All published articles of this journal are available on ScienceDirect.

Investigation into Factors Affecting Penetration Rate and Favorable Ground Types of Pipe Jacking

Abstract

Introduction:

Improper assessment of the penetration rate (PR) of pipe jacking (PJ) may lead to serious schedule delays and cost overruns. In the current practice, PR is estimated on the basis of the experience of practitioners. This has resulted in predicted PR values that are not consistent with the actual ones. A guideline that can be used to reliably predict PR and account for the effects of the significantly controlling factors is not available. This negatively affects the estimated project time and cost. The problems stem from the many factors that affect PR such as the ground conditions, installation depth, machine type, operator experience, and pipe diameter. Little research has been made in this regard. So this research will focus on two main objectives; the first is to identify, categorize and rank the factors that affect PR, and the second is to investigate the common types of ground and PJ machines in Egypt and the Middle East to determine the favorable ground types for PJ machines.

Methods:

To determine the factors that affect the PR of PJ and their relative importance, interviews were made with 17 PJ experts in Egypt. Then, a questionnaire was sent to 149 PJ experts in Egypt and the Middle East. The obtained responses were analyzed and the relative importance of all factors was determined. Based on the interviews with experts and the questionnaire survey, the favorability of ground types for the slurry and auger machines was determined.

Results:

The responses and analysis results of the interviews and questionnaire are weighted using the relative importance method and then ranked. The analysis reveals that 20 factors significantly affect PR. The top 5 factors that affect PR are 'ground type', 'ground condition', 'geotechnical investigation', 'crew/operator experience', and 'pipe lubrication'.

Conclusion:

Among the ten new factors which are introduced in this study, the four factors 'ground type', 'ground settlement', 'bentonite water ratio', and 'feed flow rate' are assessed as significant and ranked as the 1st, 7th, 16th, and 20th most important, respectively. It is also concluded that sand and silty sand are very highly favorable for the slurry machines, while silty clay is very highly favorable for the auger machines.

1. INTRODUCTION

Underground pipelines are necessary facilities that serve urban and rural areas and are used mostly for water, wastewater, stormwater, electricity, gas, oil, and telecommunication applications. Open excavation is the conventional method of installing the pipes and consists of digging trenches, placing the pipes on suitable bedding materials, embedment, and backfilling. Trenchless technology has been developed to avoid open excavation. This is necessarily needed in cases such as when crossing under existing embankments, water canals, railways, and highways. Compared to open-cut methods, trenchless methods have a higher benefit-cost ratio, better traffic control, lower reinstatement cost, less need to dig around existing utilities, and lower social costs. There are three categories of trenchless construction methods: pipe or box jacking, horizontal directional drilling, and tunneling.

There are two main types of PJ machines: slurry and auger machines. The main difference is in the spoil handling system [1, 2]. The AVN (slurry system) and EPB (auger system) machines are popular worldwide and currently in use in Egypt and the Middle East [3]. AVN stands for the German designation 'Automatischer Vortrieb Naß,' which means Automatic Driving Wet. Automatic means that the machine is remotely controlled by a steering container, driving means tunneling, and wet means that the excavated material is conveyed via a flushing (slurry) circuit. These machines are designed as full-face tunneling machines and can be jacked under the groundwater level. EPB is the abbreviation of Earth Pressure Balance. In EPB machines, the excavated material is transported by a spiral conveyor or auger casing placed through the jacking pipes. The spiral conveyor or auger feeds the excavated materials to a spoil bucket positioned below the jacking frame in the entry shaft. The first PJ machine was developed in Japan and the first drive was completed in 1970. Then, the technique spread to Europe in the 1980s, especially in Germany and the UK. It was introduced to the United States in 1984. Then, it rapidly spread worldwide [4, 5]. In Egypt, several PJ machines were used for the first time in 1980 to construct the spine tunnel of the Greater Cairo wastewater project [6]. Pipe jacking has been widely used in Egypt since the beginning of the twenty-first century. The major use has been to improve and support sanitation in crowded areas.

Development of pipe jacking time plans, cost estimates, and time and cost control necessitates an assessment of the penetration rate (PR) of pipes into the ground and time delays. PR is defined as the length of the pipe segment that is jacked into the ground divided by the corresponding operating time. PR is commonly expressed in m/hr or mm/min. PJ jobs are always fast-tracking as in most cases the pipes are installed under roads, railways, etc. Therefore, the assessment of PR is critical for PJ contractors [7-9]. Improper assessment of PR may lead to serious schedule delays and cost overruns [8, 10-12]. For a given type of PJ machine, the assessment of PR is essentially affected by many factors such as the ground type, drive length, installation depth, machine type, machine condition, operator experience, and pipe diameter [8, 9].

Little research effort has been made to determine the factors that control PR and assess their relative importance. Through a questionnaire sent to 6 experts, Nido [13] concluded the 20 factors listed in Table 1 as affecting the productivity of PJ. Though the number of experts questioned by Nido is small, the study represented a significant contribution. However, the study of Nido [13] did not consider the relative importance of the reported factors. To validate the factors reported by Nido [13] and assess their relative importance, Hegab and Salem [9] sent a questionnaire to PJ experts across the United States and Canada. On the basis of the responses obtained from 23 experts, they reported 2 additional factors and the relative importance of the 22 factors as shown in Table 1. They added two factors: 'torque' and 'jacking thrust'. Hafez et al. [14] also sent a questionnaire to experts in Dubai and Abu Dhabi (UAE). They considered the 22 factors that are reported by Hegab and Salem [9] and got responses from 8 experts. They excluded the factor 'pipe length', added the factor 'pipe diameter', and reported the relative importance shown in Table 1. Though the same factors were considered by both Hegab and Salem [9] and Hafez et al. [14]. Table 1 shows significant disagreements between their ranking results. For example, the factor 'geotechnical investigation' is ranked as 2 by Hegab and Salem [9], while it is ranked as 7 by Hafez et al. [14]. The factor 'technical support' is ranked as 14 by Hegab and Salem [9], while it is ranked as 4 by Hafez et al. [14]. Another example is the factor 'cutter shape' which is ranked as 11 by Hegab and Salem [9], while it is ranked as 6 by Hafez et al. [14]. The top 5 or 10 important factors in both studies are significantly different.

