Introduction

The use of plant-based materials represents a significant shift in construction practices, contributing to the achievement of Sustainable Development Goals 9 and 11. However, materials such as straw bales typically exhibit low compressive strength and significant displacement under compressive loads. To date, limited efforts have been made to improve the performance of straw bales. This study aimed to develop an alternative material, known as straw blocks, and assess their potential as a viable building material.

Methods

The manufacturing process of straw blocks involved preparing the binder and producing the blocks from straw. The water resistance, thermal resistance, and compressive strength of the blocks were measured, along with the structural performance of the straw block walls.

Results

The average compressive strength and thermal conductivity were recorded as 1.25 MPa and 0.06 W/m·K, respectively. The initial rate of water absorption ranged from 0.10 to 0.22 g/in2/min. Furthermore, plastered straw block assemblies withstood a uniformly distributed load of 286 kN/m2.

Discussion

The recorded compressive strength of straw block is 62 times greater than the published compressive strength of straw bale (0.02MPa). Although the value seems insignificant, the load-carrying capacity of a plastered straw block wall is higher than the minimum slab load, which is 18.2 kN/m2 for residential buildings.

Conclusion

According to the data above, the straw block is a conducive and promising building material for climate change adaptation. The small thermal conductivity obtained will improve the overall indoor thermal comfort. Straw block can be used for the construction of one-storey buildings and partition walls in multi-storey buildings.

1. INTRODUCTION

Construction materials are elements used for the construction of walls, roofs, structural elements, and for the construction of roads or bridges. The need for construction emerged when our ancestors, lacking knowledge of science or mathematics, sought a comfortable life. Hence, to protect themselves against weather (rain or sun) and animal attacks, they used traditional materials to build their infrastructure. To date, construction materials are essential for building comfortable infrastructure, such as roads and buildings. Some parameters that contribute to comfort include thermal conductivity and the strength of materials to resist loads or adversity. To provide comfort, the construction industry has undergone numerous changes in the construction materials sector. These changes are primarily driven by the evolution of technology and the changing needs of the population. Each construction material is expected to have certain properties that enable it to perform its functions properly without failure.

It has been perceived that some of the existing construction materials have failed to fulfill their intended role in construction. In hot regions, for instance, construction materials used for building envelopes (walls and roofs) do not have good thermal insulation properties. As a result, air conditioning equipment is used today in almost all residential buildings and offices as an adaptive method to provide indoor thermal comfort. The use of air conditioning is now considered an important input in the construction of buildings because the materials used for these buildings' construction will not provide a livable indoor environment without cooling. Research conducted by Kameni et al. [1], shows that, for example, in Cameroon, the temperature is increasing in an alarming manner, and demand for cooling has consequently increased. Improving the building’s envelope properties will help building occupants reduce their dependence on cooling equipment. Additionally, in low-income households, a smaller portion of disposable income will be allocated to power bills. There is therefore a need to investigate efficient and effective retrofitting methods for existing buildings, whereas exploring materials with insulating properties for new buildings may be the best solution. This study is based on the investigation of new materials with good thermal conductivity.

Nowadays, one of the key factors governing sustainability is the level of greenhouse gas emissions. It has been recorded that human activities are the main causes of pollution, which results in global warming. Hence, Innovative methods of manufacturing high-insulation materials for walls are crucial for new construction, as they contribute to the creation of more energy-efficient and sustainable buildings [2]. In general, the construction industry is one of the major sectors that contributes a substantial amount of greenhouse gases to the environment [3]. In a report published by the United Nations Environmental Programme [4], it is stated that the built environment sector is by far the largest emitter of greenhouse gases, responsible for at least 37% of global emissions. Moreover, it is a major contributor to the generation of solid waste, which poses significant challenges for landfill management and environmental degradation [5]. Compared to 2020, building energy demand increased by 4% in 2021 [6]. To meet the needs of a growing population, construction material consumption is expected to double by 2060 [7]. If urgent mitigation measures are not taken, the construction industry will account for a significant portion of CO2 emissions, which in turn will increase the average global temperature [3]. Until now, most progress in the sector has been made in reducing the operational carbon footprint of buildings (the emissions created from heating, cooling, and lighting), which is projected to decrease from 75 percent to 50 percent in the next few decades. However, solutions for reducing the embodied carbon emissions from the design, production, and deployment of building materials, such as cement, steel, and aluminum, have lagged far behind [8]. To fill this gap, one of the foremost actions is to shift technology and revolutionize building materials with green features. An effort has been made to minimize embodied carbon emissions, reduce construction costs, and provide acceptable thermal comfort through the use of bio-based materials such as straw [9]. The construction sector’s shift toward circular models is a key strategy for reducing both carbon emissions and resource consumption [10]. Using straw in construction can contribute to achieving a 40% reduction in embodied carbon by 2030 and full decarbonization of building materials by 2060.

