All published articles of this journal are available on ScienceDirect.

The Influence of Natural and Synthetic Fibre Reinforcement on Wood-Gypsum Composites

Abstract

Objective:

This paper studies the influence of natural and synthetic fibres on the mechanical behaviour of recycled wood-gypsum composites. These composites of wood waste, such as wood shavings and sawdust, were tested using different proportions of each type of recycled wood. The fibres used, straw as a natural fibre and glass fibre as a synthetic fibre, were analysed in two different proportions.

Method:

The experimental procedure was based on the analysis of the physical properties, density and mechanical properties, flexural strength and compression of the reinforced mixtures. Water absorption by capillarity and the thermal behaviour of the new wood-gypsum materials were also studied.

Results and Conclusion:

The results show that the use of both types of fibres in the mixtures produces lighter composites, and reinforcement by glass fibre represents a significant increase in their flexural strength.

1. INTRODUCTION

The industrial and construction sectors currently generate the largest volume of waste in Europe, representing 81% of the waste generated. According to Eurostat [1], 2515 million tonnes of waste were generated in the European Union in 2012, of which 33% (821 million tonnes) was construction and demolition waste (CDW). However, only an average of 50% of CDW (excluding land without hazardous substances) was recycled.

Guidelines set by the European Horizon 2020 framework show how the large amount of waste generated by the various processes linked to the construction sector can be reduced and managed. In this sense, one priority is to increase to a minimum of 70% by weight the treatment, recycling and other recovery operations for non-hazardous CDW.

One of the strategies for the management and valuation of CDW is recycling by adding it as raw material to cement, plaster and/or lime matrices for the development of new composite materials. Research has focused on creating more sustainable and economic materials, with a physical and mechanical performance that conforms to regulatory requirements. In general, the results show that the addition of certain waste products results in materials with improved physical properties, such as in density or thermal behaviour, with respect to the reference material. On the other hand, some cases have shown that there is a loss in mechanical capacity.

To improve the mechanical behaviour of the new composites, researchers have looked to natural and synthetic fibres. Traditionally, fibres have been used to reinforce poor-quality materials, such as rammed earth or adobe, increasing their cohesion and mechanical strength.

The results obtained with fibres are influenced by the type of fibre added, its length and orientation, as well as the percentage used and its contact surface. Currently, the fibres most commonly used as reinforcement are (Table 1):

| Classification of Fibers According to Their Nature | ||||

|---|---|---|---|---|

| Natural Fibers | Synthetic Fibers | |||

| Sisal | Esparto | Palm fibers | Polypropylene (PP) fibers | Polyester (PET) fibers |

| Jute | Straw | Wool | Polyethylene (PE) fibers | Glass fibers |

| Bamboo | Hemp | Cane | Nylon fibers | Steel fibers |

Table (1) includes a classification of different types of fibres according to what Mahdi et al. [2] and Romaniega et al. [3] have researched.

Adding natural fibres to gypsum-based composite materials has been analysed by several authors. Hernández-Olivares et al. studied the use of sisal fibres at different percentages and lengths. The results showed that by adding 1% of sisal fibre 2 cm in length increased compressive strength with respect to the reference material. Sisal fibres 3.5 cm in length at 3% resulted in a resistance to flexion superior to that of the reference material. As for the elasticity modulus, the best results were obtained by adding 1% fibre with a length of 4 cm [4]. Oteiza-San José studied the behaviour of sisal-reinforced plaster by applying this compound to low-cost housing products [5], and García Santos examined the reinforcing influence of natural Typha Latifolia fibres on construction applications made in plaster. This type of fibre produces a reduction in weight of up to 23.06% and an improvement in the flexural tensile strength of the compounds, but not their resistance to compression [6].

The research on the use of synthetic fibres or minerals in gypsum or plaster-based materials is quite extensive, highlighting the use of glass fibre as the main reinforcement material. Studies by Del Río-Merino et al. showed that the addition of this type of fibre to gypsum and/or plaster matrices leads to an increase in the resistance properties of these materials [7]. Based on these results, the authors also proposed new construction applications, such as self-supporting partitions made from these compounds [8].

