All published articles of this journal are available on ScienceDirect.

Study on Bearing Capacity of Prestressed Pipe Pile Foundation Under Horizontal Load

Abstract

Background and Objective:

Prestressed high strength concrete pipe pile (PHC) shows brittle fracture when subjected to more than its own bearing capacity. Therefore, the non-prestressed steel bar is added to the PHC pipe pile, that is, the mixed reinforced pipe pile (PRC). The mechanical behavior of PRC group piles and PHC group piles under horizontal force is studied, and the bending moment diagram and displacement diagram of the pile body are compared so as to find the weak parts.

Material and Method:

In this paper, Φ600 pipe piles are chosen, and the PRC pipe piles are made of non prestressed steel bars of the same number as the prestressing steel bars, and the two steel bars are spaced apart. Referring to a specific project of Binhai New Area, the geological parameters are used, and the force analysis of group piles under horizontal force is carried out by using the ANSYS software.

Results:

ANSYS simulation results show that, under the horizontal loading, when the number of piles in group piles is different, the locations of maximum bending moments are different. Increasing the number of the PRC pipe pile with non prestressed reinforcement can effectively reduce the maximum bending moment of the pile body.

Conclusion:

Under horizontal load, with the increase of pile number and the pile cap aggrandizement, the position of maximum moment of pile body is shifted from 5-8 times diameter of pile to the top of pile. When the pile number reaches a certain amount, the maximum bending moment will appear at the joint between the pile cap and the pile body. At the same time, increasing the non prestressed steel bar does not influence the bending moment, and the reinforcement of the pile cap and the pile top should be strengthened.

1. INTRODUCTION

Because of its high bearing capacity, low cost, standardized production, convenient construction and easy to detection, the prestressed concrete pipe pile is widely used in high-rise building foundation, foundation pit retaining structure and retaining structure. Because of its structural characteristics, prestressed pipe pile is prone to sudden failure of structure when it is subjected to abnormal uplift force and horizontal force. There is no warning before destruction. There are many examples of pipe failure caused by buoyancy and horizontal forces. But in practical engineering, there are usually several single pile foundations in the pile foundation, and the group piles are combined to bear the load. The group piles have the effect because of the interaction between the adjacent piles, and the mechanical behavior is different from that of the single piles.

At present, many scholars use different methods to carry out researches. The analysis method of horizontal pile can be divided into P-Y curve method, elastic theory method, foundation limit reaction method, NL method and numerical analysis method. Rase proposed the ultimate foundation reaction method [1]. Broms proposed different foundation counterforce distribution forms [2, 3]. Poulos used elastic theory to obtain the Mindlin solution between each pile group interaction coefficient [4]. Focht and Koch combined the P-Y curve with the elastic theory, and used the P-Y curve method to obtain the horizontal displacement of the pile, so as to consider the nonlinear relationship between the pile-soil interactions [5]. When studying the interaction of pile groups under a single cap, Dezi et al established a numerical model based on the elastic dynamic Green function method, however, the influence on the interaction of pile and soil of the stiffness and quality of the structure of the upper part of the pile was not taken into account [6]. Ikeda carried on the low cycle reciprocating load test on PHCΦ400 A and B pipe piles. The test shows that the two types of pipe piles undergo brittle fracture with the rupture of prestressed steel bars. Subsequently, second sets of tests were conducted to increase the placement of non prestressed steel bars in the original pipe pile, followed by the same reciprocating loading test. The test results show that the ductility of the component increases after the increase of the non prestressed steel bar, and the component has the bearing capacity after the prestressed steel bar is broken [7].