Straw bales are made from agricultural residues such as rice and wheat straw. The baling process involves compressing the straw stems and securing them with two or three strings. Handbooks on straw bale construction are published by Corum [11], Hodge [12], Nails and farm [13], and Walker et al. [14]. These books serve as a guide to those interested in building straw bale houses. Although straw is known as a biodegradable material, it is recorded that buildings made of straw bales are water, fire, and rot resistant when techniques of good practice are employed [15, 16]. Other problems associated with straw bales include low strength and high displacement. Their compressive strength is around 0.02 MPa [9, 17] while the displacement in straw bale is in the range of 32 – 90 mm [9, 18, 19]. However, studies have shown that the compressive strength of plastered straw bale assemblies depends on the plaster [20, 21] and not on the blocks. Plastered straw bale forms a composite structure that works like a sandwich panel. The relationship between plaster and straw bale is the same as in the web to flange in a steel I-beam [22]. Straw bales and plaster work together to create a composite structural system similar in concept and performance to a structural insulated panel [23]. The enduring interest and continued development of straw bale result from the fact that it is a bio-material that contributes greatly to carbon footprint reduction and resource conservation [21, 24]. For instance, straw bale is an environmentally friendly material; it provides significant benefits in terms of cost and human health [25]. It is a lightweight material; its thermal conductivity is around 0.06 W/mK [26].

Using bio-based materials has significant potential benefits in carbon sequestration [8]. However, further research is required to enhance the strength of straw bales and reduce displacement within the bale. This will provide more relevant data for designing straw bale houses. From our observation after a preliminary compression test on straw bales, it was clear that the performance improvement of straw bales can be achieved by using a binder that keeps the particles in the bale together and forms a solid material. The primary objective of this study is to recycle waste agricultural materials and develop walling materials with green features, such as low embodied energy and good thermal conductivity, thereby contributing to the reduction of energy demand in buildings.

