All published articles of this journal are available on ScienceDirect.

Construction Material-Based Methodology for Contingency Base Selection

Abstract

Background:

Military and nonmilitary organizations need the capability to support their expeditionary forces by selecting a temporary base of operations that projects a minimal footprint and reduces logistical burdens. For example, strategically sited temporary bases anticipate impacts on the local context and its population of siting and operating temporary bases.

Objective:

This paper describes a methodology to assess the practicality of incorporating local construction materials when planning for contingency operations in a given region. While the assessment methodology was originally developed for military planners, the principles and methods are applicable to any organization that is considering building and operating temporary locations in foreign nations.

Method:

The methodology assesses factors such as population densities, main building types, geographical regions, port locations, railroad locations, road networks, airport locations, flood-risk areas, and construction materials. The methodology optimizes all factors to yield the best material-based solution for site selection. To demonstrate the developed methodology, two hypothetical case studies are described–Dhaka in Bangladesh for its high-population density and Maiduguri in Nigeria for its low-population density and potential for disruption.

Results:

This methodology provides a contingency site selection process that does not currently exist and will assist in the reduction of materiel demand, minimize footprint, and reduce the risk to personnel. The methodology captures factors such as population densities, main building types, geographical regions, port locations, railroad locations, road networks, airport locations, flood-risk areas, and construction materials and optimizes all factors to yield the best material-based solution for site selection.

Conclusion:

This methodology provides a contingency site selection process that does not currently exist for mission planners. It is designed to produce a methodology with a goal of developing a GIS-based decision support tool to assist in siting bases of operations.

1. INTRODUCTION

In an era of global responsiveness, there is a continuing need for agencies and organizations to set up temporary bases of operations in foreign nations. Examples include Ebola hospitals, refugee camps and processing centers, natural disaster response headquarters, and temporary military installations. In the military context, these temporary bases are called Contingency Bases (CBs). The methodology described in this paper was developed to assist the U.S. military in CB site selection to take maximum advantage of local building resources [1, 2]. The principles and methodology, however, are applicable to any organization that is looking to build and occupy temporary operational locations in foreign nations under consideration.

Traditionally the challenges of setting up CBs have been viewed in terms of logistics, with planners determining whether to ship in all materials or to purchase materials locally based on what would be easiest or most cost effective. Often CB planners and builders are limited in their decision making choices by regulations and restrictions. For example, the U.S. military is required to build structures within CBs to U.S. building safety codes and not local standards [3]. Another impediment is simply not knowing what resources might be available through the local economy. As a result, planners often attempt to stream line the process by shipping all material and equipment needed to construct CBs to the deployment site [4]. If you bring in everything, then you know that you have everything you need. The result is often long and expensive supply chains, structures that stand out as separate on the landscape, and structures that cannot be used and/or maintained by the local population once the builders have left.

There are advantages, however, to building CBs with local resources. By procuring materials locally, an extended supply chain does not need to be maintained and defended. Local materials are often more cost efficient and available in less time than globally transported materials. Purchasing locally and leaving behind structures that can be used and maintained by the indigenous population can improve the economic outlook and sentiment of the local community. There are of course disadvantages to relying on local construction. The available material may not exist in type, quantity, or quality sufficient to meet the construction requirements. If materials are not available in sufficient quantity, the construction and maintenance needs of the CB may overwhelm the local resources and affect the availability of materials for the local population, which will affect local sentiment in turn.

The decision whether to import all construction material, to build entirely of local materials, or to purchase a combination of imported and local materials is a strategic decision. The outcome will affect construction costs, maintenance costs, security of the facility personnel, and the local sentiment towards the CB occupants. Poor decision making during the planning and construction phase of a CB can compromise the mission’s success. The worst possible situation is for these critical decisions to be made ad-hoc during CB construction in the field.

Ideally, planners would have a tool that would enable them, prior to personnel deployment, to analyze available online information about what resources are present and what physical, socioeconomic, or political barriers might limit or prohibit access to those resources. Applying this decision-making methodology on a regional scale will allow planners to select the best CB site location to maximize the use of local resources, meet the mission needs, and simultaneously minimize potential negative impacts on the local population. The methodology presented here was developed to include those factors and provide planners with a needed tool.

2. BACKGROUND

The U.S. Army requires units that are trained, equipped, organized, and prepared for rapid deployment to anywhere in the world and that can respond to a full spectrum of missions including conflict, peacekeeping, humanitarian assistance, disaster relief, and civil affairs. To meet this requirement, the army is developing rapidly deployable modular forces that can immediately and effectively begin working toward their mission goals and can sustain their presence for an unknown length of time [5, 6].

CBs differ significantly from permanent military installations in the United States, Europe, and some Asian nations or from the large Forward Operating Bases (FOBs) that were developed during recent conflicts in Iraq and Afghanistan [7]. CBs must be capable of rapid expansion and contraction in their size and manpower. They may utilize existing structures, custom-built structures, temporary structures, or even tents. CBs may have little or no access to local utilities or infrastructure as a result of either a hostile local population or a lack of these resources at the CB site. The terms of occupation of a CB are variable and indeterminate, and personnel often lack continuity. Finally, CB sites more often contain military units whose missions are more dynamic and variable then those of larger installations or FOBs.

Initial site surveys (including environmental impact surveys), construction techniques, and removal or hand over of real property are guided by the U.S. Army regulations, guidance documents, and federal laws [8-10]. The result is that some construction techniques or materials (e.g., rammed earth or adobe brick construction), are not within the choices available to site planners. There is some room within the regulations for modification and adaptation of standard plans to fit the local conditions [9], but field engineers do not often take advantage of these opportunities. As a result, there is a tendency for CB sites to follow American patterns of construction and layout regardless of the mission benefits of adapting to the deployment region.