In the current practice, PR is estimated on the basis of the experience of practitioners. This has resulted in predicted PR values that are not consistent with the actual ones [8, 10, 12]. A guideline that can be used to reliably predict PR and account for the effects of the significantly controlling factors is not available. The reported factors, their relative weights, and data cannot be used to rigorously analyze or assess PR for a given PJ job owing to the following: (1) the factors that are involved in the process are many and thus render an analysis complicated, (2) past experience indicates that other factors different from those shown in Table 1 affect the performance of PJ and thus potentially affect PR, (3) the reported relative importance of the factors is not in agreement (as mentioned above), (4) it appears that the results of past studies [9, 14] cannot be generalized for use worldwide, and (5) details that are necessary for analysis are not sufficiently reported.

Selection of the appropriate type of PJ machine for given site conditions essentially provides for better performance and higher Among the main factors that control the selection of machine type is the type of ground that dominates the jacking path [1, 2, 9, 12]. Most of the reported case histories indicate that granular soil is the favorable type for AVN machines [1-3], while cohesive soil is the favorable type for EPB machines [1, 2, 15]. ASCE [2] highlights the importance of providing information on the ground type and conditions to PJ contractors so that they can make the equipment selection and better control the steering. The selection of PJ machines is almost totally based on the experience of practitioners. A guideline that can be used for the selection of the appropriate type of PJ machine for a given job is not available. Little research effort has been made in this regard. Hegab and Salem [9] sent a questionnaire to 23 experts to determine the favorable ground types for the AVN machines. They considered 7 types of ground which are hard clay, silt clay, soft clay, silt, sand, boulders, rocks, and backfill. They concluded that sand is the most favorable ground type, while boulders and backfill are the worst for the AVN machines. However, they did not consider common types of ground, especially those which range from silt to sand. Unfortunately, to the best of the authors' knowledge, a study that determines the ground types that are favorable for the EPB (auger system) machines is not available.

The number and scale of PJ jobs have been increasing in Egypt, the Middle East, and worldwide. This has resulted in a great demand for a better assessment of PR. As a step in this direction, the current paper presents the results of a part of an ongoing research project that aims at developing a model for assessing PR for PJ works in Egypt and the Middle East. The focus of the paper is on the determination of the factors that affect PR and their relative importance. Another objective of the paper is to explore the ground types that are favorable for slurry (AVN) and auger (EPB) machines. The approach of the current investigation was to seek the opinions of a sufficient number of PJ experts in Egypt and the Middle East (ME) through exploratory sequential mixed methods of semi-structured interviews and questionnaire surveys. The paper starts by a brief description of the adopted methodology. Then, the obtained responses from the experts are presented and discussed. The obtained findings are compared with the conclusions of past studies.

2. STUDY METHODOLOGY

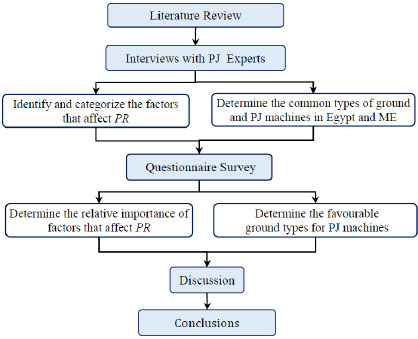

Because the available data of PR and its controlling factors are very limited, the approach of the current investigation was to seek the opinions of PJ experts. This was made through exploratory sequential mixed methods of semi-structured interviews and questionnaire surveys. The adopted methodology is shown in Fig. (1). It is known that exploratory sequential mixed methods are useful in exploratory and descriptive studies [16, 17]. They can also be used to investigate relationships between different variables as long as the questions have the same interpretation to the respondent persons [18, 19]. The literature was reviewed and the reported factors that may affect PR were collected. This resulted in the 23 factors shown in Table 1.

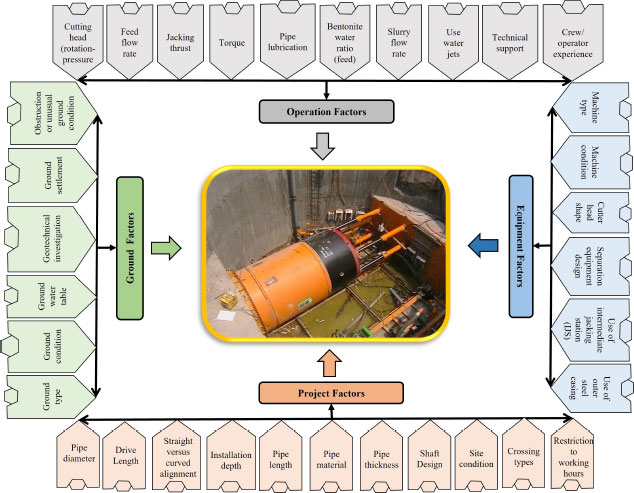

Then, interviews were made with 17 PJ operators, supervisors, technicians, and engineers in Egypt. The interviews provided knowledge elicitation, in-depth discussion, and brainstorming with the experts and thus had reliable results. The interviews resulted in a modified list of 33 factors as shown in Table 2. The new factors that were added through the interviews are ground type, ground settlement, bentonite-water ratio of the feed water, average flow rate of the feed water, rotation and pressure of the cutting head, machine condition, crossing type, site conditions, use of steel case and pipe thickness. The 33 factors were then arranged under 4 categories: project, ground, operation, and equipment factors as shown in Table 2 and Fig. (2). The interviews also indicated that: (1) silty sand is common in Egypt and the Middle East and should be included among the other types of ground when assessing the favorable types of ground for the PJ machines, and (2) not only the slurry (AVN) machines but also the auger (EPB) machines are commonly used in Egypt and the Middle East.

To evaluate the significance and relative importance of the factors, the modified list of the 33 factors was sent through a questionnaire to PJ experts. The questionnaire targeted PJ experts in Egypt and the Middle East and consisted of three sections. The first section includes questions on the particulars of the respondents: contact information, affiliation, organization, and experience. The second section includes the 33 factors listed under the four categories. The experts were requested to assess the importance of every factor on a five-point Likert scale (1 to 5), where 1 = not important, 2 = less important, 3 = moderately important, 4 = highly important, and 5 = very highly important. The experts were asked in the third section to assess the favorable ground types for both the AVN and EPB machines. The assessment was requested for the hard clay, silty clay, soft clay, silt, sand, boulders, rock, silty sand, and backfill; silty sand was added to the types considered by Hegab and Salem [9]. The assessment was made on a scale of 1 to 5, where 1 is the least favorable and 5 is the most favorable.