2. MATERIALS AND METHODS

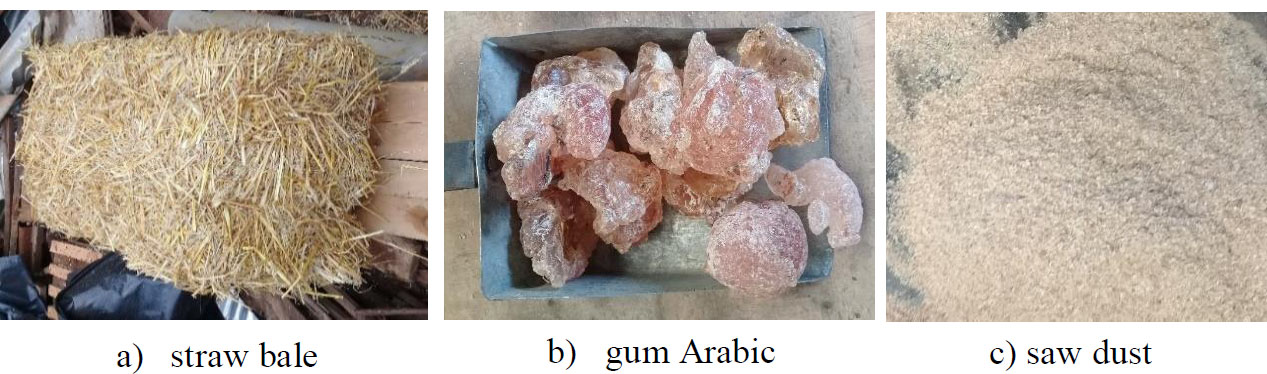

Wheat straw (Fig. 1a), gum Arabic (Fig. 1b), and sawdust (Fig. 1c) were sourced from local suppliers in Kenya. Straw is a by-product of crops such as rice and wheat. It is not toxic and is currently used as cattle feed. The sawdust was collected from a carpenter's sawing machine. It was used to provide fine particles in straw blocks. Gum Arabic is a natural gum from the hardened sap of acacia trees. Gum Arabic is found in the Middle East and North Africa [27, 28]. Gum Arabic is not harmful; its chemical properties and features are being used in a wide range of industrial sectors. It has been utilized for thousands of years, serving as an essential material in various applications due to its unique properties [29]. For example, it is used worldwide as a stabilizer in wine, soft drinks, candies, cosmetics, and traditional treatments for diverse diseases [27]. Gum Arabic has a relatively large particle size, similar to that of aggregate; therefore, it must be crushed before use.

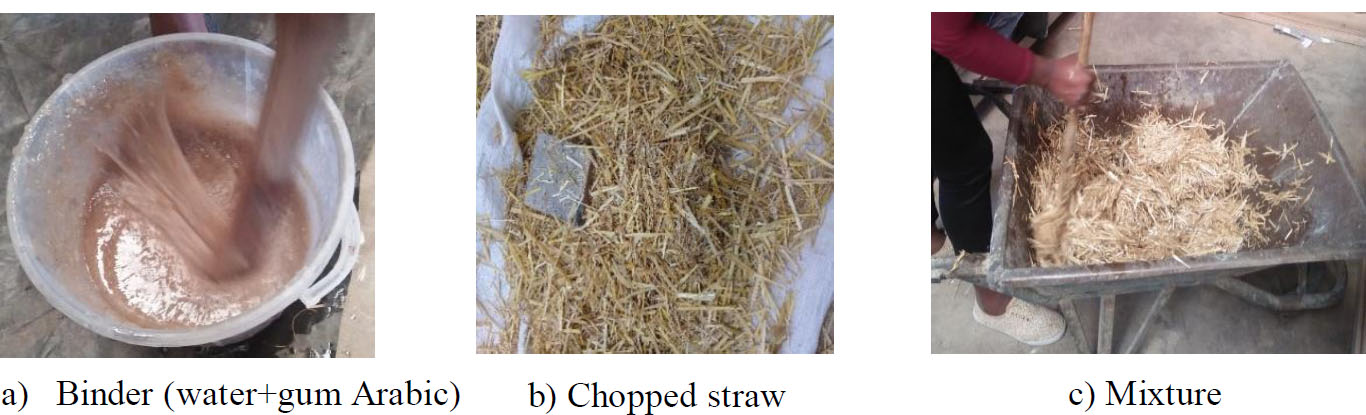

The size of powder gum Arabic does not matter because it will dissolve in water to form a viscous solution. Binder preparation consisted of mixing a suitable quantity of water with gum Arabic (Fig. 2a). Straw stems from straw bales were chopped into small lengths (1 to 9 cm) as shown in Fig. (2b). The binder and chopped straw were mixed (Fig. 2c) in a predefined proportion, and straw blocks were manufactured. Straw block is an alternative materials to straw bale. It is made of natural fibers that have a strong insulating property and a minimal environmental effect, making them suitable construction materials [30]. The manufacturing process of straw blocks consisted of mixing chopped straw stems with gum Arabic [9].

Materials used.

Straw block production procedure.

