All published articles of this journal are available on ScienceDirect.

Non-Destructive Tests on Carpentry Steels

Abstract

Background:

Industrial archaeology represents a modern branch of urbanism and architecture that studies, applying an interdisciplinary method, all the evidence inherent the process of industrialization from its origins to the actuality.

Aim:

Looking at the cities of our epoch, more and more are the testimonies of these historical artefacts, which in fact represent our cultural identity and are often intended to be recovered and converted into modern destinations of use.

Methods:

If the identification of constructive schemes is based on direct essays and surveys, the definition of material properties requires material testing and investigation. For metal structures, the standards involve destructive investigations only, with a sampling of specimens, which often conflict with the protection requirements of the artefact. This leads to the need to refine and make reliable non-destructive investigations using the Leeb method, by means of portable micro-durometers, for in-situ characterization of carpentry steels, so to suggest new regulatory guidelines for existing structures surveys.

Results:

In the paper, the classification of carpentry steels based on non-destructive hardness test was illustrated and discussed. Firstly, for the evaluation of the resistance class of a structural steel, it was recorded that the execution of tests required a careful cleaning of the surface of samples.

Subsequently, analyzing the data obtained from the experimentation, it was clear that the best methodology of data conversion from micro-hardness (Leeb method) tests for the determination of the steel class was given by tables and formulations of the ASTM standard. In the case of a few values to be converted, the most effective method was the manual use of the tables, with an average error of 0.10%.

Conclusion:

In conclusion, it should be remarked that differently from the reinforced concrete structures, where the non-destructive tests are allowed by the current Italian technical code on, for metallic structures only, destructive tests are permitted, so that the use of non-destructive ones should be encouraged, especially when interventions on cultural heritage constructions are of concern.

1. INTRODUCTION

Industrial archaeology represents a modern branch which studies, through an interdisciplinary method, all the experiences (material and immaterial, direct and indirect) of the industrialization process in order to deepen the knowledge from the past history to the current techniques. In this architectural and urbanism framework, there are numerous testimonies of historical artefacts, which represent an important social trace of the collective and urban development, becoming witnesses of an epoch. Nowadays, the renewed technical sensitivity is aimed at rediscovering and recovering such evidence with intervention methods having the prerequisites to be eco-sustainable, according to the dictates of bio-architecture, and innovative, according to home automation and intelligent architecture fundamentals [1, 2]. In this context, if the architectural challenge is to adapt volumes to new spaces and activities, the true competition starts at the engineering level in terms of both plants, being the modern functional needs always more specialized, and structures, having to operate on a historic built conceived and erected according to project and executive methodologies often disused or totally in conflict with current design philosophies and relevant regulatory frameworks. Through a project of cognitive investigations, it is possible to find adequate knowledge levels of the structure [3, 4], which allow to identify the used materials, so to carefully simulate the behaviour of structural systems.

On one hand, if it is possible to attain the whole knowledge of these systems by means of surveys and in-situ tests, in order to identify mechanical characteristics and physical properties of materials and their degradation state, it is necessary to perform an adequate campaign of tests. About metal structures, the current regulations allow to use an appropriate number of sampled specimens only [5], achieved from structural zones not too much stressed, to be subjected to destructive laboratory tests able to provide under semi-probabilistic way their mechanical and physical features. Such types of investigative campaigns, however, are often in conflict with the architectural protection constraints of artefacts under consideration, which do not allow to operate the normal sampling of specimens. On the other hand, given the need to pursue minimum levels of knowledge, the use of non-destructive testing methods, instead of destructive investigations, would allow to protect the artefact, without limiting the cognitive framework useful to carry out a proper design intervention. Among non-destructive investigations, the surface hardness measurements of steel specimens performed with portable equipment allow, within certain limits of use, for a supplementary investigation campaign partly substitutive of destructive tests.

Hardness assessment methods are multiple, they being referred to the different reading methods (Brinell - HB, Rockwell - HR, Vickers - HV), related to the type of penetrator adopted, to the value of the applied static force and to the test response value, expressed as the incision energy on the surface of the metal sample. This energy is a function of the shape and size of the impression on the basis of the predetermined load adopted for the test. Micro-hardness or “Leeb” tests are carried out with portable devices equipped with different bits which, providing rebound energy based on their impression on the metal surface, allow to see on the tool display the hardness value to be converted from the Leeb scale (HL) to a predefined more common scale (HB, HR or HV) [6]. Compared to the static tests, such investigations are much more affected by a number of factors, such as the sample thickness, the surface cleaning and imperfections, and thus have a reliability degree lower than the traditional hardness tests one.

The objective of the current experimentation is to test the reliability of the Leeb procedure, carried out with a piece of portable equipment, on different types of samples. The inspected procedure results are compared to the nominal hardness values determined by static tests, according to ASTM A956 [7] and UNI EN ISO 18265 [8] standards, which define in tabular way, the transformation and conversion parameters regulating the use of static durometers. The test is carried out in longitudinal direction according to the methodology defined in the ASTM A30-03a code [9], subsequently evaluating the type of steels according to the UNI EN 10002-1 standard [10], or using the material accompanying certificates, obtained from acceptance tests [3-5]. Currently, in the market, there are various types of equipment for Leeb hardness tests, although reliability and compliance with international standards are still being tested [11].

It should also be noted that for reinforced concrete structures, the existing Italian regulations [3-5] allow for the use of non-destructive tests, replacing 50% of destructive tests with at least a double number of non-destructive tests, such as the SONREB (SONic REBound) ones [12, 13], which are correlated to the compression resistances of cylindrical samples extracted from structural members. Contrary, for metallic structures, current standards do not envisage non-destructive tests. It seems, therefore, indispensable to prove the reliability of the Leeb tests in order to integrate and modify the regulatory contents with the purpose to both optimize and improve the goodness of experimental campaigns, working properly on existing artefacts protected by Superintendence rules, and to limit the damage to structures, where latent hazards situations can be hypothesized. So, the innovation of the present work is to set up appropriate theoretical relationships for carpentry steels able to put in relationship Leeb hardness test values with experimental tensile strengths. In this way, it will be possible to indirectly evaluate, starting from Leeb hardness values measured in-situ on carpentry steels, the strengths of those materials to be used for their mechanical characterization in the field of seismic assessment of steel artefacts.

2. TESTING METHODOLOGY

2.1. The Hardness Test

Hardness is a measure of the surface resistance of a metal to permanent plastic deformations. The metal specimen hardness is measured through a penetrator, usually with spherical, pyramidal or conical shape, which is pressed against its surface. The penetrator bit is made of tempered or tungsten carbide steel, so that it is tougher than the tested specimen material. Standard hardness tests are based on the slow application of a known force that compresses the penetrator in a perpendicular direction to the metal surface to be tested. After the impression is made, the penetrator is removed from the surface and then an empirical hardness value, based on either the impression area or the imprint depth, is calculated or read directly on the test machine. The hardness value derived from Brinell, Vickers or Rockwell tests depends on both the impression shape and the applied force.

Being achieved essentially in a conventional way, the hardness values obtained by different methods or with different scales can be compared to each other only by means of purely experimental conversion tables, which are valid for individual classes of materials.

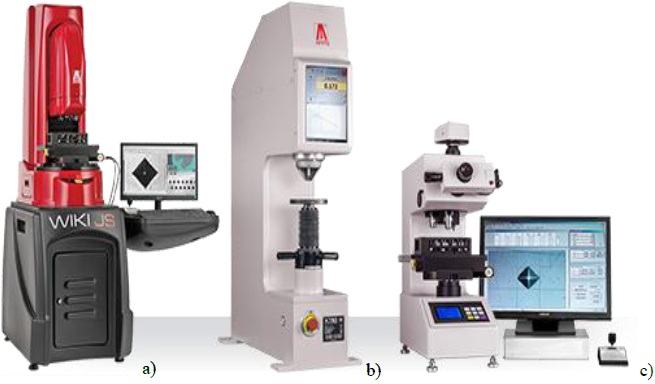

Normally hardness tests use dedicated machines called durometers (Fig. 1), so that each test is calibrated on the force value related to the used penetrator bit type.

The aim of this research work is to verify the reliability of results from non-destructive tests with the Leeb method using portable micro-durometers on steel samples with different shape, nature and origin. This allows to:

- − Verify the test reliability with respect to the hardness values provided by ASTM A956 [7] and UNI EN ISO 18265 [8] standards;

- − Define, whenever possible, the corrective coefficients to be applied to the Leeb tests for the indirect determination of the carpentry steel classes using the tabular expressions defined in ASTM A956 and UNI EN ISO 18265 standards.

2.2. Specimens

The used steel samples, provided by the Tecnolab srl company, an authorised laboratory for investigation tests on construction materials, are represented by specimens having different shape, origin and material type. In particular, the available samples are:

- Plates and sheeting of different thickness (Fig. 2);

- HE and IPE profiles (Fig. 3);

- Smooth bars with different diameters (Fig. 4).

The above samples have been tested and the achieved test values have been ordered on the basis of the average values of the achieved Brinell hardness. After these non-destructive tests, in the cases where certificates on the steel properties were not available, the various samples have been subjected to destructive mechanical tensile tests in the laboratory, to classify the steel type (S235, S275 or S355) depending on the yielding stress achieved.

2.3. Test Equipment

For the purpose of the tests, a durometer type MH100 Leeb Hardness Tester, manufactured by the Mitech CO. Ltd company, is used (Fig. 5).

Such an instrument has a lot of useful advantages, such as:

- Easiness of measurement, since the tester is portable and compact, with the impacting tip integrated into the instrument main body;

- Large measuring range, based on the principle of steel Leeb hardness;

- Large LCD display for viewing parameters and functions, with direct reading of test values in HB, HS, HV, HRB, HRC and HRA scales;

- Possibility to vary both the angle of inclination of the impact surface and the type of test to be carried out;

- Large memory, that can hold up to 100 measurement, impact, angle information and impact time values;

- Software for transferring data directly to a PC;

- Simplicity of use, due to the limited geometrical dimensions (148mm x 33mm x 28mm).

From the technical specifications (Fig. 6), the working conditions are described, allowing for very wide use of the device, which is extremely easy to be used even by not highly specialized workers.

The instrument use conditions are:

- Working temperature: -10°C ÷ 50°C;

- Storage temperature: -30°C ÷ 60°C;

- Relative humidity: <90%;

- Preparation of the contact surfaces.

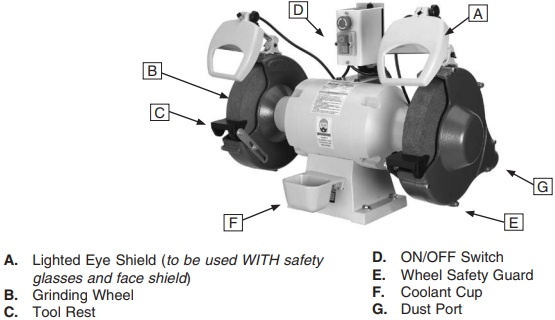

With reference to the last issue, the manufacturer requires the preliminary preparation of the test surfaces for the elimination of residues of oil or fat, traces of rust and/or varnishes. Therefore, the specimens are preliminarily cleaned using a counter-top grinder (Fig. 7), so to make the surface perfectly flat and free from oxidation spots.

This operation is particularly important and delicate, since the durometer support ring must adhere orthogonal to the surface to properly perform the measurement. Otherwise, the device returns default values only, which require to repeat the test. The test consists of three measurement gauges, carried out at different points of the sample, spaced according to the manufacturer's specifications (Table 1).

| Type of Impact Device |

Distance Between Centres of Two Indentations |

Distance from the Centre of the Indentation to the Sample Edge |

|---|---|---|

| Not Less Than (mm) | Not Less Than (mm) | |

| D | 3 1.5 |

5 6,2-20 |

| DL | 3 0,6-1,1 |

5 11-32 |

| C | 2 1.35 |

4 12 |

Initially, the loading test is carried out by pushing the loading column in contact with the surface and slowly releasing it to the rest position, so as to control the efficiency of the column stroke, paying close attention to check that the test surface adheres to the micro-durometer head ring. After positioned the tool, the release button is pressed, marking the load direction coincident with the device axis.

For each sample five tests are carried out, checking that the result data do not have values that deviate from ± 1.5HL. Excluding the largest and smallest test values, the arithmetic mean of the remaining three test values is performed.

Generally, the device has memorized a number of materials, which there are already conversion ratios in terms of hardness (Table 2) or resistance (Table 3) for, to be selected before testing. Contrary, if it is required to correlate Leeb hardness values to another hardness values for special materials (aluminium alloys, steels with different carbon content or special steels), it is necessary to execute a new static hardness test campaign to get the conversion ratios.

| Index | Material |

|---|---|

| 0 | Steel and cast steel |

| 1 | Cold work tool steel |

| 2 | Stainless steel |

| 3 | Gray cast iron |

| 4 | Nodular cast iron |

| 5 | Cast aluminum alloys |

| 6 | Copper-Zinc alloys |

| 7 | Copper –Aluminum alloys |

| 8 | Wrought copper |

| 9 | Wrought steel |

3. THE EXPERIMENTAL ACTIVITY

3.1. Preparation of Samples for Leeb Test

The specimens have been prepared for the execution of the test, assigning an acronym to each of them. In particular, the used abbreviation is ST-X-N, where ST means mild steel, X indicates the specimen type (P = plate; S = sheet; R = round) and N is the progressive number of samples of the same typology.

