All published articles of this journal are available on ScienceDirect.

Development of New Eco-Efficient Cement-Based Construction Materials and Recycled Fine Aggregates and EPS from CDW

Abstract

Background:

This research paper presents the results of the characterization and adaptation of the construction product developed by the Experimental Centre of Production of the Faculty of Architecture, Design and Urbanism of the University of Buenos Aires, Argentina (CEP FADU UBA) for Spanish regulations. Additionally, it shows the study of the industrialization of its manufacturing process in Spain. The product consists of a cement-based compound that includes recycled fine ceramic aggregates and EPS from rehabilitation works.

Objectives:

The aim of this research work is to propose a new eco-efficient construction product adapted to Spanish and European regulations in order to minimize the environmental impact of the construction activity, improve energy efficiency and reduce construction costs. Furthermore, it is presented as a solution to the problem that construction and demolition waste management represents.

Method and Results:

Samples have been tested to the water absorption and compression resistance tests according to UNE standards. These parameters serve to delimit its use in new sustainable constructive solutions for the design of zero energy consumption buildings (nZEB).

Conclusion:

Results show that it is possible to obtain certain samples that include recycled ceramic aggregates and EPS which present good response to the mechanical and water absorption tests. In addition, it is obtained that industrializing this product in Spain is complex due to the current waste management system.

1. INTRODUCTION

In recent years, sustainability has become a society’s growing concern due to the necessity of protecting the environment. In this connection, the construction of sustainable buildings acquires a leading role. Aspects such as energy efficiency and natural resources consumption, as well as the reuse of waste and the management of the life cycle of products and buildings are worldwide studied in numerous research works [1].

This growing interest in sustainability is due to the enormous environmental impact caused by the activity of the construction sector in any country all over the world because of: the excessive consumption of natural resources, the amounts of energy needed in order to produce construction products or the uncontrollable dumping of construction and demolition waste (CDW) in illegal landfills, without previous treatment or control [2].

Construction activity produces around 35% of worldwide industrial waste [3] [4] and even in 2008, 890 million tonnes of CDW were generated [5], of which only 25% were recycled [6]. At European level, it consumes 40% of the natural resources for the production of materials [7]. Recently, Spain became the fifth European country that produces more quantity of waste.

In this area, different regulations have been established to reduce these alarming numbers, emphasizing the sustainability, energy efficiency and recycling. Such is the case of Spain, which has approved the Royal Decree 105/2008 [8], the Royal Decree of Energy Certification, RD 235/2013 [9] and the Law 8/2013 [10].

Given this problematic situation generated by the construction activity (the generation of CDW and the excessive consumption of natural resources) and in compliance with new regulations on energy efficiency and sustainability, the search for new methods to reduce environmental impact, therefore, acquires a leading role [11] [12] [13].

For that matter, numerous research studies establish that construction materials are largely responsible for the environmental impact caused by this sector. They take part from the beginning to the end of the construction process, then they allow to improve the sustainable behaviour of buildings [14]. Consequently, the study of new constructive solutions (construction materials and processes) alternatives to conventional ones comes into play in the solution of the problems raised by this activity.

The regulatory framework established for the development of new eco-efficient construction products and systems is still very poor. In the case of Spain, it is only been approved the UNE 15.301:2003 standard [15], which establishes the definition of “eco-design”. It is presented as a process that must consider the environmental impact in all of the stages of buildings construction and materials and manufacturing processes. On the contrary, in Argentina, there is currently no standardised regulation governing this.

1.1. Worldwide Analysis of Different Sustainable Construction Materials and Systems

There are numerous construction products and systems that improve the degree of buildings sustainability through their incorporation in buildings design.

According to this, a product that has been postulated as the natural material with has a lower environmental impact is wood. Nevertheless, the environmental benefits derived from its use are not so clear since it needs high amounts of energy for its processing and drying [16]. Another product that is suggested as a sustainable natural material, related to wood, is bamboo. However, it is not very used due to its low availability: in Spain, it cannot be easily found [17].

On the other hand, there are some research works that develop more complex construction products related to chemical reactions or the addition of compounds in order to improve their properties [18]. However, one of the group of eco-efficient materials that has become increasingly important in the world of sustainable construction are those based on the use of CDW [19], through a previous management [20].