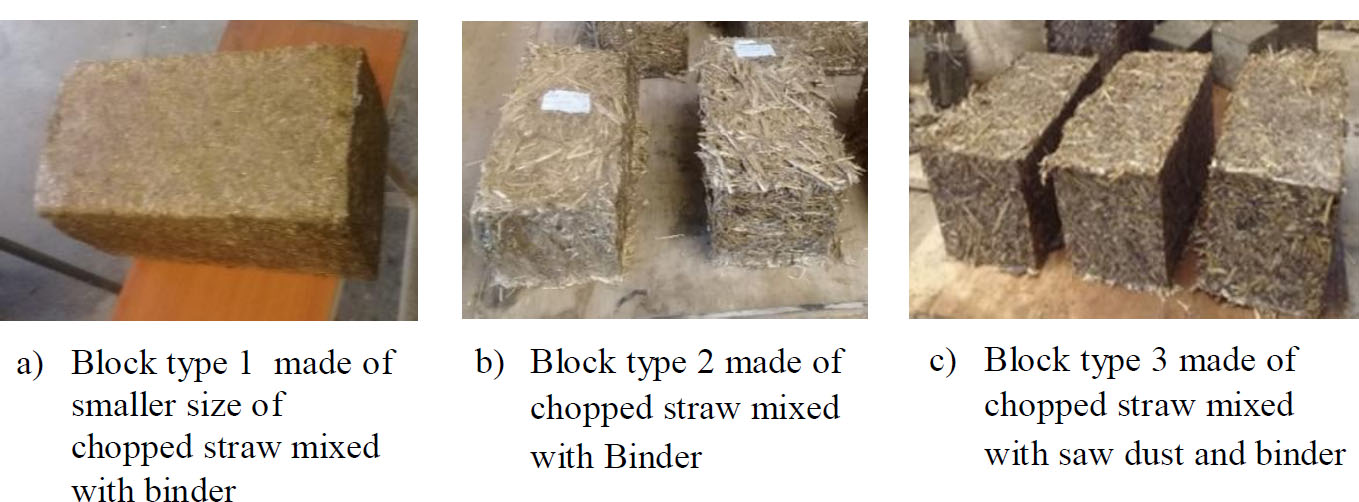

Type of blocks.

As shown in Figs. (3a-c), three types of blocks were manufactured using a hand compression machine. For each type of straw block, 3 blocks were produced. After one month of curing in the open air, the straw blocks were divided into two to ensure they were well dried. The average moisture content of each type of block was between 5 and 6%, smaller than the limit moisture content (15%) recommended in Appendix S of the International Residential Code. Straw blocks were then tested under compression load using AMSLER’S compression testing apparatus [9]. An initial rate of absorption test was conducted on a block to determine the rate at which water can penetrate from one side to the other. To do so, blocks were placed in a water tank. Only 5mm of the height was immersed in water. Furthermore, a thermal conductivity test was conducted on the block using the hot plate method. It is important to note that a statistical model was not used for data analysis; the results are based on the fact that, for a batch of mixed material, samples are taken from three different locations on the mixture to manufacture three (03) blocks. If compression test is conducted on these blocks, then the average value is considered as the representation of the compressive strength of blocks.

3. RESULTS

The primary engineering properties of masonry (density, moisture content, Compressive strength, initial rate of absorption, and thermal conductivity) were recorded. Additionally, the load-carrying capacity of straw block masonry was investigated. These tests helped to understand the behavior of straw blocks and straw block walls when subjected to loads or adverse effects. The average value for primary engineering properties is summarized in Table 1. The compressive strength and bonding strength of various types of mortar/plaster used in the construction of walls are presented in Table 2.

| Type of Blocks | Moisture Content (%) | Density (kg/m3) | Displacement in the Block (mm) | IRA in g/sq inch /min |