The samples have been cleaned by solvents from oils and fats detected on the surface. Each sample has been weighed and the related thickness (Tables 4 and 5 for plates and sheets, respectively) or diameter (Table 6), the latter in the case of round specimens, have been measured. Moreover, the steel class has been determined by destructive tensile tests. On each specimen, the area to be used for test has been delimitated by chalk lines. In addition, each sample has been cleaned by means of a bench grinder, bringing the test surface to “white iron”.

| Index | Material |

|---|---|

| 0 | Mild steel |

| 1 | High carbon steel |

| 2 | Cr steel |

| 3 | Cr-V steel |

| 4 | Cr-Ni steel |

| 5 | Cr-Mo steel |

| 6 | Cr-Ni-Mo steel |

| 7 | Cr-Mn-Si steel |

| 8 | Super strenght steel |

| 9 | Stainless steel |

| Code | Sample Number |

Thickness [mm] |

Steel Class [MPa] |

|---|---|---|---|

| ST-P-01 | 1 | 4,7 | S235 |

| ST-P-02 | 2 | 5,3 | S235 |

| ST-P-25 | 3 | 10,2 | S235 |

| ST-P-09 | 4 | 8,0 | S235 |

| ST-P-15 | 5 | 8,9 | S235 |

| ST-P-23 | 6 | 10,2 | S235 |

| ST-P-24 | 7 | 10,2 | S235 |

| ST-P-13 | 9 | 8,5 | S235 |

| ST-P-03 | 10 | 5,3 | S235 |

| ST-P-08 | 13 | 7,9 | S235 |

| ST-P-05 | 14 | 6,1 | S235 |

| ST-P-07 | 15 | 7,3 | S275 |

| ST-P-26 | 16 | 10,2 | S235(*) |

| ST-P-10 | 17 | 8,2 | S275 |

| ST-P-16 | 20 | 8,9 | S275 |

| ST-P-12 | 25 | 8,4 | S275 |

| ST-P-04 | 26 | 5,3 | S275 |

| ST-P-22 | 28 | 10,1 | S275 |

| ST-P-06 | 33 | 6,5 | S275 |

| ST-P-27 | 37 | 10,2 | S275 |

| ST-P-18 | 38 | 9,9 | S275 |

| ST-P-31 | 39 | 13,0 | S275 |

| ST-P-32 | 40 | 13,7 | S275 |

| ST-P-19 | 41 | 9,9 | S355 |

| ST-P-17 | 42 | 9,3 | S355 |

| ST-P-11 | 43 | 8,2 | S275 |

| ST-P-29 | 45 | 11,8 | S355 |

| ST-P-28 | 46 | 10,2 | S355 |

| ST-P-14 | 48 | 8,8 | S355 |

| ST-P-20 | 49 | 9,9 | S355 |

| ST-P-34 | 50 | 20,4 | S355 |

| ST-P-33 | 53 | 20,4 | S355 |

| ST-P-30 | 56 | 12,3 | S355 |

| (*) Test not performed, class assigned from the material certification | |||

| Code | Sample Number |

Thickness [mm] |

Steel Class [MPa] |

|---|---|---|---|

| ST-S-01 | 8 | 5,0 | S235 |

| ST-S-04 | 11 | 9,0 | S235 |

| ST-S-02 | 22 | 7,5 | S275 |

| ST-S-06 | 23 | 10,0 | S275 |

| ST-S-03 | 29 | 8,0 | S275 |

| ST-S-06 | 44 | 15,0 | S275 |

| ST-S-08 | 47 | 20,0 | S355 |

| ST-S-07 | 52 | 20,0 | S355 |

| ST-S-05 | 57 | 9,0 | S355 |

| Code | Sample Number |

Steel Class [MPa] |

|---|---|---|

| ST-R-02 | 18 | S275 |

| ST-R-03 | 19 | S275 |

| ST-R-04 | 21 | S275 |

| ST-R-05 | 24 | S275 |

| ST-R-06 | 27 | S275 |

| ST-R-07 | 31 | S275 |

| ST-R-08 | 32 | S275 |

| ST-R-09 | 34 | S275 |

| ST-R-10 | 35 | S275 |

| ST-R-11 | 36 | S275 |

| ST-R-12 | 51 | S355 |

| ST-R-13 | 54 | S355 |

| ST-R-14 | 55 | S355 |

Subsequently, the specimens have been left to rest for at least 6 hours in a room at standard temperature and humidity, so to allow both any remaining residual stresses and the abrasion heat to be discharged. The preparation lasted about 12 hours. The day after the preparation of specimens, Leeb micro-hardness tests have been performed. The equipment has been calibrated on mild and cast steels (with index 0 in Tables 2 and 3), taking care to carry out the test by keeping the device as firm as possible and perpendicular to the impact surface of the sample.

The tests have been conducted in three points of the test area, with a distance among them and from the sample edges not less than 5 mm (Table 1). For each specimen, the test values have been annotated separately on a laboratory register. Subsequently, the steel class (S235, S275 or S355) has been assigned to each sample according to either the material origin certificate or the result of destructive tensile tests (Tables 4, 6).

3.2. Classification of Samples According to the Leeb-HB Tests

The hardness measurements recorded for the different specimens have been renumbered in ascending order based on the average value derived from the three tests, taking care to discard the minimum and maximum values from the performed five test readings (Table 7). Subsequently, the strengths of tested specimens have been derived from conversion tables provided by ASTM and ISO standards, interpolating between two values when test results have not been found in the resistances of reference tables (Table 8).

| Code | Sample Number | Leeb - HB Hardness Conversion | Average HB Hardness | ||||

|---|---|---|---|---|---|---|---|

| HBmin | HB_1 | HB_2 | HB_3 | HBmax | HBavg | ||

| ST-P-01 | 1 | 78,0 | 81,0 | 87,0 | 98,0 | 99,0 | 88,7 |

| ST-P-02 | 2 | 80,0 | 82,0 | 94,0 | 92,0 | 95,0 | 89,3 |

| ST-P-25 | 3 | 91,0 | 93,0 | 86,0 | 90,0 | 93,0 | 89,7 |

| ST-P-09 | 4 | 91,0 | 91,0 | 98,0 | 82,0 | 85,0 | 90,3 |

| ST-P-15 | 5 | 87,0 | 92,0 | 82,0 | 98,0 | 101,0 | 90,7 |

| ST-P-23 | 6 | 80,0 | 82,0 | 96,0 | 94,0 | 97,0 | 90,7 |

| ST-P-24 | 7 | 94,0 | 97,0 | 89,0 | 93,0 | 96,0 | 93,0 |

| ST-S-01 | 8 | 94,0 | 95,0 | 91,0 | 96,0 | 99,0 | 94,0 |

| ST-P-13 | 9 | 91,0 | 92,0 | 95,0 | 101,0 | 104,0 | 96,0 |

| ST-P-03 | 10 | 85,0 | 86,0 | 107,0 | 97,0 | 100,0 | 96,7 |

| ST-S-04 | 11 | 97,0 | 99,0 | 102,0 | 100,0 | 102,0 | 100,3 |

| ST-R-01 | 12 | 90,0 | 92,0 | 107,0 | 103,0 | 105,0 | 100,7 |

| ST-P-08 | 13 | 105,0 | 108,0 | 98,0 | 105,0 | 107,0 | 103,7 |

| ST-P-05 | 14 | 97,0 | 98,0 | 112,0 | 102,0 | 104,0 | 104,0 |

| ST-S-06 | 15 | 105,0 | 107,0 | 105,0 | 120,0 | 122,0 | 110,7 |

| ST-P-07 | 16 | 121,0 | 123,0 | 95,0 | 97,0 | 99,0 | 105,0 |

| ST-P-26 | 17 | 106,0 | 108,0 | 105,0 | 107,0 | 109,0 | 106,7 |

| ST-P-10 | 18 | 101,0 | 103,0 | 120,0 | 99,0 | 101,0 | 107,3 |

| ST-R-02 | 19 | 99,0 | 100,0 | 112,0 | 115,0 | 117,0 | 109,0 |

| ST-R-03 | 20 | 115,0 | 117,0 | 101,0 | 109,0 | 111,0 | 109,0 |

| ST-P-16 | 21 | 101,0 | 104,0 | 108,0 | 115,0 | 117,0 | 109,0 |

| ST-R-04 | 22 | 115,0 | 120,0 | 106,0 | 103,0 | 105,0 | 109,7 |

| ST-S-02 | 23 | 113,0 | 117,0 | 116,0 | 96,0 | 98,0 | 109,7 |

| ST-R-05 | 24 | 115,0 | 117,0 | 97,0 | 118,0 | 120,0 | 110,7 |

| ST-P-12 | 25 | 112,0 | 113,0 | 117,0 | 103,0 | 105,0 | 111,0 |

| ST-P-04 | 26 | 102,0 | 106,0 | 110,0 | 118,0 | 120,0 | 111,3 |

| ST-R-06 | 27 | 115,0 | 119,0 | 110,0 | 106,0 | 108,0 | 111,7 |

| ST-P-22 | 28 | 107,0 | 110,0 | 114,0 | 112,0 | 114,0 | 112,0 |

| ST-S-03 | 29 | 121,0 | 124,0 | 106,0 | 109,0 | 111,0 | 113,0 |

| ST-P-21 | 30 | 107,0 | 111,0 | 116,0 | 114,0 | 116,0 | 113,7 |

| ST-R-07 | 31 | 130,0 | 132,0 | 100,0 | 111,0 | 113,0 | 114,3 |

| ST-R-08 | 32 | 97,0 | 100,0 | 124,0 | 120,0 | 122,0 | 114,7 |

| ST-P-06 | 33 | 114,0 | 117,0 | 124,0 | 107,0 | 109,0 | 116,0 |

| ST-R-09 | 34 | 112,0 | 115,0 | 114,0 | 122,0 | 124,0 | 117,0 |

| ST-R-10 | 35 | 122,0 | 125,0 | 127,0 | 101,0 | 103,0 | 117,7 |

| ST-R-11 | 36 | 115,0 | 118,0 | 123,0 | 113,0 | 115,0 | 118,0 |

| ST-P-27 | 37 | 115,0 | 116,0 | 123,0 | 129,0 | 131,0 | 122,7 |

| ST-P-18 | 38 | 119,0 | 124,0 | 119,0 | 125,0 | 127,0 | 122,7 |

| ST-P-31 | 39 | 116,0 | 117,0 | 124,0 | 136,0 | 137,0 | 125,7 |

| ST-P-32 | 40 | 126,0 | 127,0 | 133,0 | 139,0 | 140,0 | 133,0 |

| ST-P-19 | 41 | 125,0 | 128,0 | 124,0 | 139,0 | 140,0 | 130,3 |

| ST-P-17 | 42 | 137,0 | 140,0 | 125,0 | 130,0 | 131,0 | 131,7 |

| ST-P-11 | 43 | 128,0 | 129,0 | 130,0 | 147,0 | 148,0 | 135,3 |

| ST-S-06 | 44 | 135,0 | 136,0 | 129,0 | 144,0 | 145,0 | 136,3 |

| ST-P-29 | 45 | 142,0 | 143,0 | 147,0 | 129,0 | 130,0 | 139,7 |

| ST-P-28 | 46 | 142,0 | 144,0 | 157,0 | 147,0 | 148,0 | 149,3 |

| ST-S-08 | 47 | 145,0 | 147,0 | 160,0 | 152,0 | 153,0 | 153,0 |

| ST-P-14 | 48 | 151,0 | 153,0 | 146,0 | 165,0 | 166,0 | 154,7 |

| ST-P-20 | 49 | 147,0 | 148,0 | 164,0 | 155,0 | 156,0 | 155,7 |

| ST-P-34 | 50 | 162,0 | 162,0 | 168,0 | 140,0 | 141,0 | 156,7 |

| ST-R-12 | 51 | 159,0 | 160,0 | 152,0 | 162,0 | 163,0 | 158,0 |

| ST-S-07 | 52 | 160,0 | 162,0 | 160,0 | 164,0 | 165,0 | 162,0 |

| ST-P-33 | 53 | 174,0 | 175,0 | 153,0 | 162,0 | 163,0 | 163,3 |

| ST-R-13 | 54 | 164,0 | 166,0 | 159,0 | 174,0 | 175,0 | 166,3 |

| ST-R-14 | 55 | 159,0 | 159,0 | 175,0 | 169,0 | 170,0 | 167,7 |

| ST-P-30 | 56 | 170,0 | 171,0 | 167,0 | 169,0 | 170,0 | 169,0 |

| ST-S-05 | 57 | 172,0 | 173,0 | 186,0 | 150,0 | 152,0 | 169,7 |

| – | Tensile Strength Rm | ||||||

|---|---|---|---|---|---|---|---|

| Code | Sample Number | Steel Class [MPa] (*) | Average HB Hardness HBmed | ASTM A370-03a [MPa] | UNI ISO 18265 [MPa] | Rm,avg [MPa] | Average Deviation [%] |