Romaniega-Piñeiro et al. [3] have analysed the reinforcement of plaster by mineral wool fibres from recycled CDW, and their results demonstrate the feasibility of replacing the usual glass fibre reinforcement with rock wool and glass wool from CDW, which produced better resistance to bending, compression and Shore C surface hardness.

Serna et al. [9] used gum particles from recycled tyres up to 5% in weight in the gypsum matrix. The result was bending strength losses of up to 16% and up to 18.3% in compressive strength with respect to the reference material.

Vasconcelos et al. [10] proposed the reuse of frayed textile fibres in gypsum-cork compounds. This way they succeeded in counteracting the decrease in the compressive strength of the material by adding the cork aggregate and at the same time increasing the percentage of textile fibres used.

With all this in mind, the present study analyses the physico-mechanical properties of gypsum-based composites and wood from demolition waste following the addition of natural (straw) and synthetic (glass fibre) fibres, with the aim of quantifying the effect of these additions.

2. EXPERIMENTAL PLAN

2.1. Materials

The following materials have been used in the preparation of the various mixtures:

- Gypsum, as the base material, which is used for the construction of the Type 1 controlled setting, in accordance with the characteristics defined in UNE EN 13279_1 [11].

- Pinus wood waste from demolition sites. Wood waste with a particle size of less than 1 mm and greater than 0.063 mm are classified as sawdust, while waste with particles between 1 and 8 mm in size are classified as chips. Both were selected by separating them from other waste elements.

Two different fibre types were used as additives, with the aim of improving the strength capacities of the composites:

- Natural fibre: Straw is a very low cost and highly abundant material in southern Spain, where it is one of the main agricultural waste products. The straw was selected by manually removing all other types of waste and retaining the fibres that measured between approximately 3 to 6 cm.

- Artificial fibre: glass fibre. According to previous research, glass fibre provides, a priori, favourable results by improving the resistance properties of materials. In our study, the glass fibre used followed a manual dismemberment process of a chemically bonded yarn material. The yarns selected measured between 3 to 6 cm in length.

Fig. (1). shows the two types of fibres used for the reinforcement of the mixtures.

2.2. Preparing the Composites

Preparation of the composites consisted of pre-mixing the gypsum, wood waste (in the proportion indicated in each case) and fibres (natural or synthetic, with the corresponding percentage). Once all the materials had been mixed, water was added in the proportion previously determined according to the consistency tests [12]. Since the presence of wood waste implies greater water absorption, the water/gypsum ratio of the mixtures rises as the amount of wood waste added increases, in order to facilitate the workability of the mixture. In this way, a water/gypsum ratio of 0.55 was applied to the mixtures with 5 and 10% waste, 0.80 for the compound with 20%, and a ratio of 1.25 for the mixture with 40% waste. Thus, composites with a percentage of recycled wood of 5, 10, 20 and 40%, and natural or synthetic fibres at 1.25 and 2.5% were analysed.

Two types of test samples were made following the preparation of the compounds:

- Prismatic samples measuring 40x40x160 mm3. Six specimens were made per composite. In addition, three gypsum-wood composites without reinforcing fibres were prepared. In total, there were 273 prismatic specimens.

- Square test samples measuring 300x300x15 mm3. One specimen was made for each gypsum-wood composite without reinforcing fibres. In total, nine square test pieces were prepared.

Table (2) shows all the mixtures prepared, their designation, composition and the number of test samples.

2.3. Tests

Once the specimens had been prepared, the experimental campaign was divided into two phases:

- Phase 1: Physical characterization tests (density, absorption and thermal behaviour) and mechanical tests (flexural and compressive strength).

- Phase 2: Scanning electron microscopy.