In recent years, many scholars have studied prestressed pipe pile in China. Wang and Wang discussed under reciprocating loading, the increase of reinforced after fuller hysteresis curve, PHCΦ500 pile ductility better can change the failure form of pipe pile, stress performance, and seismic performance. The failure shape and hysteretic curve of the tubular pile after core filling have not changed basically, but the ultimate bearing capacity of the PHC and SFPHC pipe pile (Prestressed steel fiber reinforced high strength concrete pipe pile) after core filling is obviously higher than that of the original component [8]. Zhang assumed that the coefficient of horizontal foundation is constant along the depth. An analytic solution for the analysis of the internal forces and displacements of an elastic long pile was derived, which is usually called the constant method [9]. Liu and Ge used finite element ANSYS to simulate prestressed pipe pile under horizontal load, and found out the effect of different factors on bearing capacity of prestressed concrete pipe pile level [10]. Yin used ABAQUS software to focus on the changes of displacement field under the trend of soil pile front horizontal load, the maximum principal stress and minimum principal stress angle are analyzed under horizontal load before pile soil stress field variation, so the deformation mechanism and load transfer of horizontal static loading test of pile foundation were revealed [11]. Zhang through the analysis of PHC pipe pile under horizontal load bearing characteristics, discussed the main influencing factors of PHC pipe pile, and compared with the bearing characteristics of pile and circular pile, pile group effect, and studied of PHC pile, and compared the bearing characteristics of different types of pile under horizontal load. The results showed that the effect coefficient of pile groups increases with the increase of pile rigidity [12].

The research of these scholars shows that the pipe pile with non-prestressed reinforcement has better anti-horizontal performance. Based on a specific project in Tianjin, this paper mainly studies the mechanical behavior of double piles, four piles and nine piles under horizontal force, and the improvement of mechanical performance of PRC pipe pile in place of PHC pipe pile.

2. PROJECT OVERVIEW

The site is located on the east side of Binhai airport in Tianjin Binhai New Area. This land belongs to the coastal plain of the North China Sea, and has been deposited with huge sediment after several sea and land changes. According to the survey data, the soil layers in the region are all Quaternary, Holocene and upper Pleistocene sediments. The corresponding indicators of each soil layer in the horizontal direction are fine and low variability. The region is located in the Tianjin and Beijing handover area; it has relatively stable geological condition compared with conventional geology in coastal area. The end of the tested pile falls to the silt soil layer of the second continental layer (Quaternary, Holocene, lower river, alluvial facies, Q4 al). The soil compacting layer, only local area density in upper dense layer, stable distribution layer, the top elevation is-10.69~16.10m and the average elevation is -13.37m. General layer thickness is 1.2~7.5m, and the average thickness is 4.48m. The standard value of natural moisture content is 23.2%, eo=0.644, Es (0.1-0.2) =10.33MPa, the average standard penetration click the number N=24.7 hammer. The physical and mechanical properties and strength of the soil layer are better. It is judged to be a good bearing stratum at the end of pile.

3. MODEL ESTABLISHMENT

In this paper, ANSYS software is used for analysis. Because of the asymmetry of horizontal load, a full model is adopted. Solid45 element is used for modeling of soil structures, solid65 element is used for modeling of pile structures, link8 element is used for modeling of steel structures, targe170 element and conta174 element is used for the contact coefficient between pile and soil. The friction coefficient is 0.4. The contact type of pile and soil is plane contact, normal displacement. However, the relative sliding can occur when the friction contact is vertical.

Pile size: outer diameter 600mm, wall thickness 110mm, pile length 18m. Soil diameter is 10 times of pile diameter. The prestressed steel bars in the pipe pile adopt spiral channel bar with low tensile strength of not less than 1420MPa and ductility of grade 35(PCB-1420-35-L-HG). The prestressed reinforcement adopts 14Φ10.7 and prestressed under the load of 90kN. The non prestressed reinforcement adopts HRB400, and the stirrups are made of cold drawn low carbon steel wire, as shown in (Table 1).

| No. | Specimen Number |

Pile Diameter (mm) |

Wall Thickness (mm) |

Stirrup Diameter (mm) |

Prestressed Reinforcement |

Non prestressed Reinforcement |

|---|---|---|---|---|---|---|

| 1 | PHC | 600 | 110 | 5 | 14Φ10.7 | — |

| 2 | PRC-12 | 600 | 110 | 5 | 14Φ10.7 | 14Φ12 |

The PRC pipe pile is joined with the same number of non prestressed steel bars in the PHC pipe pile. In this paper, 14Φ12 non prestressed reinforcement is adopted, which is called PRC-12.