When analysing some alarming numbers, it is obtained that in Europe, the construction activity consumes 40% of the natural resources only for the production of materials or that in Spain only 5% of the CDW generated are recycled [21]. This situation indicates that the development of new construction materials that base their composition on the use of CDW as raw material becomes a solution to the problem that they represent and a minimization of the environmental deterioration.

Table 1 establishes some international research works of interest that try to develop alternative eco-efficient construction products and systems in order to improve the environmental impact of the construction sector. This serves as an analysis of the state of the art of this research line.

| Authors | Construction Product or System | Results |

|---|---|---|

| [22] | Wood and plastic composite with microencapsulated phase change of PCM | Energy saving and improvement of energy efficiency |

| [23] [24] | Natural bamboo: Pressed boards | Improvement of sustainability including case studies |

| [25] [26] [27] | Laminated/composite bamboo panels | Sufficient resistance with minimum thickness |

| [28] | Compound based on gypsum and wood aggregates from demolitions of rehabilitation works | Improvement of thermal properties of the compound. Reduction of mechanical resistance |

| [29] [30] | Plaster with mica or vermiculite aggregates. Plaster reinforced with CDW from mineral wool fibres | Improvement of energy efficiency |

| [31] | Structural concrete and pavement blocks with glass waste | The addition of glass waste improves the product life cycle, durability and structural behaviour |

| [32] | Hydraulic mortars using recycled plastic | Improvement of fire behaviour and sustainability |

| [33] | Panels with plasterboard waste and recycled concrete | Minimization of the environmental impact of façades construction. Same mechanical benefits as those made of natural resources |

| [34] | Cold bituminous mixtures with CDW aggregates | Reduction of resistance and natural resources consumption |

| [35] | Structural concrete with recycled aggregates | Reduction of resistance and natural resources consumption |

| [36] | Blocks of recycled plastics (including EPS) and cement | Resistance reduction. Improvement of energy efficiency |

| [37] [38] [39] [40] | Bricks with recycled aggregates from brick dust and clay tiles | Lower weight and cost. Accomplishment of environmental values of the origin country. Significant decrease of compressive resistance and increase of water absorption degree |

| [41] | Concretes with CDW and cement | Reduction of natural resources consumption |

| [42] | Plaster or plaster boards with recycled EPS | Improvement of energy efficiency |

| [43] [44] | Cobblestones with crushed ceramic materials | The water absorption degree is higher than the one for similar products on the market |

| [45] | Panels made of ashes from thermal power plants and cement | Minimization of the environmental impact in façades. Same mechanical benefits as those made of natural resources |

| [46] [47] | Plaster reinforced with glass fibres | Reduction of resource consumption. Improvement of durability |

| [48] | Gypsum with lightweight cork aggregates | Improvement of energy efficiency |

| [49] | Non-structural concrete blocks incorporating EVA waste | Improvement of energy efficiency |

| [50] | Composites with cork as raw material | Improvement of energy efficiency |

| [51] | Structural concrete and blocks with cork aggregates | Reduction of thermal conductivity |

| [52] [53] | Reinforced plaster with aggregates of crushed tires | Improvement of energy efficiency. Resistance reduction |

| [54] [55] | Plaster with aggregates of crushed rice husk residues | Reduction of resource consumption. Resistance reduction |

| [56] | Bricks using marginal soil instead of cooked clay | Improvement of sustainability |

| [57] [58] | Bricks of compact soil | Increase of water absorption degree compared to traditional pieces |

| [59] [60] | Photocatalytic mortars | Reduction of environmental impact |

| [61] | Lightweight multilayer composite walls | High level of thermal performance and interior comfort |

| [62] | Development of “trombe” wall system | Improvement of energy efficiency |

Given this situation, numerous studies [63] [64] [65], including the ones developed by the lead author, establish that the most generated CDW types are: concrete, ceramics, wood, metal, glass, plastic and cardboard. It is also indicated, that even the first four exceed the maximum thresholds established in Spanish Royal Decree 105/2008 [8]. Therefore, they are the most interesting types to study in order to achieve new ways of recycling and recovering them.