2.4. Phase 1. Physical and Mechanical Characterization

2.4.1. Density

Bulk density is determined by dividing the weight of the specimen by its volume (160x40x40 mm3), in accordance with UNE-EN 1936 [13]. The apparent densities of the test specimens are obtained in dry state at seven days, once they have been dried in a stove to constant weight at 35-40ºC.

| Samples | W/G Ratio | Wood Shavings (%) | Sawdust (%) | Straw (%) | Glass Fibre (%) | Samples |

|---|---|---|---|---|---|---|

| Reference (R) | 0.55 | - | - | - | - | 9+1 |

| V5 | 0.55 | 5 | - | - | - | 9+1 |

| V5 P1,25 | 0.55 | 5 | - | 1.25 | - | 6 |

| V5 P2,5 | 0.55 | 5 | - | 2.5 | - | 6 |

| V5 F1,25 | 0.55 | 5 | - | - | 1.25 | 6 |

| V5 F2,5 | 0.55 | 5 | - | - | 2.5 | 6 |

| V10 | 0.55 | 10 | - | - | - | 9+1 |

| V10 P1,25 | 0.55 | 10 | - | 1.25 | - | 6 |

| V10 P2,5 | 0.55 | 10 | - | 2.5 | - | 6 |

| V10 F1,25 | 0.55 | 10 | - | - | 1.25 | 6 |

| V10 F2,5 | 0.55 | 10 | - | - | 2.5 | 6 |

| V20 | 0.80 | 20 | - | - | - | 9+1 |

| V20 P1,25 | 0.80 | 20 | - | 1.25 | - | 6 |

| V20 P2,5 | 0.80 | 20 | - | 2.5 | - | 6 |

| V20 F1,25 | 0.80 | 20 | - | - | 1.25 | 6 |

| V20 F2,5 | 0.80 | 20 | - | - | 2.5 | 6 |

| V40 | 1.25 | 40 | - | - | - | 9+1 |

| V40 P1,25 | 1.25 | 40 | - | 1.25 | - | 6 |

| V40 P2,5 | 1.25 | 40 | - | 2.5 | - | 6 |

| V40 F1,25 | 1.25 | 40 | - | - | 1.25 | 6 |

| V40 F2,5 | 1.25 | 40 | - | - | 2.5 | 6 |

| S5 | 0.55 | - | 5 | - | - | 9+1 |

| S5 P1,25 | 0.55 | - | 5 | 1.25 | - | 6 |

| S5 P2,5 | 0.55 | - | 5 | 2.5 | - | 6 |

| S5 F1,25 | 0.55 | - | 5 | - | 1.25 | 6 |

| S5 F2,5 | 0.55 | - | 5 | - | 2.5 | 6 |

| S10 | 0.55 | - | 10 | - | - | 9+1 |

| S10 P1,25 | 0.55 | - | 10 | 1.25 | - | 6 |

| S10 P2,5 | 0.55 | - | 10 | 2.5 | - | 6 |

| S10 F1,25 | 0.55 | - | 10 | - | 1.25 | 6 |

| S10 F2,5 | 0.55 | - | 10 | - | 2.5 | 6 |

| S20 | 0.80 | - | 20 | - | - | 9+1 |

| S20 P1,25 | 0.80 | - | 20 | 1.25 | - | 6 |

| S20 P2,5 | 0.80 | - | 20 | 2.5 | - | 6 |

| S20 F1,25 | 0.80 | - | 20 | - | 1.25 | 6 |

| S20 F2,5 | 0.80 | - | 20 | - | 2.5 | 6 |

| S40 | 1.25 | - | 40 | - | - | 9+1 |

| S40 P1,25 | 1.25 | - | 40 | 1.25 | - | 6 |

| S40 P2,5 | 1.25 | - | 40 | 2.5 | - | 6 |

| S40 F1,25 | 1.25 | - | 40 | - | 1.25 | 6 |

| S40 F2,5 | 1.25 | - | 40 | - | 2.5 | 6 |

2.5. Absorption

Since the main objective of this study is to improve the mechanical properties of the composites by adding natural or synthetic fibres, an analysis of the absorption of the new mixtures was made from the gypsum-wood mixtures without reinforcement. The absorption of these compounds was carried out according to the procedure described in UNE-EN 1015-18 [14], which regulates this test for masonry mortars, because this test is not standardized for the characterization of gypsum composites.