According to the geological survey report, the soil layer is divided into four layers and is designed according to the data of the survey report, as shown in (Table 2).

| Entry Name | Constitutive Model | Length (m) |

Modulus of Elasticity (MPa) |

Poisson’s Ratio | Density (Kg/m3) |

Cohesion (kPa) |

Internal Friction Angle (°) |

|---|---|---|---|---|---|---|---|

| Pile | Elastoplastic | 18 | 38000 | 0.20 | 2500 | ||

| Soil layer1 | Drucker-Prager | 5 | 9 | 0.31 | 1950 | 30 | 20 |

| Soil layer 2 | Drucker-Prager | 4 | 12 | 0.31 | 1782 | 10 | 30 |

| Soil layer 3 | Drucker-Prager | 9 | 30 | 0.31 | 1940 | 25 | 29 |

| Soil layer 4 | Drucker-Prager | 7 | 18 | 0.31 | 2040 | 50 | 10 |

4. MODEL VALIDATION

4.1. Loading Equipment

The horizontal bearing capacity test of single pile is carried out for prestressed pipe pile of PHC AB 60011018, according to “People's Republic of China industry standard” technical code for building pile foundations” (JGJ106-2014) [13]. One way multi cycle test was adopted and horizontal force was exerted by jack and steel beams and counterforce piles provide counterforce.

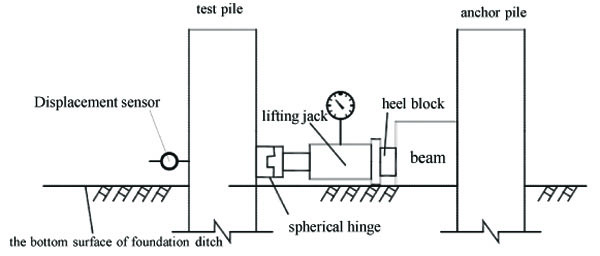

The testing system is controlled by loading system (500kN hydraulic jacks and oil pressure sensors) and displacement measuring system (waterproof and dustproof displacement sensor with range of 50mm). Loading and displacement data are recorded regularly according to the prescribed procedures. The schematic of the test equipment is shown in (Fig. 1).

4.2. Test Process

The horizontal static load test process of single pile is as follows:

- Loading classification: according to the standard requirements, each stage load is 1/10~ 1/15 of the horizontal ultimate bearing capacity, the test load of Φ600 pile is 25kN.

- Loading program and displacement observation: after applying load for four minutes, the horizontal displacement is recorded, and then unloaded to zero. After 2 minutes, residual horizontal displacement is recorded, thus completing a cyclic loading test. After 5 cycles, the test observation of the primary load can be completed.

- Termination test criterion: when the pile is broken or the horizontal displacement reaches 40mm, the horizontal displacement or maximum load reaches the design requirement.

The field test diagram is shown in (Fig. 2).

4.3. Test Result

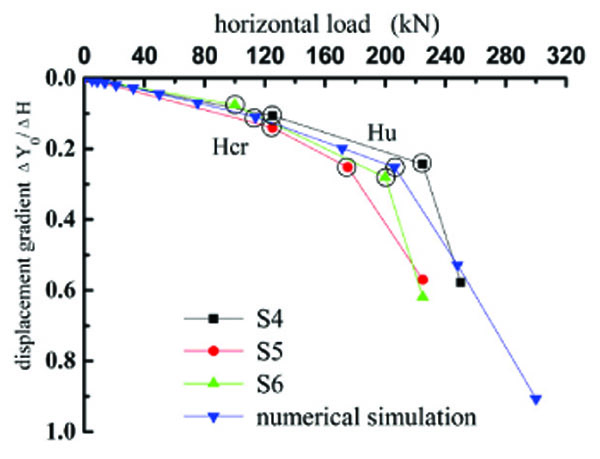

In this paper, three piles are used to test. When the S4 pile is loaded progressively to 250kN, the second cycle is completed, and the horizontal displacement exceeds 40mm. Continue loading to the third cycle, then the horizontal displacement reaches 53.21mm. At this point, abnormal sound emitted from the pipe pile. The integrity test shows that the pipe pile has been broken, so it stops loading. When the S5 piles are loaded up to 200kN, the displacement of horizontal displacement is 42.21mm, more than 40mm, so the loading is stopped and there is no fracture of pile at this time. When the S6 pile is loaded to 225kN, the horizontal displacement is 44.96mm, so the loading is stopped and there is no fracture of pile at this time.

