All published articles of this journal are available on ScienceDirect.

Toxicity of Recycled Concrete Aggregates: Review on Leaching Tests

Abstract

Background:

The toxicity of building materials can be addressed in the areas of occupational and environ-mental toxicology. In the first case, the harmful effects to workers caused by exposure to a specific substance during building materials production are analysed. In the latter case, the toxic effects of that substance on living organisms is examined.

Several studies analysed the environmental impact of concrete production, considering a significant number of concrete constituents and compositions, in order to find ways of minimizing it. However, some of the traditional constituents of concrete may be potentially hazardous, presenting different levels of toxicity, but only a few studies are focused on this area. Still, and in order to reduce the potential environmental impact, studies have already started on the incorporation of alternative raw materials, which may affect concrete toxicity.

It is important to develop more concrete toxicity studies analysing different mixes and constituents, in order to identify several ways of minimizing the potential toxicity of this construction material.

Objective:

Different procedures and results of the leaching tests of Recycled Concrete Aggregates (RCA) from previous studies will be presented and discussed in this paper.

Method:

The ecotoxicological characterization of materials is based on the analysis of the eluates resulting from leaching tests. There are several researches that apply different experimental leaching procedures according to existing standards and others with some variations in the standard test conditions: particle size, duration of the test, among others.

Results and conclusion:

The main characteristics of RCA that affect the results of the leaching tests will be identified.

1. INTRODUCTION

Depending on their origin, Recycled Concrete Aggregates (RCA) from Construction and Demolition Waste (CDW) have different characteristics [1]. If the recycling plant does not carry out adequate management, CDW can be contaminated, impairing their recovery as aggregates [2, 3]. The use of recycled aggregates has been evaluated in several applications, such as road sub-bases, being directly or indirectly in contact with soil and groundwater. Leachates resulting from the leaching of the aggregates can toxically affect and alter the characteristics of all the surrounding elements. As a consequence of pollutants accumulation, it can put ecosystems and human health at risk (Directive 2013/39/EU [4]). As an example, released metals can be transported and enter in aquatic and terrestrial environments, increasing natural compounds concentrations. These types of compounds are known to raise organ damage probability in aquatic animals and humans. Thus, the exhaustive characterization of the RCA eluates and of the concrete incorporating them is essential [5-9].

Most leaching tests are performed in the laboratory to reduce costs, and to guarantee easier control and faster results [10].

2. LEACHING TESTS

One of the leaching tests objectives is to assess the pollution potential by comparing the released contents of the relevant substances with the legal limits defined in national or Community legislation. As mentioned in the Portuguese Decree-Law No. 46/2008 [11], the use of recycled aggregates should be governed by the technical specifications defined by the National Laboratory of Civil Engineering (LNEC, Portugal). These specifications indicate that the release of dangerous substances should be evaluated in leaching tests according to European standard EN 12457-4 [12], taking into account leaching limit values established as criteria for the admissibility of waste in landfills for inert waste, non-hazardous waste and hazardous waste. Table 1 presents the limit values in Council Decision 2003/33/EC [13] wherein, as required in the LNEC Specifications mentioned, the use of recycled aggregates requires their classification as waste to be accepted for disposal in landfills for inert waste. Similar criteria have been adopted by the other Member States in their own standardization aiming to promote waste recycling and recovery [14].

| Chemical Parameters | Maximum Limit Values (mg/kg of dry mass) According to Classification | |||||

|---|---|---|---|---|---|---|

| Inert Waste | Non-Hazardous Waste | Hazardous Waste | ||||

| L/S=2 L/kg | L/S=10 L/kg | L/S=2 L/kg | L/S=10 L/kg | L/S=2 L/kg | L/S=10 L/kg | |