3. RESULTS

3.1. Reliability Analysis

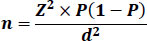

Compared to traditional construction works, PJ works are relatively specialized. Therefore, the experts of PJ are smaller in number compared to those of traditional construction. The following formula by Daniel (1999) is used to determine the minimum sample size for a certain confidence level

|

(1) |

where n = sample size required for infinite population, Z = statistic for the confidence level (Z = 1.645 for 90% confidence level), P = expected prevalence or population proportion (the critical value of P = 0.5), and d = precision or acceptable margin of error (d = 0.10 for 90% confidence level). Substituting the values of Z, P, and d for 90% confidence level in Eq. 1 results in n value of 68.

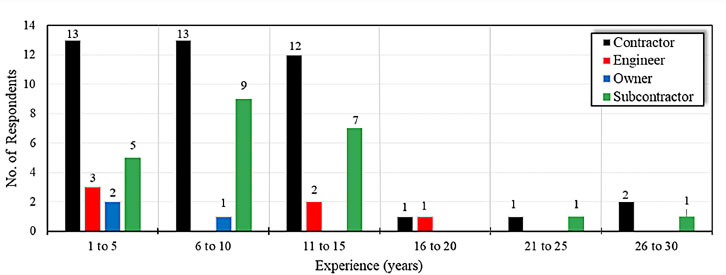

The questionnaire was sent to 184 PJ experts in Egypt and the Middle East. Seventy-four (74) responses representing a response rate of 40.2% were obtained. Therefore, the researchers are 90% certain that the obtained response represents the population's opinion with a precision level of 10%. It is worth mentioning that the obtained response is significantly larger than that reported in past studies; Hegab and Salem [9] got responses of 27 respondents and Hafez et al. [14] got responses of 8. The respondents consisted of 42 contractors (57%), 23 subcontractors (31%), 6 consultants (8%), and 3 owners (4%). The contractors and subcontractors who are essentially more familiar with the details of PJ works and factors that control PR represented 88% of the responses. The experience of the respondents as shown in Fig. (3) ranges from 1 to 30 years with an average of 10 years.

To assess the reliability of the obtained responses, the Statistical Package for Social Sciences program (SPSS) 21.0 was used to calculate Cronbach's Alpha coefficient (α). Cronbach’s Alpha coefficient is a measure of the reliability and internal consistency of statistical data. It normally ranges from zero to one; the higher the value of α, the greater the internal consistency [20, 21]. Values of α in the ranges 0.7–0.8, 0.8–0.9, and greater than 0.9 indicate acceptable, good, and excellent internal consistencies, respectively [20, 22]. The obtained values of α are 0.93 and 0.81 for the PJ factors and their categories, respectively. This reveals good to excellent consistency of the obtained responses.

3.2. Response of Experts

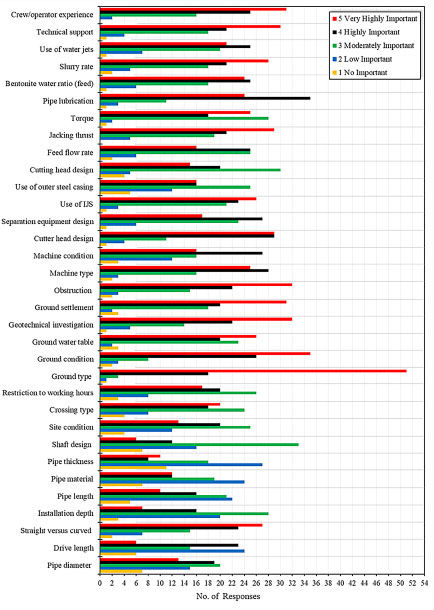

The experts were asked to assess the importance of each of the 33 factors when evaluating its effect on PR. The obtained responses are shown in Fig. (4) and range from 'low significance' to 'high significance'. Experience is important in managing and troubleshooting PJ works. To account for the experience of the respondents in assessing the relative importance of the factors, an index called Experience Relative Importance Index (ERII) is used herein. ERII is given by

|

(2) |

where Ei = experience of respondent i, Xi = score of respondent i (Xi = 1–5), and n = number of respondents. The values of ERII for the 33 factors are shown in Table 2. The rank of each factor in the category and its overall rank are also shown in the table; the ranks are based on the values of ERII. ERII has been widely used to assess the significance levels of factors [23-25]. The significance levels are:

- High (H) significance, if 4.2 < ERII< 5.0

- High–Medium (H–M) significance, if 3.4 < ERII< 4.2

- Medium (M) significance, if 2.6 < ERII< 3.4

- Medium–Low (M–L) significance, if 1.8 < ERII< 2.6

- Low (L) significance, if 1.0 < ERII< 1.8

The ERII-based significance is shown in Table 2 for all factors. It is seen that there are 2 factors assessed as 'H', 21 factors as 'H–M', 9 factors as 'M', and 1 factor as 'M-L'. No factor is assessed as 'L'. It is interesting to note that the 10 factors which are newly added in this study as a result of the interviews with the PJ experts have different levels of significance. A single factor is assessed as 'H', 6 factors as 'H-M', 2 factors as 'M', and 1 factor as 'M-L'.

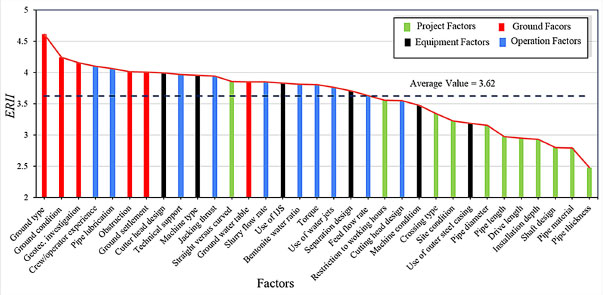

Fig. (5) shows the 33 factors arranged in descending order. Shown also in the figure is the average value of ERII which is 3.62. The concept of weighted average has also been used to assess the significance of the factors [26, 27]. Fig. (5) implies that the first 20 factors whose ERII is greater than 3.62 are assessed as significantly affecting PR. Each of these 20 factors is assessed in Table 2 as H or H–M. The 3 factors 'restriction', 'cutting head rotation/pressure' and 'machine age' represent the only exception. They are assessed in Table 2 as H–M and in Fig. (5) as insignificant (their ERII values are lower than 3.62). However, it should be noted that their ERII values are very close to the lower boundary of H–M. Therefore, it appears reasonable to conclude that the first 20 factors in Fig. (5) significantly affect PR and that their significance level ranges from H to H–M.