CBs and similar facilities cannot be analyzed in a vacuum. Their operating environment consists of the totality of the natural and built environments as well as local and regional sociocultural systems. Any insertion of a significant amount of manpower, resources, and currency into an area will have social impacts on that environment, at both individual and collective scales [11]. Aspects of social impacts that must be considered [7, 12, 13]:

- Daily life – to include peoples’ access to and free movement around their residences, workplaces, places of recreation and socialization, places of worship, places of commerce, and the transportation and communication networks that connect them all.

- Political systems – to include the people’s ability to access and participate in local, regional, and national governments, and to be secure in their personal rights; and the government institutions’ abilities to provide services to the population (including security, judiciary, and social welfare services) at levels equal to or exceeding those prior to CB construction.

- Economic systems – to include peoples’ ability to provide for their wellbeing and subsistence, and the project’s effects in property rights, market and currency stability, and the supply and demand for goods and services.

- Environment – to include issues of the quantity and quality of food, water, and sanitation, and the access and control of natural resources.

- Population wellbeing – to include all questions on the population’s health, safety, and quality of life, whether real or perceived.

- Sociocultural systems – to include questions on the community’s stability and cohesion as well as individual and group beliefs, customs, values, traditions, and language.

Failure to properly consider the social impacts of a CB site’s selection, construction, operation, and transfer or closure can affect the local population to the extent that the site’s mission and personnel’s security may be impacted or compromised. U.S. military deployments to Iraq and Afghanistan in recent decades have provided numerous examples where high levels of negative social impacts generated by FOBs and CBs have led to hostile attitudes directed toward the bases’ inhabitants and to increased insurgency activity and support [13-15].

One way to reduce negative social impacts is to have as complete an understanding as possible of the situation that will be entered t the site. Department of Defense guidance for CB site preplanning focus, however, has focused primarily on the impact to the physical environment [16, 17]. In recent years, however, army researchers have been developing an entire suite of tools to allow for optimal forward planning. The methodology proposed here is one of those tools, and it will allow the user to analyze the availability of local building materials and manpower, and then to determine how much of both can be procured on site.

When looking at the social impacts of CB construction, there are several questions that must be addressed, as listed below [13]:

- How much and what type of material is available in the immediate area and in the surrounding region?

- How is quality control to be maintained on materials?

- What is the availability of labor in the project area?

- Are the transportation networks needed to move material sufficient to the task?

- Will the construction negatively affect the available supply of construction material for the local population?

- How will the construction affect the local economy, both positively and negatively, through the related influx of currency and available work?

- Can the design of the structures and construction techniques be applied to maximize potential use of the structures by the local population after the CB site has been returned to local control?

- Can the construction be conducted to maximize partner building capacity?

These questions may be answered once the team is at the site, but such a situation is the worst-case scenario. If construction teams assume that the necessary material will be available and it is not, then the mission may suffer due to inadequate facilities. If the CB site monopolizes all available local resources to the detriment of the local population, hostile sentiment may be generated or exacerbated. If all construction material is shipped into the site, the CB may not be optimally configured to the local environment. A CB site constructed entirely of alien material and techniques will often be unusable to the local population once the original inhabitants have left. The recent U.S. experiences in Iraq and Afghanistan are rife with examples of American-planned structures that were completely unused or had to be expensively retrofitted after U.S. forces turned the sites back to the host nation [7].

In addition to minimizing negative social impacts, careful consideration of local availability has the potential to save significant costs for the constructing nations, freeing up resources that can be reapplied to the mission’s goals. Construction and maintenance of a CB can be an extremely expensive proposition. A 2008 example of the costs that a CB can incur included $259,200 for gravel and $127,000 for electrical supplies such as cables, breakers, and switches [18]. The U.S. Army has established a Force Provider System, which is a transportable system that provides basic life support areas (including housing, foodservice, hygiene services and some medical and moral supporting services) for CBs of various sizes. It has been demonstrated that the logistical support cost of a Force Provider System that supports 600 people ranges from $40 million to $80 million per year, depending on system’s deployment location [19]. If local materials and resources could be accessed, it is estimated that operational costs could be decreased by 5%–10% per year, with a total expected cost saving of $2 million to $8 million per year for each 600-person CB [7].

Preplanning the construction needs of a CB site is essential. A regional analysis of the quantity and quality of available construction material will allow CB site planners to determine how much the local economy may be relied upon to support the construction effort [1, 2]. Consideration of local resources in conjunction with transportation and support networks may even assist in selecting an appropriate location on the landscape to position the CB. CB sites also may be located near resource hubs and away from major transportation nodes such as ports and airports, further minimizing the CB’s potential disruptive impact on the local population.

The methodology developed provides a process for general regional assessment of the practicality of incorporating local construction materials when planning for contingency operations. The exercise was developed under the U.S. Army Corps of Engineers (USACE) program to support in-theater Army operations [1, 2]. As a result, methodologies were chosen that best align with Army decision-making processes. The chosen methodologies merge aspects of multi-criteria decision-making methodologies and the Army’s Military Decision Making Process (MDMP) [20]. Analysis for decision making is then performed by selecting a relevant set of influencing parameters and processing them based on their observed impacts on the outcome. This methodology provides a CB site-selection process that does not currently exist for mission planners. The methodology outlines a site-selection process in terms of accessibility of construction resources and based on CB location, transportation networks, population densities, and available centers of materials.

3. METHODOLOGY

Site-selection methodologies are expected to merge into a unified approach in which all relevant factors are addressed, analyzed, and optimized to select the best site for military missions.

Since every location in a particular region is unique in many aspects, a single general methodology would not work well because it would not capture all variables specific to the region under consideration [1, 2]. In rare cases, methodologies can be identical; however, the methodology is more likely to have some variations. The approach may be the same, but the methodology should be modified to suit other, similar geographical areas. However, it is critical in any case to identify the relevant set of variables that must be reflected in the adopted methodology. During the planning stage of any mission, a preparation study is required to finalize a methodology suitable for the mission.