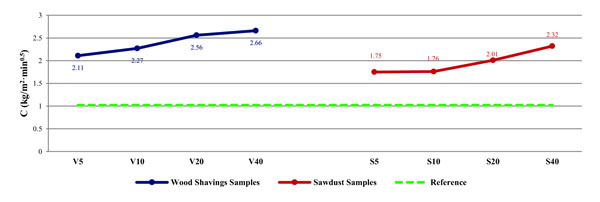

The capillarity water absorption coefficient was determined in three prismatic specimens, under prescribed test conditions at atmospheric pressure (Fig. 2). After drying to constant mass, one side of the specimen was immersed in 5 mm to 10 mm of water for a specified period. Next, the increase in mass was determined, thus obtaining the C water absorption coefficient by the following expression:

|

Where M90min is the mass of the specimens after 90 minutes’ submersion and M10min is the mass of the specimens after 10 minutes’ submersion.

2.6. Thermal Behavior

Thermal tests were carried out to obtain the thermal conductivity coefficients of the unreinforced composites by using the device known as the “thermal house” (Fig. 3). This non-standardized test enabled us to study the thermal behaviour of the new material when subjected to a steady state heat flow by measuring the temperatures on both sides of the material. The temperature register was compared to the measurements obtained on an EPS plate whose thermal conductivity coefficient is already known.

2.7. Mechanical Characterization. Flexural and Compressive Strength

Mechanical behaviour tests were performed to measure the flexural and compressive strengths of all the composites. The idea was to establish a comparative study of the behaviour of the unreinforced composites based on sawdust and wood shavings in relation to those with straw and glass fibre added. We also aimed to analyse the behaviour of all the composites against the reference gypsum. Both tests were based on the 40x40x160 mm3 prismatic specimens analysed in the Suzpecar multi-test test press. The procedure for the flexural and compressive test is shown in (Fig. 4).

Flexural strength: The test samples were subjected to flexo-tensile testing in accordance with UNE-EN 13279-2 [12], applying a perpendicular load to the centre of the piece supported on separate 100 mm rollers. The load was applied until the specimen broke. The final result would yield the mean of the six test specimens expressed in MPa or N/mm2.

Compressive strength: The compressive strength test was performed on the two pieces from the 40x40x160 mm3 broken test specimens in the flexo-tensile test. Therefore, 12 specimens were placed in the test machine between two steel plates of a 40 x 40 mm2 section, with the two faces that had been in contact with the mould supported on one of them. The specimens were subjected to a compression load according to UNE-EN 13279-2 [12] and the result would be the average value of the rupture of the 12 specimens expressed in MPa or N/mm2.

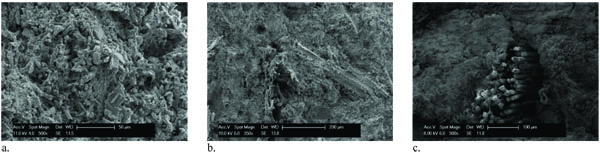

2.8. Phase 2. Scanning Electron Microscopy

In a second phase, scanning electron microscopy (SEM) was used to study the microstructural behaviour of the gypsum-wood composites reinforced with straw and glass fibre. The mixtures were analysed with 20% wood waste and a reinforcement with straw and glass fibre at 2.5%.

A Phillips XL-30 scanning electron microscope equipped with an energy-dispersive spectrometer (EDS) was used along with detectors for backscattered electrons and secondary imaging electrons. The SEM was operated by a computer to which the microscope was connected. The equipment has a resolution of 3.5 nm at 30 kV and 25 nm at 1 kV, and an acceleration range of between 0.2 and 30 kV.

