All published articles of this journal are available on ScienceDirect.

Effect of Mortar Reduction in Recycled Aggregates Used in Concrete

Abstract

Background:

Following a global environmental concern, concrete manufactured with recycled materials has been widely studied. The reuse of concrete as raw material can reduce the amount of debris and the amount of natural resources needed minimizing the environmental impact.

Objective:

One of the fundamental issues when using recycled aggregates is the mortar that remains adhered to their surfaces. The effect of this adhered mortar on aggregates, obtained from pavement demolition debris, used in recycled concrete is studied.

Method:

A mechanical abrasion process is used to reduce the amount of mortar in different degrees from the recycled aggregates that will be used to replace a 40 % of natural coarse aggregates in structural concrete. The mechanical behavior is studied through the compressive and flexural strength of the material and compared with the values obtained for a control concrete, with no recycled aggregates.

Results:

The abrasion process is proven to be effective eliminating the adhered mortar to the aggregates and the results show that a medium abrasion level, around 200rev, improves significantly the mechanical properties of the recycled concrete, increasing its compressive strength.

Conclusion:

The percentage of recycled aggregates used in structural concrete can be increased if these are treated with simple mechanical abrasion. The residuals of the eliminated mortar can be also reused as cement replacement, maximizing the material reuse.

1. INTRODUCTION

The recycling of concrete has been widely studied, following a global environmental concern. The reuse of concrete as raw material allows not only to reduce the amount of debris that end in a dumpsite but also reduces the amount of natural resources needed for minimizing the environmental impact. Also, the costs related to waste management can be minimized if the reuse of the concrete is done in the same production plant.

Several studies [1-8] have proven that replacing a limited percentage of aggregates does not modify significantly the properties of the concrete; hence, several European technical regulations allow the use of up to 30% of recycled aggregates in the production of structural concrete.

Even though in some countries the recycling rate is high, the use of recycled concretes is usually limited to concretes with low quality needs. The high absorption levels, the high porosity and the amount of cracks in the reused material make it a bad candidate for structures with strict requirements. A high absorption in the aggregates gives a low strength concrete. The high level of these parameters is caused by the old mortar adhered to the surface of the reused aggregates [9-13].

As mentioned, one of the main causes of the loss of strength of the recycled concrete is the mortar adhered to the recycled aggregates. In traditional concrete, a weak interface between the natural aggregates and the cement mix is considered. When using recycled concretes two interfaces, or weak regions, have to be considered, the one between the old mortar adhered to the recycled aggregates and the new cement matrix (new interface) and the one between the recycled aggregate and the old mortar (old interface) [9-11]. Thereby, one of the main parameters that control the mechanical behavior of the recycled concrete is the amount of old mortar adhered to the aggregates and its quality.

The usual way to control the strength loss is to reduce the amount of recycled aggregates, minimizing the probability of a weak interface union [14], but several other ways have been proposed and applied. If the major problem is the mortar, reducing the amount of mortar should enhance the mechanical behavior of the material and, maybe, allow an increase in the percentages replaced. Ismail &Ramili [15] have studied this mortar reduction using acids to minimize the amount of loose particles adhered to the aggregates surface.

Considering these precedents, we study the effect of the adhered mortar to the surface of the recycled aggregates. We use mechanical abrasion, using a Los Angeles abrasion machine, to eliminate mortar from the aggregates. We set the percentage of the replaced aggregates to 40% and vary the abrasion level through the revolutions applied to the aggregates, varying this way the amount of mortar. The compressive and flexural strength of the resulting materials is compared to a control natural sample, without recycled aggregates, and with a control recycled concrete, with recycled aggregates that have suffered no abrasion. Also, the methodology to reduce the amount of mortar is tested by measuring the absorption and density of the material.

2. MATERIALS AND METHODS

2.1. Aggregates

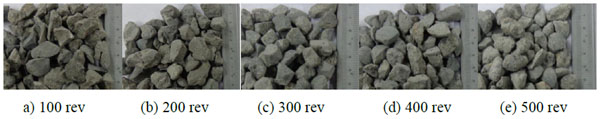

The recycled aggregates were obtained from demolished concrete pavement. Drilled concrete core specimens gave a mean compressive strength of 54MPa. Due to the mortar adhered to their surface the recycled aggregates present a rough and porous texture, as shown in Fig. (1). Fine aggregates may strongly interfere in the physical properties of the material so only coarse aggregates are replaced in the fraction 6.3-19 mm.

The mortar adhered to the surface of these aggregates was reduced using a Los Angeles abrasion machine. To evaluate the effectiveness of this mechanical abrasion different levels were established and quantified through the revolutions applied (100, 200, 300, 400 and 500 rev). In Fig. (2), the effect of the abrasion process can be observed, the aggregates that suffer a higher revolution abrasion are rounder and present a softer texture.

