All published articles of this journal are available on ScienceDirect.

Industrialized Construction Chronology: The Disputes and Success Factors for a Resilient Construction Industry in Malaysia

Abstract

Background:

The construction industry needs to be resilient in Malaysian economy because it contributes significantly to its socio-economy, gross domestic production, and positive employment ratios.

Objective:

This study is a chronological review of the fundamental issues related to the industrialization of construction in Malaysia. It covers different aspects of industrialized building systems (IBSs), which have the potential to promote productivity resiliency by stakeholders in Malaysian construction industry.

Method:

Furthermore, this study examines the fundamental issues related to current terminologies and the numerous classifications of industrialized construction. It also examines related works that support potential critical success factors and the current disputes affecting the adoption of industrialized construction in Malaysia.

Discussion and Conclusion:

This study redefines an IBS as a computer-integrated design, manufacturing, and construction system, using the concept of off-site or on-site prefabricated mass-production techniques within a controlled environment. Furthermore, the system uses proper coordination and planning to transport, position, and install building components with minimal in-situ work. With the success of modern methods of construction, IBS is expected to transform construction industry practices through the application of manufacturing and mechanization concepts. The study concludes by recommending incorporation of computer-aided learning technology at all workforces’ training levels when learning IBS applications. It is expected that this will improve performance in terms of construction quality, waste reduction, occupational safety, cost effectiveness, and productivity.

1. INTRODUCTION

The architecture, engineering, construction, and facility management (AEC-FM) sector plays a vital role in the Malaysian Construction Industry Transformation Program (CITP) 2016-2020. The construction industry plays a consistently important role in national economics, contributing significantly to countries’ socio-economic situations, gross domestic product (GDP), and employment ratios. In addition, the Malaysian CITP 2016-2020 reports that the construction industry currently contributes 4 percent to the Malaysian GDP, and is expected to contribute 5.5 percent to the GDP until 2020 [1]. The construction industry has a two-times multiplier effect, with more than 120 other industries relying on construction for their growth and sustainability. In this regard, the Malaysian construction industry provides significant employment opportunities, with a registered workforce of 1.2 million, including professionals such as engineers, architects, planners, and surveyors, in addition to skilled and non-skilled construction workers. The Malaysian construction workforce representing 9.5 percent of the national workforce in Malaysia. Therefore, the CITP 2016-2020, as part of the national agenda under the 11th Malaysia Plan (RMK11), was recognized for delivering increasingly modern practices aimed at attracting more local workforce into the industry at higher wages.

However, the construction industry faces challenges that are amplified by the recent population growth, effects of industrialization, and demand for construction [2]. The construction sector needs to transform from using traditional processes, which are unsustainable in terms of resource depletion and waste generation, to innovative methods, such as sustainable construction by means of industrialized construction [3]. Hence, the essential goal of the construction industry is to reach a level of sustainable performance that supports sustainable construction.

Prior scholars have reported that sustainable construction started developing in the early 1990s to support the creation of a healthy built environment based on ecological principles, life cycle economics, and resource efficiency [3], [4]. Van Egmond [5] agrees that sustainable construction would comprise the simultaneous pursuit of a balanced social equity, economic prosperity, and environmental quality (people, planet, and profit) in the built environment. In addition, sustainable construction should meet the needs of the present generation, without compromising the ability of future generations to respond to their need for a sustainable built environment [6]. Ultimately, there is a need to innovate construction firms, thus improving their performance to meet progressively fast and complex changing customer needs for a sustainable quality of built environment.

Sustainable construction means designers, engineers, building material producers, and contractors should propose new design concepts, building components, and building processes, and integrate these into construction projects. In addition, policymakers are expected to provide an adequate framework that facilitates improvements in construction sector. Sadafi, et al. [7] stated that the development of industrialized construction in a controlled environment, instead of using traditional methods of construction, has addressed more quickly and efficiently the issues of sustainability in the construction sector. Therefore, along with the industrialization of construction, there is a need to nurture the desire to work in the industrialized construction environment among the local workforce. This study agrees with the need to enhance and enforce the use of a skilled workforce to develop human resource capacity and capability in industrialized construction. The Construction Industry Development Board of Malaysia [8] also emphasizes strengthening the Malaysian construction industry image by enhancing professionalism and encouraging the use of ICT for sustainable construction improvement.