3. RESULTS AND DISCUSSION

3.1. Physical-Mechanical Characterization

3.1.1. Density

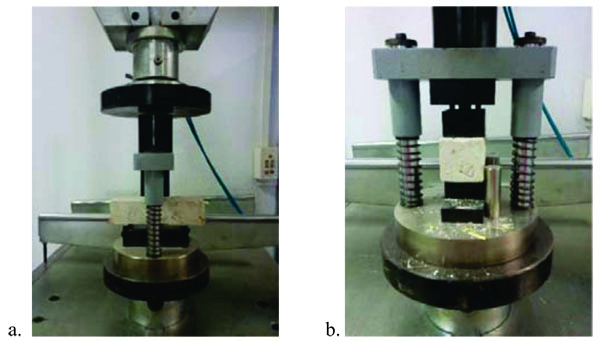

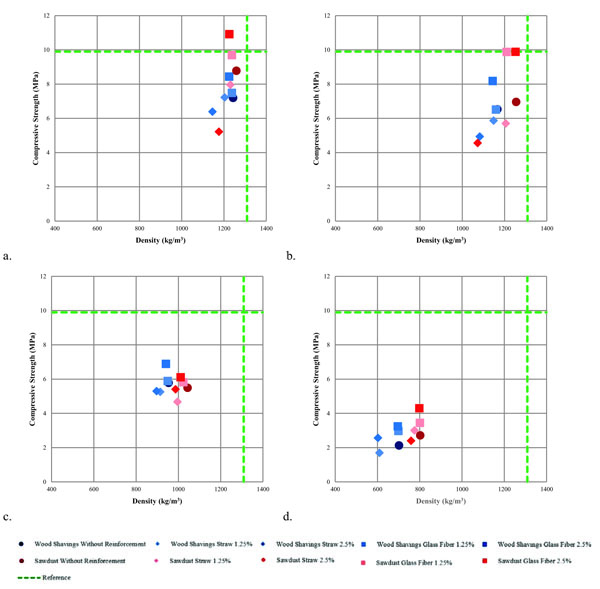

Fig. (5) shows the density values obtained for the different reinforced composites, contrasting the sawdust mixtures with those made with wood shavings at the same percentage, and comparing both to the reference value.

It was observed that, in all cases the material obtained was lighter than the reference material, with the density values decreasing as the percentage of added wood waste increased. On the other hand, reinforcement with straw and glass fibre resulted in a reduction in the density values of the composites with the same percentage of recycled wood without any fibre. The lowest density values for blends with the same amount of wood occurred in mixtures with wood shavings and a 2.5% straw reinforcement. Therefore, the major difference from the reference gypsum is found in composite V40P2.5 in which there is a fall of 53.94%.

3.2. Water Absorption by Capillarity

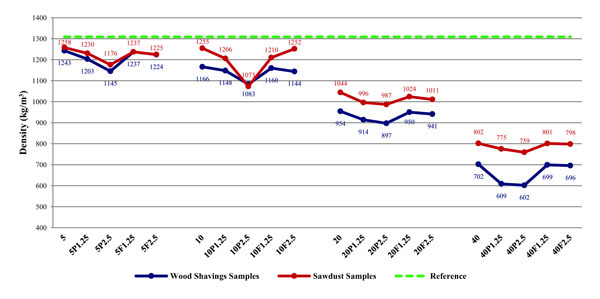

Fig. (6) presents the absorption coefficients for the different gypsum-wood mixtures:

The water absorption coefficients by capillarity obtained for each sample show, in all cases, a considerable increase (approximately double) in comparison with the reference material. In general, the increase in the percentage of added waste supposes an increase in the absorption coefficient, this being always greater for the samples with wood shavings than for those that contain sawdust at the same percentage.

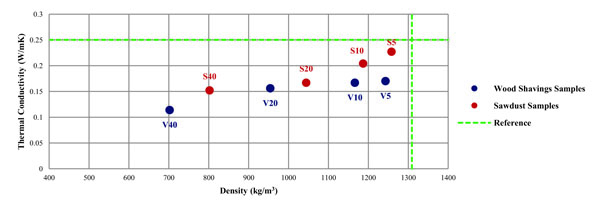

3.3. Thermal Behavior

Fig. (7) shows the results of the thermal tests in relation to the densities of the composites studied. These tests provide results on the thermal conductivity of each proportion, with these values compared to the reference sample. As can be seen, as the percentage of wood in the samples increases, the thermal conductivity of the composite decreases, thus endowing the material with better thermal behaviour. In relation to the two types of additions, the chip-based composites show better thermal behaviour than those that include sawdust in the same proportion.

It is interesting to note that the decrease in the thermal conductivity of the plate is linked to a decrease in the density of that composite. Therefore, the plate with wood shavings waste at 40% is the one that, in addition to having the lowest density of all (702 kg/m3), has best thermal behaviour, with a conductivity value close to 0.114 W/mºK, which implies a reduction of 54.4% with respect to the reference material.