Table 1 shows the density and water absorption values of the recycled aggregates. All the treated samples increase their dry density as the adhered mortar is retired from their surfaces. The recycled aggregates show water absorption values four times over the natural aggregates. However, after the abrasion process this values drops between 8% and 18%. The abrasion process is effective removing the remaining mortar from the recycled aggregates.

| Sand | Natural Aggregates | Recycledaggregates | ||||||

|---|---|---|---|---|---|---|---|---|

| 0R | 100R | 200R | 300R | 400R | 500R | |||

| DryDensity (kg/m3) | 2520 | 2640 | 2330 | 2500 | 2480 | 2500 | 2450 | 2410 |

| Waterabsorption (%) | 2.8 | 1.7 | 6.3 | 5.8 | 4.9 | 4.9 | 5.6 | 5.3 |

The water absorption values increase when the abrasion process applied is set over 300 rev. Removing the mortar decreases the water absorption but when the abrasion process continues the aggregates can suffer micro fissures that can increase the water absorption, weakening the final material reducing its compressive strength.

2.2. Concrete with Recycled Aggregates

Table 2 shows the physical properties of the pozzolanic cement used to manufacture the samples.

| Physicalproperties and Requirements | Values | NCh 148 Of. 68 Standards | |

|---|---|---|---|

| Specificgravity (g/cm3) | 2.8 | ||

| Autoclave expansión (%) | 0.1 | 1.0 max | |

| Initial setting time (hh:mm) | 02:40 | 01:00 min | |

| Final setting time (hh:mm) | 03:40 | 12:00 max | |

| Compressivestrength (MPa) | |||

| 3 days | 280 | ||

| 7 days | 320 | 180 min | |

| 28 days | 410 | 250 min | |

| Chemical requirements | |||

| Lossonignition (%) | 4.0 | 5.0 max | |

| S03 (%) | 3.5 | 4.0 max | |

The recycled aggregates replaced a 40% of natural ones in the dosing on different samples, in the 6.3-19mm size range. Note that the percentage refers to the total amount of aggregates, what means that up to 2/3 of the coarse natural aggregates were replaced in all cases. A control concrete sample (HC) and a recycled regular (no abrasion) concrete (HR) are used for result comparison. The concretes with treated recycled aggregates are designed as HRXXXR, where XXX corresponds to the number of revolutions applied to the material.

In all the concretes the maximum size of the coarse aggregates is 19 mm. The recycled aggregates only replace natural aggregates in the fraction 6.3-19 mm. because the use of smaller recycled aggregates leads to a higher percentage of mortar affecting directly the properties and quality of the final concrete [16].

The dosages of the concretes and their slump and water content are displayed in Table 3. The concretes with recycled aggregates that have suffered higher levels of abrasion present better workability values, following Manzi et al. [17], because of the changes that the procedure provokes in the shape and texture of the aggregates rather than the quantity.

| Coding | Abrasion Recycled Aggregates | Sand (kg) | Natural Aggregates (2.36-19mm) | Recycled Aggregates (6,3-19mm) | Cement (kg) | A/C | Slump (cm) | Air Content (%) |

|---|---|---|---|---|---|---|---|---|

| HC | - | 782 | 1024 | - | 382 | 0.43 | 1.7 | 1.5 |

| HR | 0 rev. | 782 | 302 | 722 | 382 | 0.43 | 1 | 1.3 |

| HR100R | 100rev. | 782 | 302 | 722 | 382 | 0.43 | 1.8 | 1.3 |

| HR200R | 200rev. | 782 | 302 | 722 | 382 | 0.43 | 2.5 | 1.4 |

| HR300R | 300rev. | 782 | 302 | 722 | 382 | 0.43 | 3.5 | 1.3 |

| HR400R | 400rev. | 782 | 302 | 722 | 382 | 0.43 | 4 | 1.2 |

| HR500R | 500rev. | 782 | 302 | 722 | 382 | 0.43 | 2.7 | 1.1 |

All the specimens were designed following Faury [18] method with dosages for a compressive strength of 30MPa after 28 days of curing with a water/cement rate of 0.42.

To calculate the final amount of water included in each sample the aggregates were pre-saturated to 80%. This previous saturation has been proven to seal the pores, limiting water interchanges and avoiding workability issues in fresh [19, 20]. All the samples were elaborated under laboratory conditions and un-molded after 24±2hours. Later, they were submerged in water with lime at 23±3°C during the appropriate curing time. All the dosages were tested for 7, 14, 28 and 90 days.

The mechanical properties of the samples were determined for each dosage by compressive and flexural tests. The compressive tests were performed following the NCh1037 [21], using three cubic 15x15x15cm test specimens after 7, 14, 28 and 90 days of curing. The flexural tests were performedfollowing the NCh1038 [22] using three prismatic 15x15x50cm test specimens after 28 and 90 days of curing. In each case the mean value of the three samples tested is considered.