Horizontal load-displacement gradient curve of numerical simulation is compared with that of the S4-S6 test pile, as shown in Table (3 and Fig. 3).

| Pile No. | Critical Load(kN) | Ultimate Bearing Capacity(kN) |

|---|---|---|

| S4 | 125 | 225 |

| S5 | 125 | 175 |

| S6 | 100 | 200 |

| numerical simulation | 114 | 206 |

The results of modeling and analysis are close to the measured results. Because the test of pile groups is difficult to achieve, this paper uses single pile test and simulation results to compare. In the following simulation, the pile group modeling uses the same soil layer and pipe pile parameters.

5. INTERNAL FORCR ANALYSIS OF PILE

5.1. Internal Force Analysis of Double Piles

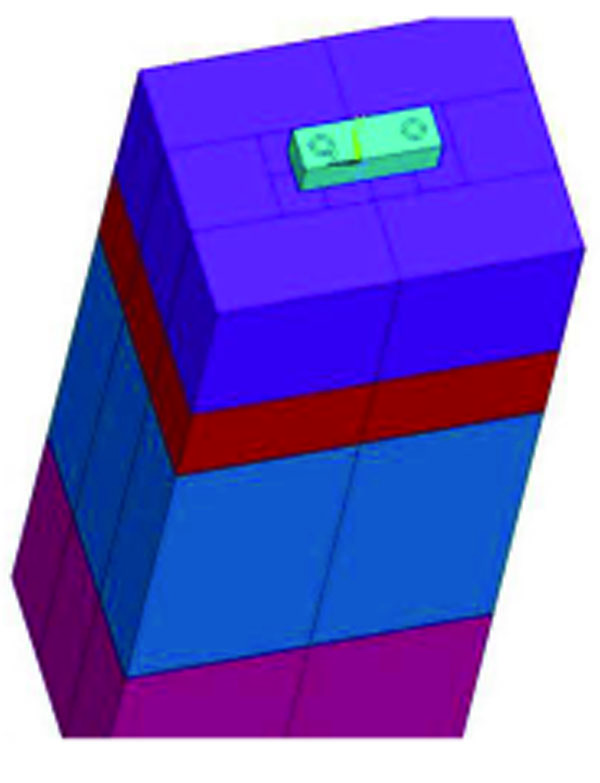

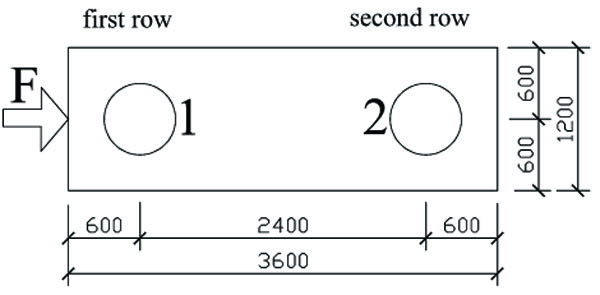

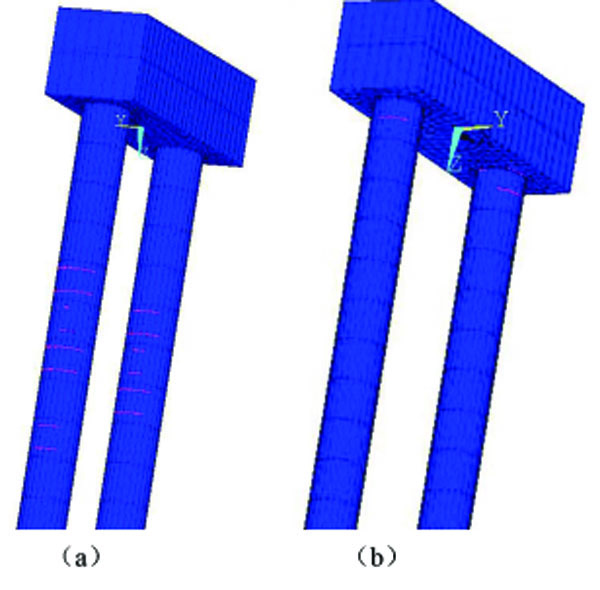

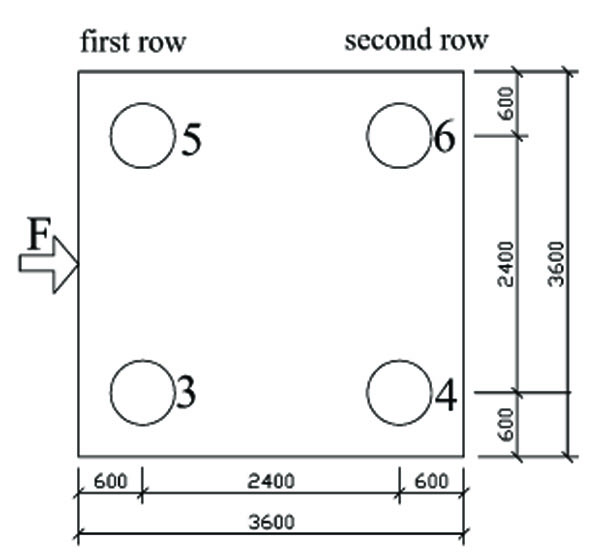

Fig. (4) is the double pile-soil model, and Fig. (5) shows the dimensions of the double piles and cap.

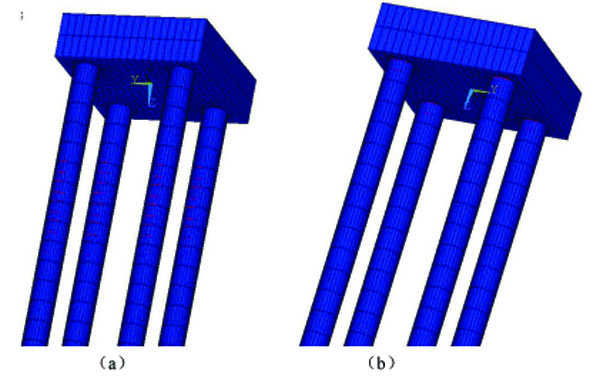

Fig. (6a) is the cracking location of the PHC pipe pile under the 250kN horizontal force. Fig. (6b) is the cracking of the joint between the pile cap and the pile top under the 400kN horizontal force. At the beginning of loading, the load