| ST-P-01 | 1 | S235 | 88,7 | 308,5 | 295,6 | 302,1 | -4,27 |

| ST-P-02 | 2 | S235 | 89,3 | 310,6 | 297,7 | 304,2 | -4,24 |

| ST-P-25 | 3 | S235 | 89,7 | 312 | 299 | 305,5 | -4,26 |

| ST-P-09 | 4 | S235 | 90,3 | 314,0 | 305,3 | 309,7 | -2,81 |

| ST-P-15 | 5 | S235 | 90,7 | 315,7 | 306,7 | 311,2 | -2,89 |

| ST-P-23 | 6 | S235 | 90,7 | 315,7 | 306,7 | 311,2 | -2,89 |

| ST-P-24 | 7 | S235 | 93,0 | 323,5 | 314,5 | 319,0 | -2,82 |

| ST-S-01 | 8 | S235 | 94,0 | 330,0 | 317,8 | 323,9 | -3,77 |

| ST-P-13 | 9 | S235 | 96,0 | 337,0 | 323,4 | 330,2 | -4,12 |

| ST-P-03 | 10 | S235 | 96,7 | 339,5 | 325,7 | 332,6 | -4,15 |

| ST-S-04 | 11 | S235 | 100,3 | 341,0 | 336,7 | 338,9 | -1,27 |

| ST-R-01 | 12 | S235 | 100,7 | 342,4 | 338,0 | 340,2 | -1,29 |

| ST-P-08 | 13 | S235 | 103,7 | 352,4 | 348,1 | 350,3 | -1,23 |

| ST-P-05 | 14 | S235 | 104,0 | 353,4 | 349,1 | 351,3 | -1,22 |

| ST-P-07 | 15 | S275 | 105,0 | 360 | 355,7 | 357,9 | -1,20 |

| ST-P-26 | 16 | S235 | 106,7 | 364 | 357,6 | 360,8 | -1,77 |

| ST-P-10 | 17 | S275 | 107,3 | 366,6 | 370 | 368,3 | 0,92 |

| ST-R-02 | 18 | S275 | 109,0 | 366,6 | 370 | 368,3 | 0,92 |

| ST-R-03 | 19 | S275 | 109,0 | 366,6 | 370 | 368,3 | 0,92 |

| ST-P-16 | 20 | S275 | 109,0 | 369 | 372,4 | 370,7 | 0,92 |

| ST-R-04 | 21 | S275 | 109,7 | 369 | 372,4 | 370,7 | 0,92 |

| ST-S-02 | 22 | S275 | 109,7 | 370 | 375,4 | 372,7 | 1,45 |

| ST-S-06 | 23 | S275 | 110,7 | 370 | 375,8 | 372,9 | 1,56 |

| ST-R-05 | 24 | S275 | 110,7 | 370 | 375,8 | 372,9 | 1,56 |

| ST-P-12 | 25 | S275 | 111,0 | 373,4 | 376,8 | 375,1 | 0,91 |

| ST-P-04 | 26 | S275 | 111,3 | 374,4 | 377,8 | 376,1 | 0,90 |

| ST-R-06 | 27 | S275 | 111,7 | 375,7 | 379,1 | 377,4 | 0,90 |

| ST-P-22 | 28 | S275 | 112,0 | 376,7 | 380,2 | 378,5 | 0,92 |

| ST-S-03 | 29 | S275 | 113,0 | 380,1 | 381,6 | 380,9 | 0,39 |

| ST-P-21 | 30 | S275 | 113,7 | 382,4 | 384 | 383,2 | 0,42 |

| ST-R-07 | 31 | S275 | 114,3 | 384,5 | 386 | 385,3 | 0,39 |

| ST-R-08 | 32 | S275 | 114,7 | 385,8 | 387,4 | 386,6 | 0,41 |

| ST-P-06 | 33 | S275 | 116,0 | 385 | 391,8 | 388,4 | 1,75 |

| ST-R-09 | 34 | S275 | 117,0 | 395 | 393,3 | 394,2 | -0,43 |

| ST-R-10 | 35 | S275 | 117,7 | 397,3 | 395,6 | 396,5 | -0,43 |

| ST-R-11 | 36 | S275 | 118,0 | 398,4 | 396,6 | 397,5 | -0,45 |

| ST-P-27 | 37 | S275 | 122,7 | 410,7 | 410,6 | 410,7 | -0,02 |

| ST-P-18 | 38 | S275 | 122,7 | 410,7 | 410,6 | 410,7 | -0,02 |

| ST-P-31 | 39 | S275 | 125,7 | 422,4 | 420,7 | 421,6 | -0,40 |

| ST-P-32 | 40 | S275 | 133,0 | 443,3 | 450 | 446,7 | 1,50 |

| ST-P-19 | 41 | S355 | 130,3 | 435 | 437,7 | 436,4 | 0,62 |

| ST-P-17 | 42 | S355 | 131,7 | 440,7 | 442,4 | 441,6 | 0,39 |

| ST-P-11 | 43 | S275 | 135,3 | 451,7 | 457,8 | 454,8 | 1,34 |

| ST-S-06 | 44 | S275 | 136,3 | 454,3 | 461,2 | 457,8 | 1,51 |

| ST-P-29 | 45 | S355 | 139,7 | 462,3 | 470,7 | 466,5 | 1,80 |

| ST-P-28 | 46 | S355 | 149,3 | 490,8 | 502,7 | 496,8 | 2,40 |

| ST-S-08 | 47 | S355 | 153,0 | 505 | 513,4 | 509,2 | 1,65 |

| ST-P-14 | 48 | S355 | 154,7 | 510,6 | 519,1 | 514,9 | 1,65 |

| ST-P-20 | 49 | S355 | 155,7 | 513,9 | 522,4 | 518,2 | 1,64 |

| ST-P-34 | 50 | S355 | 156,7 | 532,4 | 532,4 | 532,4 | 0,00 |

| ST-R-12 | 51 | S355 | 158,0 | 536,8 | 536,8 | 536,8 | 0,00 |

| ST-S-07 | 52 | S355 | 162,0 | 560 | 545 | 552,5 | -2,71 |

| ST-P-33 | 53 | S355 | 163,3 | 564,5 | 549,4 | 557,0 | -2,71 |

| ST-R-13 | 54 | S355 | 166,3 | 569,5 | 561,0 | 565,3 | -1,50 |

| ST-R-14 | 55 | S355 | 167,7 | 574,2 | 565,7 | 570,0 | -1,49 |

| ST-P-30 | 56 | S355 | 169,0 | 570 | 570,1 | 570,1 | 0,02 |

| ST-S-05 | 57 | S355 | 169,7 | 572,3 | 572,5 | 572,4 | 0,03 |

| – | (*) | Classification by destructive tensile tests | |||||

| HV | HRC | HV | HRC | HV | HRC | HV | HRC | HV | HRC |

|---|---|---|---|---|---|---|---|---|---|

| 2270 | 85 | 1950 | 81 | 1633 | 77 | 1323 | 73 | 1004 | 69 |

| 2190 | 84 | 1865 | 80 | 1556 | 76 | 1245 | 72 | 940 | 68 |

| 2110 | 83 | 1787 | 79 | 1478 | 75 | 1160 | 71 | 920 | 67,5 |

| 2030 | 82 | 1710 | 78 | 1400 | 74 | 1076 | 70 | 900 | 67 |

| HRC Diamond cone | HV Vickers 30 | HBBrinell 29400 N | HRA Diamond cone | Rm (MPa) | HRB Sphere 1/16” | HV Vickers 30 | HB Brinell 29400 N | HRA Diamond cone | Rm (MPa) |

| 68 | 940 | / | 85,6 | / | 100 | 240 | 240 | 61,5 | 800 |

| 67 | 900 | / | 85,0 | / | 99 | 234 | 234 | 60,9 | 785 |

| 66 | 865 | / | 84,5 | / | 98 | 228 | 228 | 60,2 | 750 |

| 65 | 832 | 739 | 83,9 | / | 97 | 222 | 222 | 59,5 | 715 |

| 64 | 800 | 722 | 83,4 | / | 96 | 216 | 216 | 58,9 | 705 |

| 63 | 772 | 706 | 82,8 | / | 95 | 210 | 210 | 58,3 | 690 |

| 62 | 746 | 688 | 82,3 | / | 94 | 205 | 205 | 57,6 | 675 |

| 61 | 720 | 670 | 81,8 | / | 93 | 200 | 200 | 57,0 | 650 |

| 60 | 697 | 654 | 81,2 | / | 92 | 195 | 195 | 56,4 | 635 |

| 59 | 664 | 634 | 80,7 | 2420 | 91 | 190 | 190 | 55,8 | 620 |

| 58 | 653 | 615 | 80,1 | 2330 | 90 | 185 | 185 | 55,2 | 615 |

| 57 | 633 | 595 | 79,6 | 2240 | 89 | 180 | 180 | 54,6 | 605 |

| 56 | 613 | 577 | 79,0 | 2160 | 88 | 176 | 176 | 54,0 | 590 |

| 55 | 595 | 560 | 78,5 | 2070 | 87 | 172 | 172 | 53,4 | 580 |

| 54 | 577 | 543 | 78,0 | 2010 | 86 | 169 | 169 | 52,8 | 570 |

| 53 | 560 | 525 | 77,4 | 1950 | 85 | 165 | 165 | 52,3 | 565 |

| 52 | 544 | 512 | 76,8 | 1880 | 84 | 162 | 162 | 51,7 | 560 |

| 51 | 528 | 496 | 76,3 | 1820 | 83 | 159 | 159 | 51,1 | 550 |

| 50 | 513 | 482 | 75,9 | 1760 | 82 | 156 | 156 | 50,6 | 530 |

| 49 | 498 | 468 | 75,2 | 1700 | 81 | 153 | 153 | 50,0 | 505 |

| 48 | 484 | 455 | 74,7 | 1640 | 80 | 150 | 150 | 49,5 | 495 |

| 47 | 471 | 442 | 74,1 | 1580 | 79 | 147 | 147 | 48,9 | 485 |

| 46 | 458 | 432 | 73,6 | 1520 | 78 | 144 | 144 | 48,4 | 475 |

| 45 | 446 | 421 | 73,1 | 1480 | 77 | 141 | 141 | 47,9 | 470 |

| 44 | 434 | 409 | 72,5 | 1430 | 76 | 139 | 139 | 47,3 | 460 |

| 43 | 423 | 400 | 72,0 | 1390 | 75 | 137 | 137 | 46,8 | 455 |

| 42 | 412 | 390 | 71,5 | 1340 | 74 | 135 | 135 | 46,3 | 450 |

| 41 | 402 | 381 | 70,9 | 1300 | 73 | 132 | 132 | 45,8 | 440 |

| 40 | 392 | 371 | 70,4 | 1250 | 72 | 130 | 130 | 45,3 | 435 |

| 39 | 382 | 362 | 69,9 | 1220 | 71 | 127 | 127 | 44,8 | 425 |

| 38 | 372 | 353 | 69,4 | 1180 | 70 | 125 | 125 | 44,3 | 420 |

| 37 | 363 | 344 | 68,9 | 1140 | 69 | 123 | 123 | 43,8 | 415 |

| 36 | 354 | 336 | 68,4 | 1110 | 68 | 121 | 121 | 43,3 | 405 |

| 35 | 345 | 327 | 67,9 | 1080 | 67 | 119 | 119 | 42,8 | 400 |

| 34 | 336 | 319 | 67,4 | 1050 | 66 | 117 | 117 | 42,3 | 395 |

| 33 | 327 | 311 | 66,8 | 1030 | 65 | 116 | 116 | 41,8 | 385 |

| 32 | 318 | 301 | 66,3 | 1010 | 64 | 114 | 114 | 41,4 | / |

| 31 | 310 | 294 | 65,8 | 970 | 63 | 112 | 112 | 40,9 | / |

| 30 | 302 | 286 | 65,3 | 950 | 62 | 110 | 110 | 40,4 | 370 |

| 29 | 294 | 279 | 64,6 | 630 | 61 | 108 | 108 | 40,0 | / |

| 28 | 286 | 271 | 64,3 | 900 | 60 | 107 | 107 | 39,5 | / |

| 27 | 279 | 264 | 63,8 | 880 | 59 | 106 | 106 | 39,0 | 360 |

| 26 | 272 | 258 | 63,3 | 860 | 58 | 104 | 104 | 38,6 | / |

| 25 | 266 | 253 | 62,8 | 850 | 57 | 103 | 103 | 38,1 | 350 |

| 24 | 260 | 247 | 62,4 | 820 | 56 | 101 | 101 | 37,7 | / |

| 23 | 254 | 243 | 62,0 | 810 | 55 | 100 | 100 | 37,2 | 340 |

| 22 | 248 | 237 | 61.5 | 790 | 54 | / | / | 36,8 | / |

| 21 | 243 | 231 | 61.0 | 770 | 51 | / | 94 | 35,5 | 330 |

| 20 | 238 | 226 | 60.5 | 760 | 49 | / | 92 | 34,6 | 320 |

| Legend: Bold values are reliable, but out of the ASTM table. Italic values are due to the passage from Table 2 to Table 3 of the ASTM A 370 standard. HRA: Rockwell hardness with diamond cone - load: 588 N - duration: 30” HRB: Rockwell hardness with 1/16” sphere - load: 980 N - duration: 30” HRC: Rockwell hardness with 120° diamond cone - load: 1470 N-duration: 30” HB: Brinell hardness with 10 mm diameter sphere - load: 29400 N-duration: 15” HV: Vickers hardness with 136° diamond pyramid - load: 294 N-duration: 15” Rm: Tensile strength (MPa) |

|||||||||

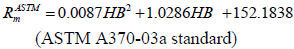

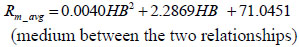

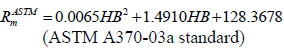

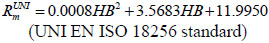

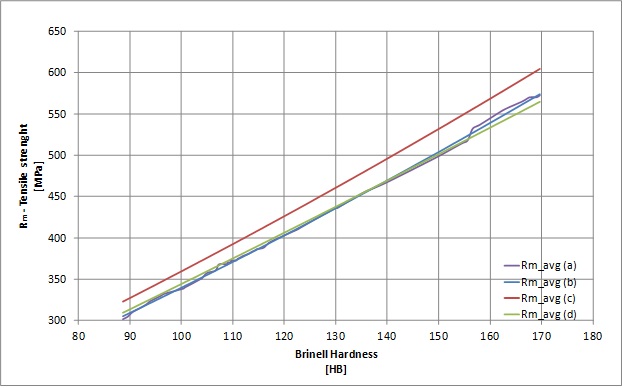

Later on, the envelope curves of the obtained data (Table 9) have been determined, as shown in Fig. (8), on the basis of the following (Eq. 1-3) :

|

(1) |

|

(2) |

|

(3) |

where:

RmASTM is the tensile strength according to the ASTM standard, expressed in MPa;

RmUNI is the tensile strength according to the UNI standard, expressed in MPa;

Rm_avg is the average tensile resistance, expressed in MPa;

HB is the Brinell scale static hardness.