3.1. Regions

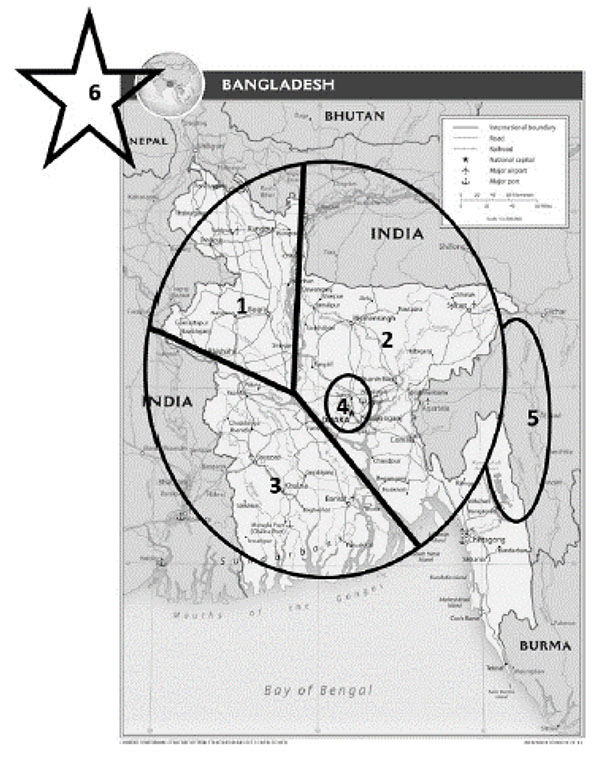

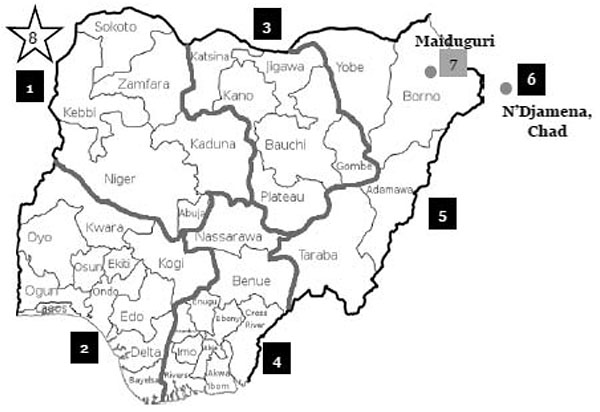

Certainly, site selection in any region is influenced by the layout of the land. An important component of any site-selection methodology is population density and regions within the country. If there are predetermined provinces or divisions, as is the case of Bangladesh, it is recommended that these are used as the main regions of analysis [1]. However, if there are no country-wide divisions, as is the case for Nigeria, it is suggested that major regions are determined by the population densities of the region [2]. These divisions should be based off high-, medium-, and low-density regions.

As previously mentioned, the major regions of Bangladesh are country-wide major divisions. The major regions of Nigeria were determined by analyzing the population densities of the region. Nigeria was divided so that there were two high-density regions (Region 2: Southwest and Region 4: Southcentral), one medium-density region (Region 3: Northcentral) and two low-density regions (Region 1: Northwest and Region 5: Eastern).

For site selection in or near the vicinity of a region of interest, the first requirement is to determine the boundaries so that the effective area can be isolated with minimum effects from adjacent areas. The following effective areas in Table 1 wasconsidered for simplicity and accuracy of this analysis:

| Case study region | Dhaka, Bangladesh | Maiduguri, Nigeria |

|---|---|---|

| City effective region | Dhaka | Maiduguri |

| Country effective region | Bangladesh | Nigeria |

| Cross-country effective region | Bangladesh and adjacent parts of India | Nigeria and adjacent parts of Cameroon and Chad |

| Cross-countries effective regions | Bangladesh and nonadjacent countries with heavy trade | Nigeria and nonadjacent countries with heavy trades |

Each region has a special level of interaction that affects the flow of construction materials that can be delivered. The aforementioned definitions of effective areas will help determine a particular region’s methodology. It was determined that the country of Bangladesh can be further subdivided into three main regions by using the rivers within the country, whereas Nigeria is sufficiently subdivided with just the six main regions that would be considered in the analysis [1, 2].

The rivers were used to divide the country of Bangladesh into sections because water barriers limit much of the trade and business actions within the country. For purposes of this construction material case study, there are three other regions considered. The first is the main city under consideration, which in this case is Dhaka. The next region is an adjacent country’s largest nearby city, which is Agartala, India. Lastly, the final region to be considered is a nonadjacent country that is a heavy trade partner with the country or city under consideration for CB location. For the purposes of this case study, it was determined that there was no heavy trade partner [1].

The density of the region of Nigeria meant that Nigeria itself was divided into five sections, since people control the activity of a country. For the purposes of this case study, three additional regions were considered. The first additional region is the main city under consideration—Maiduguri. The next region is an adjacent country’s largest nearby city—N’Djamena, Chad. Lastly, the final region to be considered is a nonadjacent country that is a heavy trade partner with the country or city under consideration for base selection. For the purposes of this case study, it was determined there was no heavy trade partner [2].