| As | 0.1 | 0.5 | 0.4 | 5 | 6 | 25 |

| Ba | 7 | 20 | 30 | 100 | 100 | 300 |

| Cd | 0.03 | 0.04 | 0.6 | 2 | 3 | 5 |

| Cr total | 0.2 | 0.5 | 4 | 20 | 25 | 70 |

| Cu | 0.9 | 2 | 25 | 50 | 50 | 100 |

| Hg | 0.003 | 0.01 | 0.05 | 0.5 | 0.5 | 2 |

| Mo | 0.3 | 0.5 | 5 | 10 | 20 | 30 |

| Ni | 0.2 | 0.4 | 5 | 10 | 20 | 40 |

| Pb | 0.2 | 0.5 | 5 | 10 | 25 | 50 |

| Sb | 0.02 | 0.06 | 0.2 | 0.7 | 2 | 5 |

| Se | 0.06 | 0.1 | 0.3 | 0.5 | 4 | 7 |

| Zn | 2 | 4 | 25 | 50 | 90 | 200 |

| Chloride | 550 | 800 | 10,000 | 50,000 | 17,000 | 25,000 |

| Fluoride | 4 | 10 | 60 | 250 | 200 | 500 |

| Sulphate | 560 | 1,000 | 10,000 | 20,000 | 25,000 | 50,000 |

| DOC | 240 | 500 | 380 | 1,000 | 480 | 1,000 |

| TDS | 2,500 | 4,000 | 40,000 | 60,000 | 70,000 | 100,000 |

2.1. Standardization

Regarding the release of dangerous substances from construction materials, there is a recent regulatory framework (CEN/TS 16637-1:2014 [15], CEN/TS 16637-2:2014 [16] and CEN/TS 16637-3:2016 [17]). However, most of the existing studies are based on results of leaching tests carried out according to other procedures. In Table 2, some of leaching test standards most commonly used in characterization studies of RCA are listed.

| Standard | Title | Year | Origin |

|---|---|---|---|

| EN 12457-3 [18] | Characterization of waste - leaching compliance test for leaching of granular waste materials and sludges. Part 3: Two-stage batch test at a liquid to solid ratio 2 and 8 L/kg for materials with a particle size below 4 mm (without or with size reduction) | 2002 | Europe |

| EN 12457-4 [12] | Characterization of waste - leaching compliance test for leaching of granular waste materials and sludges. Part 4: One stage batch test at a liquid to solid ratio of 10 L/kg for materials with a particle size below 10 mm (without or with size reduction) | 2002 | Europe |

| NEN 7343 [19] | Leaching characteristics of solid earthy and stony building and waste materials. Leaching test. Determination of the leaching of inorganic components from granular materials with the column test | 1994 | Netherlands |

| CEN/TS 14405 [20] | Characterization of waste - Leaching behaviour tests. Up-flow percolation test (under specified conditions) | 2004 | Europe |

| EN 14997 [21] | Characterization of waste - Leaching behaviour tests. Influence of pH on leaching with continuous pH-control | 2015 | Europe |

| TCLP 1311 [22] | Toxicity characteristic leaching procedure | 1992 | USA |

Leaching tests classified as batch tests are considered in standards EN 12457-3 [18] and EN 12457-4 [12], which are discussed below. These standards, which form part of a broader set, EN 12457 Parts 1 to 4, establish leaching tests to verify compliance with the legislation of each country.

In the specific case of EN 12457-3 [18], for the classification of the material under study, the concentrations of the metals and inorganic anions are analysed through eluate chemical analysis, comparing the obtained values with the limit values in Table 1. This procedure consists of two steps, placing 175 g (dry mass) of material under test in contact with deionized water (leachant) in two different liquid / solid (L/S) ratios of 2 and 8. Initially, for a ratio L/S = 2, the solution is stirred for 6 ± 0.5 h. To the same sample, after the first step, leachant is added until an L/S = 8 ratio is obtained and the solution is stirred for 18 ± 0.5 h. After decantation, the eluate’s pH, conductivity and temperature are evaluated. Lastly, the eluate is filtered by a 0.45 μm filter for assessing the concentrations of different species. According to this standard, 4 mm is the maximum particle size of the sample, allowing it to be performed with or without reducing the particle’s size.

Regarding EN 12457-4 [12], the maximum size of the aggregate corresponds to 10 mm, and the test is composed only of a leaching step with the ratio L/S = 10 L/kg. Like for EN 12457-3, the eluate is filtered and the relevant parameters are evaluated.

The column tests, allowing studying the leaching behaviour as a function of time on granular materials [23, 24], can be performed according to standards NEN 7343 [19] and CEN/TS 14405 [20].

The Dutch Standard NEN 7343 [19] simulates the leaching behaviour of a material by relating the accumulated content in the eluate of a substance for each given L/S ratio (0.1; 0.2; 0.5; 1; 2; 5 and 10 L/kg). In the column tests, the leachant in ascending flow crosses the sample of material placed in a vertical column and concentrations of different chemical parameters are measured in the collected eluate. The material’s sample must be less than 4 mm in size. To avoid small particles in the eluate, it must be filtered by two filters (1.5 μm and 0.45 μm). The leaching liquid should have a pH of 4, being acidified to the desired value using nitric acid. The duration of the test is over three weeks, approximately 21 days, including two or three days to reach equilibrium under saturated conditions. This test does not take into account temperature, duration of contact with water, the impact of materials carbonation, among others [24].