3. RESULTS AND DISCUSSION

3.1. Compressive Strength

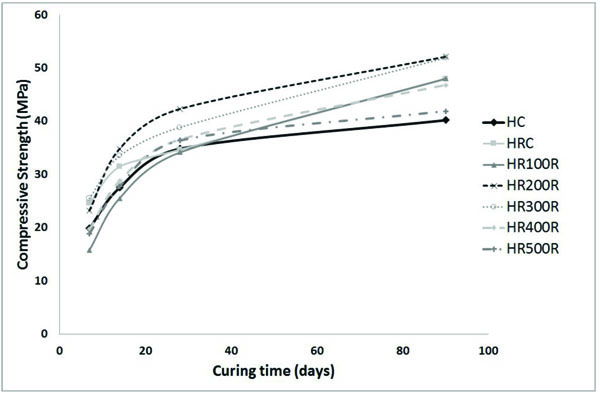

Fig. (3) shows the results of the compressive strength tests after 7, 14, 28 and 90 days of curing. All the samples with recycled aggregates show higher values than HC, evidencing the good quality of the concrete of origin. None of the series present compressive strength losses compared to the control concrete.

The mechanical abrasion process used not only eliminates the mortar but also changes the shape and texture of the aggregates, obtaining softer and rounder recycled aggregates. Matias et al. [23] consider that the use of rougherand flatter aggregates can traduce in stratification of the layers of the concrete affecting its durability and strength. These effects can be controlled using rounder aggregates.

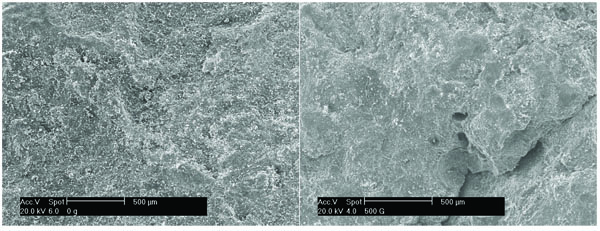

The results also show the positive effects of the abrasion process to reduce the mortar when the revolutions applied are under 300 rev. When the abrasion level is too high micro fissures can appear in the structure of the aggregates due to the aggressiveness of the process weakening the aggregates and therefore the resulting concrete, as can be observed in Fig. (4).

The compressive strength gaining rate of the recycled concretes with the curing time is higher than the one obtained for the control concrete. After 90 days of curing time the differences are significantly higher than the ones after 28 days. This situation has been found in previous studies [8, 24] concluding that recycled aggregates form stronger bonds in the interfacial zone between the cement matrix and the coarse aggregates. Yu and Shui [25] postulate that during the rehydration process of the cement there is a percentage of particles that do not react; the presence of these particles in the remaining mortar can react when a new hydration process takes place enhancing the strength of the concrete. Moreover, the development of the interfacial zone can be different for different kind of aggregates, as the hardening and hydration processes are slower than in traditional concrete [14, 26, 27]. A stronger bond between the cement and the recycled coarse aggregates may be able to compensate the negative effects of reusing weaker aggregates after long curing times.

3.2. Flexural Strength

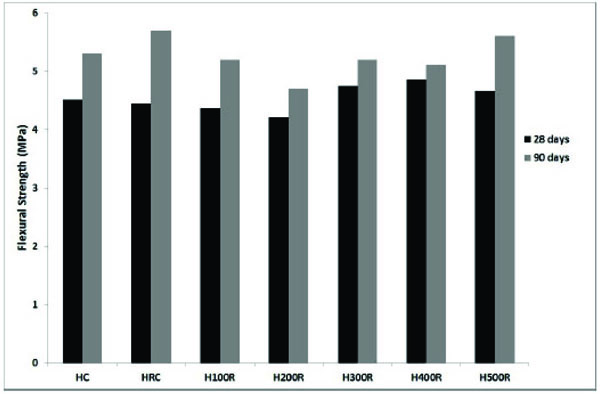

Fig. (5) shows the results of the flexural strength tests after 28 and 90 days of curing. All the samples show comparable results, concluding, as previous authors have, that the use of recycled aggregates does not have significant influence in this parameter [16, 28].

According to previous studies [29], the shape and surface texture of the aggregates have effects on the flexural strength. The weakness of the old adhered mortar can be compensated by its roughness and shape. Over 300 rev the weakness provoked by the mortar has mostly disappeared and increasing the revolutions provokes micro fissures weakening the aggregates but also creating more rough contact surfaces compensating the weakening effects.

CONCLUSION

The use of mechanical abrasion to reduce the amount of mortar adhered to the surfaces of recycled aggregates is effective, presenting its optimum performance when 200 revolution erosion is applied.

This methodology allows obtaining concrete samples that present no strength loss when a 40% of the natural coarse aggregates are replaced by high quality recycled aggregates subjected to mechanical abrasion. The gaining rate is even higher after 90 days of curing.

The percentage of recycled aggregates used in structural concrete can be increased if these are treated with simple mechanical abrasion. The residuals of the eliminated mortar can be also reused as cement replacement, maximizing the material reuse.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

The work presented in this paper was funded by the La Frontera University, Temuco Chile, as part of the project DIUFRO DI17-0013 ‘Analysis of the effect of the grinding process in the behavior of glass powder as cement replacement’ (‘Análisis del efecto de la trituración en el comportamiento del polvo de vidrio como reemplazo de cemento), which is gratefully acknowledged.