| # | Factor | Nido (1999) | Hegab and Salem (2010) | Hafez et al. (2015) |

| 1 | Ground condition | √ | 1 | 1 |

| 2 | Geotechnical investigation | √ | 2 | 7 |

| 3 | Crew/operator experience | √ | 3 | 2 |

| 4 | Obstructions or unusual ground conditions | √ | 4 | 3 |

| 5 | Pipe lubrication | √ | 5 | 13 |

| 6 | Torque | -- | 6 | 8 |

| 7 | Jacking thurst | -- | 7 | 10 |

| 8 | Separation equipment design | √ | 8 | 22 |

| 9 | Straight versus curved alignment | √ | 9 | 9 |

| 10 | Machine type | √ | 10 | 11 |

| 11 | Cutter head design | √ | 11 | 6 |

| 12 | Drive length | √ | 12 | 17 |

| 13 | Use of intermediate jacking station (IJS) | √ | 13 | 19 |

| 14 | Technical support | √ | 14 | 4 |

| 15 | Restriction to working hours | √ | 15 | 16 |

| 16 | Slurry flow rate | √ | 16 | 20 |

| 17 | Use of water jets | √ | 17 | 12 |

| 18 | Shaft design | √ | 18 | 21 |

| 19 | Ground water table | √ | 19 | 15 |

| 20 | Pipe length | √ | 20 | -- |

| 21 | Pipe material | √ | 21 | 18 |

| 22 | Installation depth | √ | 22 | 14 |

| 23 | Pipe diameter | -- | -- | 5 |

| Category / Factor | ERII | Ranking by Category | Overall Ranking | Effectiveness Level* | |

| Project Factors | Pipe diameter | 3.15 | 5 | 27 | M |

| Drive length | 2.95 | 7 | 29 | M | |

| Straight versus curved alignment | 3.85 | 1 | 12 | H–M | |

| Installation depth | 2.93 | 8 | 30 | M | |

| Pipe length | 2.97 | 6 | 28 | M | |

| Pipe material | 2.79 | 10 | 32 | M | |

| Pipe thickness | 2.48 | 11 | 33 | H–M | |

| Shaft design | 2.80 | 9 | 31 | M | |

| Site condition | 3.23 | 4 | 25 | M | |

| Crossing types | 3.34 | 3 | 24 | M | |

| Restriction to working hours | 3.56 | 2 | 21 | H–M | |

| Ground Factors | Ground type | 4.61 | 1 | 1 | H |

| Ground condition | 4.24 | 2 | 2 | H | |

| Ground water | 3.85 | 6 | 13 | H–M | |

| Geotechnical investigation | 4.15 | 3 | 3 | H–M | |

| Ground Settlement | 4.01 | 5 | 7 | H–M | |

| Obstruction or unusual ground condition | 4.01 | 4 | 6 | H–M | |

| Equipment Factors | Machine type | 3.97 | 2 | 10 | H–M |

| Machine condition | 3.48 | 5 | 23 | H–M | |

| Cutter head design | 3.99 | 1 | 8 | H–M | |

| Separation equipment design | 3.71 | 4 | 19 | H–M | |

| Use of intermediate jacking station (IJS) | 3.83 | 3 | 15 | H–M | |

| Use of outer steel casing | 3.19 | 6 | 26 | M | |

| Operation Factors | Cutting head (rotation-pressure) | 3.55 | 10 | 22 | H–M |

| feed flow rate | 3.63 | 9 | 20 | H–M | |

| Jacking thrust | 3.94 | 4 | 11 | H–M | |

| Torque | 3.81 | 7 | 17 | H–M | |

| Pipe lubrication | 4.06 | 2 | 5 | H–M | |

| Bentonite water ratio (feed) | 3.81 | 6 | 16 | H–M | |

| Slurry flow rate | 3.85 | 5 | 14 | H–M | |

| Use of water jets | 3.76 | 8 | 18 | H–M | |

| Technical support | 3.97 | 3 | 9 | H–M | |

| Crew/operator experience | 4.10 | 1 | 4 | H–M | |

| Ground Type | Slurry System Machine | Auger System Machine | ||||

| ERII | Absolute Deviation | Rank | ERII | Absolute Deviation | Rank | |

| Hard clay | 2.64 | 1.47 | 8 | 3.92 | 1.06 | 3 |

| Silty clay | 2.99 | 1.26 | 7 | 4.04 | 1.07 | 1 |

| Soft clay | 3.18 | 1.23 | 6 | 3.99 | 1.10 | 2 |

| Silt | 3.53 | 0.89 | 4 | 3.46 | 0.95 | 4 |

| Sand | 4.05 | 1.18 | 2 | 3.04 | 1.10 | 6 |

| Silty Sand | 4.12 | 1.11 | 1 | 3.05 | 1.11 | 5 |

| Boulders and rocks | 3.59 | 1.23 | 3 | 2.82 | 1.15 | 8 |

| Backfill | 3.27 | 1.16 | 5 | 2.93 | 1.21 | 7 |

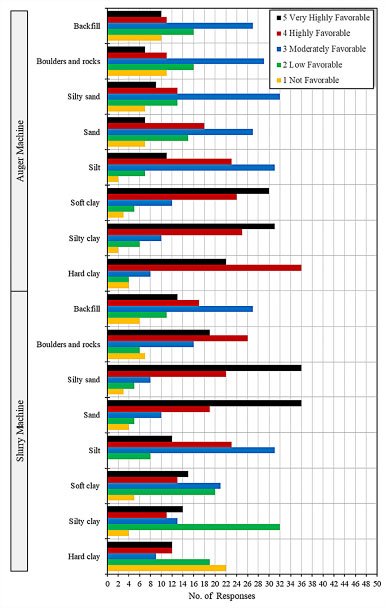

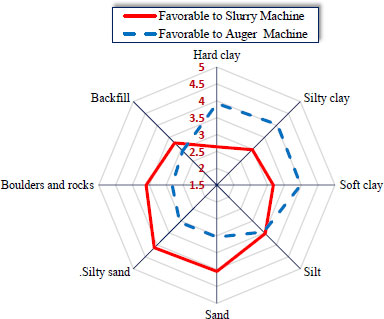

The experts were also asked to assess the favorability of ground types for the slurry (AVN) and auger (EPB) machines. The obtained response is shown in Fig. (6) and ranges from ‘Not favorable’ to ‘ Very highly favorable’. It is seen that sand and silty sand are assessed as very highly favorable for the slurry machines, while hard clay ground is assessed as very highly favorable for the auger machines. On the basis of Eq. (2), ERII was calculated for the obtained responses on ground-type favorability. Table 3 shows the calculated values of ERII and their absolute deviation. Shown also in the table is the rank of ground type favorability.