In addition, many authors state that the decrease in thermal conductivity is a key issue to develop in order to improve energy efficiency [66] [67]. Hence, many researches focus on the development of lighter compounds to improve the implementation of buildings works and fundamentally, to achieve a significant energy saving. The most widely used material for this purpose is expanded polystyrene (EPS) [68], whose generation as waste has been increased lately [69].

Therefore, the development of new eco-efficient construction products that use recycled CDW ceramic aggregates [70] and even include a reduction of buildings thermal conductivity, serves as a solution to the environmental impact caused by the construction sector. In addition, this new type of product presents a major innovation compared to the studied researches, which is the inclusion of both recycled EPS and ceramic aggregates in dosages.

Thus, this research work presents the results of the characterization and adaptation of the construction product developed by the Experimental Centre of Production of the Faculty of Architecture, Design and Urbanism of the University of Buenos Aires, Argentina (CEP FADU UBA) to Spanish regulations. Additionally, it shows the study of the industrialization of its manufacturing process in Spain. It consists of a cement-based compound that includes recycled fine ceramic aggregates and EPS from rehabilitation works. The aim of this research work is to propose a new eco-efficient construction material adapted to Spanish and European regulations in order to minimize the environmental impact, improve energy efficiency and reduce construction costs. Furthermore, it is presented as a solution to the problem that construction and demolition waste management represents. In addition, it is intended to use it in new sustainable zero energy consumption buildings (nZEB) design.

2. MATERIALS AND METHODOLOGY

2.1. Brief Summary of the Methodology Carried Out

The methodology carried out during this research is summarized in general terms in Table 2:

| Objective | Description |

|---|---|

| Analysis of the current situation of the construction sector in Spain and Argentina | Study on waste generation and its reusing possibilities Study of the bibliography on current international research works that develop eco-efficient construction products and systems |

| Development of hypotheses | Study of dosages to validate the product in Spain. Contact with Spanish companies that produce similar construction products to obtain baseline tests values Obtain the Spanish regulations for concrete blocks and bricks of low density to compare them with Argentine standards. Obtain the limit values that this product type must comply with this product type in Spain according to different tests to which they must be submitted |

| Characterization of physical and mechanical properties | Tests plan. Methodology carried out during laboratory work Manufacture of moulds and test pieces. Error test type performed in the laboratory of the Higher Technical School of Building Engineering (ETSIE) of the University of Seville Analysis of results and comparison with those obtained in Argentina |

| Study of new constructive solutions using these new materials | Use proposals as a result of an experimental campaign according to the characteristics of nZEB construction products |

2.2. The Beginning of the Research: Obtaining the Raw Material

Argentina, does not have a CDW management system unlike Spain. Hence, the development of these new construction products requires a previous work on the preparation of recycled aggregate material, which leads to a large waste of time.

This research work begins from the interest in developing a product with the utmost rigour. The idea is to use as raw material the USW (Urban Solid Waste) and CDW as they can be found during the Spanish residues treatment system. Accordingly, this research opens a new line of research in order to understand this management system, the residues state and where recycling efforts are focus on. This study cannot be performed in Argentina since there is not a waste management system.

After contacting companies dedicated to process CDW and EPS (Reciclados Arcos SL, Roycle.SL, Fermovert or Alcorec SL) and associations like ANAPE (National Association of Expanded Polystyrene) it is concluded how the residues treatment process is managed in Spain.

The production of EPS starts from the polystyrene perlite, which is inflated with gases (including pentane) that vary its properties according to density. After leaving the factory, EPS can have three general destinations: industrial, commercial and domestic uses. EPS recycling is intended for the industrial and commercial sectors, which produce large amounts of this type of waste.

Expanded polystyrene occupies a lot of space and has low density. Therefore, to optimize its transport in most cases it is compacted and in very few, it is crushed and packaged in bags. Eventually, it is taken either to commercial or industrial areas or recycling plants.

The end of the recycling process is limited to the EPS industry and it is only used for the production of new EPS products. As a particular case, it should be mentioned that the organically contaminated EPS cannot be recycled due to the high level of contamination and its last use is as fuel in cement plants. In the case of EPS recycling plants, it is received unmodified, in the form of boxes and primitive geometries. Then, it is compacted by a machine that crushes and presses it, having at no time the crushed EPS kept out of this industrial process.