of the pile cap of the pipe pile is transmitted to the pile body, the bending moment of pile body increases gradually, and then it is transmitted to the joint between the pile cap and the pile top. The two piles are cracked successively. With the increase of the force, the bending moment at the joint between the pile cap and the pile top increases, and then cracks. The ultimate maximum bending moment is 6 times of the pile diameter, and the bending moment at the joint of the cap is less than the moment of the pile body.

Since the internal forces of the two piles are very close, a single pile is chosen for comparison. No. 1 pile in the figure 5 is used in the following analysis.

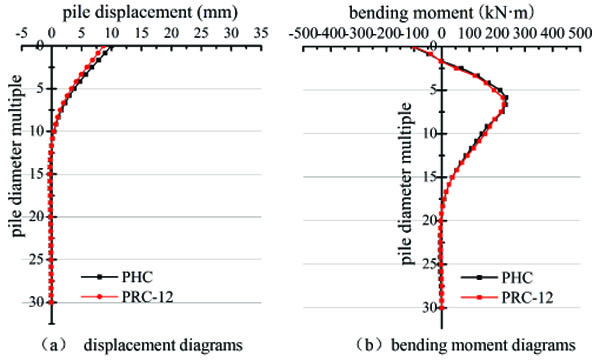

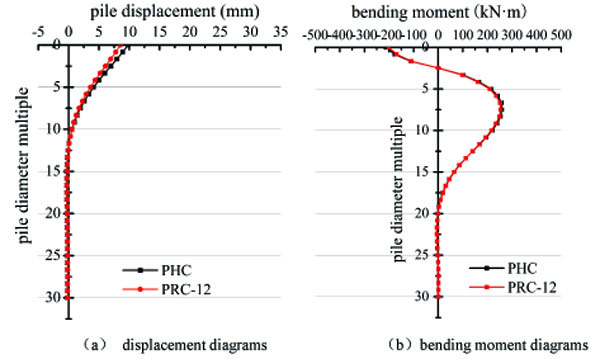

Fig. (7) shows the displacement and bending moment of the PRC-12 pipe pile and PHC pipe pile under the 250kN horizontal force. The maximum displacement of PRC-12 decreases by 10% compared to PHC, and the maximum bending moment decreases by 4.3%. The bending moment at the top of the pipe pile is basically unchanged. From the moment diagram, it can be seen that the pipe pile has just arrived at the cracking moment, and the non prestressed reinforcement has not begun to play its role.