3.3. Determination of Hardness Conversion Curves (Brinell Method)

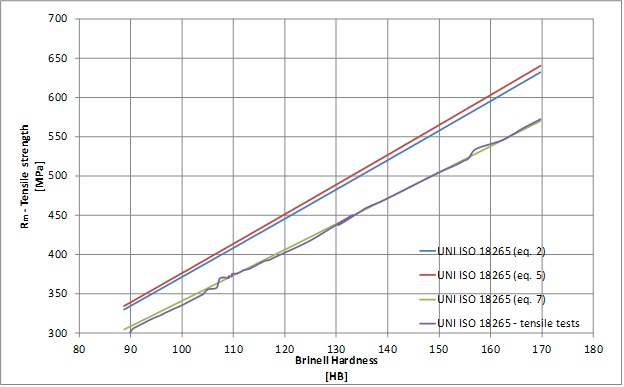

Considering the conversion tables shown in the UNI EN ISO 18256 (Table 10) and ASTM A370-03a (Table 9) standards, the formulations encompassing the values of these tables (Fig. 8) have been deduced for S235, S275 and S355 metal carpentry steels with nominal ultimate tensile strengths fuk,max in the range from 510 to 530 MPa.

| Tensile Strength MPa | Vickers Hardness HV10 | Brinell Hardness HB* | Rockwell Hardness | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HRB | HRF | HRC | HRA | HRD | HR15N | HR30N | HR45N | |||

| 255 | 80 | 76 | – | – | – | – | – | – | – | – |

| 270 | 85 | 80,7 | 41 | – | – | – | – | – | – | – |

| 285 | 90 | 58,5 | 48 | 82,6 | – | – | – | – | – | – |

| 305 | 95 | 90,2 | 52 | – | – | – | – | – | – | – |

| 320 | 100 | 95 | 56,2 | 57 | – | – | – | – | – | – |

| 335 | 105 | 99,8 | – | – | – | – | – | – | – | – |

| 350 | 110 | 105 | 62,3 | 90,5 | – | – | – | – | – | – |

| 370 | 115 | 109 | – | – | – | – | – | |||

| 385 | 120 | 114 | 66,7 | 93,6 | – | – | – | – | – | – |

| 400 | 125 | 119 | – | – | – | – | – | |||

| 415 | 130 | 124 | 71,2 | 96,4 | – | – | – | – | – | – |

| 430 | 135 | 128 | – | – | – | – | – | – | – | – |

| 450 | 140 | 133 | 75 | 99 | – | – | – | – | – | – |

| 465 | 145 | 138 | – | – | – | – | – | – | – | – |

| 480 | 150 | 143 | 78,7 | (101,4) | – | – | – | – | – | – |

| 495 | 155 | 147 | – | – | – | – | – | – | – | – |

| 510 | 160 | 152 | 81,7 | (103,6) | – | – | – | – | – | – |

| 530 | 165 | 156 | – | – | – | – | – | |||

| 545 | 170 | 162 | 85 | (105,5) | – | – | – | – | – | – |

| 560 | 175 | 166 | – | – | – | – | – | |||

| 575 | 180 | 171 | 87,1 | (107,2) | – | – | – | – | – | – |

| 595 | 185 | 176 | – | – | – | – | – | – | – | – |

| 610 | 190 | 181 | 89,5 | (108,7) | – | – | – | – | – | – |

| 625 | 195 | 185 | – | – | – | – | – | – | – | – |

| 640 | 200 | 190 | 91,5 | (110,1) | – | – | – | – | – | – |

| 660 | 205 | 195 | 92,5 | – | – | – | – | – | – | – |

| 675 | 210 | 199 | 93,5 | (111,3) | – | – | – | – | – | – |

| 690 | 215 | 204 | 94 | – | – | – | – | – | – | – |

| 705 | 220 | 209 | 95 | (112,4) | – | – | – | – | – | – |

| 720 | 225 | 214 | 96 | – | – | – | – | – | – | – |

| 740 | 230 | 219 | 69,7 | (113,4) | – | – | – | – | – | – |

| 755 | 235 | 223 | – | – | – | – | – | – | – | – |

| 770 | 240 | 228 | 98,1 | (114,3) | 20,3 | 60,7 | 40,3 | 69,6 | 41,7 | 19,9 |

| 785 | 245 | 233 | – | – | 21,3 | 61,2 | 41,1 | 70,1 | 42,5 | 21,1 |

| 800 | 250 | 238 | 99,5 | 115,1) | 22,2 | 61,6 | 41,7 | 70,6 | 43,4 | 22,2 |

| 820 | 255 | 242 | – | – | 23,1 | 62 | 42,2 | 71,1 | 44,2 | 23,2 |

| 835 | 260 | 247 | (101) | – | 24 | 62,4 | 43,1 | 71,6 | 45 | 24,3 |

| 850 | 265 | 252 | – | – | 24,8 | 62,7 | 43,7 | 72,1 | 45,7 | 25,2 |

| 865 | 270 | 257 | (102) | – | 25,6 | 63,1 | 44,3 | 72,6 | 46,4 | 26,2 |

| 880 | 275 | 261 | – | – | 26,4 | 63,5 | 44,9 | 73 | 47,2 | 27,1 |

| 900 | 280 | 266 | (104) | – | 27,1 | 63,8 | 45,3 | 73,4 | 47,8 | 27,9 |

| 915 | 285 | 271 | – | – | 27,8 | 64,2 | 46 | 73,8 | 48,4 | 28,7 |

| 930 | 290 | 276 | (105) | – | 28,5 | 64,5 | 46,5 | 74,2 | 49 | 29,5 |

| 950 | 295 | 280 | – | – | 29,2 | 64,8 | 47,1 | 74,6 | 49,7 | 30,4 |

| 965 | 300 | 285 | – | – | 29,8 | 65,2 | 47,5 | 74,9 | 50,2 | 31,1 |

| 995 | 310 | 295 | – | – | 31 | 65,8 | 48,4 | 75,6 | 51,3 | 32,5 |

| 1030 | 320 | 304 | – | – | 32,2 | 66,4 | 49,4 | 76,2 | 52,3 | 33,9 |

| 1060 | 330 | 314 | – | – | 33,3 | 67 | 50,2 | 76,2 | 52,3 | 33,9 |

| 1095 | 340 | 323 | – | – | 34,4 | 67,6 | 51,1 | 77,4 | 54,4 | 36,5 |

| 1125 | 350 | 333 | – | – | 35,5 | 68,1 | 51,9 | 78 | 55,4 | 37,8 |

| 1155 | 360 | 342 | – | – | 36,6 | 68,7 | 52,8 | 78,6 | 56,4 | 39,1 |

| 1190 | 370 | 352 | – | – | 37,7 | 69,2 | 53,6 | 79,2 | 57,4 | 40,4 |

| 1220 | 380 | 361 | – | – | 38,8 | 69,8 | 54,4 | 79,8 | 58,4 | 41,7 |

| 1255 | 390 | 371 | – | – | 39,8 | 70,3 | 55,3 | 80,3 | 59,3 | 42,9 |

| 1290 | 400 | 380 | – | – | 40,8 | 70,8 | 56 | 80,8 | 60,2 | 44,1 |

| 1320 | 410 | 390 | – | – | 41,8 | 71,4 | 56,8 | 81,4 | 61,1 | 45,3 |

| 1350 | 420 | 399 | – | – | 42,7 | 71,8 | 57,5 | 81,8 | 61,9 | 46,4 |

| 1385 | 430 | 409 | – | – | 43,6 | 72,3 | 58,2 | 82,3 | 62,7 | 47,4 |

| 1420 | 440 | 418 | – | – | 44,5 | 72,8 | 58,8 | 82,8 | 63,5 | 48,4 |

| 1455 | 450 | 428 | – | – | 45,3 | 73,3 | 59,4 | 83,2 | 64,3 | 49,4 |

| 1465 | 460 | 437 | – | – | 46,1 | 73,6 | 60,1 | 83,6 | 64,9 | 50,4 |

| 1520 | 470 | 447 | – | – | 46,9 | 74,1 | 60,7 | 83,9 | 65,7 | 51,3 |

| 1555 | 480 | 456 | – | – | 47,7 | 74,5 | 61,3 | 84,3 | 66,4 | 52,2 |

| 1595 | 490 | 466 | – | – | 48,4 | 74,9 | 61,6 | 84,7 | 67,1 | 53,1 |

| 1630 | 500 | 475 | – | – | 49,1 | 75,3 | 62,2 | 85 | 67,7 | 53,9 |

| 1665 | 510 | 485 | – | – | 49,8 | 75,7 | 62,9 | 85,4 | 68,3 | 54,7 |

| 1700 | 520 | 494 | – | – | 50,5 | 76,1 | 63,5 | 85,7 | 69 | 55,6 |

| 1740 | 530 | 504 | – | – | 51,1 | 76,4 | 63,9 | 86 | 69,5 | 56,2 |

| 1775 | 540 | 513 | – | – | 51,7 | 76,7 | 64,4 | 86,3 | 70 | 57 |

| 1810 | 550 | 523 | – | – | 52,3 | 77 | 64,8 | 86,6 | 70,5 | 57,8 |

| 1845 | 560 | 532 | – | – | 53 | 77,4 | 65,4 | 86,9 | 71,2 | 58,6 |

| 1880 | 570 | 542 | – | – | 53,6 | 77,8 | 65,8 | 87,2 | 71,7 | 59,3 |

| 1920 | 580 | 551 | – | – | 54,1 | 78 | 66,2 | 87,5 | 72,1 | 59,9 |

| 1955 | 590 | 561 | – | – | 54,7 | 78,4 | 66,7 | 87,8 | 72,7 | 60,5 |

| 1995 | 600 | 570 | – | – | 55,2 | 78,6 | 67 | 88 | 73,2 | 61,2 |

| 2030 | 610 | 580 | – | – | 55,7 | 78,9 | 67,5 | 88,2 | 73,7 | 61,7 |

| 2070 | 620 | 589 | 56,3 | 79,2 | 67,9 | 88,5 | 74,2 | 62,4 | ||

| 2105 | 630 | 599 | – | – | 56,8 | 79,5 | 68,3 | 88,8 | 74,6 | 63 |

| 2145 | 640 | 608 | – | – | 57,3 | 79,8 | 68,7 | 89 | 75,1 | 63,5 |

| 2180 | 650 | 618 | – | – | 57,8 | 80 | 69 | 89,2 | 75,5 | 64,1 |

| – | 660 | – | – | – | 58,3 | 80,3 | 69,4 | 89,5 | 75,9 | 64,7 |

| – | 670 | – | – | – | 58,8 | 80,6 | 69,8 | 89,7 | 76,4 | 65,3 |

| – | 680 | – | – | – | 59,2 | 80,8 | 70,1 | 89,8 | 76,8 | 65,7 |

| – | 690 | – | – | – | 59,7 | 81,1 | 70,5 | 90,1 | 77,2 | 66,2 |

| – | 700 | – | – | – | 60,1 | 81,3 | 70,8 | 90,3 | 77,6 | 66,7 |

| – | 720 | – | – | – | 61 | 81,8 | 71,5 | 90,7 | 78,4 | 67,7 |

| – | 740 | – | – | – | 61,8 | 82,2 | 72,1 | 91 | 79,1 | 68,6 |

| – | 760 | – | – | – | 62,5 | 82,6 | 72,6 | 91,2 | 79,7 | 69,4 |

| – | 780 | – | – | – | 63,3 | 83 | 73,3 | 91,5 | 80,4 | 70,2 |

| – | 800 | – | – | – | 64 | 83,4 | 73,8 | 91,8 | 81,1 | 71 |

| – | 820 | – | – | – | 64,7 | 83,8 | 74,3 | 92,1 | 81,7 | 71,8 |

| – | 840 | 65,3 | 84,1 | 74,8 | 92,3 | 82,2 | 72,2 | |||

| – | 860 | – | – | – | 65,9 | 84,4 | 75,3 | 92,5 | 92,7 | 73,1 |

| – | 880 | – | – | – | 66,4 | 84,7 | 75,7 | 92,7 | 83,1 | 73,6 |

| – | 900 | – | – | – | 67 | 85 | 76,1 | 92,9 | 83,6 | 74,2 |

| – | 920 | – | – | – | 67,5 | 85,3 | 76,5 | 93 | 84 | 74,8 |

| – | 40 | – | – | – | 68 | 85,6 | 76,9 | 93,2 | 84,4 |

75,4 |

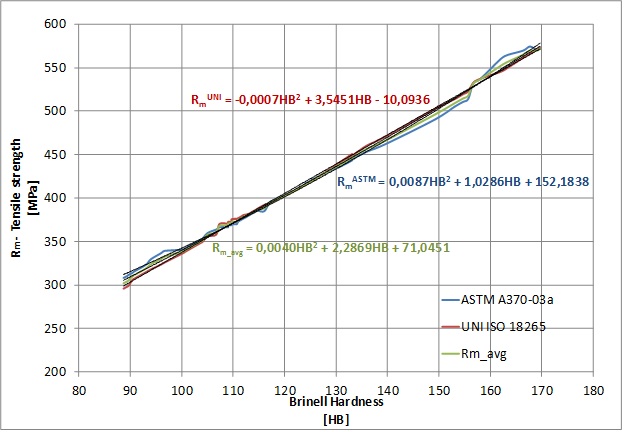

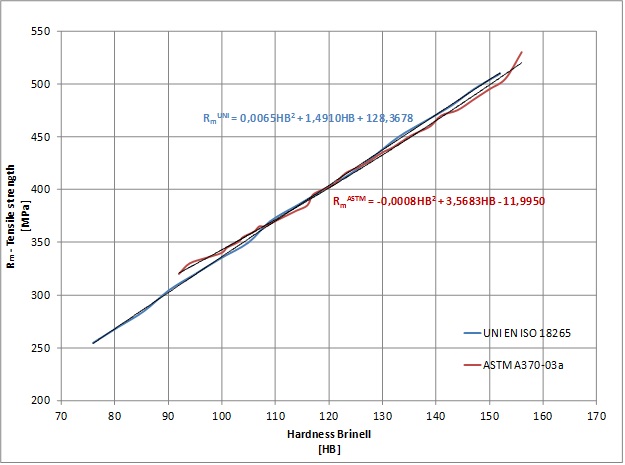

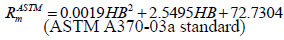

For simplicity, the envelope curves of these strength values for structural carpentry steels have been obtained from the tables as a function of the hardness value HB on the basis of the following expressions (Eq. 4 and 5) (Fig. 9):

|

(4) |

|

(5) |

where:

RmASTM is the tensile strength according to the ASTM standard, expressed in MPa;

RmUNI is the tensile strength according to the UNI standard, expressed in MPa.