This study is a chronological review of the fundamental issues related to the industrialization of construction in the architecture, engineering, and construction (AEC) industry of Malaysia. The paper is divided into four parts. The first section provides current definitions and global terminologies for industrialized construction. The second section covers related literature that supports the numerous industrialized building system (IBS) classifications, which are proposed as a way to make appropriate choices of construction systems in Malaysia and in an international construction context. The third section reviews the potential critical success factors for implementing industrialized construction in Malaysia. The final section concludes the paper with a discussion of the current push factors and disputes that are affecting the adoption of IBSs in the Malaysian construction industry.

2. INDUSTRIALIZED CONSTRUCTION

This section provides global and local terminologies, classifications, critical success factors, and current barriers to industrialization in construction, which has the potential to promote sustainability, and are one of the possible solutions to the current construction problems. Nadim [9] stated that industrialization can be considered as a business strategy that transforms the traditional construction process into a manufacturing and assembly process by embracing new and advanced technologies, engaging people, and translating clients’ needs into building requirements. In another major study in 2012, Nadim [10] points out the following aims of industrialization in construction: improving the overall business efficiency, quality of product, environmental performance, sustainability, customer satisfaction, and predictability of timescales. These can be achieved within a controlled production environment (offsite production), with minimum waste, in a safer work environment, and with better investment in the long-term economy.

On the other hand, the construction industry records low productivity levels in comparison with other sectors in Malaysia. The local and global labor productivity benchmarks reported in the CITP 2016-2020 reflect the limited modernization in Malaysian construction methods and practices, as well as a reliance on a low-skilled workforce [1]. With the problem of housing becoming increasingly serious as a result of using conventional construction methods, the Malaysian construction authorities are actively trying to utilize new technology and promote the adoption of modern methods of construction (i.e., IBS) to meet the planned targets planned under the 11th Malaysian Plan. Moreover, the IBS roadmap 2011-2015 targeted an overall adoption rate of 100 percent of projects, with an IBS score of 70 for public sector projects, and a score of 50 for private sector projects. In fact, the CITP 2016-2020 reported that the IBS adoption is still relatively nascent, with only 24 percent of public projects worth 10 Million having achieved an IBS score of 70. Therefore, it is crucial to promote the uptake of IBSs in Malaysia along with strong human capital development to undertake the industrialized construction work.

2.1. Global Terminology for Industrialized Construction

The idea of performance improvement in the construction industry is not new compared with other industries, such as the manufacturing industry. The performance improvement concept was first discussed in the 1960s when the “Future” dream was described by Carter in 1967 to improve the construction industry by using the production concept, which governs the manufacturing industry [11].

Moreover, industrialization is an idea that goes beyond the use of elements produced off-site and the assembly of buildings to a rather “Visionary” system. However, the study by the NHBC Foundation of the UK [12] stated that the amount of work required for off-site production projects prior to going to the actual site often increases in comparison to traditional construction process, thus decreasing the amount of work carried out on-site.

There are a number of other terms used globally to describe industrialized construction and prefabrication systems. Subsequently, the literature uses common terminology such as pre-assembly, prefabrication, off-site manufacturing (OSM), off-site production (OSP), and off-site construction and modern method of construction (MMC) to describe industrialized construction. The study by Kamar and Hamid [13] compiled the following terms used by other scholars to represent the industrialization of the construction sector:

- Off-site: This is a term used to describe the spectrum of applications where buildings, structures, or parts thereof are manufactured and assembled remotely prior to their final installation [14].

- Pre-assembly: Pre-assembly literally means “Assemble Before,” and covers the manufacture and assembly (usually off-site) of buildings or parts of buildings earlier than they would traditionally be constructed on-site, and their subsequent final installation [15].

- Prefabrication: Prefabrication is a manufacturing process that usually takes place at a specialized facility, where various materials are joined to form components of the final installation [16].

- Modern method of construction (MMC): The MMC is the term used by the UK government to describe a number of innovations in house building, most of which are offsite technologies, moving work from the construction site to the factory [17], [18], [11], [19].

- Off-site construction (OSC)/off-site manufacturing (OSM)/off-site production (OSP): This largely interchangeable term refers to that part of the construction process that is carried out away from the building site, for example, in a factory or a specially created temporary production facility close to the construction site (or field factories) [14], [20].