Up-flow column tests, CEN/TS 14405 [20], are very similar to the previous tests. The main differences are particle size (between 4 mm and 10 mm) and column dimensions (5 cm or 10 cm in diameter). Standard NEN 7343 considers columns with a diameter of 5 cm. With the results of this test, it is possible to determine which species are on the surface and are rapidly released by water at the initial moment. It is also possible to determine those whose later release is controlled by solubility, with physical and chemical interaction with the material.

The pH controlled leaching test standard, EN 14997 [21], analyses the mobility of substances by establishing equilibrium at a predetermined pH. At least, eight leaching tests are performed, each one characterized by a different pH value ranging from 4 to 12 (including a value equal to or less than 4, a value equal to or greater than 12, and the natural pH of the material). In order to accelerate equilibrium, particles are reduced to sizes smaller than 1 mm. Samples are shaken for 48 h using an end-over-end rotary tumbler at a speed of 10 rpm with an L/ S ratio of 10. The eluate is then filtered (0.45 μm), the electrical conductivity is determined, and its chemical analysis is performed. The pH should be monitored throughout the duration of the test, and it will be invalid if the pH shows deviations greater than 0.3 pH units.

The TCLP method [22] is used to simulate substances leaching in an acidic environment (conditions present in municipal landfills [24]), determining the release of organic and inorganic substances existent in the waste. The maximum particle size is 10 mm, and the leachant is the combination of demineralised water, acetic acid (CH3COOH) and Sodium Hydroxide (NaOH) in order to maintain a predetermined pH value. The eluate has a pH of 2.88 or 4.93 (depending on the pH of the substance), with a pH of 2.88 and an L/S ratio of 20 L/kg for the RCA. Samples are shaken for 20 hours using an end-over-end rotary tumbler at a speed of 15 rpm and the eluate is then filtered through a porosity filter of 0.6 μm to 0.8 μm.

Table 3 presents a summary of the main characteristics of the leaching tests considered in each standard referred above.

| Standard | Particle Size | L/S (L/kg) |

Leachant | pH of Leachant | Leaching Type | Duration | Temperature |

|---|---|---|---|---|---|---|---|

| EN 12457-3 [18] | < 4 mm | 2 and 8 | Demineralized water | neutral | Shaking | 6 h + 18 h | 20 ± 2 ºC |

| EN 12457-4 [12] | < 10 mm | 10 | Demineralized water | neutral | Shaking | 24 h | 20 ± 2 ºC |

| NEN 7343 [19] | < 4 mm | 0.1, 0.2, 0.5, 1, 2 and 5 | Demineralized water + nitric acid | 4 ± 0.1 | Percolation | ± 3 weeks | 20 ± 2 ºC |

| CEN/TS 14405 [20] | 4 ≤ d ≤ 10 mm | 0.1, 0.2, 0.5, 1, 2 and 5 | Demineralized water | Percolation | ± 23 days | 20 ± 5 ºC | |

| EN 14997 [21] | ≤ 1 mm | 10 | Demineralized water + nitric acid or sodium hydroxide | 4 ≤ pH ≤ 12 | pH equilibrium | ≥ 48 h | 20 ± 5 ºC |

| TCLP 1311 [22] | < 9.5 mm | 20 | Demineralized water + acetic acid + sodium hydroxide | 2.88* | Shaking + pressure filtration | 18 h ± 2 h | 23 ± 2 ºC |

The leaching tests with pH control and column tests (or percolation tests) present, in general, results expressed in mg/kg, which allows direct comparison between them for different L/S ratios [25, 26].

Some authors have analysed the relation between L/S and time [25] and between L/S ratio and saturation degrees [1]. According to some authors, the L/S ratio variation in percolation experiments is intended to simulate different degrees of saturation to which aggregates may be subjected in reality and to interpret how this parameter may affect substances leaching [1] [27].