Thus, from the surface hardness measurements, it is possible to achieve the tensile strengths of tested steels.

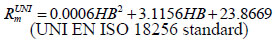

3.4. Hardness Estimation by the Complete Conversion Curves (Brinell Method)

By implementing all the values contained in the conversion tables given from both the UNI EN ISO 18256 standard (Table 10) and the ASTM A370-03a one (Table 9), the envelope formulations (Fig. 10), depending on the measurement of hardness HB, are obtained as: Eq. (6 and 7).

|

(6) |

|

(7) |

where:

RmASTM is the tensile strength according to the ASTM standard, expressed in MPa;

RmUNI is the tensile strength according to the UNI standard, expressed in MPa.

4. DISCUSSION

4.1. Determination of Steel Class Using ASTM Methods

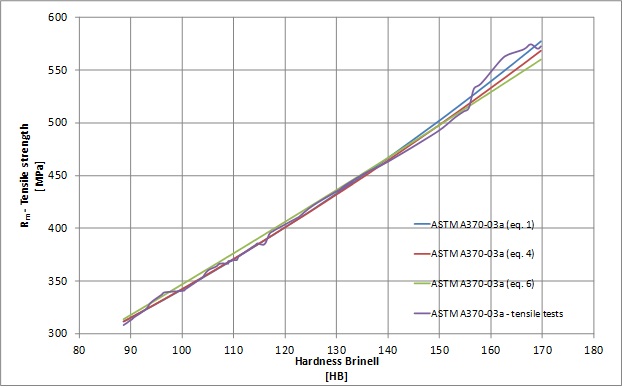

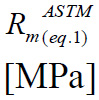

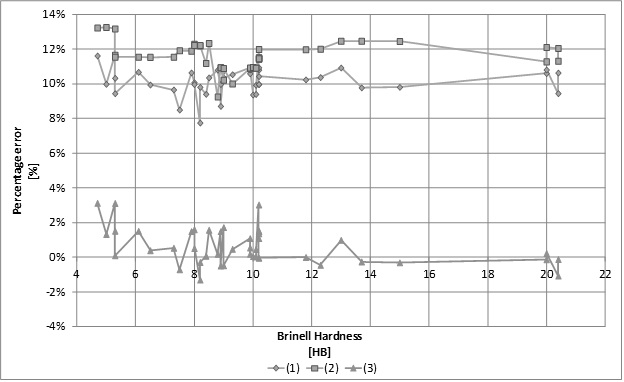

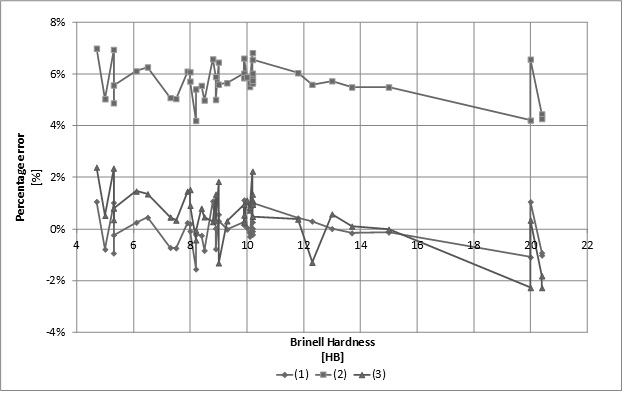

Comparing the values deriving from the ASTM A370-03a standard conversion tables (Table 9) with those achieved from relationships (1), (4) and (6), very similar trends of related curves have been observed (Fig. 11).

The errors committed by using the envelope curve from the whole ASTM table have been evaluated for all the steel classes (Table 11).

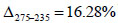

From this comparison it has been observed a maximum negative error

=-4.37%, a maximum positive error

=-4.37%, a maximum positive error

=2.35% and a maximum percentage scatter

=2.35% and a maximum percentage scatter

=6.72% (Fig. 12 and Table 12). Contrary, using the partial tables for structural steels only, a maximum negative error

=6.72% (Fig. 12 and Table 12). Contrary, using the partial tables for structural steels only, a maximum negative error

=-2.30%, a maximum positive error

=-2.30%, a maximum positive error

=1.83%, and a maximum percentage scatter

=1.83%, and a maximum percentage scatter

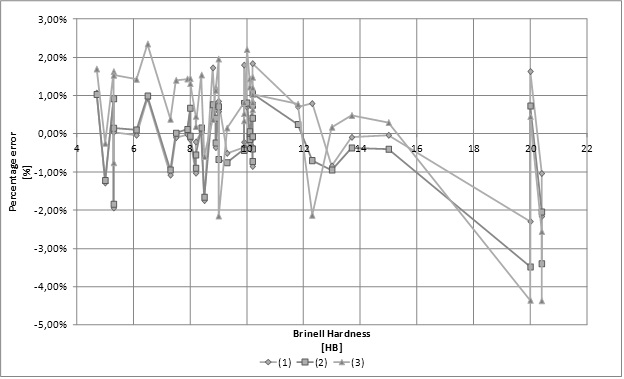

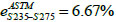

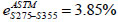

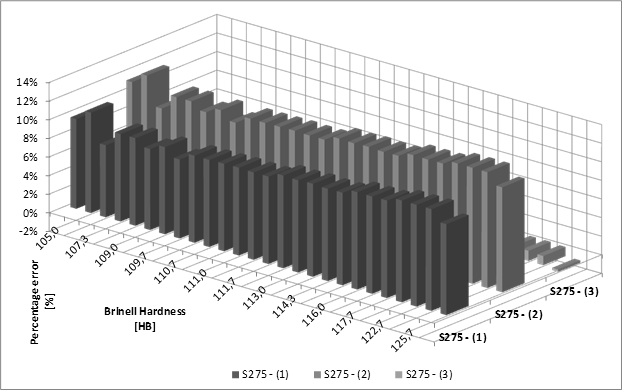

=4.13%, have been detected. Analysing separately the errors committed for the different steel classes (Table 12), it has been observed that errors found for S235 steels (Fig. 13) are lower than those obtained with S275 steels (Fig. 14).

=4.13%, have been detected. Analysing separately the errors committed for the different steel classes (Table 12), it has been observed that errors found for S235 steels (Fig. 13) are lower than those obtained with S275 steels (Fig. 14).

| Code | Sample n° |

HBavg |

|

|

|

|

e(eq.1-test) (%) |

e(eq.4-test) (%) |

e(eq.6-test) (%) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | |||||||

| ST-P-01 | 1 | 88,7 | 308,5 | 311,8 | 311,7 | 313,7 | 1,06 | 1,03 | 1,69 |

| ST-P-02 | 2 | 89,3 | 310,6 | 313,5 | 313,4 | 315,6 | 0,93 | 0,91 | 1,63 |

| ST-P-25 | 3 | 89,7 | 312 | 314,4 | 314,3 | 316,6 | 0,76 | 0,74 | 1,48 |

| ST-P-09 | 4 | 90,3 | 314,0 | 316,1 | 316,1 | 318,5 | 0,67 | 0,67 | 1,45 |

| ST-P-15 | 5 | 90,7 | 315,7 | 317,0 | 317,0 | 319,5 | 0,40 | 0,41 | 1,20 |

| ST-P-23 | 6 | 90,7 | 315,7 | 317,0 | 317,0 | 319,5 | 0,40 | 0,41 | 1,20 |

| ST-P-24 | 7 | 93,0 | 323,5 | 323,1 | 323,2 | 326,3 | -0,13 | -0,08 | 0,86 |

| ST-S-01 | 8 | 94,0 | 330,0 | 325,7 | 326,0 | 329,2 | -1,29 | -1,23 | -0,25 |

| ST-P-13 | 9 | 96,0 | 337,0 | 331,1 | 331,4 | 335,0 | -1,75 | -1,66 | -0,60 |

| ST-P-03 | 10 | 96,7 | 339,5 | 332,9 | 333,2 | 336,9 | -1,94 | -1,84 | -0,76 |

| ST-S-04 | 11 | 100,3 | 341,0 | 343,0 | 343,4 | 347,7 | 0,58 | 0,70 | 1,95 |

| ST-R-01 | 12 | 100,7 | 342,4 | 343,9 | 344,3 | 348,6 | 0,44 | 0,56 | 1,82 |

| ST-P-08 | 13 | 103,7 | 352,4 | 352,3 | 352,8 | 357,4 | -0,02 | 0,11 | 1,43 |

| ST-P-05 | 14 | 104,0 | 353,4 | 353,3 | 353,7 | 358,4 | -0,04 | 0,10 | 1,42 |

| ST-P-07 | 15 | 105,0 | 360 | 356,1 | 356,6 | 361,4 | -1,08 | -0,95 | 0,38 |

| ST-P-26 | 16 | 106,7 | 364 | 360,9 | 361,4 | 366,3 | -0,86 | -0,72 | 0,63 |

| ST-P-10 | 17 | 107,3 | 366,6 | 362,8 | 363,3 | 368,3 | -1,03 | -0,90 | 0,45 |

| ST-R-02 | 18 | 109,0 | 366,6 | 367,7 | 368,1 | 373,2 | 0,29 | 0,41 | 1,80 |

| ST-R-03 | 19 | 109,0 | 366,6 | 367,7 | 368,1 | 373,2 | 0,29 | 0,41 | 1,80 |

| ST-P-16 | 20 | 109,0 | 369 | 367,7 | 368,1 | 373,2 | -0,36 | -0,24 | 1,14 |

| ST-R-04 | 21 | 109,7 | 369 | 369,6 | 370,1 | 375,2 | 0,17 | 0,29 | 1,67 |

| ST-S-02 | 22 | 109,7 | 370 | 369,6 | 370,1 | 375,2 | -0,10 | 0,01 | 1,40 |

| ST-S-06 | 23 | 110,7 | 370 | 372,6 | 373,0 | 378,1 | 0,69 | 0,80 | 2,20 |

| ST-R-05 | 24 | 110,7 | 370 | 372,6 | 373,0 | 378,1 | 0,69 | 0,80 | 2,20 |

| ST-P-12 | 25 | 111,0 | 373,4 | 373,6 | 374,0 | 379,1 | 0,04 | 0,15 | 1,54 |

| ST-P-04 | 26 | 111,3 | 374,4 | 374,5 | 374,9 | 380,1 | 0,04 | 0,14 | 1,53 |

| ST-R-06 | 27 | 111,7 | 375,7 | 375,5 | 375,9 | 381,1 | -0,05 | 0,06 | 1,44 |

| ST-P-22 | 28 | 112,0 | 376,7 | 376,5 | 376,9 | 382,1 | -0,05 | 0,05 | 1,44 |

| ST-S-03 | 29 | 113,0 | 380,1 | 379,5 | 379,8 | 385,1 | -0,16 | -0,07 | 1,31 |

| ST-P-21 | 30 | 113,7 | 382,4 | 381,5 | 381,8 | 387,1 | -0,23 | -0,15 | 1,22 |

| ST-R-07 | 31 | 114,3 | 384,5 | 383,5 | 383,8 | 389,1 | -0,26 | -0,18 | 1,19 |

| ST-R-08 | 32 | 114,7 | 385,8 | 384,5 | 384,8 | 390,1 | -0,33 | -0,26 | 1,10 |

| ST-P-06 | 33 | 116,0 | 385 | 388,6 | 388,8 | 394,0 | 0,93 | 0,98 | 2,35 |

| ST-R-09 | 34 | 117,0 | 395 | 391,6 | 391,8 | 397,0 | -0,85 | -0,81 | 0,51 |

| ST-R-10 | 35 | 117,7 | 397,3 | 393,7 | 393,8 | 399,0 | -0,91 | -0,88 | 0,43 |

| ST-R-11 | 36 | 118,0 | 398,4 | 394,7 | 394,8 | 400,0 | -0,93 | -0,90 | 0,41 |

| ST-P-27 | 37 | 122,7 | 410,7 | 409,3 | 409,1 | 414,1 | -0,35 | -0,40 | 0,82 |

| ST-P-18 | 38 | 122,7 | 410,7 | 409,3 | 409,1 | 414,1 | -0,35 | -0,40 | 0,82 |

| ST-P-31 | 39 | 125,7 | 422,4 | 418,8 | 418,4 | 423,1 | -0,84 | -0,95 | 0,17 |

| ST-P-32 | 40 | 133,0 | 443,3 | 442,9 | 441,6 | 445,4 | -0,09 | -0,37 | 0,48 |

| ST-P-19 | 41 | 130,3 | 435 | 434,0 | 433,1 | 437,3 | -0,22 | -0,43 | 0,53 |

| ST-P-17 | 42 | 131,7 | 440,7 | 438,4 | 437,4 | 441,4 | -0,51 | -0,76 | 0,15 |

| ST-P-11 | 43 | 135,3 | 451,7 | 450,7 | 449,2 | 452,6 | -0,21 | -0,55 | 0,19 |

| ST-S-06 | 44 | 136,3 | 454,3 | 454,1 | 452,5 | 455,6 | -0,04 | -0,41 | 0,29 |

| ST-P-29 | 45 | 139,7 | 462,3 | 465,6 | 463,4 | 465,9 | 0,70 | 0,24 | 0,77 |

| ST-P-28 | 46 | 149,3 | 490,8 | 499,8 | 496,0 | 495,8 | 1,83 | 1,05 | 1,02 |

| ST-S-08 | 47 | 153,0 | 505 | 513,2 | 508,6 | 507,3 | 1,63 | 0,72 | 0,45 |

| ST-P-14 | 48 | 154,7 | 510,6 | 519,4 | 514,5 | 512,5 | 1,72 | 0,76 | 0,37 |

| ST-P-20 | 49 | 155,7 | 513,9 | 523,1 | 518,0 | 515,6 | 1,79 | 0,79 | 0,34 |

| ST-P-34 | 50 | 156,7 | 532,4 | 526,9 | 521,5 | 518,8 | -1,04 | -2,05 | -2,56 |

| ST-R-12 | 51 | 158,0 | 536,8 | 531,9 | 526,2 | 523,0 | -0,91 | -1,97 | -2,57 |

| ST-S-07 | 52 | 162,0 | 560 | 547,1 | 540,5 | 535,6 | -2,30 | -3,48 | -4,35 |

| ST-P-33 | 53 | 163,3 | 564,5 | 552,3 | 545,3 | 539,8 | -2,16 | -3,40 | -4,37 |

| ST-R-13 | 54 | 166,3 | 569,5 | 564,0 | 556,2 | 549,4 | -0,97 | -2,33 | -3,54 |

| ST-R-14 | 55 | 167,7 | 574,2 | 569,2 | 561,1 | 553,6 | -0,87 | -2,28 | -3,59 |

| ST-P-30 | 56 | 169,0 | 570 | 574,5 | 566,0 | 557,9 | 0,79 | -0,70 | -2,13 |

| ST-S-05 | 57 | 169,7 | 572,3 | 577,1 | 568,5 | 560,0 | 0,85 | -0,67 | -2,15 |

| (*) Tensile strength from conversion tables (1) Percentage error from the comparison between the curves deriving from the ASTM A370-03a data envelope (eq. 1) and the hardness data resulting from manual conversion with ASTM A370-03a tables (test values) (2) Percentage error from the comparison between the ASTM A370-03a partial conversion curves for carpentry steels (eq. 4) and the hardness data resulting from manual conversion with ASTM A370-03a tables (test values) (3) Percentage error from the comparison between the ASTM A370-03a full table curve (eq. 6) and the hardness data resulting from manual conversion with ASTM A370-03a tables (test values) |