Thermal Cond. (W.m-1K-1) |

Compressive Strength (MPa) |

|---|---|---|---|---|---|---|

| Type 1 | 5.02 | 594.00 | 29 | 0.1 | 0.06 | 1.25 |

| Type 2 | 5.62 | 541.87 | 56 | 0.1 | 0.06 | 1.25 |

| Type 3 | 5.38 | 606.09 | 48 | 0.1 | 0.06 | 1.25 |

| Type of Wall |

Ratio of Mortar/Plaster Mix (Sand:Cement:gumarabic) |

Mortar Compressive Strength (N/mm2) | Bonding Strength of Mortar-block Interface (N/mm2) |

Load Carrying Capacity of the Wall (kN/m2) |

|---|---|---|---|---|

| Type 1 | 4:1 | 3.1 | 1 | 139.75 |

| Type 2 | 4:0.75:0.25 | 2.4 | 2 | 286.40 |

| Type 3 | 4:0.5:0.5 | 1.8 | 2 | - |

4. DISCUSSION

4.1. Compressive Strength and Load Carrying Capacity

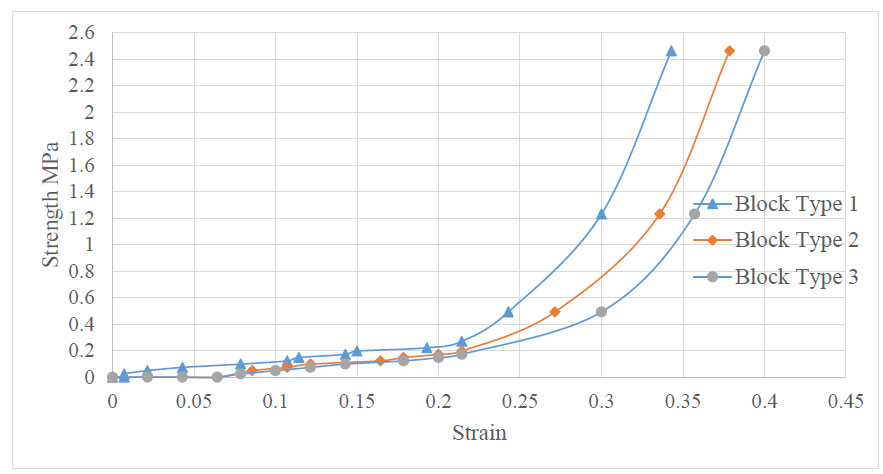

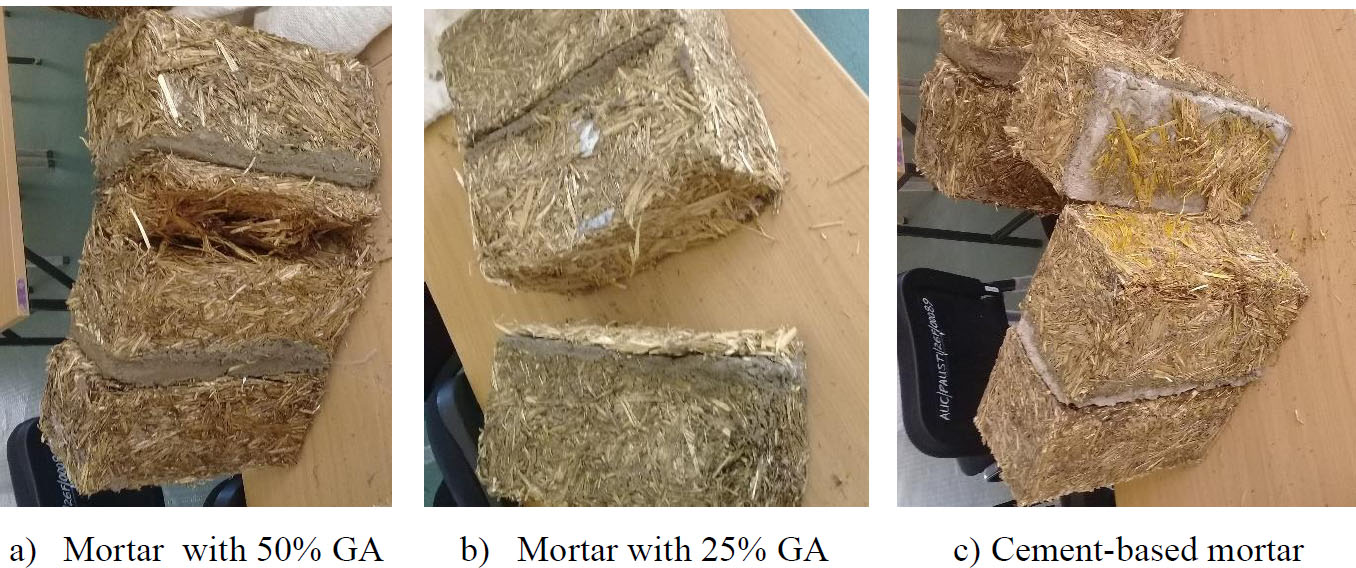

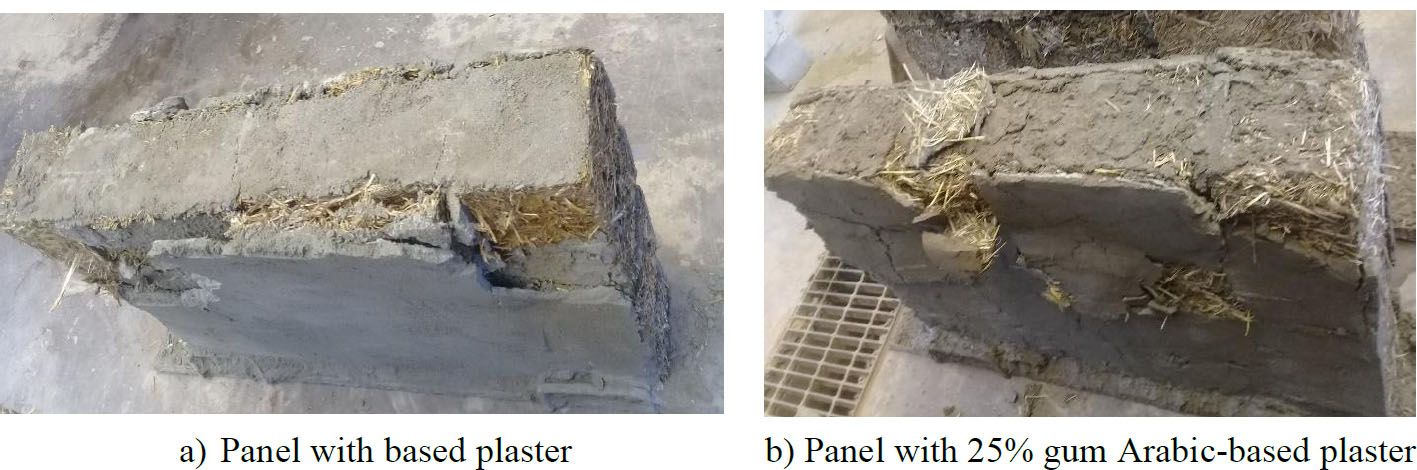

A compressive strength test was conducted on straw blocks to determine their mechanical properties, and then these properties were compared with those of straw bales. The results obtained show that, for the same load (50 kN), the three types of blocks have the same strength (Table 1). However, the displacement in these blocks was smaller in the Wheat Straw-Saw Dust Block (block type 1). Sawdust played a crucial role in the blocks by filling the voids. The average strength of the straw block recorded was 1.25 MPa. When the applied load was around 10 kN and 100 kN, the compressive strengths were 0.17 MPa and 2.4 MPa, respectively (Fig. 4). Although the compressive strength of single straw blocks was small, the load-carrying capacity of plastered straw block walls is 286 kN/m2, which is equivalent to 0.286 MPa. Since the compressive strength of the plastered straw block wall was lower than the average compressive strength of the individual blocks, it indicates that the wall failed before