- Off-site prefabrication: This is a process that incorporates prefabrication and pre-assembly. The process involves the design and manufacture of units and modules, usually remotely, and their final installation at the site [17].

Regardless of the terms, the idea of industrialization in construction is the same, namely, the manufacturing of structural components for the construction of buildings in a controlled environment, rather than doing so on site [21]. Pan [22] provides an approach to highlight and distinguish the various terms, which are categorized into four sections. Table (1) lists the term categories, which reflect the historical evolution of the concept.

Source: [22]

| Terminology | Category Term |

|---|---|

| MM | Modern Methods of Construction (MMC) |

| Modern Methods of House Construction | |

| Modern Methods of House Building | |

| OS | Off-Site Production (OSP) |

| Off-Site Manufacturing (OSM) | |

| Off-Site Fabrication (OSF) | |

| Off-Site Construction (OSC) | |

| PRE | Pre-assembly |

| Pre-fabrication | |

| Prefab | |

| Building | System Building |

| Non-traditional Building | |

| Industrialized Building |

However, according to the earlier studies, the assessment and critical review of the construction industry is essentially attributed to its low performance output in terms of cost and construction lifecycle time, poor quality of products, and poor health and safety record in comparison with other industries. With regard to the above issues, many initiatives have been instigated worldwide to effect change in the construction industry in order to mitigate and overcome these inherent problems [10]. The study by Nadim [9] summarizes the international initiatives that promote transformation in the construction industry. Table (2) extends Nadim’s findings by adding the Malaysian initiatives.

Adapted from [9]

| Report/Initiative | Year | Context |

|---|---|---|

| Australia | 1999 | Building for growth |

| Finland | 2002 | Reengineering the construction process using IT |

| Ireland | 1997 | Building our future together |

| Japan | 1998 | Future directions of the construction, industry, coping with structural changes of the market |

| Singapore | 1999 | Construction 21, Reinventing Construction |

| Malaysia | 1999 | IBS Strategic Plan 1999 |

| South Africa | 1997 | Creating an enabling environment for reconstruction growth and development in the construction industry |

| USA | 1994 | National Construction Goals |

| UK | 1962 | Greater integration of the design and construction process |

| UK | 1994 | Constructing the team (Latham report) to review contractual and procurement arrangements |

| UK | 1998 | Construction task force (rethinking construction), committed leadership, focus on consumer, integrated process and teams, quality driven agenda, commitment to people |

| Malaysia | 2003 | IBS Roadmap 2003–2010 |

| UK | 2004 | Construction Client Group CCG, to support private and public clients |

| Malaysia | 2006 | Construction Industry Master Plan (CIMP 2006–2015) |

| Malaysia | 2010 | IBS Roadmap 2011–2015 |

| Malaysia | 2015 | Construction Industry Transformation Program (CITP 2016–2020) |

A common point of departure among international initiatives that promote the construction industry emphasizes meeting clients’ needs, integrating design and construction, and benchmarking performance. Therefore, the MMC can be one of the means of developing and changing construction industry practices by applying and emphasizing the manufacturing concept and introducing different levels of mechanization in the construction industry sector.

On the other hand, the MMC may also include a variety of building approaches, such as OSM and on-site work. Accordingly, from the terminology perspective of industrialized construction, OSC, OSP, OSM, OSF, prefabrication, modular construction, industrialized building systems (IBS), and factory built assembly have often been utilized interchangeably to emphasize certain parts of the construction process that are carried out off site [10], [12], [14].

Nadim [10] shows the five levels of industrialization based on the research by Leabue and Vinals [23] in 2003, which can vary by enterprise, type of component/product produced, and region. These levels of industrialization are simple machinery, mechanization, automation, robotization, and reproduction (see Table 3).

| Level | Technology’s Degree | Description |

|---|---|---|

| 1 | Simple Machinery | Building components are produced in a factory and assembled using traditional methods |

| 2 | Mechanization | Utilization of specialized tools in order to reduce the dependence on workers |

| 3 | Automation | Replacing the workers with machines |

| 4 | Robotization | Replacing more workers by utilizing sophisticated programmable machines that accomplish complex and diversified work |

| 5 | Reproduction | Replacing the rest of traditional work with new procedures, in order to exceed mechanization and robotization to reduce the number of operations required for producing complex objects |