4. FACTORS AFFECTING PR

4.1. Ground Factors

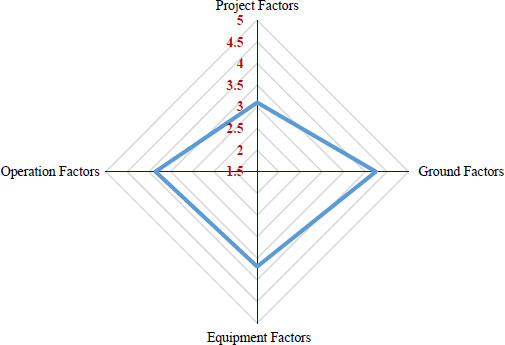

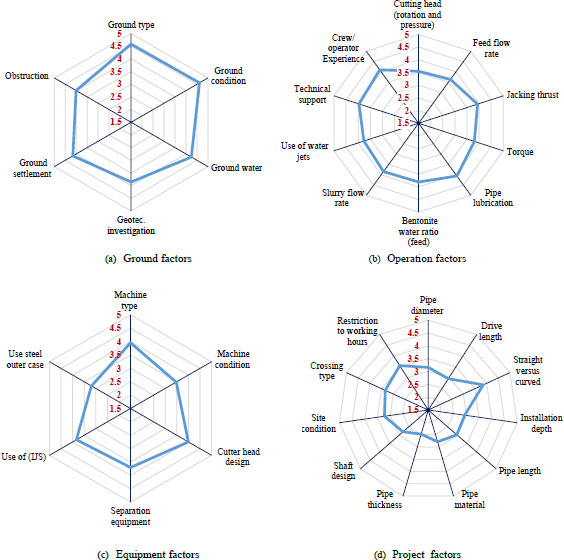

The weighted relative importance is determined for each of the four categories (ERIC) of factors as the average of ERII for all factors in the category. Fig. (7) shows that the ERIC of the ground, operation, equipment, and project categories are 4.24, 3.84, 3.69, and 3.09, respectively. It is seen that the ground category is the most important. The six factors in the ground category which are ground type, ground conditions, geotechnical investigation, obstructions/unusual ground conditions, ground settlement, and groundwater table are ranked 1, 2, 3, 6, 7, and 13 with ERII values of 4.61, 4.24, 4.15, 4.01, 4.01 and 3.85, respectively (see Fig. 5). It is seen that all values of ERII are greater than 3.80 which is the mid-value of the range H–M. Therefore, it can be practically said that the six factors are of high significance in affecting PR. A mapping chart that shows the ERII of the ground factors is shown in Fig. (8a).

Past studies considered the factor 'ground condition' and assessed it as the most important factor affecting PR; it was ranked as the first in all past studies [9, 13, 14]. In this study 'ground type' is introduced as an additional new factor. The response of experts in the interviews and to the questionnaire confirmed the importance of including and separating the two factors (ground type and condition). They are independent of one another. The ground type can be sand, silt, silty sand, silty clay, clay, rock, etc. However, the condition defines the engineering properties of a given ground type. The properties are generally divided into two groups: compositional or intrinsic factors and environmental or state variables. The intrinsic factors include, for example, mineralogy, particle shape, and grain size. The state variables determine, for example, the relative density, stress state, fabric, and water content. The inclusion and separation of the type and condition of ground are essentially useful and provide for determining their effects independently.

Past experience indicates that the performance of PJ in terms of PR in the sand, for instance, is necessarily different from that in clay or rock; PR is higher for sand, assuming the same PJ methodology is adopted. Dang [1] and Farghaly [12] indicated that PR is highly dependent on the type of ground. Hegab and Salem [28] reported a case history on the use of PJ for the construction of long sewer lines. They reported significantly different records of PR for 5 types of ground. Wilson et al. [29] also indicated that PR varies significantly with the ground type and reported values of PR of 350, 110–170, and 30–90 mm/min for soft, filled, and mixed hard ground, respectively. As for the condition of the ground, it can be said that PR in dense sand is lower than that in loose sand and in soft clay is higher than that in stiff clay. Hegab and Salem [28] reported values of PR in soft clay and hard clay for different diameters of AVN machines. For all machines, PR in soft clays was significantly higher than that in hard clays. On the basis of data collected from many actual PJ projects, Hegab et al. [11] categorized the penetrated soils according to their shear strength into 3 categories: A, B, and C. Category A indicates soils with low shear strength, which is soft clay and loose sand. Category B indicates soils with medium shear strength, which is medium clay and medium sand. Category C indicates soils with high shear strength, which are hard clay and dense sand. The collected data reveals significantly different values of PR for the 3 categories. These 3 categories actually represent the combined effects of both the soil type and soil condition. The types are sand and clay. The condition is represented in terms of the state of strength.

During PJ works, the surrounding ground experiences displacements because of ground loss at the face and closure of the overcut and shield cut as the ground moves into the annulus. Causes of ground loss at the face include overexcavation because of the improper setup of the machine, mixed-face conditions, operator error, and rapid and unexpected changes in the ground type and conditions [2, 30, 31]. The displacement may extend over a large distance and cause significant settlement at the ground surface [2, 30-32]. The amount of settlement depends on the ground type, ground condition, ground water and drainage conditions, face stability (face pressure and earth pressures), pipe depth to diameter ratio, and adopted construction method [30-33].