the blocks reached their full compressive capacity. This complies with the recorded behavior described by Sutton & Black [31] and Vardy [19]. They reported that plastered straw bale assemblies gain their strength and stiffness from the render coats. As mentioned by Njike et al. [24], the bearing capacity of plastered straw block assembly is greater than the minimum slab load (18.25KN/m2) for residential buildings. Based on this result, Straw blocks can be used for the construction of single-storey load-bearing houses. Moreover, it can be used as a non-bearing partition wall material for the construction of any building. It was also observed that the addition of gum Arabic in plaster and mortar had a positive effect on the bonding strength at the interface between mortar and straw blocks. Due to the presence of gum Arabic in type 2 and type 3 mortar (Table 2), the bonding strength of the wall with a small percentage of gum in mortar was far better than the strength of the wall made with cement-based mortar. Compared to mortar with 25% (Fig. 5a) and 50% gum (Fig. 5b) addition, cement-based mortar did not create good bonding at the interface between mortar and straw blocks (Fig. 5c). It is reported by Seaton [32] that bond strength values can be used as a means of assessing compatibility of brick and mortar which directly influence the structural and durability performance of masonry. In addition, bond strength is important in masonry because its absence at the interface between the mortar and the masonry unit may lead to moisture penetration in the walls. It is thus recommended to add a percentage of gum Arabic in the mortar in order to increase bonding between mortar and straw blocks and hence improve the structural performance of masonry. It was difficult to plaster walls with mortar having 50% gum Arabic because it was too viscous. The failure pattern (Fig. 6a) shows that the cement-based plaster will peel off the straw block wall, whereas plaster with 25% gum Arabic will stick well to straw blocks (Fig. 6b).