|||||||||

| Comparison Case |

|

|

|

|

|---|---|---|---|---|

| (1) | -2,30 | 1,83 | -0,10 | 4,13 |

| (2) | -3,48 | 1,05 | -0,33 | 4,54 |

| (3) | -4,37 | 2,35 | 0,42 | 6,72 |

| S235 - (1) | -1,94 | 1,06 | / | 3,01 |

| S235 - (2) | -1,84 | 1,03 | 0,06 | 2,87 |

| S235 - (3) | -0,76 | 1,95 | 1,04 | 2,71 |

| S275 - (1) | -1,08 | 0,93 | -0,22 | 2,01 |

| S275 - (2) | -0,95 | 0,98 | -0,16 | 1,93 |

| S275 - (3) | 0,17 | 2,35 | 1,17 | 2,18 |

| S355 - (1) | -2,30 | 1,83 | / | 4,13 |

| S355 - (2) | -3,48 | 1,05 | -0,91 | 4,54 |

| S355 - (3) | -4,37 | 1,02 | -1,24 | 5,39 |

| (1) Percentage error between the ASTM A370-03a data envelope curves and the hardness data resulting from manual conversion with ASTM A370-03a tables (2) Percentage error between the ASTM A370-03a partial conversion curves for carpentry steels and the hardness data resulting from manual conversion with ASTM A370-03a tables (3) Percentage error between the ASTM A370-03a full table curve and the hardness data resulting from manual conversion with ASTM A370-03a tables |

||||

The increase of the resistance class from S275 to S355 (Fig. 15) results in errors higher than the ones obtained with lower resistance classes. Comparing the data from non-destructive Leeb tests (Table 11) with the results of tensile tests, it has been observed that for samples ST-P-05 (n.14) and ST-P-07 (n. 15) the passage of class from S235 to the S275 takes place.

The maximum scatter between the resistances of the two samples

is equal to 6.60 MPa. In general, for 1 out of 15 samples of S235 steel class, there is an error in the identification of a higher resistance class, with a percentage error

is equal to 6.60 MPa. In general, for 1 out of 15 samples of S235 steel class, there is an error in the identification of a higher resistance class, with a percentage error

referred to the number of specimens investigated. Regarding the classification between S275 steels and S355 ones, from the data (Table 11) the passage is observed for the samples ST-P-32 (n.40) and ST-P-19 (n.41). The maximum scatter among resistances

referred to the number of specimens investigated. Regarding the classification between S275 steels and S355 ones, from the data (Table 11) the passage is observed for the samples ST-P-32 (n.40) and ST-P-19 (n.41). The maximum scatter among resistances

is equal to 20.9 MPa. In the transition between S275 class and the S355 one, for 1 out of 26 samples made of S275 steel an error

is equal to 20.9 MPa. In the transition between S275 class and the S355 one, for 1 out of 26 samples made of S275 steel an error

is committed in the assignment of the class with respect to the higher one.

is committed in the assignment of the class with respect to the higher one.

With regard to the samples ST-P-26, ST-P-11 and ST-S-06, the detected hardness values have been noticed in disagreement with the actual steel class deriving from either tensile test results or origin certificates. Moreover, comparing the resistance values for the different steel classes gotten from the different conversions from Leeb tests, it has been observed for S235 steels a maximum positive error

and a maximum negative error

and a maximum negative error

(Table 13). Therefore, the tests tend to underestimate the resistance values, going on the safe side in terms of classification. For S275 steel (Table 14), the conversion gives rise to a maximum positive error

(Table 13). Therefore, the tests tend to underestimate the resistance values, going on the safe side in terms of classification. For S275 steel (Table 14), the conversion gives rise to a maximum positive error

and a maximum negative error

and a maximum negative error

.

.

| Code |

Sample n° |

e1 (%) |

e2 (%) |

e3 (%) |

e4 (%) |

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | ||

| ST-P-01 | 1 | -14,31 | -13,39 | -13,42 | -12,85 |

| ST-P-02 | 2 | -13,72 | -12,92 | -12,93 | -12,32 |

| ST-P-25 | 3 | -13,33 | -12,68 | -12,69 | -12,05 |

| ST-P-09 | 4 | -12,78 | -12,20 | -12,20 | -11,52 |

| ST-P-15 | 5 | -12,31 | -11,96 | -11,95 | -11,25 |

| ST-P-23 | 6 | -12,31 | -11,96 | -11,95 | -11,25 |

| ST-P-24 | 7 | -10,14 | -10,25 | -10,21 | -9,37 |

| ST-S-01 | 8 | -8,33 | -9,52 | -9,46 | -8,56 |

| ST-P-13 | 9 | -6,39 | -8,03 | -7,94 | -6,95 |

| ST-P-03 | 10 | -5,69 | -7,52 | -7,43 | -6,41 |

| ST-S-04 | 11 | -5,28 | -4,73 | -4,61 | -3,43 |

| ST-R-01 | 12 | -4,89 | -4,47 | -4,35 | -3,16 |

| ST-P-08 | 13 | -2,11 | -2,14 | -2,00 | -0,71 |

| ST-P-05 | 14 | -1,83 | -1,87 | -1,74 | -0,44 |

| ST-P-07 | 15 | / | -1,08 | -0,95 | 0,38 |

| ST-P-26 | 16 | 1,11 | 0,25 | 0,38 | 1,75 |

| – |

|

1,11 | 0,25 | 0,38 | 1,75 |

| – |

|

-14,31 | -13,39 | -13,42 | -12,85 |

| – |

|

-7,64 | -7,78 | -7,72 | -6,76 |

| – |

|

15,42 | 13,64 | 13,80 | 14,60 |

| Conversion with: (1) Manual use of the table (2) Envelope from manual conversion values (3) Envelope from partial tables for carpentry steels (4) Envelope from the complete table |

|||||

| Code |

Sample n° |

e1 (%) |

e2 (%) |

e3 (%) |

e4 (%) |

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | ||

| ST-P-07 | 15 | -16,28 | -17,19 | -17,07 | -15,96 |

| ST-P-26 | 16 | -15,35 | -16,07 | -15,96 | -14,82 |

| ST-P-10 | 17 | -14,74 | -15,62 | -15,52 | -14,36 |

| ST-R-02 | 18 | -14,74 | -14,50 | -14,39 | -13,21 |

| ST-R-03 | 19 | -14,74 | -14,50 | -14,39 | -13,21 |

| ST-P-16 | 20 | -14,19 | -14,50 | -14,39 | -13,21 |

| ST-R-04 | 21 | -14,19 | -14,04 | -13,94 | -12,75 |

| ST-S-02 | 22 | -13,95 | -14,04 | -13,94 | -12,75 |

| ST-S-06 | 23 | -13,95 | -13,36 | -13,26 | -12,06 |

| ST-R-05 | 24 | -13,95 | -13,36 | -13,26 | -12,06 |

| ST-P-12 | 25 | -13,16 | -13,13 | -13,03 | -11,83 |

| ST-P-04 | 26 | -12,93 | -12,90 | -12,81 | -11,60 |

| ST-R-06 | 27 | -12,63 | -12,67 | -12,58 | -11,37 |

| ST-P-22 | 28 | -12,40 | -12,44 | -12,35 | -11,14 |

| ST-S-03 | 29 | -11,60 | -11,74 | -11,66 | -10,45 |

| ST-P-21 | 30 | -11,07 | -11,28 | -11,20 | -9,98 |

| ST-R-07 | 31 | -10,58 | -10,81 | -10,74 | -9,52 |

| ST-R-08 | 32 | -10,28 | -10,58 | -10,51 | -9,29 |

| ST-P-06 | 33 | -10,47 | -9,64 | -9,58 | -8,36 |

| ST-R-09 | 34 | -8,14 | -8,92 | -8,89 | -7,67 |

| ST-R-10 | 35 | -7,60 | -8,45 | -8,42 | -7,20 |

| ST-R-11 | 36 | -7,35 | -8,21 | -8,18 | -6,97 |

| ST-P-27 | 37 | -4,49 | -4,82 | -4,87 | -3,71 |

| ST-P-18 | 38 | -4,49 | -4,82 | -4,87 | -3,71 |

| ST-P-31 | 39 | -1,77 | -2,60 | -2,70 | -1,60 |

| – |

|

5,65 | 5,61 | 5,22 | 5,96 |

| – |

|

-16,28 | -17,19 | -17,07 | -15,96 |

| – |

|

-8,92 | -9,13 | -9,12 | -7,99 |

| – |

|

21,93 | 22,79 | 22,30 | 21,92 |

| Conversion with: (1) Manual use of the table (2) Envelope from manual conversion values (3) Envelope from partial tables for carpentry steels (4) Envelope from the complete table |

|||||

| Code |

Sample n° |

e1 (%) |

e2 (%) |

e3 (%) |

e4 (%) |

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | ||

| ST-P-19 | 41 | -14,71 | -14,90 | -15,08 | -14,26 |

| ST-P-17 | 42 | -13,59 | -14,03 | -14,24 | -13,46 |

| ST-P-11 | 43 | -11,43 | -11,62 | -11,92 | -11,26 |

| ST-S-06 | 44 | -10,92 | -10,96 | -11,28 | -10,66 |

| ST-P-29 | 45 | -9,35 | -8,71 | -9,14 | -8,65 |

| ST-P-28 | 46 | -3,76 | -2,00 | -2,75 | -2,78 |

| ST-S-08 | 47 | -0,98 | 0,63 | -0,26 | -0,53 |

| ST-P-14 | 48 | 0,12 | 1,84 | 0,88 | 0,49 |

| ST-P-20 | 49 | 0,76 | 2,57 | 1,56 | 1,11 |

| ST-P-34 | 50 | 4,39 | 3,31 | 2,25 | 1,72 |

| ST-R-12 | 51 | 5,25 | 4,29 | 3,18 | 2,55 |

| ST-S-07 | 52 | 9,80 | 7,28 | 5,98 | 5,02 |

| ST-P-33 | 53 | 10,69 | 8,29 | 6,92 | 5,85 |

| ST-R-13 | 54 | 11,67 | 10,58 | 9,06 | 7,72 |

| ST-R-14 | 55 | 12,59 | 11,61 | 10,02 | 8,55 |

| – |

|

12,59 | 13,17 | 11,46 | 9,80 |

| – |

|

-14,71 | -14,90 | -15,08 | -14,26 |

| – |

|

0,85 | 0,82 | -0,14 | -0,55 |

| – |

|

27,29 | 28,06 | 26,54 | 24,06 |

| Conversion with: (1) Manual use of the table (2) Envelope from manual conversion values (3) Envelope from partial tables for carpentry steels (4) Envelope from the complete table |