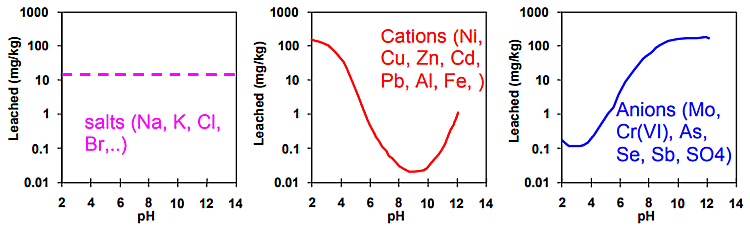

The major advantage of using a test with different pH values is that it allows simulating different environments and evaluating how they affect the content of released substances. For example, there are some metals, such as arsenic, which have a higher content in the eluates for higher pH values [24]. Fig. (1) Schematically represents the expected behaviour of the leaching curve within each group: soluble salts, cations and anions. Depending on the analysed chemical species, the curve may be shifted to higher or lower pH values and higher or lower leached content levels [25].

Batch tests may not characterize field behaviour but its purpose is to verify whether eluate concentrations, under given conditions, are below those permitted [10]. Comparison is only possible if there is a standardized test, even with different conditions from those in the field. In tests intended to simulate reality, Van der Sloot [24] mentioned that it is important to take into account different factors such as drying-wetting cycles, according to the precipitation pattern of the area in which the leachates are to be analysed, or the shape or size of material under study [28].

2.2. Recycled Concrete Aggregates Studies

In total, 17 articles were selected applying a total of 20 different tests, 8 of which were adaptations of existing standards with the aim of improving the best representation of the reality that they intend to describe Table 4.

| Author | ASTM D4793 [29] | ASTM D3987 [30] | EPA 1312 [31] | EPA 1311 TCLP [22] | EPA 1313 [32] | ASTM D5233 [33] | EN 12457-2 [34] | EN 12457-3 [18] | EN 12457-1 [35] | EN 12457-4 [12] | CEN TS 14405 [20] | CEN TS 14429 [36] | EN 14997 [21] | NEN 7343 [19] | NEN 7341 [37] | USGSLT [38] | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Abbaspour et al., 2016 [39] | x | x | |||||||||||||||

| Bestgen et al., 2016 [1] | x | x | x | x | |||||||||||||

| Bestgen et al., 2016 [27] | x | x | x | ||||||||||||||

| Barbudo et al., 2012 [40] | x | ||||||||||||||||

| Butera et al., 2014 [9] | x | ||||||||||||||||

| Butera et al., 2015 [41] | x | x | x | ||||||||||||||

| Coudray et al., 2017 [42] | x | ||||||||||||||||

| Del Rey et al., 2015 [23] | x | x | |||||||||||||||

| Engelsen et al., 2010 [5] | x | ||||||||||||||||

| Engelsen et al., 2017 [43] | x | ||||||||||||||||

| Galvín et al., 2013 [2] | x | x | x | ||||||||||||||

| Galvín et al., 2014 [44] | x | ||||||||||||||||

| Galvín et al., 2014 [45] | x | ||||||||||||||||

| Lopez Meza et al., 2008 [46] | x | ||||||||||||||||

| Roque et al., 2016 [47] | x | x | |||||||||||||||

| Saca et al., 2015 [3] | x | x | x | ||||||||||||||

| Rodrigues et al., 2017 [48] | x |

In the Lopez Meza’s study [46], RCA was analysed according to four different tests: two batch tests and two column tests. The batch tests (as a function of L/S ratio and of pH) are in accordance with the Kosson’s study [49], where different tests were defined according to different purposes. The column tests are based on the NEN 7343 method but with continuous saturated and intermittent unsaturated column.

Besides studying according to standards EN 14997 and CEN/TS 14405, Butera [41] developed leaching tests using lysimeters with the uncrushed material (with a particle size < 40 mm), representing typical road-base thicknesses (33 cm diameter by 27 cm height).

Engelsen [43] developed leaching field tests collecting leachate from different zones of highways.

Besides batch tests accordingly to EN 12457-4, Roque [47] also analysed leaching field tests with lysimeters. These tests were performed with RCA compacted in a box 1x1 m2 and reservoirs with a capacity of 65 l.