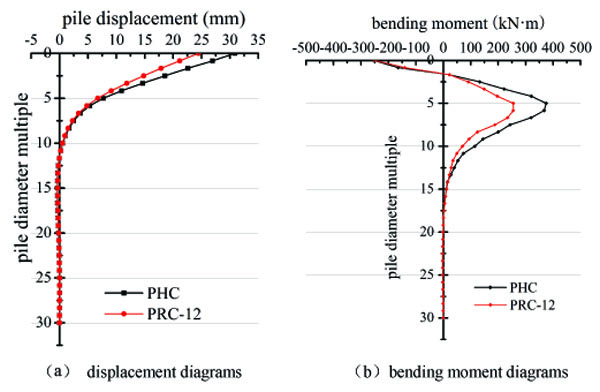

Fig. (8) shows the displacement and bending moment of the pile after the horizontal force increased to 400kN. It can be seen from the figure that the PHC pile has reached to the failure moment. Maximum displacement is decreased 12.9% after adding non prestressed steel pile. Moment of the pile cap and pile joint is reduced by 2.6% and the maximum bending moment of 6 times of the pile diameter is reduced by 31.9%. It can be seen that the increase of non prestressed steel bars has limited contribution to the bending moment at the joint between the pile cap and the pile body, and reduces the bending moment of the pile greatly.

5.2. Internal Force Analysis of Four Piles

Fig. (9) is the four pile-soil model, and Fig. (10) shows the dimensions of the four piles and cap.

Fig. (11a) is the cracking of a pile of four piles under the 450kN horizontal force, Fig. (11b) is the cracking at the pile cap of the four piles under the 750kN horizontal force. From Fig. (11) we can see the main cracks existing in the pile, the force acting on the four piles is the same as that of the two piles, the force at the joint of the cap is the biggest at the beginning of loading, and then it is transferred to the pile body. Pile cap cracks first, then cracks appear at top of the pile. Finally, the bending moment of the pile top is slightly less than the moment of the pile body.

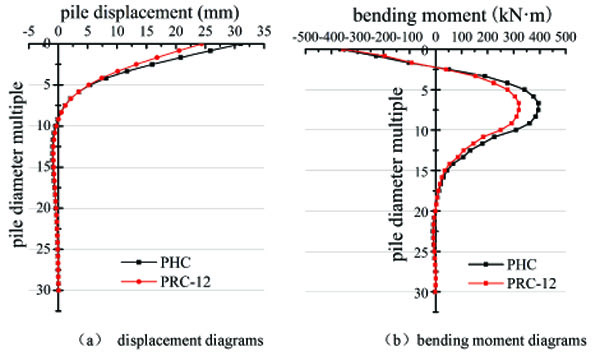

Fig. (12) shows the displacement and bending moment of the PRC-12 pipe pile and PHC pipe pile under the action of 450kN horizontal force. The maximum displacement of PRC pipe pile is lower by 9.2% than that of PHC pipe pile, and the maximum bending moment of pipe pile decreases by 2%. At this point, the pile has just cracked, and the non prestressed reinforcement has not yet played a role, so the non prestressed steel bar contributes little to the displacement and bending moment.

Fig. (13) shows the displacement and bending moment of the pile when the horizontal force is increased to 750kN. As can be seen from the graph, displacement and bending moment are obviously changed, the maximum displacement of PRC-12 pile is reduced by 9.4% and the maximum bending moment of pile cap is reduced by 19%. The bending moment at pile top is reduced decreases slightly. It can be seen that the increase of non prestressed bars can effectively improve the moment of pile body and make little contribution to the bending moment at the pile top.