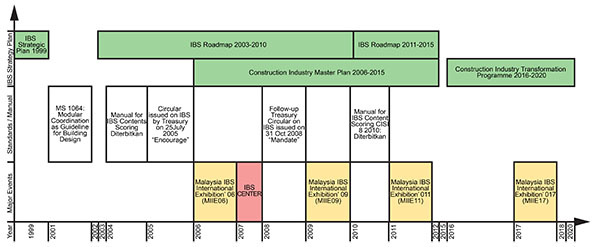

In this regard, the construction industry is affected by the increasing complexity of current construction projects, together with the advances in technologies needed to introduce a challenging proposition for the wider uptake of off-site production as a modern method for industrialization for building products. Industrialized construction has attracted the interest of countries such as Japan, Singapore, Hong Kong, Sweden, Switzerland, Germany, the United Kingdom, the United States, among others. The Ministry of Housing and Local Government of Malaysia visited several European countries in the early 1960s to evaluate their housing development programs, with the purpose of launching an IBS in the construction sector for building affordable and quality houses [24]. According to Elliot [25] an IBS often represents the processes of technical methods or the philosophic approach to the construction industry. It is vital to demonstrate the actions and events within the Malaysian IBS sector. Fig. (1) is a summarized chronology of IBS implementation in Malaysia.

The horizontal axis in the chronology graph illustrates the period (year), from 1999 to 2015. The vertical axis shows the three principle categories: IBS strategy plan, standards/manual, and major events in Malaysia. The chronology shows that over the last few decades, a number of IBS roadmaps, strategic master plans, and several workshops, seminars, and exhibitions have been developed to promote IBS in the Malaysian construction industry. The IBS implementation is proposed in order to grasp reasonable opportunities in the global market place and to meet the challenges of international competition in the construction sector [8].

2.2. Definition of an Industrialized Building System (IBS)

Indeed, the lack of a uniform definition depends heavily on user’s experience and understanding, which vary from country to country. There are various IBS definitions from more than 20 researchers who have previously studied this field from 1971 to 2011. The Construction Industry Development Board of Malaysia gave the workable definition of IBS in Malaysian context as “A construction technique in which components are manufactured in a factory controlled environment (on or off site), delivered, positioned and assembled or erected into a structure with minimal additional site works” [28].

Kamar, et al.[21] developed the following working definition for IBS: “An innovative process of building construction using concept of mass-production of industrialized systems, produced at the factory or onsite within controlled environments, it includes the logistic and assembly aspect of it, done in proper coordination with thorough planning and integration.”

According to Abdullah and Egbu [29], previous IBS definitions show authors’ positions in ontology, which define an IBS as a method, an approach, and a process, or a product, system, and technology. The definitions of IBS have been classified based on the two aforementioned categories. Kamar, et al.[21] and Kamar, et al. [13] highlighted the 20 scholars who worked on IBS definitions, and tabulated their results based on two main categories and six fundamental characteristics of IBS definitions from 1971 to 2009. Table (4) shows the list of scholars who have defined an IBS, based on two fundamental categories and the year of study.

| Year | Researchers | Category | Characteristic | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Method Approach & Process | Product, System & Technology | Industrialized Production | Transportation & Assembly Technique | On-site Fabrication | Mass-Production | Structured Planning & Standardization | Integration | ||