The material samples are mainly collected according to standard EN 932-1 [50] directly from piles of concrete waste from recycling plants, or directly from the crushing of concrete elements. Table 5 presents the concrete source of each analysed study. Some authors have analysed concrete RCA with different ages of production, including concrete recently produced in the laboratory. The Coudray’s study [42] used concrete 50 years old in RCA production and, on the other hand, Lopez Meza [46] used new concrete formulated in the laboratory. In all analysed studies, RCA produced in the laboratory or collected in recycling centres are constituted by at least 90% of ground concrete and/or mortar elements [48] [51]. An exception is the Del Rey study [23], which classifies RCA as a blend of natural aggregate, concrete and mortar, representing more than 90% of their constitution, even if the concrete content is as low as 41%. For grinding and homogenization of the samples, some authors claim to have applied the grinding method according to the EN 932-2 standard [52].

| Author | Concrete Source |

|---|---|

| Abbaspour et al, 2016 [39] | demolished concrete from various sources such as buildings, curbs and gutters, pipes, and washouts |

| Bestgen et al, 2016 [1] | stockpiles of concrete |

| Bestgen et al, 2016 [27] | collected from quarries |

| Barbudo et al, 2012 [40] | crushed concrete |

| Butera et al, 2014 [9] | collected from selected recycling facilities |

| Butera et al, 2015 [41] | crushing facilities that receive materials from demolition sites (crushed concrete) and material from pre-cast concrete production |

| Coudray et al, 2017 [42] | power plants undergoing deconstruction |

| Del Rey et al, 2015 [23] | construction and demolition waste treatment plants |

| Engelsen et al, 2010 [5] | section of highway and new concrete |

| Engelsen et al, 2017 [43] | (no information) |

| Galvín et al, 2013 [2] | different sources |

| Galvín et al, 2014 [44] | different origins |

| Galvín et al, 2014 [45] | concrete blocks |

| Lopez Meza et al, 2008 [46] | laboratory formulated concrete |

| Roque et al, 2016 [47] | crushed concrete and crushed mixed concrete |

| Saca et al, 2015 [3] | steel plant |

| Rodrigues et al., 2017 [48] | crushed concrete |

3. ANALYSED PARAMETERS

3.1. pH

Typically, the pH value of concrete elements ranges between less than 10, for fully carbonated elements, and more than 13 for fresh concrete elements [53], and it is lower in RCA relative to natural aggregates [47]. Lower pH values occur in aggregates from underground concrete elements [9], in concrete elements with high levels of carbonation [3], or bigger particles when compared with smaller particles [41]. Carbonation is directly related to the exposure during the life time of the element, significantly affecting the pH value of the RCA [23] [53] [9]. Butera [9] stated that carbonation mainly occurs after crushing and suggested that long-time exposure to atmospheric conditions in a building does not reflect in a significant increase of carbonation. On the other hand, the alkalinity of aggregates from fresh concrete elements is due to the presence of lime or Calcium oxide (CaO) and Calcium (Ca) [27].

Abbaspour [39] states that concrete aging does not significantly affect pH values, but affects the released concentrations of Al, Fe, Ca, Mg, Si, SO4-2 and Cu. However, Galvín argued that, for pH values between 4 and 7, in the acidic region, there is an increased concentration of Zn, Cu, Ni, Pb and Cd [45]. In field tests, Engelsen [43] obtained a pH range between 7.5 and 8.5.

Bestgen [1] stated that a decrease in pH occurs after adding water to the RCA. Another characteristic that affects the aggregates’ pH is their reduction to sizes defined in the standardization. Butera [41] analysed the pH value in percolation tests and concluded that, when there are no change in aggregates size, lower pH values are obtained. The increase of pH value after decrease of the size of the aggregates is due to the fact that the non-carbonated area exposed to leachate increased. However, Bestgen [27] said that, for leaching tests application, a higher pH value is more dependent on the aggregates’ chemical composition than on the variation of their size.

3.2. Heavy Metals and Anions

Although RCA present different compositions, depending on the original concrete, the leaching patterns are similar. Galvín [2] defined a metal components group that is important to analyse in future studies, including Ni, Cr, Sb, Zn and Cu.

Bestgen [1] indicates in its study that heavy metals concentrations of the RCA’s eluate do not show a correlation with their content in the constitution of the aggregates. As an example, the author indicates that RCA with lower concentrations of Cu (%) corresponds to eluate with a greater concentration of the same metal. On the other hand, smaller particles [1] and an acidic leachant [5] originate eluate with higher concentrations of heavy metals. The same author, in another study [27], indicates that decreasing aggregates’ size is a very important factor to control the leaching behaviour of metals. Engelsen [5] and Galvín [44] specify that heavy metals, namely chromium (Cr), come essentially from the mortar fraction of the recycled aggregates [44].