Hence, the regions analyzed for the two case studies are classified per Table 2 as:

| Case Study Region | Dhaka, Bangladesh | Maiduguri, Nigeria |

|---|---|---|

| Region 1 | Northwest Bangladesh | Northwest Nigeria |

| Region 2 | Southwest Bangladesh | Southwest Nigeria |

| Region 3 | Northeast and southeast Bangladesh | Northcentral Nigeria |

| Region 4 | Dhaka, Bangladesh (subset of region 2) | Southcentral Nigeria |

| Region 5 | Neighboring country’s largest nearby city – Agartala, India | Eastern Nigeria |

| Region 6 | Heavy trade partner with nonadjacent region (not applicable for this case study) | Neighboring country’s largest nearby city – N’Djamena, Chad |

| Region 7 | Not applicable | Maiduguri, Nigeria (subset of Region 5) |

| Region 8 | Not applicable | Heavy trade partner with nonadjacent region (not applicable for this case study) |

3.2. Building Types

The Federal Emergency Management Agency (FEMA) classifies 15 different main types of buildings. These building types must be examined in order to properly evaluate a region’s construction material availability and feasibility, based on the needs of each structure type. The various building types and their respective key properties are described in Table 3 and in the FEMA National Earthquake Hazards Reduction Program (NEHRP) Handbook for Seismic Evaluation of Existing Buildings [23].

| Ranking | FEMA building type, from most suitable to least suitable | |

|---|---|---|

| Bangladesh | Nigeria | |

| 1. | 13. Reinforced Masonry Walls - Flexible | 15. Unreinforced Masonry Walls |

| 2. | 1. Wood Light Frame | 13. Reinforced Masonry Walls – Flexible |

| 3. | 15. Unreinforced Masonry Walls | 1. Wood Light Frame |

| 4. | 2. Wood Frames, Commercial, and Industrial | 2. Wood Frames, Commercial and Industrial |

| 5. | 10.Concrete frames with infill Masonry Walls | 3. Steel Moment Frames |

| 6. | 7. Steel Frames with Infill Masonry Walls | 14. Reinforced Masonry Walls – Stiff |

| 7. | 14. Reinforced Masonry Walls – Stiff | 8. Concrete Moment Frames |

| 8. | 5 .Steel Light Frames | 7. Steel Frames with Infill Masonry Walls |

| 9. | 4. Steel Braced Frames | 11. Precast/Tilt-up Concrete Shear Wall Buildings |

| 10. | 3. Steel Moment Frames | 5. Steel Light Frames |

| 11. | 6. Steel Frames with Concrete Shear Walls | 12. Precast Concrete Frames |

| 12. | 11. Precast/Tilt up Concrete Shear Wall Buildings | 10. Concrete Frames with Infill Masonry Walls |

| 13. | 8. Concrete Moment Frames | 9. Concrete Shear Walls |

| 14. | 9. Concrete Shear Walls | 6. Steel Frames with Concrete Shear Walls |

| 15. | 12. Precast Concrete Frames | 4. Steel-Braced Frames |

Overall, the 15 different buildings types have different construction methods and materials, both of which must be taken into account when determining the most suitable building type for a particular region [24]. These classifications are in terms of vertical structural members that resist lateral loads and are applicable to this methodology.

As stated previously, the importance of these building types must be examined to properly evaluate a region’s construction material needs and feasibility, based on structure type. Table 3 provides a ranking of the 15 building types’ importance in terms of which are most and least suitable for the Bangladesh and Nigeria regions, respectively.

For the Dhaka region in Bangladesh, it was determined that, due to the availability of construction resources as well as conditions within the country, reinforced masonry walls – flexible (Building Type 13), wood light frames (Building Type 1), and unreinforced masonry walls (Building Type 15) are the most suitable FEMA building types.

For the Maiduguri region in Nigeria, it was determined that, due to the availability of construction resources as well as conditions within the country, unreinforced masonry walls (Building Type 15), reinforced masonry walls – flexible (Building Type 13), and wood light frames (Building Type 1) are the most suitable FEMA building types for this case study region.

3.3. Effective Proximity Factor

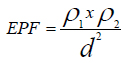

The next parameter to be considered in the methodology is the effective proximity factor (EPF) [1, 2]. This rough estimate of the influence that neighboring regions have on each other was found by using the formula below, since the combination of two neighboring regions’ population density and proximity play an important role for each respective region. It was determined that the larger the magnitude of the EPF between two regions denotes the greater influence they have on each other.

where: d is the distance between two regions in kilometers, and ρ1 and ρ2 are the density of the two regions, given in km/sq km.

Table 4 (Bangladesh) and Table 5 (Nigeria) provide the EPFs between all regions in the two case studies. Overall, the analysis demonstrates that the greater the density in each region and the closer that two regions are to each other, the greater is the EPF.

| First Region Name | Second Region Name | Density of First Region (people/sq. km) | Density of Second Region (people/sq. km) | Estimated Distance between Regions(km) | Effective Proximity Factor |