Existing adjacent or nearby utilities, railroads, roadways, structures, and other facilities must be protected against damage from ground movements because of PJ. This may necessitate adopting appropriate mitigation measures such as modifying the alignment, ground treatment, reducing the shield cut, and protecting the facility [2, 28, 31]. Alternatively, PR of PJ can be controlled to minimize the effect of PJ on the existing facilities. The concept is to control PR so that the penetration of the machine into the ground equalizes the volume of cuttings. This approach has proved useful and successful in several past projects [3, 12, 33, 34]. It is worth mentioning, as reported by Zhang et al. [33], that ground settlement can be minimized if the actual volume of excavated soil (conveyed out from the chamber) is kept within 95–98% of the theoretical volume of soil that is cut by the cutting head. It has been reported that the tunneling penetration rate affects the volume of ground loss and thus the ground movements caused by TBM excavation [35, 36]. Because of the similarities in excavation mechanisms of both slurry TBM machines and slurry PJ machines, the conclusion reported by Toan and Hung [35] and Sheng et al. [36] most likely holds good for excavation by PJ machines. Therefore, management of PJ works in the vicinity of existing structures or facilities necessitates the determination of appropriate PR that mitigates or minimizes the associated ground movements. In this study 'ground settlement' is introduced as an additional new factor. Discussions with the experts during the interviews and their answers to the questionnaire confirm the importance of ground settlement as a highly significant factor affecting PR. It is ranked as the seventh significantly controlling factor.

Geotechnical investigation, obstructions or unusual ground conditions, and groundwater table are ranked as shown in Fig. (5) as the third, sixth, and thirteenth. The ranks of the three factors in past studies are shown in Table 1. It is seen that the ranks of 'geotechnical investigation' and 'obstructions or unusual ground conditions' as reported by Hegab and Salem [9] are closer to those concluded herein. However, the rank of the 'groundwater table' as reported by Hafez et al. [14] is closer to the rank of this study. Geotechnical investigation (GI) generally consists of drilling boreholes, field testing, and laboratory testing. Sufficient and accurate GI provides for reliable determination of the ground type and condition as well as their variation throughout the alignment and as a result better assessment of PR. GI is fundamental to the selection of appropriate PJ method, machine, and cutting head and thus good jacking performance. It may further provide for changing the location and alignment so that more effective jacking is obtained. For instance, it is preferable to drive through uniform or consistent ground rather than through mixed ground. It is more favorable to drive through water-bearing silt and sand than through silty or sandy clay [31]. Assessment of ground displacement, surface settlement, and the effect of PJ on existing structures requires good information on the ground type and condition, groundwater, and earth pressures. Accurate prediction of the jacking force is important for the proper design and execution of PJ works. The jacking force depends not only on the soil type and condition and their variation throughout the alignment but also on PR [31]. Sufficient and accurate GI minimizes uncertainty of ground conditions and provides for more accurate prediction of the jacking force. The existence of obstructions or unusual ground conditions negatively impacts PR [31, 37]. If significant obstructions are identified through GI, an appropriate machine or cutting head could be decided. Past experience indicates that groundwater conditions affect the selection of PJ machine type, installation depth, and break-in and break-out of the starting and ending shafts. A partially submerged cutting face should be avoided because of advancing operation difficulties and the bad effect on the advancing performance [1]. Dang [1] and ASCE [2] reported that groundwater was one of the main factors which define the applicability of a specific type of PJ machine (slurry or auger).

4.2. Operation Factors

The operation factors as shown in Fig. (7) represent the second most important category. The ten operation factors which are crew/operator experience, pipe lubrication, technical support, jacking thurst, slurry flow rate, feed bentonite-water ratio, torque, use of water jet, feed flow rate, and cutting head rotation and pressure are ranked as 4, 5, 9, 11, 14, 16, 17, 18, 20 and 22 with ERII values of 4.10, 4.06, 3.97, 3.94, 3.85, 3.81, 3.81, 3.76, 3.63 and 3.55 respectively (Fig. 5). A mapping chart that shows ERII of the operation factors is shown in Fig. (8b).

Crew/operator experience directly affects machine performance during penetration into the ground [8, 12, 28]. On the basis of PR records for nine operators, Hegab and Salem [28] concluded that the PR of highly experienced operators is higher than that of less experienced operators. An experienced operator can better understand the operation parameters, such as the cutting pressure and thrust force, and thus solve problems faced during penetration faster than less experienced ones. For example, for the purpose of preventing soil collapse before the cutting head, the operator may increase the head pressure of the cutting wheel. This may result in the sticking of the cutting head in the soil. However, to avoid such a problem, the experienced operator usually decreases the cutting pressure by decreasing the thrust rate and increasing the slurry rate [12]. Providing technical support to the operator and crew during the PJ process helps to troubleshoot problems and improve performance and thus increasing PR. Technical support can be on mechanical, electrical, and civil issues and may also be needed from manufacturers. Technical support is usually needed such as when penetration into variable ground conditions, when working at relatively shallower depths, when penetration in the vicinity of adjacent structures or utilities, for correction of directional problems, and for analyzing recorded operation parameters. The values of ERII for the 'crew/operator experience' and 'technical support' are considerably higher than the mid-value of the range H–M and the average value in Fig. (5). In accordance with past studies [9, 13, 14], the two factors are important and significantly affect PR. The rank of 'crew/operator experience' approximates those reported by Hegab and Salem [9] and Hafez et al. [14] as shown in Table 1. However, the rank of 'technical support' is intermediate to those reported by Hegab and Salem [9] and Hafez et al. [14].

The conveying system carries muck out of the spoil champer. The spoil which is composed of water, bentonite, and soil cuttings is pumped out with a rate called slurry flow rate. This rate depends on the volume of excavated soil which directly affects the advance of the machine into the ground; the higher the slurry rate, the higher the value of PR [8, 12]. It is important to control PR so that the penetration of the machine into the ground equalizes the volume of soil cuttings. Such a control reduces the potential for settlement throughout the jacking line [8]. The value of ERII for the 'slurry flow rate' is considerably higher than the mid-value of the range H–M and the average value in Fig. (5). This implies that the slurry flow rate significantly affects PR. This is in contrast to past studies [9, 13, 14] which indicate that the slurry flow rate slightly affects PR. Depending on the ground type and condition, the properties of feed water including the bentonite-water ratio and feeding pressure have to be properly determined in order to control the pressure at the cutting face [2]; this directly affects PR. The flow rate of feed water controls the erosion of soil at the cutting face and thus affects PR. The flow rate must be carefully controlled to avoid potentially detrimental settlement at the ground surface [12, 37]. The values of ERII for the 'feed bentonite-water ratio' and 'feed flow rate' which are newly introduced in the current investigation are 3.81 and 3.63, respectively. These values are considerably higher than the mid-value of the range H–M and the average value in Fig. (5) and indicate the significance of the two factors in affecting PR.