Some authors specify Cadmium (Cd), Mercury (Hg) and Lead (Pb) as elements with values below the maximum permissible levels of leaching for wastes to be disposed of in landfills for inert waste [2] [48] [40]. In contrast, some authors indicate Chromium (Cr) as a critical element, since it presents values superior to those allowed for landfill for inert wastes [23] [41] [44]. In some studies, Antimony (Sb) [2] [9], nickel (Ni) [2] and selenium (Se) [9] also have higher values than those allowed, and aggregates are classified as wastes acceptable in a landfill for non-hazardous waste. Some studies indicate that, by increasing the batch tests duration, some elements present their maximum value on the seventh day of leaching, namely Cr [1] and Fe [27].

In general, Saca [3] indicates that, for more recent RCA, inorganic species contents are higher, as well as for higher L/S ratios. However, Lopez Meza [46] said that, after an L/S ratio of 5 mL/g, the change of pH value, conductivity and release of constituents was not significant.

Regarding anions, authors [9] [23] [44] suggest that those with critical values are Chlorides (Cl-) [41] and Sulphates (SO42-). Chlorides can promote reinforcement corrosion [3] and sulphates are present in RCA cementitious matrix and in natural aggregates [40].

From an environmental point of view, Cr and sulphates are limiting components and have the highest potential environmental risks [23].

4. FINAL NOTES

Column leaching tests are the ones that best reproduce existing conditions in reality [10], presenting results with lower standard deviation [2]. Batch tests represent an advantage for being simpler and have shorter duration [3].

The Toxicity Characteristic Leaching Procedure applied by Bestgen [1] shows the highest leached concentrations when using an acidic leachant (pH ~2,9).

Bestgen [27] indicates that, with the increase in the L/S ratio, heavy metal concentrations are diluted resulting in a significant decrease of leached metals, contrary to what is referred by Saca [3].

At the seventh day of leaching, there is a maximum concentration of released metals originated by rehydration of cement paste from recycled concrete aggregate matrix [1]. Variations in the cement paste composition present in aggregates directly influence neutralization capacity of acids and, at work, affect their capacity of resistance to existing pH levels [53].

Recycled concrete aggregates are subjected to different environmental conditions that can hardly be reproduced in the laboratory, because it is a very expensive process. The amount of precipitation, the degree of saturation, temperature, materials and pH levels on site in contact with the aggregates, the external load and porosity are some of the characteristics mentioned for different mobilization of chemical species [10] [43].

Even applying the same RCA leaching test methods, studies of different authors show differences in the obtained values. These differences are mainly due to the heterogeneity of the aggregates and different management policies of recycling plants that change their properties, among others [23].

Among all analysed studies, only Rodrigues [48] presented RCA’s ecotoxicity results.

CONCLUSION

This paper analysed previous studies that applied different procedures for the leaching tests of recycled concrete aggregates. From this literature review, the following major conclusions are drawn:

- Considering RCA’s heterogeneity, it is important to analyse their eluates and check whether they are appropriate for the intended use and are in conformity with existing legislation;

- Leaching test results depend on the recycled concrete aggregates’ source, size, and previous exposure, and from the L/S ratio test used;

- he pH value of the leachant affects directly anion and cation releases behaviour;

- Some common critical compounds of recycled concrete aggregates are sulphate, chromium, antimony and selenium. On the other hand, cadmium, mercury and lead usually present lower concentrations relative to their critical values;

- Taking into account leaching tests currently used in RCA, it is important to define the purpose of the intended study prior to the definition of the test to be applied. As noted, each test is characterized by different objectives and should also be selected based on future RCA’s application.

The technical report CEN/TR 17105: 2017 - Construction products - Guidance on the use of ecotoxicity tests applied to construction products, recently published, foresees the use of biological tests on selected fractions of eluates produced by leaching according to guidance given in CEN/TS 16637-1. It also refers to existing methods to test the ecotoxicity of building products in aquatic or terrestrial organisms, providing information on how to combine leaching tests with biological tests, on transport sampling and eluate storage, and on ecotoxicity tests selection.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Authors are grateful for CERIS-ICIST’s support and that of Instituto Superior Técnico, Universidade de Lisboa. This work is financed by national funds through FCT - Fundação para a Ciência e a Tecnologia, I.P., with scholarship PD/BD/135258/2017.