|---|---|---|---|---|---|

| Rangpur | Rajshahi | 967.6 | 1,015.8 | 120 | 68.30 |

| Rangpur | Dhaka | 967.6 | 1,772.8 | 230 | 32.40 |

| Rangpur | Mymensingh | 967.6 | 1,039.9 | 165 | 37.00 |

| Rangpur | Sylhet | 967.6 | 12,596.0 | 280 | 155.50 |

| Rangpur | Khulna | 967.6 | 704.4 | 330 | 6.26 |

| Rangpur | Barisal | 967.6 | 626.1 | 360 | 4.67 |

| Rangpur | Chittagong | 967.6 | 841.6 | 460 | 3.85 |

| Rangpur | Agartala | 967.6 | 6,831.0 | 300 | 73.40 |

| Rajshahi | Khulna | 1,015.8 | 704.4 | 205 | 17.00 |

| Rajshahi | Dhaka | 1,015.8 | 1,772.8 | 165 | 66.10 |

| Rajshahi | Mymensingh | 1,015.8 | 1,039.9 | 185 | 30.90 |

| Rajshahi | Sylhet | 1,015.8 | 12,596.0 | 340 | 110.70 |

| Rajshahi | Barisal | 1,015.8 | 626.1 | 260 | 9.41 |

| Rajshahi | Chittagong | 1,015.8 | 841.6 | 400 | 5.34 |

| Rajshahi | Agartala | 1,015.8 | 6,831.0 | 280 | 88.50 |

| Khulna | Dhaka | 704.4 | 1,772.8 | 145 | 59.40 |

| Khulna | Barisal | 704.4 | 626.1 | 90 | 54.40 |

| Khulna | Mymensingh | 704.4 | 1,039.9 | 235 | 13.30 |

| Khulna | Sylhet | 704.4 | 12,596.0 | 330 | 81.50 |

| Khulna | Chittagong | 704.4 | 841.6 | 240 | 10.30 |

| Khulna | Agartala | 704.4 | 6,831.0 | 210 | 109.10 |

| Mymensingh | Dhaka | 1,039.9 | 1,772.8 | 85 | 255.20 |

| Mymensingh | Sylhet | 1,039.9 | 12,596.0 | 145 | 623.00 |

| Mymensingh | Barisal | 1,039.9 | 626.1 | 230 | 12.30 |

| Mymensingh | Chittagong | 1,039.9 | 841.6 | 305 | 9.41 |

| Mymensingh | Agartala | 1,039.9 | 6,831.0 | 135 | 389.80 |

| Dhaka | Sylhet | 1,772.8 | 12,596.0 | 180 | 689.20 |

| Dhaka | Barisal | 1,772.8 | 626.1 | 140 | 56.60 |

| Dhaka | Chittagong | 1,772.8 | 841.6 | 230 | 28.20 |

| Dhaka | Agartala | 1,772.8 | 6,831.0 | 80 | 1,892.20 |

| Barisal | Chittagong | 626.1 | 841.6 | 155 | 21.90 |

| Barisal | Sylhet | 626.1 | 12,596.0 | 280 | 100.60 |

| Barisal | Agartala | 626.1 | 6,831.0 | 155 | 178.00 |

| Sylhet | Chittagong | 12,596.0 | 841.6 | 285 | 130.50 |

| Sylhet | Agartala | 12,596.0 | 6,831.0 | 130 | 5,091.30 |

| Chittagong | Agartala | 841.6 | 6,831.0 | 140 | 293.30 |

| First Region No. and Name | Second Region No. and Name | Density of First Region (people/sq. km) | Density of Second Region (people/sq. km) | Estimated Distance between Regions(km) | Effective Proximity Factor |