The interest of this research is finding crushed EPS, and also ceramic aggregates, to save time of laboratory work which will represent a progress comparing to the Argentina procedure. It is pretended to industrialize the elaboration process. Therefore, the search is redirected to obtain the raw material from the production plants of the virgin EPS since the process of cutting the material generates crushed EPS residue. However, during this process, this material is reintroduced back into the manufacturing chain. Although the product is crushed, it is not possible to use this material for the research since it cannot be obtained.

In the case of CDW aggregates, the Spanish management plants receive residues vats of all types of aggregates. After the contact with Spanish treatment plants, it does insist that given the situation of the regional and international recycling scenario is very difficult to achieve the objectives set out by competent authorities. Currently in Spain, there are no landfills in which aggregates are separated according to different sources: they are all concentrated in heterogeneous mixtures of ceramics, concrete, asphalt and different soils from excavations.

Therefore, it is not possible to obtain both raw materials from an industrial origin. Then, for this research, it is designated to collect them from street vats, as is the case of ceramic aggregates and to obtain EPS from commercial activities.

2.3. Recycled Materials

The first of the recycled materials are the ceramic and mortars aggregates from demolition works. As the composition of these is quite heterogeneous, it is performed a manual selection of the pieces with the highest percentage of ceramic material corresponding to double hollow bricks, as this is the brick type used for the research in Argentina.

Once the material is selected, it is crushed in a crushing machine until it passes through an 8mm sieve. The dust obtained from crushing the material is discarded whenever it passes through a 2mm sieve. In Fig. (1), it can be observed the crushing process of ceramic waste.

The other recycled material used in dosages is EPS. It comes from commercial activities and is sieved following the same process described above.

2.4. Other Materials

The cement used is gray Portlant CEM II-32.5N, suitable for structural elements. The last of the materials is the fine river sand.

2.5. Samples and Dosages

The designation of dosages is performed during the research work. It starts from a base dosage corresponding to a product that complies with the tests limit values established in the Spanish regulations. This initial dosage is obtained from the contact with commercial companies that produce concrete bricks. The dosage is 10:1 (Sand:Cement). Of this base dosage and comparing it with the ones obtained by the CEP-FADU-UBA, the percentages of virgin materials are modified or replaced by the addition of recycled ceramic aggregates and EPS.

First, it is added the CDW ceramic aggregates in different percentages of substitution of the sand of the base dosage. It is incorporated until it is verified which limit dosage complies with the minimum values of mechanical compression resistance and water absorption degree stablished in the Spanish CTE (Technical Building Code) [71]. This limit values are: 5 N/mm2 for the minimum mechanical compression and 3g/m2s or 4.2g/m2s for the maximum water absorption degree. These parameters serve to delimit its use in every façade design in Spain.

Once ceramic aggregates samples tests have been carried out, crushed EPS is added in dosages by replacing virgin materials and, as a last step, in mixtures that incorporate ceramic aggregates.

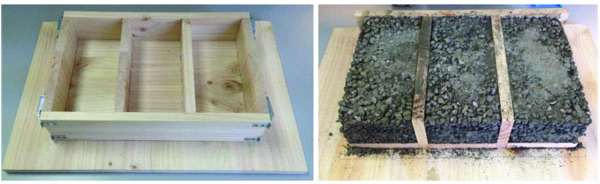

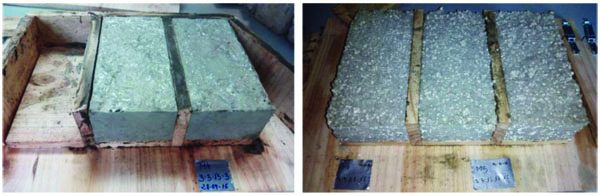

Furthermore, it is determined that the design of the piece will be compact without hollows, since it is intended to achieve a considerable percentage of recycled aggregates. The dimensions of the pieces are equivalent to conventional bricks to facilitate buildings works and thus to obtain a faster construction process. The dimensions are 24x11.5x7cm. The final design of the mould allows to produce several samples at a time, 3 in total, as it can be observed in Fig. (2). It is made of pinewood and it is treated with a product that prevents the absorption of water from mixtures. Vertical pieces can be removed to obtain the samples. Moreover, before filling the mould with mixtures, a coffering removal layer is applied to easily obtain the pieces, (Fig. 3).