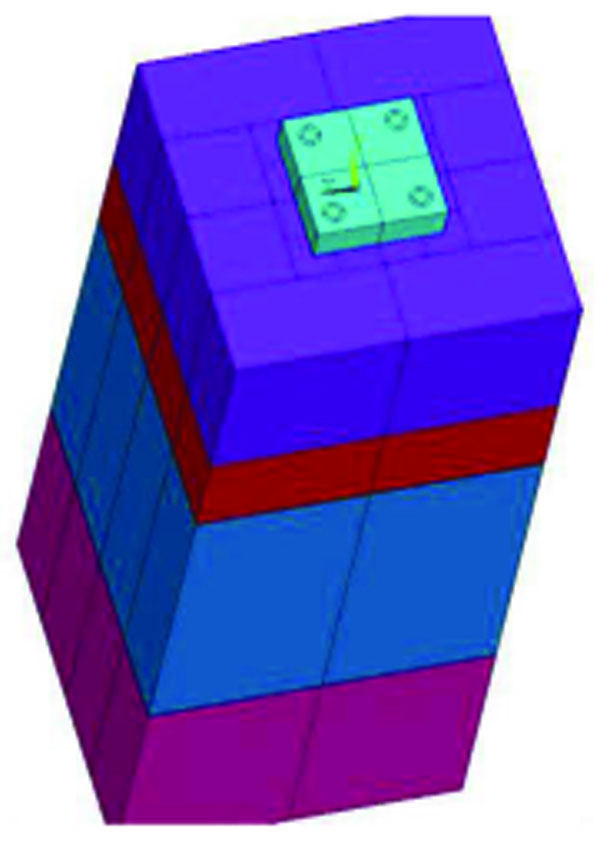

5.3. Internal Force Analysis of Nine Piles

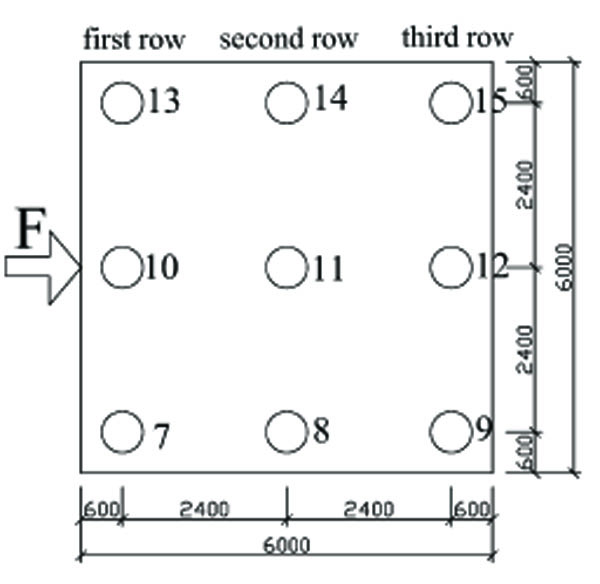

Fig. (14) is the nine pile-soil model, and Fig. (15) shows the dimensions of the nine piles and cap.

Fig. (16) shows the crack location of the nine piles at the 1500kN horizontal force. From the diagram, it can be seen that the crack exists mainly at the pile top. The process of nine piles is different from that of double piles or four piles. At the beginning of loading, the force at the joint of the cap is the largest and then it shifts to the pile. However, the moment of the pile is much smaller than the moment at the joint of the cap, and cracks appear at the joint between the pile cap and the pile top.