| 1971 | Dietz [30] | * | * | * | * | ||||

| 1986 | Junid [31] | * | * | * | * | * | |||

| 1997 | Parid [32] | * | * | * | |||||

| 1998 | Esa & Nuruddin [33] | * | * | * | |||||

| Sarja [34] | * | * | |||||||

| 1999 | Trikha [35] | * | * | * | * | ||||

| Warszawski [36] | * | * | |||||||

| 2002 | Badir, Kadir, & Hashim [37] | * | * | * | |||||

| 2003 | Shaari & Ismail [38] | * | * | * | |||||

| 2004 | MIGHT [39] | * | * | * | * | * | |||

| 2005 | Haron, Hassim, Kadir, & Jaafar [40] | * | * | * | |||||

| 2006 | Lessing [41] | * | * | * | * | ||||

| Chung [42] | * | * | * | * | * | * | |||

| Hong [43] | * | * | * | * | |||||

| Rahman & Omar [44] | * | * | * | * | |||||

| 2007 | CIDB [45] | * | * | * | |||||

| 2008 | Hamid, Kamar, Zain, Ghani, & Rahim [46] | * | * | * | * | ||||

| 2009 | Hassim, Jaafar, & Sazalli [47] | * | * | * | * | ||||

| Abdullah & Egbu [48] | * | * | |||||||

| 2011 | Kamar, Zuhairi, Azman & Ahmad [21] | * | * | * | * | * | * | * | * |

In Table (4), 15 researchers defined an IBS as the process, approach, and method. However, five researchers defined an IBS as a technology, product, and system. In addition, IBS definitions emphasize other characteristics, such as industrialized production, the transportation and assembly technique, on-site fabrication, mass-production, structured planning and standardization, and process integration. Each definition covers at least two or three other categories and characteristics of an IBS mentioned earlier. Here, the widely accepted IBS definition in Malaysia of the CIDB Malaysia does not cover aspects of structured planning, mass-production, standardization, and process integration in its definitions. For instance, Chung [42] defined an IBS as a method, approach, and process, a definition that includes five of the six characteristics listed in the table.

The results show that all of the above characteristics and fundamental categories of IBS definitions are essential and should be included in a holistic workable IBS definition. For this purpose, this study defines IBS as “a computer-integrated design, manufacturing and construction system using the concept of off-site or on-site prefabricated mass-production technique within a controlled environment while utilizing proper coordination and planning to transport, position and install building components with minimal in-situ works.”

2.3. Industrialized Construction Classification

The classifications of industrialized construction are numerous, and documented based on the material, process, and system approach. Mazjub [49] proposed a classic classification of industrialized construction that classifies them based on systems and building materials. Kamar, Hamid, Azman, and Ahmad [21] summarized the industrialized construction classifications (see Table 5). The table compares different classifications and makes appropriate choices on construction methods for the Malaysian construction industry.

Adapted from [21]

| Classification | Sub categories | Author |

|---|---|---|

| Mazjub’s Building System Classification | Panel system | Mazjub [49] |

| Box system | ||

| Frame system | ||

| Warszawski’s Building System Classification 1 | Timber | Warszawski [36] |

| Steel | ||

| Cast in situ concrete | ||

| Precast concrete | ||

| Warszawski’s Building System Classification 2 | Linear | Warszawski [36] |

| Skeleton | ||

| Planar | ||

| Planar Systems | ||

| Three-dimensional box systems | ||

| Industrialized System Classification (Razali-Badir’s Classification) | Conventional building system | Badir, Kadir and Hashim [37] |

| Cast in situ formwork system | ||

| Table or tunnel formwork | ||

| Prefabricated system | ||

| Composition system | ||

| Pre-assembly and Pre-fabrication Classification | Component manufacture and sub-assembly | Gibb and Issac [15] |

| Non-volumetric sub-assembly | ||

| Volumetric pre-assembly | ||

| Modular system | ||

| IBS Classification (CIDB) | Pre-cast concrete framing | CIDB [28], Shaari and Ismail [38], MIGHT [39], Chung [42], CIDB [45] |

| Panel and box systems | ||

| Steel formwork systems | ||

| Steel framing systems | ||

| Prefabricated timber framing system | ||

| Block work system | ||

| MMC Classification | Volumetric | Gibb and Pendiebury [20] |

| Panelized | ||

| Hybrid | ||

| Subassemblies and components | ||

| Non-off-site-Modern Methods of Construction | ||

| IBS Classification (UTM) | Pre-cast concrete-framed building | Rahman and Omar [44] |

| Pre-cast concrete wall system | ||

| Reinforced concrete building with pre-cast concrete slab | ||

| Steel formwork system | ||

| Steel-framed building and roof trusses | ||

| Bruno-Richard’s IBS Classification | Site intense kit part | Richard [50] |

| Factory made module | ||

| Hybrid | ||

| OSM Classification | Volumetric system | Abosaad, Underwood, and Boveny [51] |

| Panelized system | ||

| Hybrid system | ||

| Sub-assemblies and component system | ||

| Modular system | ||

| Mesaros-Mandicak’s MMC Classification | Frame system | Mesaros and Mandicak [52] |

| Panel system | ||

| Modular system | ||

| Modularity in Construction | Pure modular | Doran and Giannakis [53] |

| Hybrid modular | ||

| Onsite modular |

In 2003, the CIDB of Malaysia proposed a classification for IBS that is widely approved of in the Malaysian context, and is used by scholars and practitioners in the construction sector [54]. The CIDB [28] classified IBSs based on structural aspects of the systems into five major groups:

- Precast concrete framed buildings, panel and box systems: Precast concrete elements such as columns, beams, slabs, and walls, and “3D” components such as balconies, staircases, toilets, lift chambers, refuse chambers, and lightweight precast concrete and permanent concrete formworks are classified as the most common group of IBS products in this classification.