|---|---|---|---|---|---|

| 1. Ondo | 2. Oshiri | 221.4 | 267.5 | 350 | 0.48 |

| 1. Ondo | 3. Tsauni | 221.4 | 93.5 | 475 | 0.09 |

| 1. Ondo | 4. Miya | 221.4 | 182.8 | 690 | 0.09 |

| 1. Ondo | 5. Damboa | 221.4 | 57.6 | 980 | 0.01 |

| 1. Ondo | 6. N'Djamena | 221.4 | 28.2 | 1,255 | 0.004 |

| 2. Oshiri | 3. Tsauni | 267.5 | 93.5 | 605 | 0.07 |

| 2. Oshiri | 4. Miya | 267.5 | 182.8 | 570 | 0.15 |

| 2. Oshiri | 5. Damboa | 267.5 | 57.6 | 775 | 0.03 |

| 2. Oshiri | 6. N'Djamena | 267.5 | 28.2 | 1,035 | 0.01 |

| 3. Tsauni | 4. Miya | 93.5 | 182.8 | 425 | 0.10 |

| 3. Tsauni | 5. Damboa | 93.5 | 57.6 | 745 | 0.01 |

| 3. Tsauni | 6. N'Djamena | 93.5 | 28.2 | 1,000 | 0.003 |

| 4. Miya | 5. Damboa | 182.8 | 57.6 | 320 | 0.10 |

| 4. Miya | 6. N'Djamena | 182.8 | 28.2 | 585 | 0.02 |

| 5. Damboa | 6. N'Djamena | 57.6 | 28.2 | 270 | 0.02 |

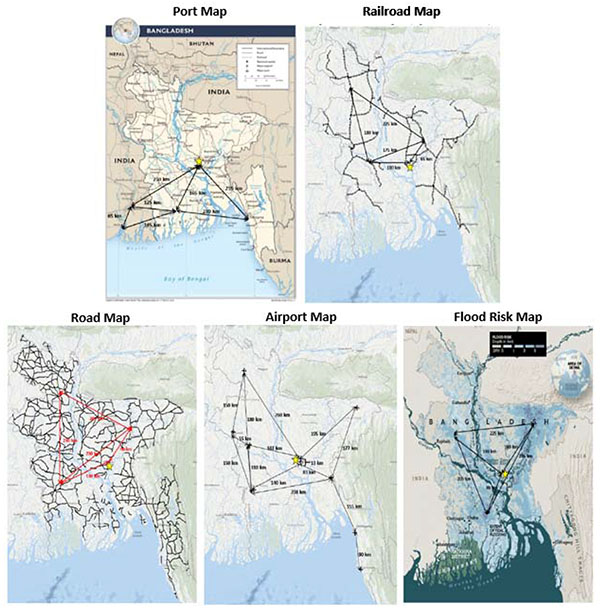

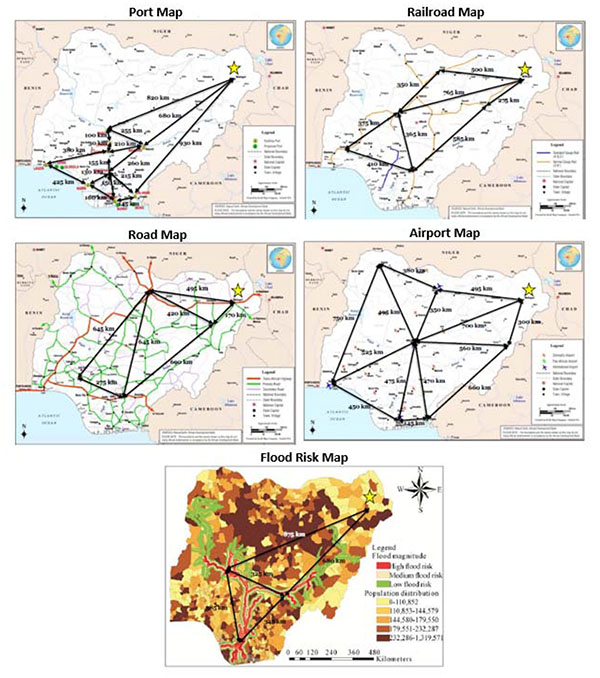

3.4. Infrastructure

The next parameters examined were the travel infrastructure, other necessary infrastructure parameters to transport construction materials (i.e., ports, railroads, roads, and airports), and other essential parameters (i.e., flood risk) for CB construction within each case study [1, 2].

The locations and distances between the major water course ports, centers of railroads and roadways networks, major airport facilities, and centers of high flood-risk areas in Bangladesh and Nigeria were each determined through the steps described here. First, the types and layout of infrastructure in the respective country were determined. Next, the distance between each infrastructure center was determined with respect to the main region being analyzed (Bangladesh and Nigeria). Once the distances between the infrastructure centers were determined, the results were examined to understand the ease of transport of construction materials within the respective region. The port, railroad, road, airport, and flood-risk maps are provided in Figs. (3 and 4) for Bangladesh and Nigeria, respectfully.

3.5. Centers of Construction Resources

3.5.1. Data Collection

Data collection and research of materials used to produce concrete and cement were limited to those directly involved in production process. Secondary materials used to produce raw materials were disregarded. For the case of natural resources (e.g., aggregate for use as a construction material), research was conducted on resources that are currently being exploited, along with reserves of these materials. If the reserves were present in a particular area, they were included in the collected information. The research for wood was limited to companies who sell wood products directly. That is, locations of where companies obtain various wood products were not determined. There were also assumptions made based on available information of raw materials. Whether or not these materials are suitable for construction purposes was absent from a number of sources, which may lead to extraneous collected information.

Three different types of spatial data were collected for each of the construction materials of interest [1, 2], as listed here:

- The first type of data is specific and of exact site locations. This latitude-longitude coordinate pair will spatially represent what it describes with precision. However, because the preciseness of material sites may vary based on available information, some information may be limited to a much broader area such as a city or a region, which is what the second type of data aims to represent.

- The second type of data is approximate locations of individual sites based on limited information. If information on individual sites was not provided, but data representing a larger area was given, then the third type of data was used. It is also important to note that point data were used to capture lines and shapes in addition to specific locations, with the lines and shapes being of greater concern for geographical areas of interest such as mountains or rivers. In those cases, a single pinpoint may not accurately represent the data. In some cases, multiple approximate pinpoints were used when expressing the location.

- The third type of data is a cluster of sites that represent the characteristics of what is contained within the region. Cluster sites are also created based on research information for each material, to quantify the behavior of the industry within centers of activity.

The extent of research on spatial data for countries and their surrounding countries was limited to the extent of available information. For instance, because of differences in the political system for each country, the availability of government information on products and raw materials may vary.

Cement suppliers were established by using a cement industry sector search through Google’s search engine. For Nigeria, information about the prominent companies and locations of their plants was determined from a series of articles and Nigerian government sources. A similar approach was used for the surrounding countries’ cement industries, for which media articles provided names of major players in the industry. Additional companies were found by using a Google Maps search for cement. For each resource, the locations were then validated by using company websites, Google Maps, Wikimapia, and geographic information source (GIS) data from the U.S. Geological Survey (USGS).

One of the major sources of spatial data and company identification was Google Maps. Searches for materials using Google Maps unveiled various established locations including corporate offices, plants, and mines. Precise coordinates of sites are reliable through this approach; however, the accuracy for smaller-scale company sites was somewhat questionable because data was usually limited to a name and a location. If these sites did not visually represent what was described, then the data was disregarded. This method was used for all materials except natural resource deposits such as aggregates, iron ore, and limestone.

Wikimapia was also used to obtain spatial data for plants and mines. Through this method, boundaries of sites are clearly identified using the maps, and this method usually presented more search results than Google Maps. The category of “production” was selected from the menu, which helped filter the points of interest. Similar to Google Maps, precise coordinates were very reliable, but smaller-scale company locations were limited in information and researchers’ judgment was used as to whether data was pertinent to include. This method was used for all materials except aggregates, wood, and ready-mix concrete (RMC).

GIS data resources were used for spatial data of mines, deposits, and (very minimally) for plants. The USGS provided most of this information through a number of databases. The data itself was very plentiful, yet it was deemed unreliable. Many of the locations did not fully reflect what was described by the data. However, due to the number of data points and clusters of points, it was still possible to determine centers of activity. This method was used for all natural resource deposits.

After spatial data sources were exhausted, company websites were used to fill in the gaps in data and to find remaining locations of material sites. The amount of information provided on a company website varied significantly. However, almost all of the company websites list corporate offices and a significant portion provided plant locations. A fair number of company websites provide addresses, which were untraceable in Google Maps, and so approximations for locations were made. Other pertinent data was found using these websites, including capacity, quality, product, employees, and power usage. A number of the larger-scale companies produce multiple construction materials; therefore, data overlapped for various construction materials. This method was used for cement, RMC, steel, and some raw material.