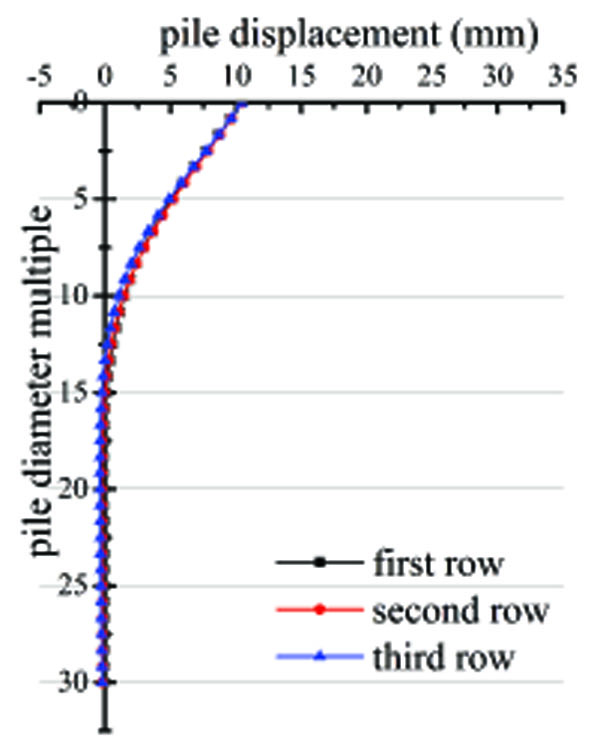

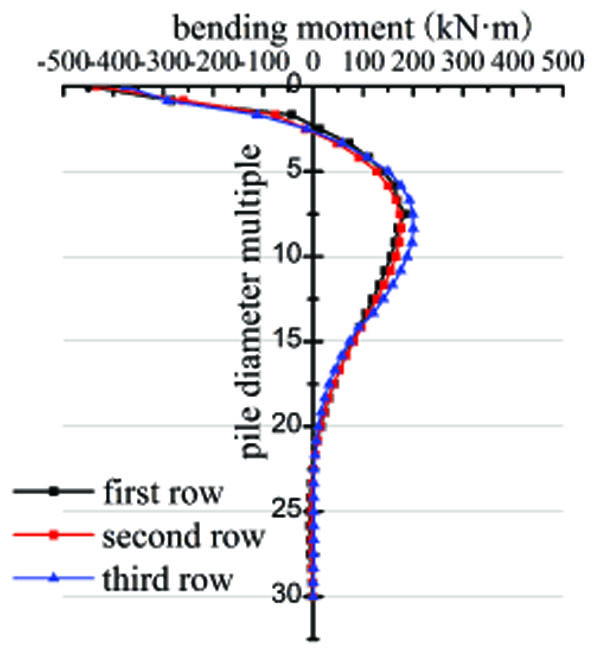

Figs. (17 and 18) show the displacement and bending moment of the three row piles in the nine piles under the 1500kN horizontal force. As can be seen from the diagram, the maximum horizontal displacement of each row of piles is basically the same. The reverse bending point of the third row piles is 13 times the diameter of the pile, and the second row is 15 times the diameter of the pile, and the first row is at 16 times the diameter of the pile. The maximum bending moment occurs at the pile top, and it is much larger than the bending moment of the pile body. The third row piles bear the greatest bending moment, while the first row and second row are basically identical. Compared to the first row, the moment of the third row is increased 18.4%. In the pile top, the moment of the first row of piles is basically identical with that of the second row piles; the third row of pile bending moment is minimum. The bending moment of the third row piles is 16.2% lower than that of the first row. When the bending moment of the cap joint has reached the breaking moment, the pile body is not cracked yet.

CONCLUSION

The numerical analysis shows that:

- Maximum force position of double piles is located at 5-8 times the diameter of the pile. The bending moment at the pile top is much less than the bending moment of the pile body. The maximum bending moment of the pile can be reduced effectively with the increasing of the non prestressed steel bar. Thus, when the pile is suddenly subjected to a large horizontal force load, the sudden failure of the pile due to insufficient carrying capacity can be avoided.

- Maximum force position of four piles is located at 5-8 times the diameter of the pile. The bending moment at the pile top is slightly less than the bending moment of the pile body. The maximum bending moment of the pile can be reduced effectively with the increasing of the non prestressed steel bar, but it can not reduce the bending moment at the pile top. Because the moment of the pile top of four piles is relatively large, it is necessary to strengthen the connection between the pile top and the pile cap.

- Maximum force position of nine piles is located at the pile top, and its bending moment is much larger than the moment of pile body. Therefore, for nine piles, the increasing of non prestressed reinforcement has no effect, so it is necessary to reinforce the connection between the pile top and the pile cap.

The main reasons for the above conclusion are as follows: when the pile top is the free end, the bending moment of the pile top is zero. When the pile top is the embedded end, the bending moment of the pile top is the greatest. The pile top constraint of the pile with cap is between free end and embedded end. With the increase of the pipe, the pile top constraint gradually changes from the free to the embedded, and the bending moment gradually moves from the pile body to the pile top.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGMENTS

Declared none.