The jacking thrust should overcome the resisting force resulting from the overburden pressure at the cutting face and the friction force between the jacked pipes and soil [1, 2, 12]. It is therefore responsible for advancing the machine into the ground and directly affects PR. The jacking thurst has to be controlled and must not exceed the allowable strength of pipes. Wilson et al. [29] reported that jacking force varies according to the ground type and advance rate. They reported jacking forces of 70–120, 190–480, and 300–330 tons for filled ground, hard ground, and soft ground, respectively. Increasing the thurst rate leads to an increase of PR. However, it must be controlled to minimize the potential stuck of the cutting wheel. The cutting head torque and cutting head rotation and pressure are operational parameters that control the excavation process and volume of soil cuttings and thus PR [1, 2, 9, 12, 14, 37]. The curring wheel pressure depends on the thrust rate and soil pressure and must be carefully adjusted for better jacking performance [2]. The values of ERII for the 'jacking thrust' and 'torque' are considerably higher than the mid-value of the range H–M and the average value in Fig. (5). In accordance with past studies [9, 14], the two factors are important and significantly affect PR. Their ranks as concluded herein are closer to those reported by Hafez et al. [14] as shown in Table 1. The value of ERII for the 'cutting head rotation and pressure' is 3.55. This value is lower than the mid-value of the range H–M and the average value in Fig. (5); it is slightly higher than the lower limit of the range H–M. The insignificance of the 'cutting head rotation and pressure' may be explained by the mechanism of cutting the soil which is mainly controlled by the torque of the cutting head.

Lubricants are used during PJ to minimize the friction between pipes and the surrounding ground and to fill and support the annular space around the pipes [1-3, 12]. This directly affects the penetration process and results in higher PR [2, 8, 12, 37]. The use of water jet contributes to eroding the soil at the cutting head and cleaning the cutting teeth and discs [8]. This essentially increases the cutting efficiency and positively affect PR. The values of ERII for the ' pipe lubrication' and 'use of jet water' are considerably higher than the average value in Fig. (5). The two factors are therefore assessed as significantly affecting PR. The ranks of 'pipe lubrication' and 'use of water jet' are almost exactly the same as those reported by Hegab and Salem [9].

4.3. Equipment Factors

Fig. (7) shows that the equipment factors represent the third most important category. The six equipment factors which are the cutter head design, machine type, use of IJS, separation equipment design, machine condition, and use of outer steel casing are ranked 8, 10, 15, 19, 23, and 26 with ERII values of 3.99, 3.97, 3.83, 3.71, 3.48 and 3.19, respectively (Fig. 5). A mapping chart that shows ERII of the equipment factors is shown in Fig. (8c).

The cutter head includes the teeth and cutting discs that cut the soil and facilitate the advancement of the machine into the ground. It should be fitted with cutters and knives for excavation in cohesive soils or discs and chisels for excavation in rocks [1]. Therefore, the design of the cutter head including the shape, number, layout, and strength of the cutting tools controls the advancement of the machine [1]. An appropriate cutter head should be carefully selected on the basis of the ground type and conditions that are anticipated along a drive [1, 2]. Different cutter heads maybe required in a project, depending on the variability of the ground. For higher performance, the cutter head and its cutting tools should be frequently inspected for potential maintenance and replacement [29]. PJ machine types are generally classified into two types: AVN and EBP. The differences are mainly in the soil conveying system and cutting tools. Selection of the appropriate type is key to the effectiveness and success of PJ jobs. The AVN type is generally preferred for granular soils and under the groundwater, while the EPB type is preferred for cohesive soils [1-3, 12]. The values of ERII for the 'cutter head design' and 'machine type' are higher than 3.80 which is the mid-value of the range H–M and higher than the average value in Fig. (5). The two factors are important and significantly affect PR. This is in accordance with past studies [9, 13, 14]. The rank of the two factors as concluded herein is closer to that reported by Hafez et al. [14] as shown in Table 1.

For relatively long drives or in case of driving through difficult ground, jacking loads that exceed the capacity of pipes may be required. In such cases, IJSs are used to reduce the maximum stress by distributing the load over a number of points in the line. The locations and number of IJSs are determined on the basis of the estimated jacking force and the allowable loads on the pipes. Many examples of successful use of IJSs for lengthy drives are reported [3, 31]. Because it reduces the jacking loads, the use of IJSs directly affects PR. A separation system is needed to separate the slurry from the excavation muck. The separated slurry is then reused. The slurry mixing and charging system is closely integrated with the separation system. The design of the separation system should therefore take into account the advancement rate of the PJ machine. On the other hand, the density of the separated slurry has a considerable effect on the jacking performance [1, 2, 31]. The value of ERII for the factor 'use of IJS' is 3.83. This is higher than the mid-value of the range H–M and the average value in Fig. (5). The value of ERII for the factor 'separation equipment design' is 3.71. This is slightly less than the mid-value of the range H–M and sufficiently higher than the average value in (Fig. 5). The two factors are important and significantly affect PR. The ranks of the two factors as concluded herein are intermediate to those reported by Hegab and Salem [9] and Hafez et al. [14] as shown in Table 1.

During the interviews with experts, 'machine condition' and 'use of outer steel casing' were recommended as new factors that potentially affect PR. It is generally known that the condition of construction equipment affects equipment productivity [38-40]. Outer steel casings can be used to provide for jacking pipes of diameters larger than the diameter of the used PJ machine [3, 34]. However, the responses of the experts to the questionnaire survey resulted in ERII values of 3.48 and 3.19 for 'machine condition' and 'use of outer steel casing', respectively. These values are lower than the mid-value of the range H–M and the average value in Fig. (5); ERII of 3.48 is slightly larger than the lower limit of the range H–M. This implies that these two factors do not significantly affect PR. The insignificance of 'machine condition' may be explained as follows:

- The 'cutter head design' is a factor that was included in the questionnaire survey and was assessed as significantly affecting PR.

- The cutter head is the main part of the PJ machine.

- The cutting tools in the cutter head should be routinely inspected for potential maintenance and/or replacement.

4.4. Project Factors

The eleven project factors which are straight versus curved alignment, restrictions to working hours, crossing types, site condition, pipe diameter, pipe length, drive length, installation depth, shaft design, pipe material, and pipe thickness are ranked as 12, 21, 24, 25, 27, 28, 29, 30, 31, 32 and 33 with ERII values of 3.85, 3.56, 3.34, 3.23, 3.15, 2.95, 2.93, 2.80, 2.79 and 2.48, respectively (Fig. 5). A mapping chart that shows ERII of the project factors is shown in Fig. (8d).