Lastly, material supplier directories were utilized for additional information. For some directories, networks such as CemNet1 for cement or Fordaq2 for timber, data was reliable but was limited to companies that are a part of the particular collection. Other directories proved to be very unreliable since many of companies listed may represent another line of work, such as material traders, or they may be out of business. It proved to be impossible to validate this information because company websites or other reliable sources were unavailable. The company addresses listed were also unreliable and varied across multiple directories. This method was used as a last resort, but it was used extensively for timber and somewhat used for cement and RMC.

For RMC, an initial collection of factories within Nigeria and Dhaka, respectively, was located through using any available published resources about the material industry sector. Corporate offices and additional batching plant locations were located through company websites. The office locations were typically available and may even coincide with those in the cement industry. However, most of the data on batching plants was not available, or only a region was provided for the plant location. Additional plants were found by using a Google Maps search for RMC plants, which provided exact locations for a number of companies.

Determination of a majority of the aggregate and wood/lumber suppliers was made through online government databases from each of the respective countries. The online sources contained information regarding locations where a given company had a mining title and/or permit within Bangladesh or Nigeria. Lastly, information about raw materials and minerals in the country was investigated by using the USGS Minerals Yearbook.3

The above steps developed a method of data collection that has a high level of reproducibility and has provided the most current information about suppliers [1, 2].

3.5.2. Bangladesh

As part of the research on the construction material industry in Dhaka, determining what geographical spatial data is pertinent to include in the study was investigated [1]. The regions of interest for each raw and fabricated material were decided based on assumptions of how the material is transported and what data was feasible to collect. The regions of interest and study areas for each construction resource are shown in (Table 6).

| Industry | Region of Interest | Reason for Study Region |

|---|---|---|

| Cement, aggregate, steel, iron ore/ recycled steel | Bangladesh, northeast India, and Myanmar | Key players can be easily assessed within study area |

| Wood, masonry | Bangladesh | Larger number of producers |

| Ready-mix concrete | Dhaka region | Time-sensitive product |

For instance, RMC is a time-sensitive product that is used within a short distance of its source. Therefore, the study for the material was limited to the city of Dhaka. Cement, aggregate, steel, and iron ore were given a much wider area of interest that includes all of Bangladesh as well as the bordering countries of India and Myanmar. The studies on timber and masonry were limited to the country of Bangladesh due to the exceedingly large number of fabricators within the country (more than 5,000 producers for each industry).

Due to the size of India, the study was limited to the eastern and northeastern regions under the assumption that most trade and general interaction with Bangladesh is within close proximity to the country.

3.5.3. Nigeria

The region of interest for construction materials is one of the most important factors when determining what materials are plausible for construction purposes. Methods of transportation were used to determine the region boundaries for each construction material and the respective constituents [2].

For example, since RMC is concrete that is manufactured and batched in a plant off-site of the actual construction process, a short distance range was used as the boundary. As a result, the analysis of the RMC market was conducted for Nigeria alone.

Conversely, the boundaries for determining cement and aggregate locations were much larger due to the ease of transport of each material. The study boundaries for cement and aggregate were limited to Nigeria and its surrounding countries: Benin, Cameroon, Chad, and Niger.

Lastly, wood is a widely available material in Nigeria; thus, the region for wood was limited to locations within the country of Nigeria.

3.5.4. Geographical Centers

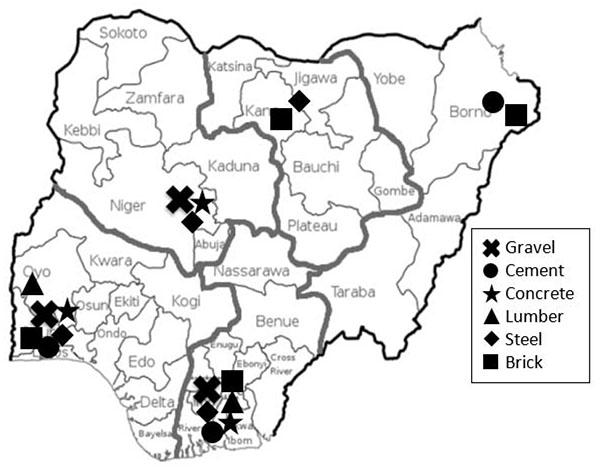

Upon determination of locations for various construction resources, the spatial data was used to infer the geographical centers for the various construction resources in each of the regions in Bangladesh and Nigeria. The construction resources analyzed were gravel, cement, RMC, lumber, steel, and brick. In some cases, there were multiple central areas in a given region if a particular industry was found to be very large in that region. For other construction resources, there may not have been a geographical center for a particular resource in that area if the resource is not heavily or widely produced there. The geographical centers for Bangladesh and Nigeria are provided in Figs. (5 and 6), respectfully.

3.6. Material-Based Site Selection Factors

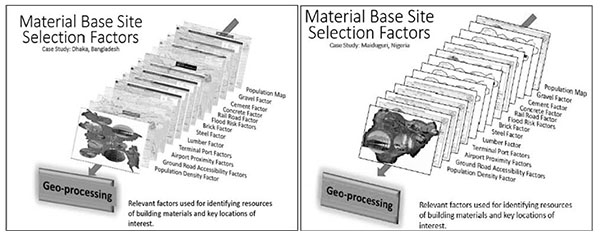

The most widely available and used construction resource for the regions of Bangladesh and Nigeria were determined using a combination of the effective proximity factor, infrastructure considerations, and the centers of construction resources [1, 2]. Fig. (7) provides a visual representation of the overlay of each of the important factors which are used in the methodology in part to determine the most suitable construction resources for each region.