The studied samples dosages are set out in Table 3. It is important to indicate the following data worked with. Sand density: 1500kg/m3. Cement density: 1500kg/m3. Aggregate density: 1500kg/m3. The laboratory work have been performed according to UNE standards. Therefore, the measurement of materials weight has been carried out with a balance with a 0.1% accuracy of the material mass.

| Sample | Dosage | Sand (kg) | Cement (kg) | Ceramic Aggregates (kg) | Water (kg) | EPS (kg) |

|---|---|---|---|---|---|---|

| Nº1 | 2:2:2:1:0 | 0,828 | 0,828 | 0,828 | 0,414 | 0 |

| Nº2 | 10:1:0:1:0 | 2,63 | 0,263 | 0 | 0,263 | 0 |

| Nº3 | 5:1:5:1:0 | 1,32 | 0,265 | 1,32 | 0,265 | 0 |

| Nº4 | 3:3:3:1,5:0 | 0,966 | 0,966 | 0,966 | 0,483 | 0 |

| Nº5 | 3:3:1,5:1,5:2:1,5 | 1,932 | 1,932 | 1,288 | 0,644 | 0,019 |

| Nº6 | 3:3:1:1,5:2:2 | 1,932 | 1,932 | 0,8586 | 0,644 | 0,025 |

| Nº7 | 3:3:1:3:4:2 | 1,932 | 1,932 | 0,8586 | 1,288 | 0,025 |

| Nº8 | 3:3:1,5:3:4:1,5 | 1,932 | 1,932 | 1,288 | 1,288 | 0,019 |

| Nº9 | 2:3:2:3:4:2 | 1,2879 | 1,932 | 1,7172 | 1,288 | 0,025 |

During samples elaboration process, it is obtained that dosage Nº1, after a visual analysis, lacks of cohesion between aggregates and the rest of the mixture. It is analysed that it is necessary to add more percentage of cement and that the aggregates should be further sieved to make them thinner. In the case of Nº3, although its appearance is much better than the first one, it is obtained that the aggregates must be previously wetted before being added to the mixture. Sample Nº4 has the correct cement ratio while Nº5 has too much EPS.

The standards used in this research are the ones corresponding to a low density brick since currently there are no regulations for the elaboration of this new type of eco-efficient products, or is still very deficient in both countries. After studying the normative and the contact with a Spanish company specialized in laboratory tests called LAENSA, it is obtained the tests to which samples must be submitted in Spain:

- UNE:EN 772-16/20: Parallelism and planning.

- UNE:EN 772-13: Density.

- UNE:EN 772-1/772-6: Compression resistance (used to discard applications).

- UNE:EN 772-7: Water absorption (used to discard applications).

- UNE:EN 67036: Humidity expansion.

- UNE:EN 13501-1+A1: Fire reaction.

- UNE:EN 1745: Thermal properties.

- UNE:EN 772-3: Hollows percentage.

- UNE:EN 772-5: Soluble salts.

- Anexo D RP 34.14: Mass.

- UNE:EN 1052-3: Adherence.

Once tests have been established, samples are submitted, as indicated above, to the water absorption and mechanical compression resistance tests. These are the initial tests to perform in order to discard possible applications in façades design. Once favourable results have been obtained for these tests, their thermal properties and reaction to fire should be studied in the following phases of this research project, which are mandatory tests according to UNE standards.

3. RESULTS

Tests have been performed in accordance with UNE standards. Moreover, processes and limit results are obtained from these regulations. Besides, all elaborated samples are tested.

3.1. Water Absorption Test

Firstly, the response of samples to water absorption according to UNE: EN 772-7 [72] is studied. The objective is the analysis of the incorporation of water in the pieces mass.

Dry samples have been weighed on a scale. Then, they were deposited in trays with a flat surface of more than 400mm2 of surface and a depth of 20mm, as shown in Fig. (4). As only one of the samples faces must be in contact with water, they have been placed on a support that raises them about 10mm to achieve this effect. Once placed, they have been immersed according to a system that ensures that the water level of the trays is constant at all times: 15mm, that is 5mm above the submerged face. In addition, they have been covered while they have been submerged to avoid the water evaporation.

The duration that samples have to be submerged has been timed which is 10 minutes according to the standard. Once they have been taken out of water and dried, they have been reweighed in a balance.