Curved alignment could affect the laser guidance and cause more complicated operations than in the case of straight alignment [8, 12, 14]. For example, the time of steering control for curved alignment is longer than that for straight alignment. Hence, it is recommended to use straight-line pipe drives whenever possible [8, 12]. The jacking thrust should exceed the friction around pipe segments and soil resistance to driving. Therefore, the jacking thrust which directly affects PR increases with the increase of the drive length. The soil resistance to penetration increases with the increase of installation depth. Therefore, depth indirectly affects PR. The value of ERII for the factor 'straight versus curved alignment' is slightly higher than the mid-value of the range H–M and the average value in Fig. (5) and indicates its significance in affecting PR. The values of ERII for the factors 'drive length' and 'installation depth' indicate that they are not significantly affecting PR.

PJ is usually performed for crossing under existing embankments, water canals, railways, or highways. The type of crossing affects the settlement limitation and precautions that the contractor must take [34]. The effect of crossing type is most likely inherent in other significant factors such as ground settlement. For a given PJ job, the site conditions may limit the work time, supply of resources, or storage of spoil. Shaft design includes the shaft shape, material, size, and depth. It is reported that the size of the entry shaft affects the performance of the PJ machine [8, 12, 34]. The values of ERII for the factors 'crossing type', 'site conditions', and 'shaft design' are lower than the lower value of the range H–M and the average value in Fig. (5). This indicates the insignificance of the three factors in affecting PR.

The friction around pipe segments and thus the jacking force depend on the pipe diameter and material. Hence, the pipe diameter and material affect the penetration performance [8, 12, 28, 34]. The pipe segment length affects the time needed to control the steering and the alignment while the machine advances into the ground [8, 12]. The allowable jacking force depends on the pipe design in terms of its material and thickness. Lubrication may be used to reduce the friction around pipes. IJS may also be adopted to reduce the stresses on pipes [3, 9, 34]. The values of ERII for the factors 'pipe diameter', 'pipe length', 'pipe material', and 'pipe thickness' are lower than the lower value of the range H–M and the average value in Fig. (5). This indicates the insignificance of the four factors in affecting PR. It is worth mentioning that Hafez et al. [14] ranked the factor 'pipe diameter' as one of the top five important factors.

'Restriction to working hours' is a management factor that may be constrained by the owner or contractor. For example, crossing under existing railway lines may require special precautions such as decreasing the speed of trains and fixing certain and limited working times. The value of ERII for the factor 'restriction of the working hours' is slightly higher than the lower value of the range H–M and slightly lower than the average value in Fig. (5). It is believed that the factor 'restriction to working hours' essentially controls the total duration of a given PJ job, but does not significantly affect PR.

5. FAVORABILITY OF GROUND TYPES FOR PJ MACHINES

The values of ERII in Table 3 are plotted in Fig. (9). Table 3 and Fig. (9) show for the slurry machines that the favorability of the eight soil types which are silty sand, sand, boulders, silt, backfill, soft clay, silty clay, and hard clay is ranked as 1, 2, 3, 4, 5, 6, 7, 8 with ERII values of 4.21, 4.16, 3.74, 3.43, 3.28, 3, 2.88, 2.51, respectively. For the auger machines, the favorability of silty clay, soft clay, hard clay, silt, silty sand, sand, backfill, and boulders are ranked as 1, 2, 3, 4, 5, 6, 7, 8 with ERII values of 4.06, 4.03, 4.00, 3.49, 3.02, 2.99, 2.85, 2.82, respectively. The chart in Fig. (9) provides a useful guideline for the selection of the appropriate PJ machine for a given type of ground. The following observations however can be made on the results in Fig. (9):

- For silt soil or backfill, both the slurry and auger machines experience approximate performances.

- Silty sand and sand are the two most favorable soils for slurry machines. This is in agreement with the conclusions of Hegab and Salem [9] and the observations of El-Demerdash et al. [3].

- Silty clay, soft clay, and hard clay are the most favorable soils for auger machines. This is in accordance with the case history of Jiang et al. [15] in which the contractor preferred the EBP auger machines for pipe jacking into silty clay strata.

- This implies that granular and cohesive soils are generally preferred for the slurry and auger machines, respectively.

- In the case of jacking through boulders or rock, slurry machines should be recommended.

CONCLUSION

To determine the factors that affect the PR of PJ and their relative importance, interviews were made with 17 PJ experts in Egypt. In addition to the 22 factors that were reported in the literature, the interviews resulted in 10 new factors. The 33 factors were then sent through a questionnaire survey to 149 PJ experts in Egypt and the Middle East to assess their relative importance. Seventy-four (74) responses representing a response rate of 40.2% were obtained. A reliability analysis indicates good to excellent consistency of the obtained responses. The responses were analyzed and the relative importance of all factors were determined as shown in (Fig. 5). The analysis reveals that 20 factors significantly affect PR. The top 5 factors that affect PR are 'ground type', 'ground condition', 'geotechnical investigation', 'crew/operator experience', and 'pipe lubrication'. Among the new factors that are introduced in this study, the following four factors 'ground type', 'ground settlement', 'bentonite water ratio', and 'feed flow rate' are assessed as significant and ranked as the 1st, 7th, 16th and 20th most important, respectively. The interviews with experts also indicated that silty sand is common in Egypt and the Middle East and should be included among the types of ground when assessing the favorable types of ground for the PJ machines. On the basis of analysis of the obtained responses to the questionnaire survey, the favorability of different types of ground for the slurry and auger PJ machines is determined as shown in Fig. (9). Sand and silty sand are assessed as very highly favorable for the slurry machines, while Silty and hard clay are assessed as very highly favorable ground types for the auger machines. Fig. (9) represents a useful guideline for the selection of the appropriate PJ machine for a given type of ground.

LIST OF ABBREVIATIONS

| PR | = Penetration Rate |

| PJ | = Pipe Jacking |

| AVN | = 'Automatischer Vortrieb Naß,' which means Automatic Driving Wet |

| EPB | = Earth Pressure Balance |

| ME | = Middle East |

| ERII | = Experience Relative Importance Index |

| H | = High Significance |

| H–M | = High–Medium Significance |

| M | = Medium Significance |

| M-L | = Medium–Low Significance |

| L | = Low significance |

| ERIC | = Experience Relative Importance of Category |

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data sets used and analysed during this study are available from the corresponding author [A.E-D] upon request

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

However, the authors acknowledge, thankfully, those who took part in this survey for their valuable opinions and time in preparing their responses.