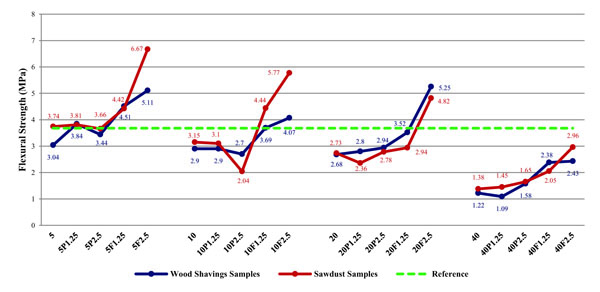

3.4. Flexural Strength

Fig. (8) shows the flexural strength values of each composite

From the data obtained, it is observed that the addition of straw as a reinforcing fibre does not result in any significant improvement in the flexural strength of the composites. There is only a slight improvement when it is used in the following mixtures with wood waste: V5P1.25, S5P1.25, S20P2.5 and S40P1.25. On the other hand, when reinforcing with glass fibre, an evident improvement in the strength values of the composites is achieved with respect to the unreinforced reference composite. In this way, 13 composites were obtained, seven of them with 5% (V5P1.25, V5F1.25, V5F2.5, S5, S5P1.25, S5F1.25, S5F2.5), four with 10% (V10F1.25, V10F2.5, S10F1.25, S10F2.5) and two (V20F2.5, S20F2.5) with 20% recycled wood, all of which have better flexural behaviour than the reference gypsum material, due mainly to the addition of glass fibre as reinforcement. The highest increase occurs in composite S5F2.5, in which a value 81.25% above the reference value is reached. In all cases, with or without reinforcement, the flexural strength values are higher than the minimum 1 MPa established by the standard [11].

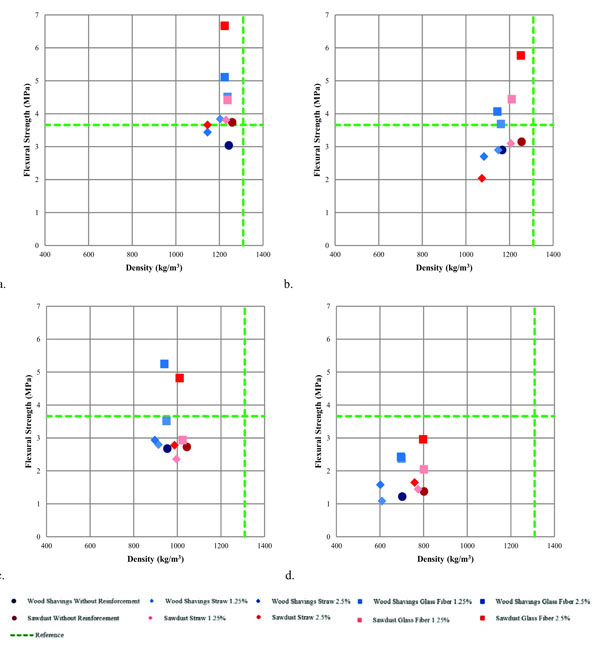

By relating the flexural strength of the composites to their density, it is observed that it is possible to obtain materials that are lighter and with better mechanical behaviour than the reference gypsum. Fig. (9) relates the flexural strength of the compounds to their densities. Thus, it can be seen that the addition of glass fibre as reinforcement to the mixtures allows the composites with 5, 10 and 20% of recycled wood to reach a level of flexural behaviour that is superior to the reference gypsum while also making them lighter.