- Formwork system: This system is considered one of the “Least Prefabricated” IBS products, because it involves site casting such as tunnel forms, tilt-up systems, and permanent steel formworks, and the products offer high-quality finishes, subject to the structural quality control and to delivering fast construction with lower site labor and material requirements.

- Steel framing system: This system has always been popular and is used extensively in the fast-track construction of skyscrapers. Recent developments for this type of IBS include the usage of light steel trusses consisting of cost-effective, profiled, cold-formed channels and steel portal frame systems as alternative to the traditional heavier hot-rolled sections.

- Prefabricated timber framing system: This system consists of timber building frames and timber roof trusses. The system offers interesting designs from simple dwelling units to buildings with high aesthetical value, such as chalets for resorts.

- Blockwork system: This construction system uses conventional bricks, which have been revolutionized using of interlocking concrete masonry units (CMU) and lightweight concrete blocks to save on construction time and to simplify the usage of effective alternative solutions.

A recent study by Doran and Giannakis [53] in 2011 covered modularity in construction and classified modular building systems into three groups: pure modular, hybrid modular, and onsite modular. The pure modular category is the most standardized modular building system, and does not accommodate change, whereas the onsite modular building system group allows for a high degree of customization [53]. According to the above study, the classification of IBSs by the CIDB in 2003 can be expanded to cater to the scope of modularity (volumetric) in construction. These new classifications of IBS methods lifted the Malaysian construction industry to another level of industrialization. Hence, IBSs have the potential to be involved in the entire lifecycle of project delivery by initiating reproduction levels of industrialization in the Malaysian construction industry.

2.4. Critical Success Factors of IBS

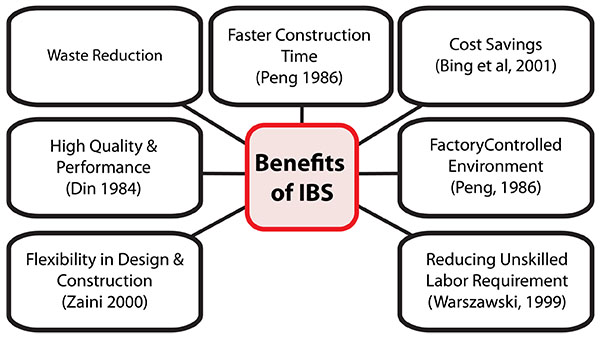

There are several push factors that encourage the adoption of IBSs in the construction sector, such as health and safety risk reduction, dealing with environment and sustainability issues, client influences, and addressing skills shortages [18], [55], [56], [36]. Therefore, a considerable number of studies have investigated the benefits of an IBS compared with conventional construction methods. Abdullah and Egbu [29] highlighted the following benefits of the IBS method Fig. (2) [57], [58], [36], [59], [60]. By utilizing this system, the dependency on foreign construction workers and the inherent social problems caused by foreign workers will also be minimized.

Kamar, et al. [2] investigated the CSFs in the implementation of IBS in Malaysia. Their research identifies potential CSFs in the implementation of IBS through a literature search and a case study survey of construction companies in Malaysia (see Table 6).

| Potential CSFs | Author |

|---|---|

| Good Working Collaboration | Pan, Gibb, and Dainty [18] |

| Effective Communication Channel | Pan, Gibb, and Dainty [55] |

| Continues Improvement and Learning | Neala, Price, and Suer [61] |

| Coordination of Design, Manufacture, and Construction | Haas and Fangerlund [62] |

| Key Decisions on Strategy, Application, Design, Logistic, and Detail Unit Should be Made as Early as Possible Between all Parties involved | Gibb [17], Neala, Price, and Suer [61] |

| Team members Involved During the Design Stage | Blismas [63], Pan, Gibb, and Dainty [55] |