Stress-strain curve of straw blocks.

Failure pattern of the prism.

Failure partner of plastered wall.

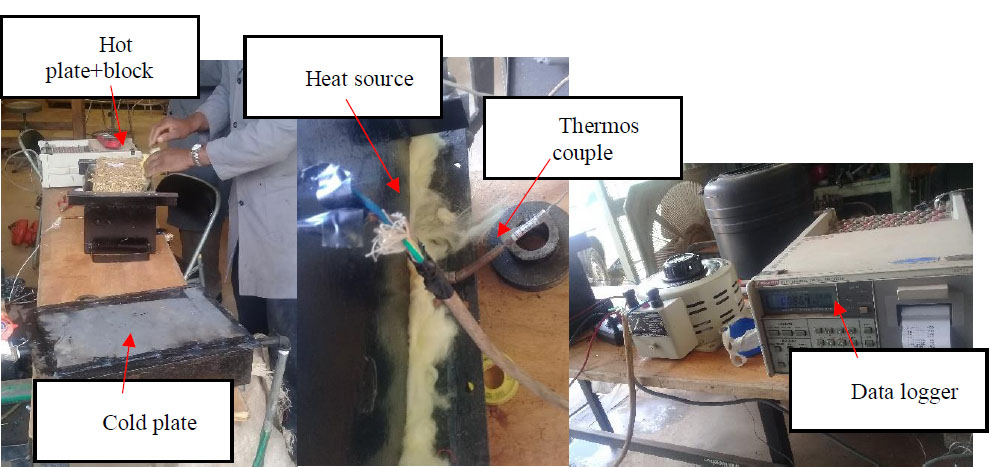

4.2. Heat Resistivity Characteristics of Straw Blocks

Thermal conductivity is the ability of a material to conduct heat. To build thermal resilient infrastructures, it is crucial to select materials that resist heat transfer. The thermal conductivity/resistivity of materials is therefore an important parameter to consider for the building envelope. From the thermal test conducted on straw blocks (Fig. 7), it was recorded that the thermal conductivity of the straw blocks is approximately 0.06 W/mK. Costes et al. [26], Douzane et al. [33] and Ghadie et al. [30] reported a similar value for the thermal conductivity of straw bale. This means that gum Arabic did not interfere with the thermal performance of straw blocks. The thermal properties of a construction material indicate how effectively the material resists heat flow from outside into the building. Given that thermal resistivity is the inverse of thermal conductivity, it is known that a material with low thermal conductivity indicates good resistivity and, hence, such a material will provide good indoor thermal comfort. In comparison with other construction materials, the thermal conductivity of straw blocks is smaller than that of solid cement blocks, which is 0.51 W/mK [34], and clay bricks (0.16 W/mK) [35]. This indicates that straw blocks will provide good indoor thermal comfort compared to clay bricks and cement blocks.