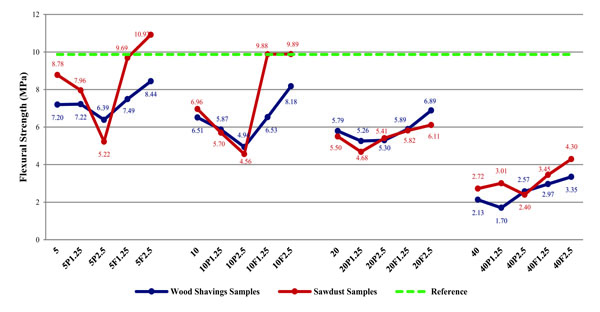

3.5. Compressive Strength

Fig. (10) presents the results for the compressive strength of the composites, which show that, in general, adding wood waste in any percentage is detrimental to mechanical capacity in terms of the compressive strength of the new materials. A case in particular is composite S5F2.5, which is the only one that manages to exceed the value for the reference material, by 10.63%. On the other hand, adding glass fibre as reinforcement in the 10% sawdust-based compounds (S10F1.25 and S10F2.5) enables the compressive strength to reach that of the reference gypsum. As regards gypsum-wood composites, it can be observed that, in general, glass fibre-reinforced specimens always achieve an increase in strength with respect to the fibre-free composite, this increase being higher when added at a rate of 2.5%. In contrast, the addition of straw as natural reinforcement in the mixtures results in a decrease in compressive strength with respect to the unreinforced material, except in composites V5P1.25, S40P1.25 and V40P2.5. Finally, it should be noted that in all cases the minimum value of 2 MPa of compressive strength established by the regulation [11] is exceeded, with the exception of compound V40P1.25 which has a value of 1.70 MPa.

By relating the compressive strength of the new composites to their densities it is observed that, although the addition of wood waste makes the material lighter, the addition of natural or synthetic fibres to reinforce the material does not allow it to reach the compressive strength value of the reference material, with the exception of the S5F2.5 blend. Similarly, there are two composites (S10F1.25 and S10F2.5) which, despite being 7.74% and 4.42% lighter than the reference material respectively, manage to match its compressive strength with the addition of 10% wood waste. Fig. (11) shows the ratio of the density of each composite to its compressive strength.

3.2. Scanning Electron Microscopy (SEM)

The analysis of the images via scanning electron microscopy for samples of 20% recycled wood justifies some of the results obtained. The addition of sawdust and wood shavings involves a discontinuity in the initial gypsum matrix, which results in a decrease in resistance with the increase in size of the particle diameter of the waste being added. Thus, we observe in all the mechanical tests that the drop in the resistance values is more pronounced in samples containing waste in the form of wood shavings than in those with sawdust, due to the fact that its particle diameter is smaller. The addition of new materials such as straw also entails further disintegration of the gypsum matrix without adding, in most cases, improvements to resistance in the samples. In the case of the addition of the glass fibre, however, the disintegration of the gypsum matrix is supplemented by the resistance values of the glass fibre, in all cases obtaining net increases in strength.

CONCLUSION

The results obtained in the present work allow us to draw the following conclusions:

- The addition of wood waste in the form of shavings and sawdust leads to a decrease in the density of the composites in relation to the reference gypsum. The addition of fibres results in lighter gypsum-wood composites, with the lightness increasing with the use of straw as reinforcement.

- The absorption of water by capillarity of gypsum-wood composites is greater as the percentage of wood waste added increases; absorption is greater with mixtures containing wood shavings than those with sawdust at the same percentage. On the other hand, the thermal behaviour of the new materials differs in that the mixtures with wood shavings at a higher proportion are those with a lower thermal conductivity coefficient.

- The addition of glass fibre as reinforcement to gypsum-wood mixtures in all cases results in an increase in the flexural strength of the material. This rise is greater as the percentage of fibre used increases. In this way, we have obtained composites that are lighter and with better resistance to flexural strength than the reference material, with the use of up to 20% wood waste. The biggest increase occurs in compound S5F2.5, which is 81.25% higher than the reference value. In contrast, the addition of straw as reinforcement against flexural strength does not represent a significant improvement.

- Although adding glass fibre to the gypsum-wood mixtures improves their capacity to withstand compressive stresses, it does not significantly exceed the values for the reference material, unlike in flexion.

- Scanning electron microscopy shows that straw produces significant disintegration in the gypsum matrix, which justifies the reduction in strength when this type of reinforcement is used.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

This research has been supported by the Ministry of Economy and Competitiveness of Spain (reference number BIA2013-43061-R). Also, the author Morales-Conde, María J acknowledges the financial support of the V Research Plan of the University of Seville. The author Pedreño-Rojas, MA acknowledges the financial support of the FPU Program of the Ministry of Education of Spain (FPU15/02939).