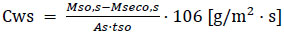

|

(1) |

Where:

Cws= sample water absorption (%)

Mso,s = sample mass after submerged (g)

Mseco,s = sample mass after drying (g)

As = Gross submerged surface (mm2)

Tso = submerged time (s)

Results obtained after the water absorption test are set out in Table 4 and the best and worst response samples are designated in green and red. Sample Nº2 has not been tested since it corresponds with the base dosage from a commercial company, which has already been tested and complies with the standards.

| Results of Water Absorption Test | |||||

|---|---|---|---|---|---|

| Sample | Mseco,s (g) | Mso,s (g) | As (mm2) | Tso (s) | Cws (g/m2·s) |

| Nº1 | 2783 | 3271 | 27600 | 600 | 29,47 |

| Nº 3 | 2196 | 2737 | 27600 | 600 | 32,67 |

| Nº 4 | 3218 | 3277 | 27600 | 600 | 3,56 |

| Nº 5 | 2638 | 2667 | 27600 | 600 | 1,75 |

| Nº 6 | 2485 | 2510 | 27600 | 600 | 1,51 |

| Nº 7 | 2597 | 2632 | 27600 | 600 | 2,11 |

| Nº 8 | 2033 | 2143 | 27600 | 600 | 6,64 |

| Nº 9 | 2183 | 2417 | 27600 | 600 | 14,13 |

Once results have been established, it is obtained that the samples with the highest water absorption degree are samples Nº1 and Nº3. Samples Nº5, Nº6 and Nº7 have the best response and their values comply with the limits established in the standard. Sample Nº9 has the worst behaviour because it has the highest percentage of ceramic aggregates and it includes EPS. In addition, it is important to indicate that it is possible to obtain samples with a certain range of ceramic contents that comply with mandatory standards.

3.2. Mechanical Compression Resistance Test

The following test measures the compression resistance response, according to UNE: EN 772-1 [73] and UNE: EN 772-772-6 [74] standards. This test consists of applying a load at a given speed so that the maximum load is reached in not less than 1 minute. Table 5 shows the results of the maximum load applied on each sample in tonnes and its equivalent value in N/mm2 according to samples dimensions. The samples with the best and worst response are designated in green and red. Furthermore, it is important to indicate that the samples used for this test are not the same ones used in the previous test since the mould is prepared to elaborate three pieces of each dosage.

| Mechanical Compaction Test Results | ||

|---|---|---|

| Sample | Result in Tons | Result in N/mm2 |

| Nº 1 | 14 | Unreliable result |

| Nº 2 | 7 | 2.48 |

| Nº 3 | 2,1 | 0.76 |

| Nº 4 | 5,4 | 1.91 |

| Nº 5 | 9,4 | 3.34 |

| Nº 6 | 7,7 | 2.73 |

| Nº 7 | 5,20 | 1.84 |

| Nº 8 | 2,77 | 0.98 |

| Nº 9 | 3,33 | 1.18 |

The sample with a better response to this test is Nº5, followed by Nº6. The ones with the worst response are Nº3 and Nº8. Sample Nº1 has a much higher response level than the rest due to its composition so obtained results are unreliable and discarded. This could have happened because it is the first sample that was analysed and test procedure was not correctly performed. None of the studied samples has a higher compression resistance value than the limit established in the CTE (5 N/mm2). However, certain samples behave better than others do. In Fig. (5), it is possible to observe the machine used for the test and an instant thereof.

4. DISCUSSION

4.1. The Current Situation of Recycling in Spain and Argentina

Proper waste management is a key aspect for its recycling and reuse [75]. After this study, it is obtained that, generally, the use of these aggregates in the province of Seville (Spain), is filling up quarries. This use closes the cycle of the arid and is very practical given the quality of the aggregates. In the case of Argentina, the typical use of CDW is as aggregates of roads construction.

Their general composition varies according to the CDW that the activity of the construction produces at each moment and as different studies establish [76], CDW composition is very heterogeneous. It is widely known that most are composed of aggregates of concrete, stone, ceramics, gravel and sand, and to a lesser extent wood, metals, glass, paper, plastics and other elements.

In general, there is no research work of this type in both countries. Therefore, this work spreads the use of this type of waste as new eco-efficient construction products besides current uses like fillings of roads and quarries.