| Experienced Workforce and Technical Capable | Warszawski [36] |

| Information and Communication Technology (ICT) | Eichert and Kazi [64] |

| Close Relationship with Suppliers | Pan, Gibb, and Dainty [18], [55] |

| Extensive Planning and Scheduling | Haas and Fangerlund [62] |

| Improvement in Procurement Strategy and Contracting | Pan, Gibb, and Dainty [18], [55] |

| Risk Management Strategy | Hassim, Jaafar, and Sazalli [47] |

| Design Standardization and Repetition | Mole [65], National Audit Office [66] |

| Management of Supply Chain and Logistics | Lessing, Stehn, and Ekholm [67] |

| Top-down Commitment | BSRIA [68] |

| Training the Skilled Workforce for Site Installation | BSRIA [68], Thanoon, Peng, Kadir, Jaafar, and Salit [24] |

| Strategy and Business Approach | Malik [69] |

The aforementioned scholars indicate that applying the CSFs to implement industrialized construction in the Malaysian construction context needs initial thought and a fundamental transformation of the current system in Malaysia.

Kamar, et al. [2] indicated the following changes based on the aforementioned CSFs in order to appropriately implement an IBS in Malaysia:

- Key success factors for off-site construction projects lie in good management (both on- and off-site) and in the planning and control of the overall project life cycle.

- The integration of IBS components and modules into the building construction system requires that the various parties and the supply chain create a good communication channel in order to implement an integrated approach to the design, manufacturing, and construction of buildings.

- The Malaysian construction industry needs to learn about effective logistics management to include the management and sustained improvement of the production process in order to eliminate waste and to ensure the right components are produced and transported at the right time, in the right order, and without defects.

Based on the above issues, a successful IBS implementation requires extensive knowledge of processes, design, and manufacturing. In addition, the IBS implementation needs to improve the skill level of the current workforce by increasing the quality of training at all levels. This requires a tremendous education and training effort, particularly for construction practitioners who are involved in handling, positioning, and erecting the prefabricated components as on-site activities. It is important to select an appropriate technology, such as an IT/ICT support tool, to improve construction business viability.

Moreover, there are many issues and challenges in implementing an IBS. These include poor knowledge in this area, resistance from customers and professionals, misunderstanding building regulations, cost issues, IT/ICT integration, few codes and standards, a market monopoly, a lack of integration in design and construction, complex interfacing between systems, manufacturing capabilities, and cultural issues [46], [55], [70], [56], [8]. A recent study on the drivers and barriers for industrialization in construction shows the most frequent barriers relate to a lower degree of customization and reduced flexibility in producing to meet customers’ requirements [71]. Building production systems with a high degree of industrialization are often regarded as having lower performance, owing to the need to freeze a design early, and being more resistant to product innovations because off-site building production requires a high capital investment in fixed assets and depends on high production volumes to offset the capital investment [71].

On the other hand, most IBS project deliveries in the Malaysian construction industry apply the fragmentation approach, which was identified as one of the main barriers to adopting an IBS in Malaysia [72]. The fragmentation issue (traditional design and construction process) means that all design and construction processes are conducted in a sequential manner throughout the project life cycle [72]. In addition, a characteristic of the Malaysian IBS construction process is that it is conducted in a sequential manner, based on the segregation of professionals during the design and construction processes. In fact, the segregation of professionals throughout the project lifecycle results in inefficiencies during the construction phase, such as increased project complexity, rework, increasing costs, and longer construction durations [72], [73]. Therefore, it is recommended that the IBS project lifecycle process adopt modern technology, such as building information modeling (BIM), through a holistic package of policy, specific training programs, and related initiatives in order to minimize the fragmentation gap in current Malaysian construction projects.

3. DISCUSSION AND CONCLUSION

The review of relevant literature supports the IBS as a potential modern method of construction in Malaysia. It can improve the overall performance of quality, construction time, cost effectiveness, waste reduction, safety, and labor productivity in construction projects. In this regard, this study proposed a new working definition for IBS, which does not necessarily restrict its scope to a specific predefined IBS category based on prior researcher’s positions in ontology. The IBS can cover both categories of characteristics (process and product) in order to promote the integrated technology and the systematic process for designing, manufacturing, and constructing final building products within controlled environments to achieve the targeted productivity in the construction industry.