The possible construction resources included: concrete, lumber, steel, and brick. The ranking of feasibility for each resource in each region is listed in Table 7 for Bangladesh and Nigeria. It should be noted that the various construction resource industries may be seasonal in nature due to climatic conditions. Therefore, Table 7 represents optimal conditions, with no limitations to any of the construction resource industries for the respective countries.

| Region | Most Suitable Construction Resource | Second-Most Suitable Construction Resource |

Third-Most Suitable Construction Resource |

Least Suitable Construction Resource |

|---|---|---|---|---|

| Bangladesh | ||||

| Northeast Bangladesh (Region 1) | Brick | Lumber | Steel | Concrete |

| Southeast Bangladesh (Region 2) | Brick | Steel | Lumber | Concrete |

| Northwest and Southwest Bangladesh (Region 3) | Brick | Concrete | Lumber | Steel |

| Nigeria | ||||

| Southern Nigeria (Region 2 and 4) | Brick | Concrete | Lumber | Steel |

| Central and Northwestern Nigeria (Region 1 and 3) |

Brick | Concrete | Steel | Lumber |

| Northeastern Nigeria (Region 5 - Maiduguri) | Brick | Steel | Lumber | Concrete |

Due to the wide availability of bricks throughout Bangladesh, this construction material was determined to be the most suitable construction resource for all three main regions in the country. However, the brick industry is seasonal in nature due to the wet season. As such, the second construction resource for each region must be considered when selecting a CB. Concrete was determined to be the least suitable construction resource for the regions not containing Dhaka, because the case study limited the determination of concrete production facilities to the areas in and around Dhaka, Bangladesh, since the construction resource is time-sensitive in nature.

In Nigeria, brick/block was determined to be the most suitable construction resource for all three of the main regions as a result of the wide availability of this construction resource throughout Nigeria.

4. DISCUSSION

The overall goal of this work was to develop a methodology that defines accessibility of construction resources based on CB location, transportation network, population densities, and centers of construction materials.

4.1. Effective Proximity Factor

The EPF is a key factor since neighboring regions may have a significant influence on each other. The combination of two neighboring regions’ population density and proximity play an important role for each respective region, this factor is computed as follows:

|

(1) |

Where d is the distance between the two regions in km. ρ1, ρ2 are the population densities of the two regions. A Larger EPF value between two regions indicates that the regions have greater influence on each other.

4.2. Infrastructure

The physical (roads, airports, railroads, etc.) and natural (flood-risk) infrastructure were examined and analyzed since accessibility is a vital piece of construction world-wide, and a good level of infrastructure directly correlates to a high level of accessibility. The physical infrastructure allows food goods, materials, and people to be transported from region to region. This is important when building contingency bases since all three of these components are necessary for efficient, effective, and sustainable construction to occur. Along with this, the natural infrastructure is significant since flooding may significantly impact construction progress and/or damage or destroy a building/structure completely. A flood-risk assessment allows for the various risks to be investigated and taken into account when planning where to site a contingency base.

4.3. Construction Materials

The methodology primarily targeted data about local building materials that can be used in CB site selection and construction. A main consideration when determining locations of construction materials was a location’s quality of materials. The quality of various construction materials was analyzed based on customer testimonials and/or through manufacturers’ product descriptions. When using this methodology for other regions, both raw (local) and manufactured (imported) construction materials should be targeted, as was done for the two case studies outlined.

4.4. Overall Methodology

This methodology provides a contingency site selection process that does not currently exist for mission planners. The more efficient siting of CBs will assist in the reduction of materiel demand, minimize footprint, reduce risk to Soldiers, and preserve freedom of maneuver and action. This methodology, known as Engineer Base Site Identification for the Tactical Environment (ENSITE) will enable expeditionary planning to occur prior to deployment. As a geospatial decision support tool that integrates the operational environment into considerations for CB design, ENSITE can also be used to train future planners, designers, builders, operators, and managers of CBs. When given a capability to display real-time effects that flow from parametric changes, instructors would have the means to prepare students for both expected and unexpected operational situations, once deployed. This resource would also provide CB operators and managers a tool to help analyze a camp’s operational effectiveness as well as to test potential operational/design outcomes based on available local resources and sociocultural impacts, prior to initiating them in the field. This methodology is well-suited to be adapted in a manner which allows for computer-aided determination of CB site selection based on the aforementioned parameters. Overall, the methodology outlines a site-selection process in terms of accessibility of construction resources based on CB location, transportation network, population densities, and centers of materials.

The methodology captured factors such as population densities, main building types, geographical regions, port locations, railroad locations, road networks, airport locations, flood-risk areas, and construction materials. The methodology optimizes all factors to yield the best material-based solution for site selection. Higher EFP values are best in friendly environments and lower EFPs are better in more hostile environments. A centroid is calculated independently for each of the remaining factors. These centroids are then combined and the centroid of the centroids will be the ideal location for site placement (based on construction materials availability).

CONCLUSION

Construction of military facilities is one of the most important aspects of military missions, and this effort is designed to produce a methodology with a goal of developing a GIS-based decision support tool to assist in siting CBs in theater. Key factors included in the analysis and determination of materials and location are local materials accessibility, quality and quantity, local transportation infrastructure, and population densities. The case studies used to develop this methodology are unique due to Bangladesh’s high flood-risk level and dense population and Maiduguri’s relatively isolated high level of population and potential hostility in the region. Special care was taken into account for these factors in each of the case studies, and care should be taken to account for any unique factors to a particular region when applying this methodology to the particular region. The EPF also allowed the central locations of each construction resource within the respective regions to be determined and tied into each other.

Overall, these case studies provide examples of the methodology and serve as tests for the methodology being applied to a megacity and a potentially hostile region. Every region will have a unique methodology; however, other regions can be adapted from this methodology by determining and analyzing a given region’s EPF, infrastructure, and centers of construction materials.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

This study was conducted at the Department of the Army under applied research program element T45, Project 45509, “Engineer Base Site Evaluations for Tactical Environment.”