However, the industrialization of its production process is complex because of how raw materials are found in both countries. This would require a change of mentality of both entrepreneur and regulatory levels, since it would mean updating the CDW management system installed in Spain and the necessary incorporation of one in Argentina

4.2. The Development of New Construction Products Using CDW in its Composition

It has been possible to obtain an eco-efficient construction material composed of fine ceramic aggregates and recycled EPS from CDW. It has been developed a cement-based compound that complies with the limit valuesestablished in Spanish regulations and can be used in new facades design. It contributes to the reduction of CDW production, the consumption of natural resources as well as it means an improvement of buildings energy efficiency.

However, during the development of this research, it has been found that there is no applicable regulations for the development of this new type of products. It has been necessary to use the limitations for materials that use natural resources. Hence, the data obtained must be reviewed and after the elaboration of this work, it will be necessary to study new regulations for the elaboration of this new type of products.

4.3. Current Use of Eco-Efficient Construction Products and Systems in the Professional Field of Construction

In order to obtain a more sustainable construction sector, it is necessary to take measures to comply with current and future regulations on energy efficiency and consumption of natural resources minimization in Spain and Argentina. The use of sustainable construction products and systems emerges as a solution to the construction sector problems, since they are participants in the entire buildings life cycle.

However, even though they play a fundamental role in improving buildings sustainability, their use in the professional field is not completely established. The construction industry remains on the conventional approach of the production [77] [78]. Hence, there is an important line of separation between research, which advocates for the development of these products and the conception of the private sector that exclusively considers their industrialization and commercialization costs. The research world tries to comply with the demands of regulations and understands the environmental benefits of their use. Therefore, it will be necessary to study and establish actions and measures that will motivate the industry to change this perception and spread the possibilities that these new sustainable products propose.

CONCLUSSION

This research work has studied the experimental characterization and adaptation of the construction material developed by the CEP-FADU-UBA to current Spanish regulations. In addition, it has studied the industrialization of its manufacturing process in Spain. It finally concludes:

According to the construction sector and the waste management system in Spain and Argentina:

- In Argentina, unlike Spain, there is not a waste management system and it is necessary. Therefore, a large amount of previous work is needed to prepare the recycled aggregate material.

- The industrialization of the process is complex due to the state that raw materials are found in both countries. It would require a change of mentality of both entrepreneur and regulatory levels.

- Despite the Spanish waste management system, it has not been possible to use raw materials from an industrial origin. The residues are not separated in treatment plants and are heterogeneous. Therefore, it is not possible to clearly obtain the composition and origin of these which is essential to any research.

According to samples elaboration and subsequent adaptation to Spanish standards:

- It has been possible to obtain a construction material composed of recycled fine ceramic aggregates and EPS from CDW. It consists of a cement-based compound that complies in a certain way with the limit values established in Spanish legislation. It would be necessary to elaborate more samples to obtain convincing results.

- Its use allows the reduction of the amount of waste generated by the construction activity, the consumption of natural resources and an energy saving. These levels of improvement must be studied.

- It has been possible to obtain samples with a certain range of ceramic contents that comply with Spanish standards.

According to possible lines of development of this research work:

- There is no regulation for the elaboration of eco-efficient products that use recycled aggregates in their composition. After this research, it is concluded that it is necessary to study and implement new regulations to elaborate this type of products.

- The requirements established in Spanish regulations are more restrictive than those in Argentina. It will be necessary to study the response of samples to fire behaviour and thermal conductivity tests in Spain to completely define their possibilities of use.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

This research is part of the international research project: REEB “Eco-efficient rehabilitation of buildings and neighbourhoods: the management of the CDW in Argentina and the application of eco-efficient products of the CEP to Spanish legislation” (reference CCPI2015). It is included in the specific research agreement between the University of Seville and Buenos Aires. Also, it is the result of the work developed thanks to the support received by the Ministry of Education, Culture and Sport from the Government of Spain through a Collaboration Grant in the Department of Building Constructions I of the Higher Technical School of Architecture of Seville during the academic year 2015/2016.

Authors would like to thanks the Higher Technical School of Building Engineering for the support and availability to use its laboratory and the work of Domingo Galán Caro, collaborator of the Department of Building Constructions I.