|||||

| Code | Sample n° |

HBavg |

|

|

|

|

e(eq.2-test) (%) |

e(eq.5-test) (%) |

e(eq.7-test) (%) |

|---|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | |||||||

| ST-P-01 | 1 | 88,7 | 295,6 | 329,9 | 334,7 | 304,8 | 11,61 | 13,22 | 3,12 |

| ST-P-02 | 2 | 89,3 | 297,7 | 332,4 | 337,1 | 307,0 | 11,65 | 13,25 | 3,12 |

| ST-P-25 | 3 | 89,7 | 299 | 333,6 | 338,4 | 308,1 | 11,57 | 13,17 | 3,03 |

| ST-P-09 | 4 | 90,3 | 305,3 | 336,0 | 340,9 | 310,2 | 10,07 | 11,65 | 1,61 |

| ST-P-15 | 5 | 90,7 | 306,7 | 337,3 | 342,1 | 311,3 | 9,97 | 11,54 | 1,49 |

| ST-P-23 | 6 | 90,7 | 306,7 | 337,3 | 342,1 | 311,3 | 9,97 | 11,54 | 1,49 |

| ST-P-24 | 7 | 93,0 | 314,5 | 345,8 | 350,8 | 318,8 | 9,97 | 11,53 | 1,37 |

| ST-S-01 | 8 | 94,0 | 317,8 | 349,5 | 354,5 | 322,0 | 9,98 | 11,54 | 1,33 |

| ST-P-13 | 9 | 96,0 | 323,4 | 356,9 | 361,9 | 328,5 | 10,35 | 11,91 | 1,58 |

| ST-P-03 | 10 | 96,7 | 325,7 | 359,3 | 364,4 | 330,6 | 10,32 | 11,88 | 1,52 |

| ST-S-04 | 11 | 100,3 | 336,7 | 372,8 | 378,1 | 342,5 | 10,73 | 12,29 | 1,72 |

| ST-R-01 | 12 | 100,7 | 338,0 | 374,1 | 379,3 | 343,6 | 10,67 | 12,22 | 1,65 |

| ST-P-08 | 13 | 103,7 | 348,1 | 385,1 | 390,5 | 353,3 | 10,64 | 12,18 | 1,49 |

| ST-P-05 | 14 | 104,0 | 349,1 | 386,4 | 391,8 | 354,4 | 10,67 | 12,22 | 1,51 |

| ST-P-07 | 15 | 105,0 | 355,7 | 390,0 | 395,5 | 357,6 | 9,66 | 11,19 | 0,54 |

| ST-P-26 | 16 | 106,7 | 357,6 | 396,2 | 401,7 | 363,0 | 10,79 | 12,34 | 1,52 |

| ST-P-10 | 17 | 107,3 | 370 | 398,7 | 404,2 | 365,2 | 7,75 | 9,25 | -1,30 |

| ST-R-02 | 18 | 109,0 | 370 | 404,8 | 410,4 | 370,6 | 9,41 | 10,93 | 0,16 |

| ST-R-03 | 19 | 109,0 | 370 | 404,8 | 410,4 | 370,6 | 9,41 | 10,93 | 0,16 |

| ST-P-16 | 20 | 109,0 | 372,4 | 404,8 | 410,4 | 370,6 | 8,71 | 10,22 | -0,48 |

| ST-R-04 | 21 | 109,7 | 372,4 | 407,3 | 412,9 | 372,8 | 9,37 | 10,89 | 0,10 |

| ST-S-02 | 22 | 109,7 | 375,4 | 407,3 | 412,9 | 372,8 | 8,50 | 10,00 | -0,70 |

| ST-S-06 | 23 | 110,7 | 375,8 | 411,0 | 416,7 | 376,0 | 9,36 | 10,88 | 0,06 |

| ST-R-05 | 24 | 110,7 | 375,8 | 411,0 | 416,7 | 376,0 | 9,36 | 10,88 | 0,06 |

| ST-P-12 | 25 | 111,0 | 376,8 | 412,2 | 417,9 | 377,1 | 9,40 | 10,92 | 0,08 |

| ST-P-04 | 26 | 111,3 | 377,8 | 413,5 | 419,2 | 378,2 | 9,44 | 10,95 | 0,10 |

| ST-R-06 | 27 | 111,7 | 379,1 | 414,7 | 420,4 | 379,3 | 9,39 | 10,90 | 0,04 |

| ST-P-22 | 28 | 112,0 | 380,2 | 415,9 | 421,7 | 380,3 | 9,40 | 10,91 | 0,04 |

| ST-S-03 | 29 | 113,0 | 381,6 | 419,6 | 425,4 | 383,6 | 9,97 | 11,49 | 0,52 |

| ST-P-21 | 30 | 113,7 | 384 | 422,1 | 427,9 | 385,8 | 9,92 | 11,44 | 0,46 |

| ST-R-07 | 31 | 114,3 | 386 | 424,6 | 430,4 | 387,9 | 9,99 | 11,51 | 0,50 |

| ST-R-08 | 32 | 114,7 | 387,4 | 425,8 | 431,7 | 389,0 | 9,91 | 11,43 | 0,42 |

| ST-P-06 | 33 | 116,0 | 391,8 | 430,7 | 436,7 | 393,4 | 9,94 | 11,46 | 0,40 |

| ST-R-09 | 34 | 117,0 | 393,3 | 434,5 | 440,4 | 396,6 | 10,46 | 11,99 | 0,84 |

| ST-R-10 | 35 | 117,7 | 395,6 | 436,9 | 442,9 | 398,8 | 10,45 | 11,97 | 0,80 |

| ST-R-11 | 36 | 118,0 | 396,6 | 438,2 | 444,2 | 399,9 | 10,48 | 12,00 | 0,82 |

| ST-P-27 | 37 | 122,7 | 410,6 | 455,5 | 461,7 | 415,1 | 10,93 | 12,46 | 1,09 |

| ST-P-18 | 38 | 122,7 | 410,6 | 455,5 | 461,7 | 415,1 | 10,93 | 12,46 | 1,09 |

| ST-P-31 | 39 | 125,7 | 420,7 | 466,6 | 473,0 | 424,9 | 10,92 | 12,44 | 0,99 |

| ST-P-32 | 40 | 133,0 | 450 | 494,0 | 500,7 | 448,9 | 9,77 | 11,27 | -0,25 |

| ST-P-19 | 41 | 130,3 | 437,7 | 484,0 | 490,7 | 440,1 | 10,58 | 12,10 | 0,55 |

| ST-P-17 | 42 | 131,7 | 442,4 | 489,0 | 495,7 | 444,5 | 10,53 | 12,05 | 0,47 |

| ST-P-11 | 43 | 135,3 | 457,8 | 502,7 | 509,6 | 456,5 | 9,80 | 11,31 | -0,28 |

| ST-S-06 | 44 | 136,3 | 461,2 | 506,4 | 513,3 | 459,8 | 9,80 | 11,31 | -0,31 |

| ST-P-29 | 45 | 139,7 | 470,7 | 518,9 | 526,0 | 470,7 | 10,24 | 11,74 | / |

| ST-P-28 | 46 | 149,3 | 502,7 | 555,1 | 562,7 | 502,5 | 10,42 | 11,94 | -0,04 |

| ST-S-08 | 47 | 153,0 | 513,4 | 568,9 | 576,7 | 514,6 | 10,81 | 12,32 | 0,23 |

| ST-P-14 | 48 | 154,7 | 519,1 | 575,1 | 583,0 | 520,1 | 10,80 | 12,32 | 0,19 |

| ST-P-20 | 49 | 155,7 | 522,4 | 578,9 | 586,8 | 523,4 | 10,82 | 12,34 | 0,19 |

| ST-P-34 | 50 | 156,7 | 532,4 | 582,7 | 590,7 | 526,7 | 9,44 | 10,94 | -1,07 |

| ST-R-12 | 51 | 158,0 | 536,8 | 587,7 | 595,8 | 531,1 | 9,48 | 10,98 | -1,06 |

| ST-S-07 | 52 | 162,0 | 545 | 602,8 | 611,1 | 544,3 | 10,60 | 12,12 | -0,12 |

| ST-P-33 | 53 | 163,3 | 549,4 | 607,8 | 616,2 | 548,8 | 10,63 | 12,15 | -0,12 |

| ST-R-13 | 54 | 166,3 | 561,0 | 619,1 | 627,7 | 558,7 | 10,36 | 11,88 | -0,41 |

| ST-R-14 | 55 | 167,7 | 565,7 | 624,2 | 632,8 | 563,1 | 10,34 | 11,86 | -0,46 |

| ST-P-30 | 56 | 169,0 | 570,1 | 629,2 | 637,9 | 567,5 | 10,37 | 11,89 | -0,45 |

| ST-S-05 | 57 | 169,7 | 572,5 | 631,7 | 640,4 | 569,8 | 10,35 | 11,87 | -0,48 |

| (*) Tensile strength from conversion tables (1) Percentage error from the comparison between the curves deriving from the UNI ISO 18265 data envelope (eq. 2) and the hardness data resulting from manual conversion with UNI ISO 18265 tables (test values) (2) Percentage error from the comparison between the UNI ISO 18265 partial conversion curves for carpentry steels (eq. 5) and the hardness data resulting from manual conversion with UNI ISO 18265 tables (test values) (3) Percentage error from the comparison between the UNI ISO 18265 full table curve (eq. 7) and the hardness data resulting from manual conversion with UNI ISO 18265 tables (test values) |

|||||||||

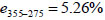

The percentage scatter in terms of stress between the S275 class and the S235 one is defined as Eq. (8):

|

(8) |

and herein assumes the value of 16.28%, which is greater than the maximum negative error recorded. However, the test does not imply problems in the class assignment.

For S355 steel class (Table 15), the conversion provides a maximum positive error

and a maximum negative error

and a maximum negative error

.

.

The percentage scatter between these two steel classes

is 15.69%, a value greater than the maximum negative error recorded.

is 15.69%, a value greater than the maximum negative error recorded.

The tests conducted on 2 out of the total 19 specimens have provided values with an error

in the class assignment, while for higher values this problem is not felt.

in the class assignment, while for higher values this problem is not felt.

4.2. Determination of Steel Class Using UNI ISO Methods

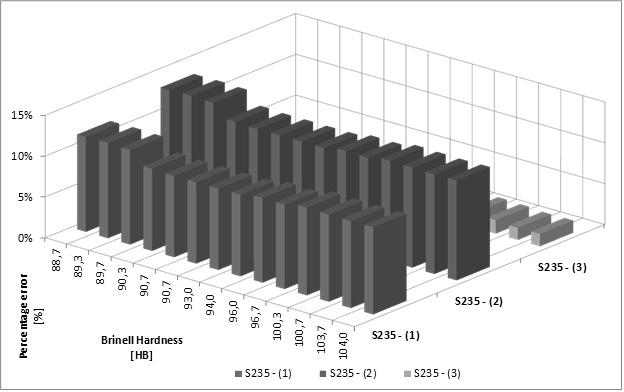

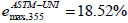

Comparing the results deriving from relationships (2), (5) and (7), the achieved curves have trends very similar to each other (Fig. 16).

Nevertheless, these values are very far from those gotten from the UNI ISO 18265 standard conversion tables (Table 16). In particular, when values deriving from the previously mentioned relationships are compared with the UNI complete table ones, it has been recorded a maximum error

, a minimum error

, a minimum error

and a maximum percentage scatter

and a maximum percentage scatter

(Fig. 17 and Table 17).

(Fig. 17 and Table 17).

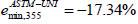

Contrary, in the case of conversion using either only partial tables for carpentry steels or envelope formulas from manual conversion data, it has been noticed that the committed errors are higher than the previous case (Table 17). In fact, the maximum error is

, the minimum error is

, the minimum error is

and the maximum scatter is

and the maximum scatter is

. Analysing the error detected for the different steel classes (Table 17), it has been observed that for S235 (Fig. 18), S275 (Fig. 19) and S355 (Fig. 20) steels, the errors tends to reduce only in the case of relationship (7).

. Analysing the error detected for the different steel classes (Table 17), it has been observed that for S235 (Fig. 18), S275 (Fig. 19) and S355 (Fig. 20) steels, the errors tends to reduce only in the case of relationship (7).

Analyzing the data from non-destructive Leeb tests (Table 18), the transition from S235 class to S275 class does not take place in a univocal manner, depending on the different assessments made. The error committed is much wider and implies that, according to the criterion used for 9 out of 17 samples of class S235 (samples n.9-17), an error in the identification of a higher resistance class can be made (Table 18), with a percentage error

. Similarly, in the transition from S275 steel to S355 one, it is observed that for 10 out of 26 samples a percentage error

. Similarly, in the transition from S275 steel to S355 one, it is observed that for 10 out of 26 samples a percentage error

is committed in the assignment to a higher class (Table 19).

is committed in the assignment to a higher class (Table 19).

| Comparison Case |

|

|

|

|

|---|---|---|---|---|

| (1) | 9,79 | 12,41 | 11,06 | 2,62 |

| (2) | 8,23 | 10,88 | 9,54 | 2,65 |

| (3) | -3,03 | 1,32 | -0,53 | 4,35 |

| S235 - (1) | 9,79 | 10,55 | 10,11 | 0,76 |

| S235 - (2) | 8,23 | 9,02 | 8,56 | 0,79 |

| S235 - (3) | -3,03 | -1,32 | -1,82 | 1,71 |

| S275 - (1) | 10,59 | 11,56 | 10,93 | 0,97 |

| S275 - (2) | 9,07 | 10,05 | 9,42 | 0,98 |

| S275 - (3) | -1,49 | 1,32 | -0,30 | 2,81 |

| S355 - (1) | 11,48 | 12,41 | 12,04 | 0,93 |

| S355 - (2) | 9,98 | 10,88 | 10,52 | 0,90 |

| S355 - (3) | -0,55 | 1,08 | 0,19 | 1,63 |

| (1) Percentage error between the UNI ISO 18265 data envelope curves and the hardness data resulting from manual conversion with UNI ISO 18265 tables (2) Percentage error between the UNI ISO 18265 partial conversion curves for carpentry steels and the hardness data resulting from manual conversion with UNI ISO 18265 tables (3) Percentage error between the UNI ISO 18265 full table curve and the hardness data resulting from manual conversion with UNI ISO 18265 tables |

||||

| Code |

Sample n° |

e1 (%) |

e2 (%) |

e3 (%) |

e4 (%) |

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | ||

| ST-P-01 | 1 | -17,89 | -8,35 | -7,04 | -15,32 |

| ST-P-02 | 2 | -17,31 | -7,67 | -6,35 | -14,73 |

| ST-P-25 | 3 | -16,94 | -7,33 | -6,00 | -14,43 |

| ST-P-09 | 4 | -15,19 | -6,65 | -5,32 | -13,83 |

| ST-P-15 | 5 | -14,81 | -6,31 | -4,97 | -13,53 |

| ST-P-23 | 6 | -14,81 | -6,31 | -4,97 | -13,53 |

| ST-P-24 | 7 | -12,64 | -3,93 | -2,56 | -11,44 |

| ST-S-01 | 8 | -11,72 | -2,91 | -1,53 | -10,55 |

| ST-P-13 | 9 | -10,17 | -0,87 | 0,53 | -8,75 |

| ST-P-03 | 10 | -9,53 | -0,19 | 1,22 | -8,15 |

| ST-S-04 | 11 | -6,47 | 3,56 | 5,02 | -4,86 |

| ST-R-01 | 12 | -6,11 | 3,91 | 5,36 | -4,56 |

| ST-P-08 | 13 | -3,31 | 6,98 | 8,47 | -1,86 |

| ST-P-05 | 14 | -3,03 | 7,32 | 8,82 | -1,56 |

| ST-P-07 | 15 | -1,19 | 8,35 | 9,86 | -0,66 |

| ST-P-26 | 16 | -0,67 | 10,06 | 11,59 | 0,84 |

| ST-P-10 | 17 | 2,78 | 10,74 | 12,28 | 1,44 |

| – |

|

2,78 | 10,74 | 12,28 | 1,44 |

| – |

|

-17,89 | -8,35 | -7,04 | -15,32 |

| – |

|

-9,35 | 0,02 | 1,44 | -7,97 |

| – |

|

20,67 | 19,09 | 19,32 | 16,76 |

| Conversion with: (1) Manual use of the table (2) Envelope from manual conversion values (3) Envelope from partial tables for carpentry steels (4) Envelope from the complete table |