4.3. Absorption Properties of Straw Blocks

The absorption properties of straw blocks demonstrate how quickly or slowly water penetrates them from one side to the other. Since the main role of walls is to protect building occupants and properties from adversity, such as water, straw block will only resist water if it is not porous. To measure this, an Initial Rate of Absorption test was conducted on the blocks. The result obtained shows that after 24 hours in water, the Straw stems did not absorb water until all the surrounding gum Arabic had dissolved. As shown in Fig. (8), only the part immersed in water was wet, while the other part of the block remained dry. However, if the straw block is saturated with water, the binder will lose its strength very fast. It is rare to see such a situation in a building.

Set up for thermal conductivity test.

Failure pattern after the Initial Rate of Absorption test.

As presented in Table 1, the straw block’s rate of water absorption (0.1 g/sq inch/min) is less than the recommended maximum value (1 g/sq inch/min). It can be said that gum Arabic protects straw from absorbing water. Therefore, straw blocks will not absorb water from the mortar at a rapid rate; consequently, it will limit shrinkage in plastering.

CONCLUSION

A straw bale is made of straw tied with two or three strings. While straw block is an improved scaled model of straw bale, made from a mixture of chopped straw and a natural glue (water with gum Arabic). Based on this, straw blocks can be classified as lightweight construction materials capable of providing indoor thermal comfort in hot climates. Straw block houses can be classified as a sustainable and resilient home. It is made of eco-friendly materials and minimizes energy consumption while providing a comfortable indoor environment. Therefore, straw is a potential construction material. However, some precautions must be taken during construction to render straw block structures resistant to water, fire, and termites. These precautions will help minimize future problems, such as moisture in the straw block buildings, thereby improving their durability. Among such precautions are roof overhangs, an increased height of the slab beam from the floor, and the use of a moisture barrier at the bottom course of the straw blocks. In this work, a straw block wall was tested as a load-bearing panel. The use of straw blocks is not limited to load-bearing walls; they can also be used for the elevation of partition/non-bearing walls in multi-storey buildings. Furthermore, if compared with straw bale, the compressive strength of straw block, which is 1.25MPa, is 62 times greater than the published compressive strength of straw bale (0.02MPa). Hence, the use of binder in the manufacturing process of straw blocks results in an improvement in strength. Additionally, builders are more familiar with the shape of straw blocks (Fig. 1a) compared to that of straw bales (Fig. 3), which require skilled workers during construction.

LIMITATIONS

In the manufacturing process of straw blocks, water was mixed with powder gum Arabic to form a binder. The presence of water in the mixture causes the straw blocks to take considerable time (approximately 1 month) to dry. There was no autoclave or hot press. This constituted the main challenge faced during the manufacturing of straw blocks. For future investigation, hot press can be used for the production of straw blocks. Moreover, blocks can be dried in the autoclave. Furthermore, the compression machine used was operated manually and could not measure the displacement in blocks after a 20KN load was applied [9]. Hence, displacement was measured with a ruler. Since the operation was manual and not fully automated, this could result in errors in the recorded data.

AUTHOR'S CONTRIBUTIONS

The authors confirm their contribution to the paper as follows: M.N.: Draft manuscript; W.O.O., S.O.A.: Supervision. All authors reviewed the results and approved the final version of the manuscript.

AVAILABILITY OF DATA AND MATERIALS

Data supporting the findings can be found in the appendix of the thesis at jkuat repository (http://ir.jkuat.ac.ke).

FUNDING

The research was founded by African union commission through the pan African university scholarship.

ACKNOWLEDGEMENTS

Declared none.