This comprehensive review identified several factors affecting IBSs. First, a successful IBS implementation requires extensive knowledge of design, manufacturing, and construction processes. Second, an IBS implementation needs to improve the skill of the current workforce by increasing the quality of training at all levels. In fact, the study by Sandberg, et al.[74] on Swedish prefabricators of domestic timber housing suggested that an IT support tool procedure could enable the automation of activities and the availability of a modeled product in a virtual format. The data could control the time and cost factors and reduce manufacturability issues, because design flaws can be found at an early stage. Hence, the IBS implementation requires integrating IT/ICT in the design and construction process in order to improve the productivity of construction projects.

This study proposes accelerating the adoption of the IBS method by using mechanization and modern practices in the Malaysian construction industry, along with the four targets of the CITP 2016-2020. The CITP 2016-2020 calls for accelerating the adoption and utilization of modern construction methods and technologies by improving the economics of IBS adoption, improving the enablers of IBS adoption by introducing a comprehensive IBS catalogue together with building information modeling to address the productivity challenges in the industry. In addition, the CITP 2016-2020 proposes measures to raise productivity levels by continued up-skilling of the local workforce and entrepreneurs to equip them with specialized skills. A comprehensive manpower planning model is needed to improve the capability of the local workforce and capacity building. This has the a potential to gradually reduce the dependency on a general foreign workforce and to increase the number of local resilient multi-skilled workers by using technical education and a computer-aided vocational training curriculum to improve the overall construction performance in terms of quality, waste reduction, occupational safety, cost effectiveness, and productivity.

This study found that the IBS method of construction has a significant effect on resilient construction labor productivity compared with that of conventional methods in Malaysia. The evolution of construction technology has prompted the industry to rely on the off-site production with the intention of using IT/ICT tools in a more widespread manner. We agree that the use of IBS components can bring about considerable savings on workers in construction projects, if implemented properly. The IBS sector requires the compliance of well-trained workers, engineers, and managers of the construction site with good practices in job-site tasks. Additionally, highly technical knowledge in design, manufacturing, and construction is required to achieve good quality final buildings. For a successful IBS implementation, this study recommends improving the skill level of the current workforce by increasing the quality of their training at all levels. Hence, we propose focusing efforts on educating and training construction practitioners on handling, positioning, and erecting prefabricated components that are critical on project sites. Thus, this study identified opportunities the construction industry can explore to integrate an IT/ICT support tool for advanced construction training and developing support tools.

Recent studies by Malaysian scholars, such as Ghafar, Ibrahim, Shari, and Rahimian [75], have indicated an increasing awareness, and the use of BIM has emerged in the country. In the CITP 2016–2020, goals are set to ensure its spread and practice from design to facility management. We see opportunities in reusing the BIM objects of building projects to train the workforce involved in prefabricating and erecting objects, albeit on the real scale of an actual site. Studies such as Dawood and Sikka [76] and Dawood, et al. [77] have experimented with 3D objects for human resource (HR) training in complex building projects, while Goulding and Alshawi [78] have considered a total integrated delivery process for a building lifecycle. The study by Clements-Croome [79] proposed sustainable intelligent buildings are required to be responsive to occupants, organizations, and society. According to above, at a strategic level, achieving sustainable intelligent buildings needs an integration of planning, designing, constructing, and operating buildings, with their various systems that benefit people and organizations. Therefore, the development of mixed reality scenarios will facilitate the proper training and educating by the design and management team to fulfill the social, environmental, and economic requirements for the design and management of intelligent buildings. With available and ready-made 3D objects during the design phase, this study proposes extending their usage into computer-aided learning technology for all levels of workforce training on industrialized construction projects. We foresee that their availability on mixed reality game technology platforms could be considered as supporting capability training for the construction workforce, whether in the prefabrication or implementation phase. Such integration would support the recommendation of Ibrahim and Paulson [80] to ensure seamless knowledge flows of information at critical interdependent junctures in the complex building development process.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

This study is part of a doctoral thesis by the first author at Universiti Putra Malaysia sponsored by the Ministry of Education Malaysia Ref. PRGS 5528300, and partly by Universiti Putra Malaysia Ref. RUGS 9363300. We acknowledge the contributions of Assoc. Prof. Normahdiah Sheik Said and Prof. Dr. Mohd. Shahwahid Othman.