|||||

| Code |

Sample n° |

e1 (%) |

e2 (%) |

e3 (%) |

e4 (%) |

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | ||

| ST-P-26 | 16 | -16,84 | -7,86 | -6,58 | -15,58 |

| ST-P-10 | 17 | -13,95 | -7,29 | -6,00 | -15,07 |

| ST-R-02 | 18 | -13,95 | -5,85 | -4,55 | -13,81 |

| ST-R-03 | 19 | -13,95 | -5,85 | -4,55 | -13,81 |

| ST-P-16 | 20 | -13,40 | -5,85 | -4,55 | -13,81 |

| ST-R-04 | 21 | -13,40 | -5,28 | -3,97 | -13,31 |

| ST-S-02 | 22 | -12,70 | -5,28 | -3,97 | -13,31 |

| ST-S-06 | 23 | -12,60 | -4,42 | -3,10 | -12,56 |

| ST-R-05 | 24 | -12,60 | -4,42 | -3,10 | -12,56 |

| ST-P-12 | 25 | -12,37 | -4,13 | -2,81 | -12,30 |

| ST-P-04 | 26 | -12,14 | -3,85 | -2,52 | -12,05 |

| ST-R-06 | 27 | -11,84 | -3,56 | -2,23 | -11,80 |

| ST-P-22 | 28 | -11,58 | -3,27 | -1,93 | -11,55 |

| ST-S-03 | 29 | -11,26 | -2,41 | -1,06 | -10,79 |

| ST-P-21 | 30 | -10,70 | -1,84 | -0,48 | -10,29 |

| ST-R-07 | 31 | -10,23 | -1,26 | 0,10 | -9,78 |

| ST-R-08 | 32 | -9,91 | -0,98 | 0,39 | -9,53 |

| ST-P-06 | 33 | -8,88 | 0,17 | 1,55 | -8,52 |

| ST-R-09 | 34 | -8,53 | 1,04 | 2,43 | -7,77 |

| ST-R-10 | 35 | -8,00 | 1,61 | 3,01 | -7,26 |

| ST-R-11 | 36 | -7,77 | 1,90 | 3,30 | -7,01 |

| ST-P-27 | 37 | -4,51 | 5,93 | 7,38 | -3,47 |

| ST-P-18 | 38 | -4,51 | 5,93 | 7,38 | -3,47 |

| ST-P-31 | 39 | -2,16 | 8,52 | 10,01 | -1,19 |

| ST-P-32 | 40 | 4,65 | 14,88 | 16,45 | 4,38 |

| – |

|

4,65 | 14,88 | 16,45 | 4,38 |

| – |

|

-16,84 | -7,86 | -6,58 | -15,58 |

| – |

|

-10,13 | -1,34 | 0,03 | -9,85 |

| – |

|

21,49 | 22,74 | 23,03 | 19,96 |

| Conversion with: (1) Manual use of the table (2) Envelope from manual conversion values (3) Envelope from partial tables for carpentry steels (4) Envelope from the complete table |

|||||

Analyzing the resistance values deriving from the different conversions from Leeb tests to the reference values of classes, for S235steels a maximum error

and a minimum error

and a minimum error

is observed (Table 18).

is observed (Table 18).

The test, therefore, tends to overestimate the resistance values, classifying S235 steel samples as S275 steel ones, and, thus, operating not on the safe side in terms of classification. For S275 class steel (Table 19) the conversion involves a maximum error

and a minimum error

and a minimum error

. Given a percentage difference between S235 class and S275 one, defined by h) is equal to

. Given a percentage difference between S235 class and S275 one, defined by h) is equal to

, it is not possible to assign the class in an unambiguous way.

, it is not possible to assign the class in an unambiguous way.

For S355 steel class (Table 20) the conversion involves a maximum error

and a minimum error

and a minimum error

. The percentage difference between S275 class and S355 one is

. The percentage difference between S275 class and S355 one is

, higher than the minimum error committed. The tests conducted for 2 out of 19 samples provide limited values, which could lead to an error

, higher than the minimum error committed. The tests conducted for 2 out of 19 samples provide limited values, which could lead to an error

in the assignment to the samples of a steel lower class.

in the assignment to the samples of a steel lower class.

4.3. Relationship Between the Two Conversion Methods

Using the average values deriving from formulations provided by ASTM A370-03a and UNI ISO 18265 methods (Table 21), an intermediate trend between the two curves ones is achieved (Fig. 21).

| Code |

Sample n° |

e1 (%) |

e2 (%) |

e3 (%) |

e4 (%) |

|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | ||

| ST-P-31 | 39 | -17,51 | -8,50 | -7,25 | -16,69 |

| ST-P-32 | 40 | -11,76 | -3,14 | -1,82 | -11,99 |

| ST-P-19 | 41 | -14,18 | -5,09 | -3,79 | -13,70 |

| ST-P-17 | 42 | -13,25 | -4,12 | -2,81 | -12,85 |

| ST-P-11 | 43 | -10,24 | -1,43 | -0,09 | -10,49 |

| ST-S-06 | 44 | -9,57 | -0,70 | 0,66 | -9,85 |

| ST-P-29 | 45 | -7,71 | 1,74 | 3,13 | -7,70 |

| ST-P-28 | 46 | -1,43 | 8,84 | 10,33 | -1,47 |

| ST-S-08 | 47 | 0,67 | 11,55 | 13,07 | 0,90 |

| ST-P-14 | 48 | 1,78 | 12,77 | 14,32 | 1,98 |

| ST-P-20 | 49 | 2,43 | 13,51 | 15,07 | 2,63 |

| ST-P-34 | 50 | 4,39 | 14,25 | 15,82 | 3,28 |

| ST-R-12 | 51 | 5,25 | 15,23 | 16,82 | 4,14 |

| ST-S-07 | 52 | 6,86 | 18,19 | 19,81 | 6,73 |

| ST-P-33 | 53 | 7,73 | 19,18 | 20,82 | 7,60 |

| ST-R-13 | 54 | 10,00 | 21,40 | 23,07 | 9,55 |

| ST-R-14 | 55 | 10,92 | 22,39 | 24,07 | 10,41 |

| ST-P-30 | 56 | 11,78 | 23,37 | 25,08 | 11,28 |

| ST-S-05 | 57 | 12,25 | 23,87 | 25,58 | 11,72 |

| – |

|

12,25 | 23,87 | 25,58 | 11,72 |

| – |

|

-17,51 | -8,50 | -7,25 | -16,69 |

| – |

|

-0,61 | 9,65 | 11,15 | -0,76 |

| – |

|

29,76 | 32,37 | 32,82 | 28,41 |

| Conversion with: (1) Manual use of the table (2) Envelope from manual conversion values (3) Envelope from partial tables for carpentry steels (4) Envelope from the complete table |

|||||

| Code | Sample n° |

HBavg |

|

|

|

|

e(b-a)% | e(c-a)% | e(d-a)% |

|---|---|---|---|---|---|---|---|---|---|

| [MPa] | [MPa] | [MPa] | [MPa] | (1) | (2) | (3) | |||

| ST-P-01 | 1 | 88,7 | 302,1 | 305,3 | 323,2 | 309,3 | 1,06% | 6,99% | 2,39% |

| ST-P-02 | 2 | 89,3 | 304,2 | 307,3 | 325,3 | 311,3 | 1,02% | 6,95% | 2,36% |

| ST-P-25 | 3 | 89,7 | 305,5 | 308,3 | 326,4 | 312,3 | 0,90% | 6,83% | 2,24% |

| ST-P-09 | 4 | 90,3 | 309,7 | 310,3 | 328,5 | 314,4 | 0,20% | 6,08% | 1,53% |

| ST-P-15 | 5 | 90,7 | 311,2 | 311,3 | 329,5 | 315,4 | 0,02% | 5,89% | 1,35% |

| ST-P-23 | 6 | 90,7 | 311,2 | 311,3 | 329,5 | 315,4 | 0,02% | 5,89% | 1,35% |

| ST-P-24 | 7 | 93,0 | 319,0 | 318,3 | 337,0 | 322,5 | -0,21% | 5,65% | 1,11% |

| ST-S-01 | 8 | 94,0 | 323,9 | 321,4 | 340,2 | 325,6 | -0,78% | 5,04% | 0,53% |

| ST-P-13 | 9 | 96,0 | 330,2 | 327,5 | 346,7 | 331,7 | -0,83% | 4,99% | 0,47% |

| ST-P-03 | 10 | 96,7 | 332,6 | 329,5 | 348,8 | 333,8 | -0,94% | 4,88% | 0,36% |

| ST-S-04 | 11 | 100,3 | 338,9 | 340,8 | 360,7 | 345,1 | 0,57% | 6,46% | 1,84% |

| ST-R-01 | 12 | 100,7 | 340,2 | 341,8 | 361,8 | 346,1 | 0,47% | 6,36% | 1,74% |

| ST-P-08 | 13 | 103,7 | 350,3 | 351,1 | 371,6 | 355,4 | 0,24% | 6,11% | 1,46% |

| ST-P-05 | 14 | 104,0 | 351,3 | 352,1 | 372,7 | 356,4 | 0,26% | 6,12% | 1,47% |

| ST-P-07 | 15 | 105,0 | 357,9 | 355,3 | 376,0 | 359,5 | -0,72% | 5,08% | 0,46% |

| ST-P-26 | 16 | 106,7 | 360,8 | 360,5 | 381,5 | 364,7 | -0,09% | 5,75% | 1,07% |

| ST-P-10 | 17 | 107,3 | 368,3 | 362,6 | 383,7 | 366,7 | -1,55% | 4,19% | -0,43% |

| ST-R-02 | 18 | 109,0 | 368,3 | 367,8 | 389,3 | 371,9 | -0,12% | 5,70% | 0,98% |

| ST-R-03 | 19 | 109,0 | 368,3 | 367,8 | 389,3 | 371,9 | -0,12% | 5,70% | 0,98% |

| ST-P-16 | 20 | 109,0 | 370,7 | 367,8 | 389,3 | 371,9 | -0,77% | 5,01% | 0,32% |

| ST-R-04 | 21 | 109,7 | 370,7 | 369,9 | 391,5 | 374,0 | -0,20% | 5,61% | 0,88% |

| ST-S-02 | 22 | 109,7 | 372,7 | 369,9 | 391,5 | 374,0 | -0,74% | 5,04% | 0,34% |

| ST-S-06 | 23 | 110,7 | 372,9 | 373,1 | 394,8 | 377,1 | 0,06% | 5,88% | 1,12% |

| ST-R-05 | 24 | 110,7 | 372,9 | 373,1 | 394,8 | 377,1 | 0,06% | 5,88% | 1,12% |

| ST-P-12 | 25 | 111,0 | 375,1 | 374,2 | 395,9 | 378,1 | -0,25% | 5,56% | 0,80% |

| ST-P-04 | 26 | 111,3 | 376,1 | 375,2 | 397,1 | 379,1 | -0,23% | 5,57% | 0,81% |

| ST-R-06 | 27 | 111,7 | 377,4 | 376,3 | 398,2 | 380,2 | -0,29% | 5,50% | 0,74% |

| ST-P-22 | 28 | 112,0 | 378,5 | 377,4 | 399,3 | 381,2 | -0,29% | 5,51% | 0,73% |

| ST-S-03 | 29 | 113,0 | 380,9 | 380,5 | 402,6 | 384,3 | -0,08% | 5,72% | 0,92% |

| ST-P-21 | 30 | 113,7 | 383,2 | 382,7 | 404,9 | 386,4 | -0,14% | 5,66% | 0,84% |

| ST-R-07 | 31 | 114,3 | 385,3 | 384,8 | 407,1 | 388,5 | -0,12% | 5,68% | 0,84% |

| ST-R-08 | 32 | 114,7 | 386,6 | 385,9 | 408,2 | 389,5 | -0,19% | 5,60% | 0,76% |

| ST-P-06 | 33 | 116,0 | 388,4 | 390,1 | 412,7 | 393,7 | 0,45% | 6,27% | 1,36% |

| ST-R-09 | 34 | 117,0 | 394,2 | 393,4 | 416,1 | 396,8 | -0,20% | 5,57% | 0,68% |

| ST-R-10 | 35 | 117,7 | 396,5 | 395,5 | 418,4 | 398,9 | -0,23% | 5,53% | 0,62% |

| ST-R-11 | 36 | 118,0 | 397,5 | 396,6 | 419,5 | 399,9 | -0,23% | 5,54% | 0,61% |

| ST-P-27 | 37 | 122,7 | 410,7 | 411,8 | 435,4 | 414,6 | 0,27% | 6,03% | 0,95% |

| ST-P-18 | 38 | 122,7 | 410,7 | 411,8 | 435,4 | 414,6 | 0,27% | 6,03% | 0,95% |

| ST-P-31 | 39 | 125,7 | 421,6 | 421,6 | 445,7 | 424,0 | 0,01% | 5,73% | 0,58% |

| ST-P-32 | 40 | 133,0 | 446,7 | 446,0 | 471,2 | 447,1 | -0,15% | 5,49% | 0,11% |

| ST-P-19 | 41 | 130,3 | 436,4 | 437,1 | 461,9 | 438,7 | 0,16% | 5,85% | 0,54% |

| ST-P-17 | 42 | 131,7 | 441,6 | 441,5 | 466,5 | 442,9 | -0,01% | 5,66% | 0,31% |

| ST-P-11 | 43 | 135,3 | 454,8 | 453,8 | 479,4 | 454,5 | -0,21% | 5,42% | -0,05% |

| ST-S-06 | 44 | 136,3 | 457,8 | 457,2 | 482,9 | 457,7 | -0,13% | 5,49% | -0,01% |